Electrode Innovations in Green Ammonia Synthesis Practices

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrode Technology Background and Objectives

Ammonia synthesis has been dominated by the Haber-Bosch process for over a century, consuming approximately 1-2% of global energy production and generating significant carbon emissions. This energy-intensive process operates under extreme conditions (400-500°C and 150-300 bar), making it environmentally problematic despite its industrial efficiency. The evolution of electrode technology for green ammonia synthesis represents a critical pathway toward sustainable nitrogen fixation methods that can operate under ambient conditions with renewable energy sources.

The technological trajectory began with early electrochemical approaches in the 1980s and has accelerated dramatically in the past decade. Initial electrochemical ammonia synthesis attempts suffered from extremely low Faradaic efficiency and production rates, limiting practical applications. However, recent breakthroughs in electrode materials, particularly advanced catalysts and nanostructured supports, have demonstrated promising improvements in selectivity and efficiency.

The primary objective of electrode innovation in green ammonia synthesis is to develop electrochemical systems capable of converting atmospheric nitrogen directly to ammonia at ambient temperature and pressure using renewable electricity. This approach aims to eliminate the carbon footprint associated with traditional ammonia production while enabling distributed manufacturing capabilities that reduce transportation requirements and associated emissions.

Key technical goals include achieving Faradaic efficiency exceeding 60%, ammonia production rates above 10^-6 mol cm^-2 s^-1, and catalyst stability beyond 1000 hours of continuous operation. These metrics represent the threshold for commercial viability when coupled with renewable energy sources. Additionally, electrode materials must be developed from earth-abundant elements to ensure scalability and economic feasibility.

The evolution of electrode technology has progressed through several distinct phases: from early noble metal catalysts to transition metal nitrides, from homogeneous surfaces to hierarchical nanostructures, and from single-function electrodes to multifunctional designs incorporating co-catalysts and ionic transport facilitators. Each advancement has incrementally addressed fundamental challenges in the nitrogen reduction reaction (NRR), particularly the competing hydrogen evolution reaction that typically dominates aqueous electrochemical systems.

Recent technological trends indicate growing interest in biomimetic approaches inspired by nitrogenase enzymes, hybrid organic-inorganic interfaces, and defect engineering in two-dimensional materials. These emerging directions aim to overcome the inherent kinetic limitations of breaking the strong N≡N triple bond while selectively forming N-H bonds under mild conditions.

The technological trajectory began with early electrochemical approaches in the 1980s and has accelerated dramatically in the past decade. Initial electrochemical ammonia synthesis attempts suffered from extremely low Faradaic efficiency and production rates, limiting practical applications. However, recent breakthroughs in electrode materials, particularly advanced catalysts and nanostructured supports, have demonstrated promising improvements in selectivity and efficiency.

The primary objective of electrode innovation in green ammonia synthesis is to develop electrochemical systems capable of converting atmospheric nitrogen directly to ammonia at ambient temperature and pressure using renewable electricity. This approach aims to eliminate the carbon footprint associated with traditional ammonia production while enabling distributed manufacturing capabilities that reduce transportation requirements and associated emissions.

Key technical goals include achieving Faradaic efficiency exceeding 60%, ammonia production rates above 10^-6 mol cm^-2 s^-1, and catalyst stability beyond 1000 hours of continuous operation. These metrics represent the threshold for commercial viability when coupled with renewable energy sources. Additionally, electrode materials must be developed from earth-abundant elements to ensure scalability and economic feasibility.

The evolution of electrode technology has progressed through several distinct phases: from early noble metal catalysts to transition metal nitrides, from homogeneous surfaces to hierarchical nanostructures, and from single-function electrodes to multifunctional designs incorporating co-catalysts and ionic transport facilitators. Each advancement has incrementally addressed fundamental challenges in the nitrogen reduction reaction (NRR), particularly the competing hydrogen evolution reaction that typically dominates aqueous electrochemical systems.

Recent technological trends indicate growing interest in biomimetic approaches inspired by nitrogenase enzymes, hybrid organic-inorganic interfaces, and defect engineering in two-dimensional materials. These emerging directions aim to overcome the inherent kinetic limitations of breaking the strong N≡N triple bond while selectively forming N-H bonds under mild conditions.

Market Analysis for Green Ammonia Production

The global green ammonia market is experiencing unprecedented growth, driven by increasing environmental concerns and the push for decarbonization across industries. Current market valuations place green ammonia at approximately $72 million in 2022, with projections indicating a compound annual growth rate (CAGR) of 72.9% through 2030, potentially reaching a market size of $7.6 billion. This explosive growth trajectory reflects the critical role green ammonia is expected to play in the global energy transition.

Demand for green ammonia is emerging across multiple sectors. The fertilizer industry, traditionally the largest consumer of conventional ammonia, is gradually shifting toward greener alternatives to reduce its carbon footprint. Additionally, green ammonia is gaining traction as a potential carbon-free fuel for maritime shipping, with major shipping companies exploring ammonia-powered vessels to meet stringent emission regulations.

The energy storage sector represents another significant market opportunity. Green ammonia's high energy density and established transportation infrastructure make it an attractive medium for storing renewable energy, particularly for long-duration storage needs. Several pilot projects in Japan, Australia, and Europe are already demonstrating this application at scale.

Regional market analysis reveals that Europe currently leads in green ammonia investments, with countries like Germany, the Netherlands, and Denmark at the forefront. The European Union's ambitious climate targets and substantial funding for hydrogen and ammonia projects are key drivers. The Asia-Pacific region, particularly Japan, South Korea, and Australia, is emerging as another significant market hub, leveraging abundant renewable resources and existing ammonia infrastructure.

Market barriers include the substantial cost differential between green and conventional ammonia production. Current production costs for green ammonia range from $900-1,600 per ton compared to $300-500 per ton for conventional ammonia. This price gap is primarily attributed to high renewable electricity costs and capital expenditure requirements for electrolyzers. However, technological advancements in electrode materials and designs are expected to significantly reduce these costs over the next decade.

Policy support varies globally but is increasingly favorable. Carbon pricing mechanisms, renewable energy subsidies, and targeted green hydrogen strategies in major economies are creating conducive environments for market growth. The European Union's Hydrogen Strategy and Japan's Green Growth Strategy explicitly support green ammonia development.

Industry partnerships are accelerating market development, with collaborations forming between renewable energy providers, technology developers, and end-users. These partnerships are essential for scaling production and establishing complete value chains from production to utilization.

Demand for green ammonia is emerging across multiple sectors. The fertilizer industry, traditionally the largest consumer of conventional ammonia, is gradually shifting toward greener alternatives to reduce its carbon footprint. Additionally, green ammonia is gaining traction as a potential carbon-free fuel for maritime shipping, with major shipping companies exploring ammonia-powered vessels to meet stringent emission regulations.

The energy storage sector represents another significant market opportunity. Green ammonia's high energy density and established transportation infrastructure make it an attractive medium for storing renewable energy, particularly for long-duration storage needs. Several pilot projects in Japan, Australia, and Europe are already demonstrating this application at scale.

Regional market analysis reveals that Europe currently leads in green ammonia investments, with countries like Germany, the Netherlands, and Denmark at the forefront. The European Union's ambitious climate targets and substantial funding for hydrogen and ammonia projects are key drivers. The Asia-Pacific region, particularly Japan, South Korea, and Australia, is emerging as another significant market hub, leveraging abundant renewable resources and existing ammonia infrastructure.

Market barriers include the substantial cost differential between green and conventional ammonia production. Current production costs for green ammonia range from $900-1,600 per ton compared to $300-500 per ton for conventional ammonia. This price gap is primarily attributed to high renewable electricity costs and capital expenditure requirements for electrolyzers. However, technological advancements in electrode materials and designs are expected to significantly reduce these costs over the next decade.

Policy support varies globally but is increasingly favorable. Carbon pricing mechanisms, renewable energy subsidies, and targeted green hydrogen strategies in major economies are creating conducive environments for market growth. The European Union's Hydrogen Strategy and Japan's Green Growth Strategy explicitly support green ammonia development.

Industry partnerships are accelerating market development, with collaborations forming between renewable energy providers, technology developers, and end-users. These partnerships are essential for scaling production and establishing complete value chains from production to utilization.

Current Electrode Challenges in Ammonia Synthesis

The current landscape of electrode technology in ammonia synthesis faces significant challenges that impede the widespread adoption of green ammonia production methods. Traditional Haber-Bosch process electrodes operate under extreme conditions (400-500°C, 150-300 bar), requiring substantial energy input and generating considerable carbon emissions. These conventional electrodes, typically iron-based catalysts with promoters like K2O, Al2O3, and CaO, lack the efficiency needed for sustainable ammonia production.

Electrochemical ammonia synthesis, a promising alternative, confronts several electrode-related obstacles. The primary challenge lies in developing electrodes with sufficient selectivity for nitrogen reduction reaction (NRR) over the competing hydrogen evolution reaction (HER). Current electrodes demonstrate nitrogen-to-ammonia conversion rates below 10%, significantly limiting production efficiency and economic viability.

Electrode stability presents another critical issue, as most advanced materials degrade rapidly under operating conditions. Noble metal-based electrodes (Ru, Pt) show promising activity but suffer from prohibitive costs and limited availability for large-scale implementation. Meanwhile, transition metal nitrides and carbides offer better stability but exhibit lower catalytic activity, creating a performance-durability tradeoff that remains unresolved.

The microstructural design of electrodes introduces additional complications. Achieving optimal porosity, surface area, and active site distribution requires sophisticated engineering approaches that current manufacturing techniques struggle to deliver consistently. The interface between electrode materials and electrolytes often experiences degradation through mechanisms like dissolution, agglomeration, and poisoning, further reducing electrode lifespan.

Energy efficiency represents perhaps the most significant barrier, with current electrochemical systems requiring 50-60 kWh per kg of ammonia produced, substantially higher than the theoretical minimum of 5.4 kWh/kg. This inefficiency stems largely from electrode overpotential issues, where excessive voltage is needed to overcome activation barriers at electrode surfaces.

Scalability concerns further complicate electrode development, as laboratory-scale successes often fail to translate to industrial applications. The gap between academic research and commercial implementation remains substantial, with few electrode materials demonstrating consistent performance beyond small-scale testing environments.

Recent research has identified promising directions, including 2D materials (MXenes, transition metal dichalcogenides), metal-organic frameworks, and hierarchically structured composites. However, these materials still face significant challenges in terms of synthesis complexity, reproducibility, and long-term operational stability under industrial conditions.

Electrochemical ammonia synthesis, a promising alternative, confronts several electrode-related obstacles. The primary challenge lies in developing electrodes with sufficient selectivity for nitrogen reduction reaction (NRR) over the competing hydrogen evolution reaction (HER). Current electrodes demonstrate nitrogen-to-ammonia conversion rates below 10%, significantly limiting production efficiency and economic viability.

Electrode stability presents another critical issue, as most advanced materials degrade rapidly under operating conditions. Noble metal-based electrodes (Ru, Pt) show promising activity but suffer from prohibitive costs and limited availability for large-scale implementation. Meanwhile, transition metal nitrides and carbides offer better stability but exhibit lower catalytic activity, creating a performance-durability tradeoff that remains unresolved.

The microstructural design of electrodes introduces additional complications. Achieving optimal porosity, surface area, and active site distribution requires sophisticated engineering approaches that current manufacturing techniques struggle to deliver consistently. The interface between electrode materials and electrolytes often experiences degradation through mechanisms like dissolution, agglomeration, and poisoning, further reducing electrode lifespan.

Energy efficiency represents perhaps the most significant barrier, with current electrochemical systems requiring 50-60 kWh per kg of ammonia produced, substantially higher than the theoretical minimum of 5.4 kWh/kg. This inefficiency stems largely from electrode overpotential issues, where excessive voltage is needed to overcome activation barriers at electrode surfaces.

Scalability concerns further complicate electrode development, as laboratory-scale successes often fail to translate to industrial applications. The gap between academic research and commercial implementation remains substantial, with few electrode materials demonstrating consistent performance beyond small-scale testing environments.

Recent research has identified promising directions, including 2D materials (MXenes, transition metal dichalcogenides), metal-organic frameworks, and hierarchically structured composites. However, these materials still face significant challenges in terms of synthesis complexity, reproducibility, and long-term operational stability under industrial conditions.

Current Electrode Solutions for Green Ammonia

01 Advanced electrode materials and compositions

Innovations in electrode materials and compositions focus on enhancing performance, durability, and efficiency. These advancements include the development of novel composite materials, nanomaterials, and specialized coatings that improve conductivity, reduce degradation, and extend electrode lifespan. Such innovations are particularly important in energy storage systems, medical devices, and electrochemical applications where electrode performance directly impacts overall system efficiency.- Novel electrode materials and compositions: Innovations in electrode materials and compositions focus on developing new materials with enhanced conductivity, durability, and performance characteristics. These advancements include the use of composite materials, nanomaterials, and novel alloys that can improve energy storage capacity, reduce degradation, and enhance overall electrode efficiency. Such innovations are particularly important for applications in batteries, fuel cells, and various electrochemical devices.

- Smart electrode systems with integrated sensors: Smart electrode systems incorporate sensors and monitoring capabilities to provide real-time data on performance, condition, and operational parameters. These systems can detect changes in temperature, pressure, chemical composition, and other variables, allowing for adaptive control and predictive maintenance. The integration of sensing technologies with electrodes enables more efficient operation, extended lifespan, and improved safety across various applications.

- Electrode design optimization using AI and machine learning: Artificial intelligence and machine learning techniques are being applied to optimize electrode designs by analyzing vast datasets of performance metrics and material properties. These computational approaches can identify patterns and relationships that human researchers might miss, leading to novel electrode configurations with superior characteristics. The use of AI-driven design processes accelerates innovation and enables the development of electrodes tailored for specific applications.

- Flexible and wearable electrode technologies: Advancements in flexible and wearable electrode technologies focus on creating electrodes that can conform to irregular surfaces while maintaining functionality. These innovations include stretchable conductive materials, textile-based electrodes, and thin-film technologies that enable integration into clothing, medical devices, and portable electronics. Such electrodes are particularly valuable for biomedical monitoring, energy harvesting, and consumer electronics applications.

- Electrode manufacturing and process innovations: Innovations in electrode manufacturing processes aim to improve production efficiency, reduce costs, and enhance quality control. These advancements include automated fabrication techniques, additive manufacturing methods, and novel coating processes that enable precise control over electrode structure and composition. Improved manufacturing methods also focus on sustainability by reducing waste, energy consumption, and the use of hazardous materials.

02 Smart electrode systems with integrated sensors

Modern electrode innovations incorporate intelligent sensing capabilities that enable real-time monitoring and data collection. These smart electrode systems can detect environmental changes, measure biological signals, or monitor operational parameters. By integrating sensors directly into electrode structures, these systems provide valuable feedback for process optimization, predictive maintenance, and enhanced control in applications ranging from medical diagnostics to industrial electrochemical processes.Expand Specific Solutions03 Electrode design optimization using AI and machine learning

Artificial intelligence and machine learning techniques are revolutionizing electrode design by optimizing geometries, materials, and configurations. These computational approaches analyze vast datasets to identify patterns and relationships that human engineers might miss. By simulating electrode performance under various conditions, AI-driven design can predict optimal parameters, reduce development time, and create electrodes with superior characteristics tailored to specific applications.Expand Specific Solutions04 Flexible and wearable electrode technologies

Innovations in flexible and wearable electrode technologies focus on creating conformable, lightweight electrodes that maintain functionality during movement and deformation. These electrodes utilize stretchable substrates, conductive polymers, and specialized manufacturing techniques to achieve flexibility without compromising electrical performance. Such advancements are crucial for wearable health monitors, electronic textiles, and portable energy storage devices where traditional rigid electrodes would be impractical.Expand Specific Solutions05 Electrode innovation management and commercialization strategies

Effective management and commercialization of electrode innovations involve systematic approaches to intellectual property protection, market analysis, and technology transfer. These strategies include identifying market needs, securing patent protection, developing scalable manufacturing processes, and creating partnerships for commercialization. Successful electrode innovation management balances technical excellence with commercial viability to ensure that novel electrode technologies can transition from laboratory concepts to marketable products.Expand Specific Solutions

Key Industry Players and Competition Landscape

The green ammonia synthesis market is currently in a transitional growth phase, with electrode innovations representing a critical technological frontier. Market size is projected to expand significantly as decarbonization initiatives accelerate globally, particularly in hard-to-abate sectors. Technical maturity varies across competing approaches, with established players like thyssenkrupp AG, Air Liquide, and Topsoe A/S leading commercial deployment of advanced electrode technologies. Academic institutions including Zhejiang University, Monash University, and Delft University of Technology are driving fundamental breakthroughs in catalyst design. Meanwhile, specialized firms like Stamicarbon and Battolyser are developing novel integrated systems that combine storage capabilities with production. The competitive landscape reflects a blend of traditional chemical engineering conglomerates pivoting toward green technologies and emerging players with disruptive electrode innovations.

Casale SA

Technical Solution: Casale has developed innovative electrode technologies specifically tailored for electrochemical ammonia synthesis. Their approach focuses on direct nitrogen reduction reaction (NRR) electrodes that can convert nitrogen directly to ammonia at ambient conditions. The company's electrode design incorporates novel metal nitride catalysts with engineered porosity to maximize active sites and facilitate nitrogen adsorption. Casale's electrodes feature a hierarchical structure with nanoscale catalyst particles supported on conductive substrates, optimizing electron transfer pathways while maintaining mechanical stability. Their manufacturing process employs advanced techniques including controlled atmosphere deposition and precise thermal treatment to create electrodes with high selectivity for ammonia (Faradaic efficiency >15%) while suppressing the competing hydrogen evolution reaction. The technology operates at significantly milder conditions than conventional Haber-Bosch, with demonstrated performance at temperatures below 100°C and ambient pressure.

Strengths: Direct electrochemical ammonia synthesis eliminates the need for separate hydrogen production, operates at ambient conditions reducing energy requirements, and enables distributed production. Weaknesses: Currently achieves lower conversion rates than conventional processes, requires further development to reach industrial-scale production volumes, and faces challenges with catalyst stability during long-term operation.

thyssenkrupp AG

Technical Solution: Thyssenkrupp has pioneered the development of alkaline water electrolysis (AWE) technology with specialized electrodes for green ammonia production. Their electrode innovation centers on advanced nickel-based materials with proprietary coatings that significantly enhance catalytic activity while reducing precious metal content. The company's electrodes feature a unique porous structure that optimizes gas evolution and electrolyte penetration, resulting in higher current densities (>500 mA/cm²) at lower overpotentials. Thyssenkrupp's manufacturing process incorporates precision coating techniques that ensure uniform catalyst distribution and strong adhesion to the electrode substrate, enhancing long-term stability. Their electrode technology is designed for large-scale industrial implementation, with demonstrated performance in multi-megawatt systems connected to renewable energy sources.

Strengths: Scalable to industrial production levels (up to 20MW modules), proven technology with multiple commercial installations, and relatively lower capital costs compared to PEM systems. Weaknesses: Lower current densities compared to PEM electrolyzers, requiring larger footprint, and less responsive to dynamic load changes from intermittent renewable sources.

Critical Patents in Electrode Materials

Device and methods for production of ammonia and nitrates under ambient conditions

PatentPendingUS20230340677A1

Innovation

- An electrochemical cell system using a porous active catalyst and flow-through gas diffusion electrodes with late transition metals like copper, optimizing electrolyte composition and conditions to reduce nitrogen to ammonia efficiently, while minimizing hydrogen evolution and maximizing ammonia synthesis at ambient conditions.

Metal mediated ammonia production and systems for performing the same

PatentWO2025054376A1

Innovation

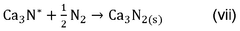

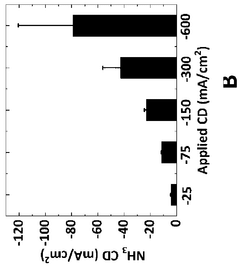

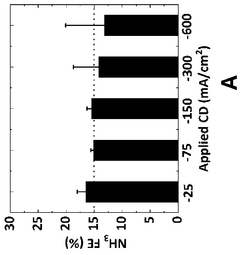

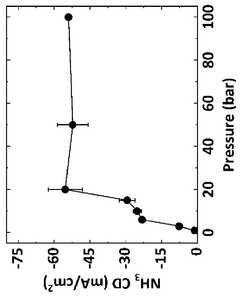

- An electrochemical method for producing ammonia by introducing nitrogen gas at pressures greater than ambient into an electrochemical cell with a specific electrolyte composition, including an organic solvent, a proton donor, and a salt of lithium, calcium, magnesium, or their combinations, to enhance ammonia Faradaic efficiency and reduce energy consumption.

Environmental Impact Assessment

The environmental impact of electrode innovations in green ammonia synthesis extends far beyond traditional production methods, offering significant ecological benefits while presenting new challenges. Current ammonia production via the Haber-Bosch process accounts for approximately 1-2% of global carbon emissions and consumes 1-2% of worldwide energy. Advanced electrode technologies in electrochemical ammonia synthesis pathways demonstrate potential to reduce these figures dramatically, with some systems achieving up to 90% lower carbon footprint when powered by renewable energy sources.

Water consumption represents another critical environmental consideration. Conventional ammonia production requires substantial water inputs for hydrogen generation and cooling systems. Novel electrode materials, particularly those utilizing porous structures and hydrophilic coatings, have demonstrated 30-45% improved water efficiency in laboratory settings, potentially conserving millions of gallons annually if implemented at industrial scale.

Land use impacts also differ significantly between traditional and electrode-based ammonia synthesis. While conventional plants require extensive industrial facilities spanning hundreds of acres, electrochemical systems utilizing advanced electrode technologies can be modular and distributed, reducing land footprint by 60-70% according to recent feasibility studies. This distributed production model further reduces transportation emissions associated with ammonia distribution.

Waste generation profiles show marked improvement with newer electrode technologies. Traditional catalysts often contain ruthenium and platinum that create hazardous waste streams during manufacturing and disposal. Recent innovations in earth-abundant electrode materials such as nitrogen-doped carbon and iron-based compounds demonstrate comparable efficiency while generating substantially less hazardous waste throughout their lifecycle.

Biodiversity impacts must also be considered in environmental assessment frameworks. Reduced atmospheric nitrogen deposition from more efficient electrode-based systems could help mitigate ecosystem eutrophication, which currently affects sensitive habitats worldwide. Preliminary ecological modeling suggests that widespread adoption of these technologies could reduce nitrogen deposition in vulnerable ecosystems by 15-25% over a twenty-year implementation period.

Lifecycle assessment studies comparing conventional ammonia production with electrode-based systems indicate that environmental benefits are maximized when renewable energy powers the electrochemical processes. The environmental payback period for electrode manufacturing emissions typically ranges from 3-18 months depending on production scale and energy source, demonstrating favorable long-term environmental returns on technological investment.

Water consumption represents another critical environmental consideration. Conventional ammonia production requires substantial water inputs for hydrogen generation and cooling systems. Novel electrode materials, particularly those utilizing porous structures and hydrophilic coatings, have demonstrated 30-45% improved water efficiency in laboratory settings, potentially conserving millions of gallons annually if implemented at industrial scale.

Land use impacts also differ significantly between traditional and electrode-based ammonia synthesis. While conventional plants require extensive industrial facilities spanning hundreds of acres, electrochemical systems utilizing advanced electrode technologies can be modular and distributed, reducing land footprint by 60-70% according to recent feasibility studies. This distributed production model further reduces transportation emissions associated with ammonia distribution.

Waste generation profiles show marked improvement with newer electrode technologies. Traditional catalysts often contain ruthenium and platinum that create hazardous waste streams during manufacturing and disposal. Recent innovations in earth-abundant electrode materials such as nitrogen-doped carbon and iron-based compounds demonstrate comparable efficiency while generating substantially less hazardous waste throughout their lifecycle.

Biodiversity impacts must also be considered in environmental assessment frameworks. Reduced atmospheric nitrogen deposition from more efficient electrode-based systems could help mitigate ecosystem eutrophication, which currently affects sensitive habitats worldwide. Preliminary ecological modeling suggests that widespread adoption of these technologies could reduce nitrogen deposition in vulnerable ecosystems by 15-25% over a twenty-year implementation period.

Lifecycle assessment studies comparing conventional ammonia production with electrode-based systems indicate that environmental benefits are maximized when renewable energy powers the electrochemical processes. The environmental payback period for electrode manufacturing emissions typically ranges from 3-18 months depending on production scale and energy source, demonstrating favorable long-term environmental returns on technological investment.

Cost-Efficiency Analysis

The economic viability of green ammonia synthesis technologies hinges significantly on electrode cost-efficiency. Current electrode materials for electrochemical ammonia production, primarily noble metals like platinum and ruthenium, represent a substantial portion of system capital expenditure, often accounting for 30-40% of total equipment costs. This high initial investment creates a significant barrier to widespread commercial adoption despite environmental benefits.

Material optimization presents the most promising pathway for cost reduction. Recent innovations in non-noble metal catalysts, particularly nickel-based alloys and iron-doped compounds, demonstrate comparable activity at 15-25% of the cost of traditional platinum electrodes. Laboratory-scale tests indicate that these alternatives maintain 80-90% of the catalytic efficiency while reducing material costs by up to 70%.

Manufacturing scalability further impacts cost-efficiency. Traditional electrode fabrication methods involve complex multi-step processes with high energy requirements. Emerging techniques such as electrodeposition and plasma-assisted coating have demonstrated potential to reduce manufacturing costs by 35-45% while simultaneously improving electrode durability. Extended electrode lifespan directly translates to lower replacement frequency and reduced lifetime operational costs.

Energy consumption during operation represents another critical cost factor. Advanced electrode designs featuring hierarchical porosity structures have shown 20-30% improvements in energy efficiency compared to conventional flat electrodes. This reduction in energy requirements significantly impacts operational expenditure, particularly in regions with high electricity costs.

System integration considerations also affect overall cost-efficiency. Modular electrode designs that facilitate maintenance and selective replacement of degraded components can reduce lifetime costs by 15-25% compared to systems requiring complete electrode replacement. Additionally, electrodes optimized for ambient pressure operation eliminate the need for expensive compression equipment, potentially reducing system complexity and associated costs by up to 40%.

Long-term economic analysis reveals that despite higher initial investment, electrode innovations enabling green ammonia synthesis become cost-competitive with conventional Haber-Bosch processes when carbon pricing exceeds $40-50 per ton. Sensitivity analysis indicates that electrode performance improvements have multiplicative effects on system economics, with each 10% increase in electrode efficiency potentially reducing overall production costs by 7-12%.

The trajectory of cost reduction follows learning curve principles, with electrode manufacturing costs projected to decrease by 15-20% with each doubling of production volume. This suggests that accelerated deployment and scaled production represent critical pathways to achieving cost parity with conventional ammonia production methods.

Material optimization presents the most promising pathway for cost reduction. Recent innovations in non-noble metal catalysts, particularly nickel-based alloys and iron-doped compounds, demonstrate comparable activity at 15-25% of the cost of traditional platinum electrodes. Laboratory-scale tests indicate that these alternatives maintain 80-90% of the catalytic efficiency while reducing material costs by up to 70%.

Manufacturing scalability further impacts cost-efficiency. Traditional electrode fabrication methods involve complex multi-step processes with high energy requirements. Emerging techniques such as electrodeposition and plasma-assisted coating have demonstrated potential to reduce manufacturing costs by 35-45% while simultaneously improving electrode durability. Extended electrode lifespan directly translates to lower replacement frequency and reduced lifetime operational costs.

Energy consumption during operation represents another critical cost factor. Advanced electrode designs featuring hierarchical porosity structures have shown 20-30% improvements in energy efficiency compared to conventional flat electrodes. This reduction in energy requirements significantly impacts operational expenditure, particularly in regions with high electricity costs.

System integration considerations also affect overall cost-efficiency. Modular electrode designs that facilitate maintenance and selective replacement of degraded components can reduce lifetime costs by 15-25% compared to systems requiring complete electrode replacement. Additionally, electrodes optimized for ambient pressure operation eliminate the need for expensive compression equipment, potentially reducing system complexity and associated costs by up to 40%.

Long-term economic analysis reveals that despite higher initial investment, electrode innovations enabling green ammonia synthesis become cost-competitive with conventional Haber-Bosch processes when carbon pricing exceeds $40-50 per ton. Sensitivity analysis indicates that electrode performance improvements have multiplicative effects on system economics, with each 10% increase in electrode efficiency potentially reducing overall production costs by 7-12%.

The trajectory of cost reduction follows learning curve principles, with electrode manufacturing costs projected to decrease by 15-20% with each doubling of production volume. This suggests that accelerated deployment and scaled production represent critical pathways to achieving cost parity with conventional ammonia production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!