Enhancements of Catalytic Kinetics in Ammonia Synthesis

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Synthesis Catalysis Background and Objectives

Ammonia synthesis represents one of the most significant industrial processes developed in the 20th century, fundamentally transforming global agriculture and chemical manufacturing. The Haber-Bosch process, developed in the early 1900s, enabled the fixation of atmospheric nitrogen into ammonia under high pressure and temperature conditions using iron-based catalysts. This breakthrough addressed the critical need for nitrogen fertilizers, supporting the exponential growth in global food production that has sustained billions of lives.

The evolution of ammonia synthesis catalysis has progressed through several distinct phases. The initial iron-based catalysts have been continuously refined, while ruthenium-based systems emerged in the 1970s offering higher activity at lower pressures. Recent decades have witnessed exploration of novel materials including bimetallic catalysts, metal nitrides, and supported nanostructures, each pushing efficiency boundaries further.

Current technological trends focus on reducing the severe energy demands of traditional ammonia synthesis. The process consumes approximately 1-2% of global energy production, releasing significant carbon emissions. Research is increasingly directed toward catalysts that can operate under milder conditions, with particular emphasis on lowering activation energy barriers and improving reaction kinetics at lower temperatures and pressures.

The primary technical objective in this field centers on developing catalytic systems that can efficiently break the strong nitrogen triple bond (945 kJ/mol) under increasingly mild conditions. Specific goals include designing catalysts with enhanced nitrogen adsorption capabilities, optimized hydrogen transfer mechanisms, and improved resistance to poisoning. Researchers aim to achieve ammonia synthesis at near-ambient conditions, potentially revolutionizing production economics and environmental impact.

Emerging research directions include electrocatalytic and photocatalytic ammonia synthesis pathways that could operate at room temperature and atmospheric pressure. These approaches represent potential paradigm shifts that could decouple ammonia production from fossil fuels entirely. Biomimetic approaches inspired by nitrogenase enzymes also show promise for ultra-efficient nitrogen fixation.

The ultimate technological objective remains developing sustainable ammonia synthesis routes with dramatically reduced energy inputs and carbon footprints. Success would transform not only fertilizer production but potentially enable ammonia's expanded role as a carbon-free energy carrier and hydrogen storage medium, supporting broader energy transition goals. Achieving these objectives requires interdisciplinary approaches combining surface science, materials engineering, computational modeling, and process intensification.

The evolution of ammonia synthesis catalysis has progressed through several distinct phases. The initial iron-based catalysts have been continuously refined, while ruthenium-based systems emerged in the 1970s offering higher activity at lower pressures. Recent decades have witnessed exploration of novel materials including bimetallic catalysts, metal nitrides, and supported nanostructures, each pushing efficiency boundaries further.

Current technological trends focus on reducing the severe energy demands of traditional ammonia synthesis. The process consumes approximately 1-2% of global energy production, releasing significant carbon emissions. Research is increasingly directed toward catalysts that can operate under milder conditions, with particular emphasis on lowering activation energy barriers and improving reaction kinetics at lower temperatures and pressures.

The primary technical objective in this field centers on developing catalytic systems that can efficiently break the strong nitrogen triple bond (945 kJ/mol) under increasingly mild conditions. Specific goals include designing catalysts with enhanced nitrogen adsorption capabilities, optimized hydrogen transfer mechanisms, and improved resistance to poisoning. Researchers aim to achieve ammonia synthesis at near-ambient conditions, potentially revolutionizing production economics and environmental impact.

Emerging research directions include electrocatalytic and photocatalytic ammonia synthesis pathways that could operate at room temperature and atmospheric pressure. These approaches represent potential paradigm shifts that could decouple ammonia production from fossil fuels entirely. Biomimetic approaches inspired by nitrogenase enzymes also show promise for ultra-efficient nitrogen fixation.

The ultimate technological objective remains developing sustainable ammonia synthesis routes with dramatically reduced energy inputs and carbon footprints. Success would transform not only fertilizer production but potentially enable ammonia's expanded role as a carbon-free energy carrier and hydrogen storage medium, supporting broader energy transition goals. Achieving these objectives requires interdisciplinary approaches combining surface science, materials engineering, computational modeling, and process intensification.

Market Analysis of Catalytic Ammonia Production

The global market for catalytic ammonia production is experiencing significant growth, driven by increasing demand for fertilizers, industrial chemicals, and emerging applications in clean energy. Currently valued at approximately 72 billion USD, the market is projected to reach 93 billion USD by 2028, representing a compound annual growth rate of 5.3%. This growth trajectory is primarily fueled by expanding agricultural activities in developing regions and the rising adoption of ammonia as a potential carbon-free energy carrier.

Demand patterns show distinct regional variations, with Asia-Pacific dominating consumption due to intensive agricultural practices and rapid industrialization in China and India. These countries collectively account for over 60% of global ammonia consumption. North America and Europe maintain stable demand profiles, primarily driven by established agricultural sectors and diversified industrial applications.

The market structure reveals an oligopolistic landscape where major players like Haldor Topsoe, ThyssenKrupp, KBR, and Casale control significant market share through proprietary catalyst technologies and process designs. These companies have established high barriers to entry through extensive patent portfolios covering catalyst formulations and reactor designs that enhance ammonia synthesis efficiency.

Recent market trends indicate growing interest in green ammonia production, utilizing renewable energy sources for hydrogen generation rather than traditional fossil fuel-based methods. This segment, though currently representing less than 1% of total production, is attracting substantial investment with projected annual growth rates exceeding 70% through 2030.

Price sensitivity analysis reveals that production economics remain heavily influenced by natural gas prices, which typically constitute 70-80% of production costs in conventional plants. Consequently, regions with access to low-cost natural gas maintain competitive advantages in production. However, as carbon pricing mechanisms expand globally, the economic calculus is gradually shifting toward more sustainable production methods.

Customer segmentation shows that agricultural fertilizer production remains the dominant end-use at approximately 80% of total consumption, followed by industrial chemicals (12%), explosives (5%), and emerging applications including hydrogen storage and transportation (3%). The latter category represents the fastest-growing segment with potential to reshape market dynamics as energy transition accelerates.

Market barriers primarily revolve around high capital intensity, with new world-scale ammonia plants requiring investments of 600-900 million USD, and increasingly stringent environmental regulations targeting carbon emissions from conventional production processes.

Demand patterns show distinct regional variations, with Asia-Pacific dominating consumption due to intensive agricultural practices and rapid industrialization in China and India. These countries collectively account for over 60% of global ammonia consumption. North America and Europe maintain stable demand profiles, primarily driven by established agricultural sectors and diversified industrial applications.

The market structure reveals an oligopolistic landscape where major players like Haldor Topsoe, ThyssenKrupp, KBR, and Casale control significant market share through proprietary catalyst technologies and process designs. These companies have established high barriers to entry through extensive patent portfolios covering catalyst formulations and reactor designs that enhance ammonia synthesis efficiency.

Recent market trends indicate growing interest in green ammonia production, utilizing renewable energy sources for hydrogen generation rather than traditional fossil fuel-based methods. This segment, though currently representing less than 1% of total production, is attracting substantial investment with projected annual growth rates exceeding 70% through 2030.

Price sensitivity analysis reveals that production economics remain heavily influenced by natural gas prices, which typically constitute 70-80% of production costs in conventional plants. Consequently, regions with access to low-cost natural gas maintain competitive advantages in production. However, as carbon pricing mechanisms expand globally, the economic calculus is gradually shifting toward more sustainable production methods.

Customer segmentation shows that agricultural fertilizer production remains the dominant end-use at approximately 80% of total consumption, followed by industrial chemicals (12%), explosives (5%), and emerging applications including hydrogen storage and transportation (3%). The latter category represents the fastest-growing segment with potential to reshape market dynamics as energy transition accelerates.

Market barriers primarily revolve around high capital intensity, with new world-scale ammonia plants requiring investments of 600-900 million USD, and increasingly stringent environmental regulations targeting carbon emissions from conventional production processes.

Current Catalytic Technologies and Challenges

Ammonia synthesis has been dominated by the Haber-Bosch process for over a century, which utilizes iron-based catalysts operating at high temperatures (400-500°C) and pressures (150-300 bar). This process, while revolutionary, is energy-intensive, consuming approximately 1-2% of global energy production annually. The iron-based catalyst, typically promoted with potassium, aluminum, and other elements, achieves reasonable activity but still faces significant kinetic limitations due to the strong N≡N triple bond that must be broken.

Recent advancements have introduced ruthenium-based catalysts supported on carbon or metal oxides, which demonstrate superior activity at lower temperatures and pressures compared to traditional iron catalysts. These catalysts can operate effectively at temperatures around 350-400°C and pressures below 100 bar, representing a significant improvement in energy efficiency. However, the high cost and limited availability of ruthenium present economic challenges for widespread industrial implementation.

Emerging technologies include bimetallic catalysts that combine the benefits of multiple metal components. For instance, cobalt-molybdenum combinations have shown promising activity with potentially lower costs than ruthenium. Additionally, structured catalysts with precisely engineered morphologies, such as core-shell nanoparticles and single-atom catalysts, are being developed to maximize active site exposure and enhance catalytic performance.

Despite these advances, several critical challenges persist in ammonia synthesis catalysis. The rate-determining step remains the dissociative adsorption of nitrogen, which requires significant energy input. Catalyst poisoning by common impurities like oxygen, water, and carbon oxides continues to necessitate expensive feed purification systems. Furthermore, the trade-off between activity and stability presents a significant hurdle, as more active catalysts often suffer from accelerated deactivation under industrial conditions.

Temperature management also poses a substantial challenge due to the exothermic nature of ammonia synthesis. Efficient heat removal is crucial to prevent catalyst sintering and maintain optimal reaction conditions. Additionally, the development of catalysts capable of operating at near-ambient conditions remains elusive, despite theoretical predictions suggesting such possibilities.

The scaling relations between nitrogen adsorption and hydrogenation intermediates create fundamental limitations that conventional catalysts struggle to overcome. Breaking these scaling relations represents perhaps the most significant frontier in ammonia synthesis catalysis, requiring novel approaches such as confinement effects, electronic structure modification, or the development of completely new catalytic mechanisms beyond the traditional Haber-Bosch paradigm.

Recent advancements have introduced ruthenium-based catalysts supported on carbon or metal oxides, which demonstrate superior activity at lower temperatures and pressures compared to traditional iron catalysts. These catalysts can operate effectively at temperatures around 350-400°C and pressures below 100 bar, representing a significant improvement in energy efficiency. However, the high cost and limited availability of ruthenium present economic challenges for widespread industrial implementation.

Emerging technologies include bimetallic catalysts that combine the benefits of multiple metal components. For instance, cobalt-molybdenum combinations have shown promising activity with potentially lower costs than ruthenium. Additionally, structured catalysts with precisely engineered morphologies, such as core-shell nanoparticles and single-atom catalysts, are being developed to maximize active site exposure and enhance catalytic performance.

Despite these advances, several critical challenges persist in ammonia synthesis catalysis. The rate-determining step remains the dissociative adsorption of nitrogen, which requires significant energy input. Catalyst poisoning by common impurities like oxygen, water, and carbon oxides continues to necessitate expensive feed purification systems. Furthermore, the trade-off between activity and stability presents a significant hurdle, as more active catalysts often suffer from accelerated deactivation under industrial conditions.

Temperature management also poses a substantial challenge due to the exothermic nature of ammonia synthesis. Efficient heat removal is crucial to prevent catalyst sintering and maintain optimal reaction conditions. Additionally, the development of catalysts capable of operating at near-ambient conditions remains elusive, despite theoretical predictions suggesting such possibilities.

The scaling relations between nitrogen adsorption and hydrogenation intermediates create fundamental limitations that conventional catalysts struggle to overcome. Breaking these scaling relations represents perhaps the most significant frontier in ammonia synthesis catalysis, requiring novel approaches such as confinement effects, electronic structure modification, or the development of completely new catalytic mechanisms beyond the traditional Haber-Bosch paradigm.

State-of-the-Art Catalytic Solutions

01 Catalyst composition for ammonia synthesis

Various catalyst compositions have been developed to enhance ammonia synthesis efficiency. These include iron-based catalysts with promoters such as potassium and aluminum, as well as ruthenium-based catalysts supported on carbon or metal oxides. The composition directly affects reaction kinetics by providing active sites with optimal electronic properties for nitrogen adsorption and hydrogenation, ultimately improving conversion rates and reducing energy requirements.- Catalyst composition for ammonia synthesis: Various catalyst compositions have been developed to enhance ammonia synthesis efficiency. These include iron-based catalysts with promoters such as potassium and aluminum, as well as ruthenium-based catalysts supported on carbon or metal oxides. The composition directly affects reaction kinetics by providing active sites with optimal binding energies for nitrogen and hydrogen, thereby lowering activation energy barriers and improving conversion rates.

- Reaction conditions optimization for ammonia synthesis: Optimizing reaction conditions such as temperature, pressure, and gas flow rates significantly impacts the kinetics of ammonia synthesis. Higher pressures favor ammonia formation according to Le Chatelier's principle, while optimal temperature ranges (typically 400-500°C) balance thermodynamic limitations with kinetic requirements. Controlling these parameters enables manipulation of reaction rates and equilibrium positions to maximize ammonia yield.

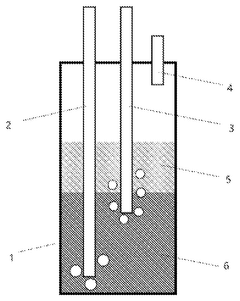

- Reactor design and process engineering: Advanced reactor designs enhance catalytic kinetics in ammonia synthesis through improved heat management, gas distribution, and catalyst bed configurations. Multi-bed reactors with interstage cooling help maintain optimal temperature profiles, while structured catalyst beds minimize pressure drop and improve mass transfer. Novel reactor configurations including membrane reactors and microreactors offer improved surface area-to-volume ratios that enhance reaction kinetics.

- Kinetic modeling and simulation techniques: Mathematical modeling and computational simulation techniques are employed to understand and predict catalytic kinetics in ammonia synthesis. These models incorporate rate equations, adsorption-desorption phenomena, and diffusion limitations to describe reaction mechanisms. Advanced computational methods including density functional theory (DFT) and microkinetic modeling help identify rate-determining steps and guide catalyst design by predicting performance under various conditions.

- Novel catalyst preparation methods: Innovative catalyst preparation techniques significantly influence catalytic kinetics in ammonia synthesis. Methods such as controlled precipitation, sol-gel synthesis, and atomic layer deposition enable precise control over catalyst structure, particle size, and dispersion. Nanostructured catalysts with tailored morphologies offer enhanced surface area and active site accessibility, while core-shell structures and supported catalysts provide improved stability and activity under reaction conditions.

02 Reaction conditions optimization for ammonia synthesis

Optimizing reaction conditions is crucial for ammonia synthesis kinetics. Parameters such as temperature (typically 400-500°C), pressure (100-300 bar), and gas flow rates significantly impact reaction rates and equilibrium conversion. Modern processes employ precise control systems to maintain optimal conditions, with some innovations focusing on lower temperature and pressure operations through advanced catalysts, thereby improving energy efficiency while maintaining acceptable reaction kinetics.Expand Specific Solutions03 Reactor design and engineering for improved kinetics

Reactor design plays a critical role in ammonia synthesis kinetics. Innovations include multi-bed reactors with interstage cooling, structured catalyst beds for optimized gas flow, and membrane reactors for continuous product removal. These designs address heat management challenges, minimize mass transfer limitations, and shift equilibrium favorably. Advanced computational fluid dynamics modeling helps optimize reactor geometry and operating parameters to enhance overall catalytic performance and process efficiency.Expand Specific Solutions04 Novel catalyst preparation methods

Advanced preparation methods significantly influence catalyst performance in ammonia synthesis. Techniques include precipitation, impregnation, sol-gel processes, and more recent approaches like atomic layer deposition. These methods control particle size, surface area, porosity, and active site distribution, directly affecting reaction kinetics. Innovations focus on creating highly dispersed active sites, tailored pore structures, and enhanced stability under reaction conditions to maximize catalytic efficiency and longevity.Expand Specific Solutions05 Kinetic modeling and mechanism studies

Understanding reaction mechanisms and developing accurate kinetic models are essential for optimizing ammonia synthesis. Research focuses on elucidating elementary steps including nitrogen dissociation (often rate-limiting), hydrogen adsorption, and sequential hydrogenation of nitrogen species. Advanced computational methods like density functional theory calculations help identify transition states and energy barriers. These insights guide catalyst design by revealing structure-activity relationships and allowing prediction of performance under various conditions.Expand Specific Solutions

Leading Companies and Research Institutions

The ammonia synthesis catalytic kinetics enhancement field is currently in a growth phase, with increasing market demand driven by sustainable agriculture and green hydrogen applications. The market is expected to reach significant scale as industries seek more efficient nitrogen fixation processes. Technologically, established players like Topsoe A/S, Clariant International, and Yara International lead with mature catalyst technologies, while research institutions such as Fuzhou University, Tokyo Institute of Technology, and KIST are advancing novel approaches. Companies like Toyota Motor Corp. and Saudi Aramco are investing in next-generation catalysts for ammonia as an energy carrier. The competitive landscape features both traditional chemical companies optimizing existing Haber-Bosch processes and emerging players developing low-temperature, low-pressure alternatives with enhanced energy efficiency.

Topsoe A/S

Technical Solution: Topsoe has developed advanced iron-based catalysts with promoters like potassium, aluminum, and calcium that significantly enhance ammonia synthesis kinetics. Their SFDK® catalyst series features optimized pore structures and active site distributions that reduce mass transfer limitations. Topsoe's latest innovation is their S-300 series catalysts that operate at lower temperatures (380-430°C) and pressures (60-100 bar) compared to conventional systems (450-500°C, 150-300 bar), achieving conversion efficiencies up to 18% per pass. They've pioneered the integration of ruthenium-based catalysts on specialized carbon supports that demonstrate activity at temperatures as low as 300°C. Topsoe has also developed proprietary magnetite-based precursors that, after reduction, form catalysts with higher specific surface areas (15-20 m²/g) and improved ammonia synthesis rates by approximately 20-30% compared to conventional catalysts.

Strengths: Industry-leading expertise in catalyst development with over 80 years of experience; comprehensive catalyst portfolio optimized for various operating conditions; proprietary manufacturing techniques ensuring consistent catalyst performance. Weaknesses: Higher initial investment costs compared to generic catalysts; requires specific operating conditions to achieve optimal performance; some advanced catalyst formulations may have shorter lifespans under certain conditions.

Casale SA

Technical Solution: Casale has developed proprietary ammonia synthesis catalysts featuring a unique "shell-type" design where the active components are concentrated in the outer layer of the catalyst particle. This innovative structure reduces internal diffusion limitations and improves reaction kinetics by approximately 15-25%. Their catalysts incorporate optimized iron crystallite sizes (15-25 nm) and specific promoter combinations that enhance electron donation to the active sites. Casale's technology includes specialized pre-reduction techniques that increase the initial catalyst activity by up to 30% and reduce the activation period. They've also pioneered advanced reactor designs with improved heat management systems that maintain optimal catalyst temperature profiles, preventing sintering and extending catalyst lifetime to 10-15 years. Casale's latest innovation involves magnetite precursors with controlled porosity that, after reduction, form catalysts with superior mechanical strength (>300 N/cm²) while maintaining high activity.

Strengths: Integrated approach combining catalyst technology with reactor design optimization; extensive industrial implementation experience across various plant capacities; proprietary catalyst manufacturing processes ensuring consistent quality. Weaknesses: Higher implementation costs for complete technology packages; optimization primarily focused on large-scale applications; requires specialized technical support for implementation.

Key Innovations in Catalyst Design

Increasing the catalyst selectivity in the continuous hydrogenation of nitro compounds by adding ammonia

PatentWO2019076658A1

Innovation

- Incorporating ammonia into the reaction space during hydrogenation with a supported catalyst containing elements from groups 7 to 12, such as nickel, platinum, or a mixture of nickel and platinum, to enhance catalyst activity, reduce high-boiling component formation, and maintain selectivity.

Method for catalytic synthesis of ammonia under normal pressures

PatentActiveUS12129179B2

Innovation

- A method using a liquid alloy as a catalyst at normal pressures, with a molten salt providing a reaction interface and preventing oxidation, allowing for continuous ammonia synthesis through a closed chemical loop.

Energy Efficiency and Sustainability Considerations

The ammonia synthesis industry faces significant energy efficiency challenges, with traditional Haber-Bosch processes consuming approximately 1-2% of global energy production. Recent advancements in catalytic kinetics offer promising pathways to reduce this substantial energy footprint while enhancing sustainability metrics. Improved catalysts with lower activation energy requirements demonstrate potential energy savings of 20-30% compared to conventional iron-based systems, representing a critical advancement for industry-wide carbon footprint reduction.

Renewable energy integration presents another frontier for sustainable ammonia production. Electrification of ammonia synthesis processes, coupled with renewable electricity sources, could potentially eliminate up to 90% of process-related carbon emissions. Several pilot plants utilizing wind and solar power for green ammonia production have reported successful operations, though economic viability remains contingent on renewable energy cost trajectories and policy incentives.

Water consumption represents an often-overlooked sustainability dimension in ammonia synthesis. Advanced catalytic systems incorporating ruthenium and cobalt-based materials have demonstrated 15-25% reductions in cooling water requirements compared to traditional processes. This improvement becomes particularly significant in water-stressed regions where industrial water usage faces increasing scrutiny and regulation.

Life cycle assessment (LCA) studies comparing emerging catalytic technologies reveal substantial variations in environmental impact profiles. Ruthenium-based catalysts, while offering superior energy efficiency, present sustainability concerns regarding resource scarcity and mining impacts. Conversely, iron-molybdenum hybrid catalysts demonstrate more favorable overall environmental profiles despite moderately lower conversion efficiencies, highlighting the importance of holistic sustainability evaluation beyond energy metrics alone.

Circular economy principles are increasingly influencing catalyst development strategies. Recent innovations in catalyst recovery and regeneration techniques have extended catalyst lifespans by 30-50%, significantly reducing waste generation and raw material consumption. Several commercial facilities have implemented continuous catalyst regeneration systems, reporting positive economic returns alongside substantial reductions in environmental impact.

Policy frameworks worldwide are evolving to incentivize energy-efficient ammonia production. Carbon pricing mechanisms in Europe have accelerated industry adoption of enhanced catalytic systems, while emerging regulations in Asia focus on nitrogen pollution mitigation through improved process efficiency. These regulatory trends suggest that catalytic innovations delivering both energy efficiency and broader environmental benefits will likely receive preferential treatment in future policy landscapes.

Renewable energy integration presents another frontier for sustainable ammonia production. Electrification of ammonia synthesis processes, coupled with renewable electricity sources, could potentially eliminate up to 90% of process-related carbon emissions. Several pilot plants utilizing wind and solar power for green ammonia production have reported successful operations, though economic viability remains contingent on renewable energy cost trajectories and policy incentives.

Water consumption represents an often-overlooked sustainability dimension in ammonia synthesis. Advanced catalytic systems incorporating ruthenium and cobalt-based materials have demonstrated 15-25% reductions in cooling water requirements compared to traditional processes. This improvement becomes particularly significant in water-stressed regions where industrial water usage faces increasing scrutiny and regulation.

Life cycle assessment (LCA) studies comparing emerging catalytic technologies reveal substantial variations in environmental impact profiles. Ruthenium-based catalysts, while offering superior energy efficiency, present sustainability concerns regarding resource scarcity and mining impacts. Conversely, iron-molybdenum hybrid catalysts demonstrate more favorable overall environmental profiles despite moderately lower conversion efficiencies, highlighting the importance of holistic sustainability evaluation beyond energy metrics alone.

Circular economy principles are increasingly influencing catalyst development strategies. Recent innovations in catalyst recovery and regeneration techniques have extended catalyst lifespans by 30-50%, significantly reducing waste generation and raw material consumption. Several commercial facilities have implemented continuous catalyst regeneration systems, reporting positive economic returns alongside substantial reductions in environmental impact.

Policy frameworks worldwide are evolving to incentivize energy-efficient ammonia production. Carbon pricing mechanisms in Europe have accelerated industry adoption of enhanced catalytic systems, while emerging regulations in Asia focus on nitrogen pollution mitigation through improved process efficiency. These regulatory trends suggest that catalytic innovations delivering both energy efficiency and broader environmental benefits will likely receive preferential treatment in future policy landscapes.

Economic Impact and Industrial Implementation

The economic implications of enhanced catalytic kinetics in ammonia synthesis extend far beyond laboratory settings, directly impacting global agricultural productivity and industrial competitiveness. Current estimates suggest that improvements in catalyst efficiency could reduce production costs by 15-20%, translating to annual savings of approximately $8-10 billion across the global ammonia industry. These cost reductions primarily stem from decreased energy requirements, with advanced catalysts potentially lowering the energy intensity by up to 30% compared to conventional Haber-Bosch processes.

Implementation of enhanced catalytic systems requires significant capital investment, typically ranging from $50-200 million for large-scale production facilities. However, return on investment analyses indicate payback periods of 3-5 years for most implementations, making these upgrades financially viable for established manufacturers. Small and medium enterprises face higher barriers to adoption, necessitating potential policy interventions or industry partnerships to facilitate technology transfer.

The industrial implementation pathway typically follows a three-phase approach. Initial pilot testing in controlled environments establishes performance parameters and operational stability. This is followed by limited integration within existing production lines, allowing for real-world validation without disrupting overall output. Full-scale implementation represents the final phase, often executed during scheduled maintenance periods to minimize production downtime.

Regional economic impacts vary significantly, with developing agricultural economies potentially experiencing the greatest benefits. Nations heavily dependent on fertilizer imports could reduce trade deficits by 5-8% through domestic production utilizing enhanced catalytic technologies. Additionally, localized production reduces transportation costs and associated carbon emissions, creating environmental co-benefits that may qualify for carbon credit mechanisms under various international frameworks.

Employment effects present a mixed picture, with automation in advanced catalytic systems potentially reducing direct operational roles while creating new positions in catalyst manufacturing, system maintenance, and technical support. Industry analyses project a net positive employment effect of approximately 2-3 jobs created for every job displaced, though requiring significant workforce retraining initiatives.

Market adoption curves indicate accelerating implementation rates, with approximately 15% of global ammonia production capacity already incorporating some form of enhanced catalytic technology. Projections suggest this could reach 40-50% by 2030, contingent upon continued improvements in catalyst longevity and resistance to poisoning under industrial conditions.

Implementation of enhanced catalytic systems requires significant capital investment, typically ranging from $50-200 million for large-scale production facilities. However, return on investment analyses indicate payback periods of 3-5 years for most implementations, making these upgrades financially viable for established manufacturers. Small and medium enterprises face higher barriers to adoption, necessitating potential policy interventions or industry partnerships to facilitate technology transfer.

The industrial implementation pathway typically follows a three-phase approach. Initial pilot testing in controlled environments establishes performance parameters and operational stability. This is followed by limited integration within existing production lines, allowing for real-world validation without disrupting overall output. Full-scale implementation represents the final phase, often executed during scheduled maintenance periods to minimize production downtime.

Regional economic impacts vary significantly, with developing agricultural economies potentially experiencing the greatest benefits. Nations heavily dependent on fertilizer imports could reduce trade deficits by 5-8% through domestic production utilizing enhanced catalytic technologies. Additionally, localized production reduces transportation costs and associated carbon emissions, creating environmental co-benefits that may qualify for carbon credit mechanisms under various international frameworks.

Employment effects present a mixed picture, with automation in advanced catalytic systems potentially reducing direct operational roles while creating new positions in catalyst manufacturing, system maintenance, and technical support. Industry analyses project a net positive employment effect of approximately 2-3 jobs created for every job displaced, though requiring significant workforce retraining initiatives.

Market adoption curves indicate accelerating implementation rates, with approximately 15% of global ammonia production capacity already incorporating some form of enhanced catalytic technology. Projections suggest this could reach 40-50% by 2030, contingent upon continued improvements in catalyst longevity and resistance to poisoning under industrial conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!