Green Ammonia Synthesis: Evaluating Electrolysis Efficiency

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green Ammonia Technology Evolution and Objectives

Ammonia production has been a cornerstone of global agriculture and industry since the development of the Haber-Bosch process in the early 20th century. This conventional process, while revolutionary, relies heavily on fossil fuels, contributing significantly to global carbon emissions. The evolution of green ammonia synthesis represents a paradigm shift in this critical industry, aiming to maintain production capacity while drastically reducing environmental impact.

The technological trajectory of green ammonia began in earnest during the early 2000s when renewable energy sources became increasingly viable. Initial research focused on adapting traditional synthesis methods to accommodate intermittent renewable power sources. By 2010, pilot projects demonstrated the feasibility of using electrolysis-derived hydrogen for ammonia production, though at limited scales and efficiencies below 40%.

The period from 2015 to 2020 marked significant advancements in electrolysis technology, with alkaline electrolyzers giving way to more efficient proton exchange membrane (PEM) and solid oxide electrolysis cells (SOEC). These developments pushed system efficiencies toward 60-70%, making green ammonia production increasingly economically competitive with conventional methods.

Current technological objectives center on achieving electrolysis efficiency exceeding 80% while maintaining durability under variable power conditions typical of renewable energy sources. Research is particularly focused on catalyst development, with novel materials showing promise in reducing activation energy requirements and improving reaction kinetics at lower temperatures and pressures than traditional processes demand.

Another critical objective is system integration optimization, as green ammonia production facilities must effectively balance hydrogen production via electrolysis with nitrogen separation and subsequent ammonia synthesis. This integration challenge represents a significant engineering hurdle that impacts overall system efficiency and economic viability.

Scale remains a fundamental challenge, with current green ammonia facilities producing orders of magnitude less than conventional plants. The technology roadmap aims to achieve gigawatt-scale production facilities by 2030, requiring substantial advances in electrolyzer manufacturing, modular design, and process intensification.

The ultimate technological goal extends beyond mere production efficiency to encompass the entire ammonia value chain. This includes developing advanced storage solutions, transportation infrastructure, and end-use applications that can fully leverage ammonia's potential as both a fertilizer and an energy carrier. The dual-use potential of green ammonia as both an agricultural input and a hydrogen carrier for renewable energy storage represents a compelling technological convergence that could accelerate adoption across multiple sectors.

The technological trajectory of green ammonia began in earnest during the early 2000s when renewable energy sources became increasingly viable. Initial research focused on adapting traditional synthesis methods to accommodate intermittent renewable power sources. By 2010, pilot projects demonstrated the feasibility of using electrolysis-derived hydrogen for ammonia production, though at limited scales and efficiencies below 40%.

The period from 2015 to 2020 marked significant advancements in electrolysis technology, with alkaline electrolyzers giving way to more efficient proton exchange membrane (PEM) and solid oxide electrolysis cells (SOEC). These developments pushed system efficiencies toward 60-70%, making green ammonia production increasingly economically competitive with conventional methods.

Current technological objectives center on achieving electrolysis efficiency exceeding 80% while maintaining durability under variable power conditions typical of renewable energy sources. Research is particularly focused on catalyst development, with novel materials showing promise in reducing activation energy requirements and improving reaction kinetics at lower temperatures and pressures than traditional processes demand.

Another critical objective is system integration optimization, as green ammonia production facilities must effectively balance hydrogen production via electrolysis with nitrogen separation and subsequent ammonia synthesis. This integration challenge represents a significant engineering hurdle that impacts overall system efficiency and economic viability.

Scale remains a fundamental challenge, with current green ammonia facilities producing orders of magnitude less than conventional plants. The technology roadmap aims to achieve gigawatt-scale production facilities by 2030, requiring substantial advances in electrolyzer manufacturing, modular design, and process intensification.

The ultimate technological goal extends beyond mere production efficiency to encompass the entire ammonia value chain. This includes developing advanced storage solutions, transportation infrastructure, and end-use applications that can fully leverage ammonia's potential as both a fertilizer and an energy carrier. The dual-use potential of green ammonia as both an agricultural input and a hydrogen carrier for renewable energy storage represents a compelling technological convergence that could accelerate adoption across multiple sectors.

Market Demand Analysis for Sustainable Ammonia Production

The global ammonia market is experiencing a significant shift towards sustainable production methods, driven by increasing environmental concerns and regulatory pressures. Traditional ammonia production via the Haber-Bosch process accounts for approximately 1.8% of global CO2 emissions, creating an urgent need for greener alternatives. The market for sustainable ammonia production is projected to grow at a compound annual growth rate of 9.5% through 2030, with the total addressable market expected to reach $72 billion by 2032.

Industrial sectors represent the primary demand drivers for green ammonia. The fertilizer industry, which consumes over 80% of globally produced ammonia, is facing mounting pressure to reduce its carbon footprint. Major agricultural companies and fertilizer manufacturers are increasingly committing to carbon neutrality targets, creating substantial demand for sustainably produced ammonia.

The shipping industry has emerged as another significant market for green ammonia. As the International Maritime Organization implements stricter emissions regulations, ammonia is gaining traction as a zero-carbon marine fuel. Several major shipping companies have announced pilot projects for ammonia-powered vessels, with full commercial deployment expected by 2025-2030.

Energy storage represents a third major market opportunity. Green ammonia's high energy density and established transportation infrastructure make it an attractive medium for storing renewable energy, particularly for long-duration and seasonal storage applications. Countries with abundant renewable resources but limited grid infrastructure are exploring ammonia as an energy export vector.

Regional analysis reveals varying demand patterns. The European Union, with its ambitious European Green Deal, has established a strong regulatory framework supporting green ammonia development. Japan and South Korea have positioned themselves as potential major importers of green ammonia, while Australia, Chile, and Morocco are emerging as production hubs due to their renewable energy resources.

Economic factors currently present the most significant barrier to widespread adoption. Green ammonia production costs remain 2-3 times higher than conventional methods, primarily due to the capital expenditure requirements for electrolysis equipment and renewable energy infrastructure. However, cost projections indicate potential price parity by 2030, driven by economies of scale, technological improvements in electrolysis efficiency, and declining renewable energy costs.

Consumer willingness to pay premiums for green products varies by sector, with end-consumer facing industries showing greater acceptance of price premiums than industrial applications. Government incentives, carbon pricing mechanisms, and corporate sustainability commitments are expected to bridge the cost gap during the transition period.

Industrial sectors represent the primary demand drivers for green ammonia. The fertilizer industry, which consumes over 80% of globally produced ammonia, is facing mounting pressure to reduce its carbon footprint. Major agricultural companies and fertilizer manufacturers are increasingly committing to carbon neutrality targets, creating substantial demand for sustainably produced ammonia.

The shipping industry has emerged as another significant market for green ammonia. As the International Maritime Organization implements stricter emissions regulations, ammonia is gaining traction as a zero-carbon marine fuel. Several major shipping companies have announced pilot projects for ammonia-powered vessels, with full commercial deployment expected by 2025-2030.

Energy storage represents a third major market opportunity. Green ammonia's high energy density and established transportation infrastructure make it an attractive medium for storing renewable energy, particularly for long-duration and seasonal storage applications. Countries with abundant renewable resources but limited grid infrastructure are exploring ammonia as an energy export vector.

Regional analysis reveals varying demand patterns. The European Union, with its ambitious European Green Deal, has established a strong regulatory framework supporting green ammonia development. Japan and South Korea have positioned themselves as potential major importers of green ammonia, while Australia, Chile, and Morocco are emerging as production hubs due to their renewable energy resources.

Economic factors currently present the most significant barrier to widespread adoption. Green ammonia production costs remain 2-3 times higher than conventional methods, primarily due to the capital expenditure requirements for electrolysis equipment and renewable energy infrastructure. However, cost projections indicate potential price parity by 2030, driven by economies of scale, technological improvements in electrolysis efficiency, and declining renewable energy costs.

Consumer willingness to pay premiums for green products varies by sector, with end-consumer facing industries showing greater acceptance of price premiums than industrial applications. Government incentives, carbon pricing mechanisms, and corporate sustainability commitments are expected to bridge the cost gap during the transition period.

Electrolysis Efficiency: Current Status and Challenges

Electrolysis technology for green ammonia synthesis has made significant strides in recent years, yet continues to face substantial efficiency challenges. Current state-of-the-art water electrolysis systems operate at efficiency levels between 60-80% for alkaline electrolyzers and 65-82% for proton exchange membrane (PEM) systems. However, when integrated into ammonia synthesis processes, overall system efficiency drops considerably to approximately 40-50%, representing a major barrier to commercial viability.

The primary technical challenge remains the high energy consumption of water electrolysis, requiring 4.5-6.5 kWh of electricity per Nm³ of hydrogen produced. This energy requirement translates to approximately 10-12 MWh per ton of ammonia, significantly higher than the conventional Haber-Bosch process powered by natural gas (around 8-9 MWh/ton). The capital expenditure for electrolysis equipment further compounds economic challenges, with current costs ranging from $800-1,500 per kW of installed capacity.

Catalyst performance presents another critical limitation. Noble metal catalysts like platinum and iridium deliver superior performance but face scalability constraints due to scarcity and high costs. Alternative catalysts based on transition metals show promise but currently exhibit lower activity and durability, with degradation rates of 1-2% per 1,000 operating hours compared to 0.1-0.5% for premium catalysts.

Geographical distribution of electrolysis technology development shows concentration in Europe, particularly Germany, Denmark, and the UK, which collectively account for approximately 65% of research publications and 58% of patents in the field. North America contributes about 20% of research output, while Asia, led by Japan and China, has rapidly increased its share to approximately 15% over the past five years.

System integration challenges persist, particularly in balancing the intermittent nature of renewable energy sources with the continuous operation requirements of ammonia synthesis. Current buffer systems and hydrogen storage solutions add 15-25% to overall system costs while introducing additional efficiency losses of 3-7%.

Temperature management represents another significant hurdle, as electrolyzers operate optimally at 50-80°C while the Haber-Bosch process requires temperatures of 400-500°C. This thermal mismatch necessitates additional energy inputs and complex heat management systems that further reduce overall efficiency.

Recent innovations in high-temperature solid oxide electrolysis cells (SOECs) operating at 700-850°C show theoretical efficiency improvements of 10-15% compared to conventional technologies, but material stability and system integration challenges have limited their practical implementation to demonstration projects below 1 MW scale.

The primary technical challenge remains the high energy consumption of water electrolysis, requiring 4.5-6.5 kWh of electricity per Nm³ of hydrogen produced. This energy requirement translates to approximately 10-12 MWh per ton of ammonia, significantly higher than the conventional Haber-Bosch process powered by natural gas (around 8-9 MWh/ton). The capital expenditure for electrolysis equipment further compounds economic challenges, with current costs ranging from $800-1,500 per kW of installed capacity.

Catalyst performance presents another critical limitation. Noble metal catalysts like platinum and iridium deliver superior performance but face scalability constraints due to scarcity and high costs. Alternative catalysts based on transition metals show promise but currently exhibit lower activity and durability, with degradation rates of 1-2% per 1,000 operating hours compared to 0.1-0.5% for premium catalysts.

Geographical distribution of electrolysis technology development shows concentration in Europe, particularly Germany, Denmark, and the UK, which collectively account for approximately 65% of research publications and 58% of patents in the field. North America contributes about 20% of research output, while Asia, led by Japan and China, has rapidly increased its share to approximately 15% over the past five years.

System integration challenges persist, particularly in balancing the intermittent nature of renewable energy sources with the continuous operation requirements of ammonia synthesis. Current buffer systems and hydrogen storage solutions add 15-25% to overall system costs while introducing additional efficiency losses of 3-7%.

Temperature management represents another significant hurdle, as electrolyzers operate optimally at 50-80°C while the Haber-Bosch process requires temperatures of 400-500°C. This thermal mismatch necessitates additional energy inputs and complex heat management systems that further reduce overall efficiency.

Recent innovations in high-temperature solid oxide electrolysis cells (SOECs) operating at 700-850°C show theoretical efficiency improvements of 10-15% compared to conventional technologies, but material stability and system integration challenges have limited their practical implementation to demonstration projects below 1 MW scale.

Current Electrolysis Solutions for Ammonia Production

01 Electrolysis cell design optimization for green ammonia synthesis

Advanced electrolysis cell designs can significantly improve the efficiency of green ammonia production. These designs focus on optimizing electrode materials, membrane configurations, and cell architecture to enhance electron transfer and reduce energy consumption. Innovations include specialized catalysts, improved ion exchange membranes, and novel cell geometries that maximize contact between reactants while minimizing resistance. These optimizations collectively contribute to higher conversion rates and lower energy requirements in the electrolytic synthesis of ammonia.- Electrolysis cell design for green ammonia synthesis: Advanced electrolysis cell designs can significantly improve the efficiency of green ammonia production. These designs focus on optimizing electrode materials, membrane configurations, and cell architecture to enhance electron transfer and reduce energy consumption. Innovations include specialized catalysts, improved ion exchange membranes, and integrated cooling systems that maintain optimal operating temperatures during the electrolysis process.

- Catalyst innovations for efficient nitrogen reduction: Novel catalytic materials play a crucial role in improving the efficiency of the nitrogen reduction reaction in green ammonia synthesis. These catalysts facilitate the breaking of the strong N≡N triple bond under milder conditions, reducing the energy requirements of the process. Recent developments include transition metal-based catalysts, metal-organic frameworks, and nanostructured materials that provide higher selectivity, stability, and activity at lower overpotentials.

- System integration and process optimization: Integrated systems that combine renewable energy sources with electrolysis units for ammonia production can significantly enhance overall efficiency. These systems incorporate smart control algorithms, energy recovery mechanisms, and optimized process parameters to maximize ammonia yield while minimizing energy consumption. Advanced heat management, pressure control, and reactant flow optimization contribute to improved system performance and reduced operational costs.

- Renewable energy integration for electrolysis: Efficient coupling of renewable energy sources with electrolysis systems is essential for truly green ammonia production. This integration involves advanced power electronics, energy storage solutions, and load management strategies to handle the intermittent nature of renewable energy. Technologies such as direct coupling of photovoltaic arrays or wind turbines with electrolyzers, along with buffer storage systems, help maintain stable operation and maximize the utilization of renewable electricity.

- Low-temperature and low-pressure synthesis methods: Developing electrolysis processes that can operate efficiently at lower temperatures and pressures compared to conventional Haber-Bosch process represents a significant advancement in green ammonia synthesis. These methods reduce the energy requirements and simplify the equipment needed for ammonia production. Innovations include specialized electrolytes, membrane technologies, and reactor designs that enable nitrogen reduction at ambient or near-ambient conditions while maintaining acceptable conversion rates and selectivity.

02 Catalyst innovations for low-temperature ammonia electrosynthesis

Novel catalyst materials are being developed to enable efficient ammonia synthesis at lower temperatures and pressures than traditional Haber-Bosch processes. These catalysts include transition metal nitrides, nanostructured materials, and composite electrodes that can facilitate nitrogen reduction at ambient conditions. By lowering the activation energy required for N₂ reduction, these catalysts significantly improve the energy efficiency of the electrolysis process. Research focuses on enhancing catalyst stability, selectivity, and activity to achieve commercially viable conversion rates with minimal energy input.Expand Specific Solutions03 Integrated renewable energy systems for ammonia production

Integrating renewable energy sources directly with electrolysis systems creates more efficient green ammonia production pathways. These systems incorporate smart power management to handle the intermittent nature of renewable energy, utilizing excess wind or solar power for ammonia synthesis. Advanced control systems optimize operation based on energy availability, while energy storage components ensure continuous production. This integration reduces the carbon footprint of ammonia production while improving overall system efficiency through dynamic operation and reduced energy transmission losses.Expand Specific Solutions04 Process intensification techniques for ammonia electrosynthesis

Process intensification approaches enhance the efficiency of electrolytic ammonia production through innovative reactor designs and operating conditions. These techniques include pulsed electrolysis, pressure-swing operations, and temperature modulation to optimize reaction kinetics. Advanced separation methods improve product recovery while reducing energy consumption. Microreactor and flow-cell technologies increase surface-to-volume ratios and mass transfer rates, leading to higher conversion efficiencies. These approaches collectively reduce energy requirements while increasing ammonia yield per unit of electricity consumed.Expand Specific Solutions05 Solid-state electrolyte systems for ammonia synthesis

Solid-state electrolyte systems represent an emerging approach to green ammonia synthesis with potentially higher efficiency than liquid electrolytes. These systems utilize proton-conducting ceramics, composite membranes, or solid polymer electrolytes that can operate at various temperature ranges. By eliminating liquid phases, these systems reduce resistance, prevent electrode flooding, and enable more precise control of reaction conditions. Research focuses on developing materials with high ionic conductivity, mechanical stability, and compatibility with electrode materials to achieve breakthrough improvements in electrolysis efficiency.Expand Specific Solutions

Leading Companies and Research Institutions in Green Ammonia

Green ammonia synthesis through electrolysis is evolving rapidly, with the market currently in an early growth phase. The global market is projected to expand significantly as industries seek carbon-neutral alternatives to conventional ammonia production. Companies like Topsoe A/S and thyssenkrupp AG are leading technological advancement with established electrolysis solutions, while Siemens Energy and ACWA Power are developing large-scale implementation projects. Academic institutions such as Delft University of Technology and Technical University of Denmark are driving fundamental research innovations. Emerging players like Atmonia and Battolyser are introducing novel catalytic approaches and integrated storage solutions. The technology is approaching commercial viability, with pilot projects transitioning to industrial-scale demonstrations, though challenges in efficiency and cost-competitiveness remain significant barriers to widespread adoption.

Topsoe A/S

Technical Solution: Topsoe has developed the SOEC (Solid Oxide Electrolysis Cell) technology for green ammonia synthesis, which operates at high temperatures (700-850°C) to achieve superior electrical efficiency. Their eSMR™ (electrified Steam Methane Reforming) technology combines conventional catalytic processes with electrical heating, achieving up to 30% reduction in CO2 emissions compared to conventional methods. Topsoe's Power-to-X solutions integrate renewable electricity for hydrogen production with their proprietary ammonia synthesis catalysts, enabling direct ammonia production with reported electrolysis efficiency of 70-80%. Their dynamic load response system allows the electrolysis units to operate efficiently even with fluctuating renewable energy inputs, maintaining performance at partial loads down to 20% of capacity while preserving catalyst longevity.

Strengths: High temperature operation provides superior electrical efficiency (up to 80%) compared to alkaline or PEM electrolyzers; integrated systems approach optimizes the entire ammonia production chain; proven catalyst technology with decades of industrial implementation. Weaknesses: Higher CAPEX requirements for SOEC technology; system complexity requires specialized operational expertise; high temperature operation introduces additional material challenges and safety considerations.

thyssenkrupp AG

Technical Solution: Thyssenkrupp has pioneered the alkaline water electrolysis (AWE) technology for green ammonia production through their 20MW module design that can be scaled to multi-hundred MW plants. Their system achieves hydrogen production efficiency of 70-75% (LHV basis) with a specific energy consumption of approximately 4.1-4.3 kWh/Nm³ H₂. The modular design allows for flexible operation between 20-100% load capacity, making it compatible with fluctuating renewable energy sources. Their integrated approach combines electrolysis with Uhde's ammonia synthesis technology, which operates at pressures of 150-200 bar and temperatures around 400-500°C, using an iron-based catalyst. The system includes proprietary gas purification technology that removes oxygen traces to prevent catalyst poisoning, achieving ammonia production rates of up to 3,000 metric tons per day with renewable hydrogen input.

Strengths: Proven alkaline technology with established track record in industrial applications; modular design allows for scalability and reduced CAPEX for initial deployment; integrated solution from hydrogen production to ammonia synthesis. Weaknesses: Lower efficiency compared to SOEC technology; requires significant water purification systems to prevent electrode degradation; alkaline technology has slower response times to load changes compared to PEM systems.

Key Patents and Innovations in Electrolysis Efficiency

Catalytic synthesis method, device and system for ammonia synthesis through orderly regulation of the electronic domain of nitrogen

PatentActiveUS20240199435A1

Innovation

- A catalytic synthesis method using a multi-component magnetic material catalyst with a thermal, magnetic, or electromagnetic field to regulate the electronic domain of nitrogen and hydrogen, allowing for ammonia synthesis at low temperatures and pressures, enhancing the efficiency and sustainability of the process.

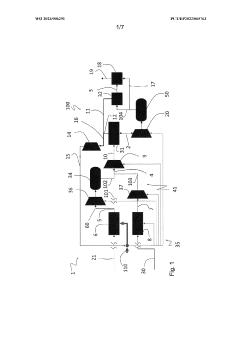

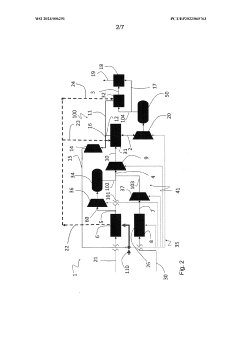

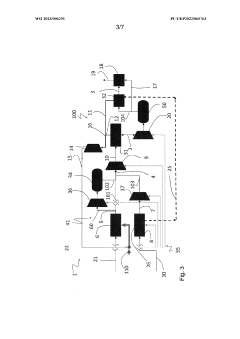

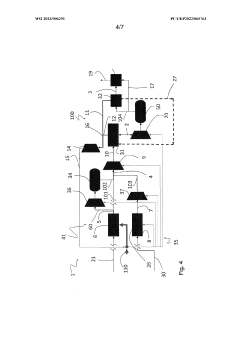

Integrated process for the synthesis of ammonia and nitric acid

PatentWO2023006291A1

Innovation

- A method for controlling the integrated ammonia-nitric acid process that selectively switches between two modes of operation based on the availability of power for water electrolysis, allowing for adaptive regulation of ammonia and nitric acid production, with excess ammonia stored for later use and thermal/electric power transferred from nitric acid production to ammonia synthesis to maintain constant production.

Energy Integration and System Optimization Approaches

Energy integration and system optimization represent critical approaches for enhancing the overall efficiency and economic viability of green ammonia synthesis systems. By strategically integrating various components and optimizing energy flows, significant improvements in electrolysis efficiency can be achieved, reducing both operational costs and environmental impact.

Heat recovery systems play a fundamental role in energy integration strategies. The electrolysis process generates substantial waste heat that can be captured and repurposed throughout the ammonia synthesis chain. Advanced heat exchangers can transfer thermal energy from electrolyzers to other system components, such as nitrogen separation units or ammonia synthesis reactors, reducing the overall energy demand by 15-25% in optimized systems.

Process intensification techniques further enhance system performance by combining multiple operations into single units. Integrated electrolyzer-reactor designs, where hydrogen production and ammonia synthesis occur in proximity, minimize energy losses associated with gas compression and transport. These configurations have demonstrated efficiency improvements of up to 30% compared to conventional segregated systems.

Smart grid integration enables dynamic operation of electrolysis units in response to renewable energy availability. Advanced control algorithms can modulate electrolyzer operation based on real-time electricity pricing and renewable generation forecasts. This approach not only reduces operational costs but also maximizes the utilization of intermittent renewable resources, with pilot projects showing potential cost reductions of 20-40% through intelligent load management.

Pressure management optimization across the system boundary represents another significant opportunity. By carefully balancing pressure requirements between electrolysis, gas separation, and synthesis processes, energy consumption for compression can be minimized. Studies indicate that optimized pressure cascades can reduce compression energy requirements by 10-15% compared to conventional approaches.

Water and oxygen management strategies complete the system optimization picture. Recirculating process water reduces freshwater consumption while recovering trace elements and thermal energy. Meanwhile, oxygen produced during electrolysis—often considered a byproduct—can be monetized for industrial applications or used to enhance other processes within the facility, improving the overall economics of green ammonia production.

Digital twin technologies and advanced simulation tools now enable comprehensive system optimization before physical implementation. These computational approaches allow engineers to evaluate thousands of potential configurations and operating parameters, identifying optimal solutions that might otherwise remain undiscovered through conventional design methodologies.

Heat recovery systems play a fundamental role in energy integration strategies. The electrolysis process generates substantial waste heat that can be captured and repurposed throughout the ammonia synthesis chain. Advanced heat exchangers can transfer thermal energy from electrolyzers to other system components, such as nitrogen separation units or ammonia synthesis reactors, reducing the overall energy demand by 15-25% in optimized systems.

Process intensification techniques further enhance system performance by combining multiple operations into single units. Integrated electrolyzer-reactor designs, where hydrogen production and ammonia synthesis occur in proximity, minimize energy losses associated with gas compression and transport. These configurations have demonstrated efficiency improvements of up to 30% compared to conventional segregated systems.

Smart grid integration enables dynamic operation of electrolysis units in response to renewable energy availability. Advanced control algorithms can modulate electrolyzer operation based on real-time electricity pricing and renewable generation forecasts. This approach not only reduces operational costs but also maximizes the utilization of intermittent renewable resources, with pilot projects showing potential cost reductions of 20-40% through intelligent load management.

Pressure management optimization across the system boundary represents another significant opportunity. By carefully balancing pressure requirements between electrolysis, gas separation, and synthesis processes, energy consumption for compression can be minimized. Studies indicate that optimized pressure cascades can reduce compression energy requirements by 10-15% compared to conventional approaches.

Water and oxygen management strategies complete the system optimization picture. Recirculating process water reduces freshwater consumption while recovering trace elements and thermal energy. Meanwhile, oxygen produced during electrolysis—often considered a byproduct—can be monetized for industrial applications or used to enhance other processes within the facility, improving the overall economics of green ammonia production.

Digital twin technologies and advanced simulation tools now enable comprehensive system optimization before physical implementation. These computational approaches allow engineers to evaluate thousands of potential configurations and operating parameters, identifying optimal solutions that might otherwise remain undiscovered through conventional design methodologies.

Economic Viability and Scaling Considerations

The economic viability of green ammonia production through electrolysis hinges critically on several interconnected factors. Current cost analyses indicate that green ammonia production costs range between $650-1,300 per ton, significantly higher than conventional methods ($200-450 per ton). This price differential represents the primary barrier to widespread adoption, despite the environmental benefits of zero-carbon production pathways.

Capital expenditure for electrolysis-based ammonia plants remains substantially higher than traditional Haber-Bosch facilities, with electrolyzer costs constituting approximately 60-70% of total plant investment. Recent technological improvements have reduced electrolyzer costs from $1,200/kW to approximately $700-800/kW, though further reductions to $400/kW or below are necessary to achieve cost parity with conventional methods.

Operational expenses are dominated by electricity costs, which account for 60-80% of production expenses. Green ammonia becomes economically competitive when renewable electricity prices fall below $30-40/MWh, coupled with high capacity utilization factors exceeding 70%. Regions with abundant renewable resources like Australia, Chile, and parts of the Middle East and North Africa present optimal locations for cost-effective production.

Scaling considerations reveal promising pathways toward economic viability. Industrial-scale electrolyzers (100+ MW) benefit from economies of scale, potentially reducing capital costs by 20-30% compared to smaller installations. Integrated plant designs that optimize heat recovery between electrolysis and ammonia synthesis stages can improve overall system efficiency by 10-15%, significantly enhancing economic performance.

Policy frameworks substantially influence economic feasibility. Carbon pricing mechanisms, renewable energy subsidies, and targeted green hydrogen/ammonia incentives can effectively bridge the cost gap. Countries implementing comprehensive policy packages have demonstrated accelerated investment in pilot and commercial-scale projects, with carbon prices above $50-75 per ton CO₂ significantly improving green ammonia's competitive position.

Future cost trajectories appear promising, with industry projections suggesting green ammonia could reach cost parity with conventional production by 2030-2035 in optimal locations. This timeline depends on continued electrolyzer technology improvements, renewable electricity cost reductions, and supportive policy environments. Early adopters in shipping, power generation, and specialized chemical applications will likely drive initial market growth before broader industrial adoption becomes economically viable.

Capital expenditure for electrolysis-based ammonia plants remains substantially higher than traditional Haber-Bosch facilities, with electrolyzer costs constituting approximately 60-70% of total plant investment. Recent technological improvements have reduced electrolyzer costs from $1,200/kW to approximately $700-800/kW, though further reductions to $400/kW or below are necessary to achieve cost parity with conventional methods.

Operational expenses are dominated by electricity costs, which account for 60-80% of production expenses. Green ammonia becomes economically competitive when renewable electricity prices fall below $30-40/MWh, coupled with high capacity utilization factors exceeding 70%. Regions with abundant renewable resources like Australia, Chile, and parts of the Middle East and North Africa present optimal locations for cost-effective production.

Scaling considerations reveal promising pathways toward economic viability. Industrial-scale electrolyzers (100+ MW) benefit from economies of scale, potentially reducing capital costs by 20-30% compared to smaller installations. Integrated plant designs that optimize heat recovery between electrolysis and ammonia synthesis stages can improve overall system efficiency by 10-15%, significantly enhancing economic performance.

Policy frameworks substantially influence economic feasibility. Carbon pricing mechanisms, renewable energy subsidies, and targeted green hydrogen/ammonia incentives can effectively bridge the cost gap. Countries implementing comprehensive policy packages have demonstrated accelerated investment in pilot and commercial-scale projects, with carbon prices above $50-75 per ton CO₂ significantly improving green ammonia's competitive position.

Future cost trajectories appear promising, with industry projections suggesting green ammonia could reach cost parity with conventional production by 2030-2035 in optimal locations. This timeline depends on continued electrolyzer technology improvements, renewable electricity cost reductions, and supportive policy environments. Early adopters in shipping, power generation, and specialized chemical applications will likely drive initial market growth before broader industrial adoption becomes economically viable.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!