Why New Thermal Processes are Essential for Ammonia

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Thermal Process Evolution and Objectives

Ammonia production has undergone significant evolution since its industrial inception with the Haber-Bosch process in the early 20th century. This groundbreaking technology, which combines nitrogen from the air with hydrogen under high pressure and temperature in the presence of a catalyst, revolutionized agriculture by enabling mass production of nitrogen fertilizers. For over a century, this fundamental process has remained largely unchanged in its core principles, though incremental improvements in catalysts and energy efficiency have been implemented.

The traditional ammonia synthesis process is notably energy-intensive, consuming approximately 1-2% of global energy production and generating substantial carbon emissions—roughly 1.8% of global CO2 emissions. This significant environmental footprint stems primarily from the thermal processes required to maintain reaction conditions of 400-500°C and 150-300 bar pressure, as well as from hydrogen production via steam methane reforming.

Current technological objectives in ammonia production are increasingly focused on sustainability and efficiency. The industry aims to develop thermal processes that can significantly reduce energy consumption while maintaining or improving production yields. This includes exploring lower temperature and pressure synthesis routes that could fundamentally transform the energy economics of ammonia production.

Emerging research is targeting novel catalysts capable of facilitating ammonia synthesis under milder conditions, potentially reducing the thermal energy requirements by 20-30%. Additionally, there is growing interest in electrification of thermal processes, utilizing renewable electricity rather than fossil fuel combustion to provide the necessary reaction energy.

Another critical objective is the integration of green hydrogen production methods with ammonia synthesis. This approach seeks to eliminate the carbon-intensive steam methane reforming step by using hydrogen produced through water electrolysis powered by renewable energy sources, creating a pathway to carbon-neutral ammonia.

The development of modular and distributed production systems represents another important goal. These systems aim to optimize thermal management at smaller scales, potentially allowing for more efficient heat recovery and integration with local renewable energy resources, thereby reducing both energy consumption and transmission losses.

As global demand for ammonia continues to rise—not only for fertilizer production but also for its emerging role as a potential carbon-free energy carrier—the evolution of more sustainable thermal processes becomes increasingly essential. The industry's technological roadmap now clearly prioritizes innovations that can decouple ammonia production from fossil fuel dependence while maintaining economic viability.

The traditional ammonia synthesis process is notably energy-intensive, consuming approximately 1-2% of global energy production and generating substantial carbon emissions—roughly 1.8% of global CO2 emissions. This significant environmental footprint stems primarily from the thermal processes required to maintain reaction conditions of 400-500°C and 150-300 bar pressure, as well as from hydrogen production via steam methane reforming.

Current technological objectives in ammonia production are increasingly focused on sustainability and efficiency. The industry aims to develop thermal processes that can significantly reduce energy consumption while maintaining or improving production yields. This includes exploring lower temperature and pressure synthesis routes that could fundamentally transform the energy economics of ammonia production.

Emerging research is targeting novel catalysts capable of facilitating ammonia synthesis under milder conditions, potentially reducing the thermal energy requirements by 20-30%. Additionally, there is growing interest in electrification of thermal processes, utilizing renewable electricity rather than fossil fuel combustion to provide the necessary reaction energy.

Another critical objective is the integration of green hydrogen production methods with ammonia synthesis. This approach seeks to eliminate the carbon-intensive steam methane reforming step by using hydrogen produced through water electrolysis powered by renewable energy sources, creating a pathway to carbon-neutral ammonia.

The development of modular and distributed production systems represents another important goal. These systems aim to optimize thermal management at smaller scales, potentially allowing for more efficient heat recovery and integration with local renewable energy resources, thereby reducing both energy consumption and transmission losses.

As global demand for ammonia continues to rise—not only for fertilizer production but also for its emerging role as a potential carbon-free energy carrier—the evolution of more sustainable thermal processes becomes increasingly essential. The industry's technological roadmap now clearly prioritizes innovations that can decouple ammonia production from fossil fuel dependence while maintaining economic viability.

Market Demand Analysis for Green Ammonia Production

The global ammonia market is experiencing a significant transformation driven by the urgent need for decarbonization. Traditional ammonia production, primarily through the Haber-Bosch process, accounts for approximately 1.8% of global CO2 emissions, making it one of the most carbon-intensive industrial processes. This environmental impact has created substantial market pressure for greener alternatives, particularly as industries and governments worldwide commit to net-zero targets.

Market analysis indicates that the green ammonia sector is poised for exponential growth, with projections suggesting a compound annual growth rate of over 70% between 2023 and 2030. This growth is primarily fueled by ammonia's potential as both a carbon-free fuel and an efficient hydrogen carrier, addressing two critical aspects of the energy transition simultaneously.

The demand for green ammonia spans multiple sectors. In agriculture, which currently consumes about 80% of global ammonia production for fertilizers, there is increasing pressure from consumers and regulators for sustainable farming practices. Major agricultural regions including Europe, North America, and progressive markets in Asia have begun implementing carbon taxation and incentive schemes that favor low-carbon fertilizer production methods.

In the energy sector, ammonia is gaining traction as a promising alternative fuel for maritime shipping, which faces stringent emission regulations from the International Maritime Organization. Several major shipping companies have already announced pilot projects for ammonia-powered vessels, creating a new demand stream that did not exist five years ago.

Additionally, ammonia's potential as a hydrogen carrier presents significant market opportunities. Its higher energy density and easier storage characteristics compared to pure hydrogen make it an attractive solution for long-distance renewable energy transport. Countries with abundant renewable resources but limited industrial bases, such as Chile, Morocco, and Australia, are positioning themselves as future green ammonia exporters to energy-hungry regions like Europe and East Asia.

The investment landscape reflects this growing market confidence, with venture capital funding for green ammonia technologies increasing by over 300% since 2020. Major industrial players including BASF, Yara, CF Industries, and Mitsubishi Heavy Industries have announced substantial investments in green ammonia production facilities and technologies.

Policy support is further accelerating market development, with the European Union's Carbon Border Adjustment Mechanism, Japan's Green Innovation Fund, and various national hydrogen strategies explicitly including ammonia in their decarbonization roadmaps. These regulatory frameworks are creating both push and pull factors that drive demand for new thermal processes essential for sustainable ammonia production.

Market analysis indicates that the green ammonia sector is poised for exponential growth, with projections suggesting a compound annual growth rate of over 70% between 2023 and 2030. This growth is primarily fueled by ammonia's potential as both a carbon-free fuel and an efficient hydrogen carrier, addressing two critical aspects of the energy transition simultaneously.

The demand for green ammonia spans multiple sectors. In agriculture, which currently consumes about 80% of global ammonia production for fertilizers, there is increasing pressure from consumers and regulators for sustainable farming practices. Major agricultural regions including Europe, North America, and progressive markets in Asia have begun implementing carbon taxation and incentive schemes that favor low-carbon fertilizer production methods.

In the energy sector, ammonia is gaining traction as a promising alternative fuel for maritime shipping, which faces stringent emission regulations from the International Maritime Organization. Several major shipping companies have already announced pilot projects for ammonia-powered vessels, creating a new demand stream that did not exist five years ago.

Additionally, ammonia's potential as a hydrogen carrier presents significant market opportunities. Its higher energy density and easier storage characteristics compared to pure hydrogen make it an attractive solution for long-distance renewable energy transport. Countries with abundant renewable resources but limited industrial bases, such as Chile, Morocco, and Australia, are positioning themselves as future green ammonia exporters to energy-hungry regions like Europe and East Asia.

The investment landscape reflects this growing market confidence, with venture capital funding for green ammonia technologies increasing by over 300% since 2020. Major industrial players including BASF, Yara, CF Industries, and Mitsubishi Heavy Industries have announced substantial investments in green ammonia production facilities and technologies.

Policy support is further accelerating market development, with the European Union's Carbon Border Adjustment Mechanism, Japan's Green Innovation Fund, and various national hydrogen strategies explicitly including ammonia in their decarbonization roadmaps. These regulatory frameworks are creating both push and pull factors that drive demand for new thermal processes essential for sustainable ammonia production.

Current Thermal Technologies and Challenges in Ammonia Synthesis

The Haber-Bosch process, developed in the early 20th century, remains the dominant industrial method for ammonia synthesis, accounting for approximately 1-2% of global energy consumption. This energy-intensive process operates at high temperatures (400-500°C) and pressures (150-300 bar), utilizing iron-based catalysts to facilitate the reaction between nitrogen and hydrogen. Despite its widespread implementation, the process suffers from significant thermal inefficiencies, with energy conversion rates typically below 65%.

Current thermal management in ammonia synthesis relies heavily on fossil fuel combustion to achieve and maintain the necessary reaction conditions. Natural gas serves as both feedstock for hydrogen production and energy source for the process, creating a double dependency on carbon-intensive resources. Heat integration systems attempt to recover waste heat through complex exchanger networks, but substantial thermal losses persist throughout the production chain.

The conventional thermal approach faces several critical challenges. First, the high activation energy barrier for nitrogen triple-bond dissociation necessitates severe reaction conditions, resulting in substantial energy expenditure. Second, the exothermic nature of ammonia formation (ΔH = -92.4 kJ/mol) creates heat management complexities, as excessive temperatures shift equilibrium away from product formation according to Le Chatelier's principle.

Catalyst performance under thermal stress represents another significant challenge. Iron-based catalysts suffer from sintering and deactivation at sustained high temperatures, requiring periodic replacement and regeneration. More advanced ruthenium-based catalysts offer improved activity but remain susceptible to thermal degradation and poisoning, particularly in the presence of oxygen or sulfur compounds.

Heat transfer inefficiencies within reactor designs contribute substantially to energy waste. Traditional multi-tube fixed-bed reactors exhibit temperature gradients that reduce catalyst utilization and conversion efficiency. While fluidized bed technologies improve thermal uniformity, they introduce mechanical complexity and attrition concerns.

The carbon footprint associated with conventional thermal processes has become increasingly problematic in the context of climate change mitigation efforts. Each ton of ammonia produced via traditional methods generates approximately 1.6-3 tons of CO2 emissions, positioning the industry as a significant contributor to greenhouse gas emissions globally.

Recent regulatory pressures and sustainability initiatives have intensified scrutiny on thermal inefficiencies in ammonia production. The European Union's carbon border adjustment mechanism and similar policies worldwide are creating economic incentives for developing less carbon-intensive synthesis routes, driving interest in alternative thermal approaches and non-thermal activation methods.

Current thermal management in ammonia synthesis relies heavily on fossil fuel combustion to achieve and maintain the necessary reaction conditions. Natural gas serves as both feedstock for hydrogen production and energy source for the process, creating a double dependency on carbon-intensive resources. Heat integration systems attempt to recover waste heat through complex exchanger networks, but substantial thermal losses persist throughout the production chain.

The conventional thermal approach faces several critical challenges. First, the high activation energy barrier for nitrogen triple-bond dissociation necessitates severe reaction conditions, resulting in substantial energy expenditure. Second, the exothermic nature of ammonia formation (ΔH = -92.4 kJ/mol) creates heat management complexities, as excessive temperatures shift equilibrium away from product formation according to Le Chatelier's principle.

Catalyst performance under thermal stress represents another significant challenge. Iron-based catalysts suffer from sintering and deactivation at sustained high temperatures, requiring periodic replacement and regeneration. More advanced ruthenium-based catalysts offer improved activity but remain susceptible to thermal degradation and poisoning, particularly in the presence of oxygen or sulfur compounds.

Heat transfer inefficiencies within reactor designs contribute substantially to energy waste. Traditional multi-tube fixed-bed reactors exhibit temperature gradients that reduce catalyst utilization and conversion efficiency. While fluidized bed technologies improve thermal uniformity, they introduce mechanical complexity and attrition concerns.

The carbon footprint associated with conventional thermal processes has become increasingly problematic in the context of climate change mitigation efforts. Each ton of ammonia produced via traditional methods generates approximately 1.6-3 tons of CO2 emissions, positioning the industry as a significant contributor to greenhouse gas emissions globally.

Recent regulatory pressures and sustainability initiatives have intensified scrutiny on thermal inefficiencies in ammonia production. The European Union's carbon border adjustment mechanism and similar policies worldwide are creating economic incentives for developing less carbon-intensive synthesis routes, driving interest in alternative thermal approaches and non-thermal activation methods.

Current Thermal Process Solutions for Ammonia Production

01 Advanced ammonia synthesis processes

Modern thermal processes for ammonia synthesis focus on improving efficiency through optimized reactor designs and catalysts. These innovations include modified Haber-Bosch processes that operate at lower temperatures and pressures, reducing energy requirements while maintaining production rates. Advanced catalysts enable more efficient nitrogen fixation, and integrated heat recovery systems capture and reuse thermal energy throughout the process, significantly improving overall thermal efficiency.- Advanced thermal processes for ammonia production: Modern thermal processes for ammonia production focus on improving thermal efficiency through innovative reactor designs and process configurations. These advancements include optimized heat integration systems, improved catalysts, and novel reaction pathways that reduce energy requirements. Such processes often incorporate waste heat recovery systems and thermal energy storage to maximize overall efficiency and minimize energy losses during ammonia synthesis.

- Heat recovery and integration systems: Heat recovery and integration systems play a crucial role in enhancing the thermal efficiency of ammonia production processes. These systems capture and reuse waste heat from various process streams, reducing the overall energy consumption. Technologies such as heat exchangers, thermal integration networks, and energy recovery units help to minimize energy losses and improve the overall thermal efficiency of ammonia production facilities.

- Low-carbon ammonia production methods: Low-carbon approaches to ammonia production focus on reducing the carbon footprint while maintaining or improving thermal efficiency. These methods include electrolysis-based ammonia synthesis, renewable energy integration, and carbon capture technologies. By utilizing renewable energy sources and innovative process designs, these methods aim to produce ammonia with significantly lower greenhouse gas emissions while optimizing thermal efficiency.

- Catalytic improvements for ammonia synthesis: Advanced catalysts significantly enhance the thermal efficiency of ammonia production processes by lowering activation energy requirements and improving reaction kinetics. These catalytic innovations enable ammonia synthesis at lower temperatures and pressures, reducing the overall energy demand. Research focuses on developing catalysts with higher activity, selectivity, and stability to optimize the thermal efficiency of ammonia production processes.

- Process intensification techniques: Process intensification techniques for ammonia production involve redesigning conventional processes to achieve higher efficiency in smaller equipment volumes. These approaches include membrane reactors, microreactors, and combined unit operations that enhance heat and mass transfer. By integrating reaction and separation processes and optimizing operating conditions, these techniques significantly improve the thermal efficiency of ammonia production while reducing capital and operating costs.

02 Renewable energy integration in ammonia production

Integration of renewable energy sources into ammonia production processes enhances thermal efficiency while reducing carbon footprint. These systems utilize intermittent renewable electricity for electrolysis to produce hydrogen, which is then combined with nitrogen in modified thermal processes. Solar thermal energy and wind power can directly power certain process components, while smart control systems optimize energy use based on renewable availability, creating more sustainable ammonia production pathways.Expand Specific Solutions03 Heat recovery and energy integration systems

Advanced heat recovery systems significantly improve the thermal efficiency of ammonia production. These technologies capture waste heat from various process stages and redirect it to preheat feedstocks, generate steam, or power other process units. Multi-stage heat exchangers, thermal energy storage systems, and pinch analysis optimization techniques minimize energy losses throughout the production cycle, resulting in substantial reductions in overall energy consumption and improved process economics.Expand Specific Solutions04 Novel reactor designs for ammonia synthesis

Innovative reactor designs enhance the thermal efficiency of ammonia synthesis processes. These include microreactor technologies that improve heat and mass transfer, membrane reactors that selectively separate products to drive equilibrium reactions forward, and structured catalyst beds that optimize flow patterns. Fluidized bed reactors provide better temperature control, while modular designs allow for more efficient scaling and heat management, collectively reducing energy requirements while improving conversion rates.Expand Specific Solutions05 Process intensification techniques

Process intensification approaches combine multiple unit operations into more compact, efficient systems for ammonia production. These techniques include reactive distillation, which combines reaction and separation steps, and sorption-enhanced reaction processes that continuously remove products to improve conversion. Advanced control systems optimize operating parameters in real-time, while novel separation technologies reduce energy-intensive purification steps. These integrated approaches significantly improve thermal efficiency by reducing heat losses between process steps.Expand Specific Solutions

Leading Companies and Research Institutions in Ammonia Technology

The ammonia production industry is currently in a transformative phase, with thermal processes becoming essential due to increasing demand for cleaner production methods. The market is projected to grow significantly as ammonia's role expands beyond traditional fertilizer applications into emerging energy carrier applications. While conventional Haber-Bosch technology dominates, new thermal processes are gaining traction but remain in early commercial stages. Key players driving innovation include established industrial giants like Air Products & Chemicals, thyssenkrupp AG, and SABIC Global Technologies, alongside research institutions such as Fuzhou University and Technical University of Denmark. University-industry collaborations are accelerating development, with companies like Ammonia Casale and NuScale Power introducing novel thermal approaches to address efficiency and sustainability challenges in ammonia production.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed advanced autothermal reforming (ATR) technology for blue ammonia production, which integrates carbon capture capabilities. Their thermal process innovation centers on heat integration systems that recover and utilize waste heat throughout the ammonia synthesis process, reducing overall energy consumption by approximately 15-20%. The company has pioneered a novel heat exchange network that maintains optimal temperature profiles during ammonia synthesis, particularly in the critical 400-500°C range where catalyst activity is maximized. Their technology incorporates specialized heat transfer fluids that improve thermal efficiency in high-pressure ammonia synthesis environments, enabling more stable operation and extended catalyst life. Additionally, Air Products has developed proprietary thermal management systems for their ammonia plants that reduce startup and shutdown thermal stresses, significantly extending equipment lifespan.

Strengths: Industry-leading heat integration expertise; extensive commercial implementation experience; proven carbon capture integration capabilities. Weaknesses: Higher capital costs compared to conventional systems; requires specialized operational expertise; technology primarily optimized for large-scale production facilities rather than distributed applications.

Ammonia Casale SpA

Technical Solution: Ammonia Casale has developed the "Casale Axial-Radial" thermal management system specifically for ammonia synthesis reactors, which optimizes heat transfer and reaction kinetics simultaneously. Their technology features a proprietary catalyst bed arrangement that creates controlled temperature gradients, improving conversion efficiency by up to 25% compared to conventional designs. The company's thermal innovation includes specialized heat exchangers integrated directly into the synthesis loop that recover approximately 85% of reaction heat for steam generation and process heating. Casale's approach addresses the critical challenge of managing the exothermic nature of ammonia synthesis by implementing a series of intercoolers with precise temperature control, maintaining optimal catalyst activity while preventing thermal degradation. Their latest innovation incorporates dynamic thermal response systems that can adjust to fluctuating production demands while maintaining thermal efficiency.

Strengths: Specialized expertise in ammonia synthesis reactor design; proven technology with multiple commercial implementations; adaptable to both new plants and retrofits. Weaknesses: Higher initial investment costs; requires specialized catalyst configurations; optimization primarily focused on conventional feedstocks rather than renewable inputs.

Key Innovations in Low-Energy Ammonia Synthesis

Ammonia manufacturing apparatus and ammonia manufacturing method

PatentPendingUS20240092646A1

Innovation

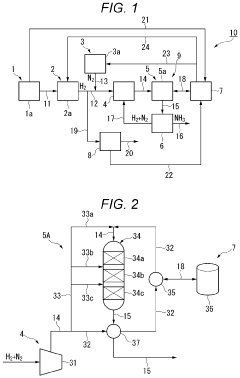

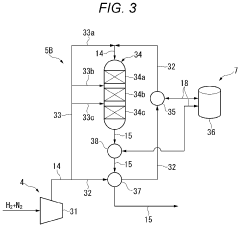

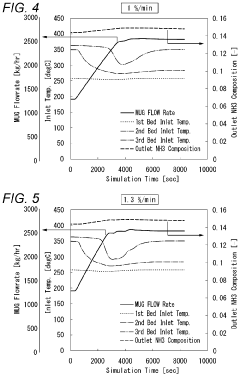

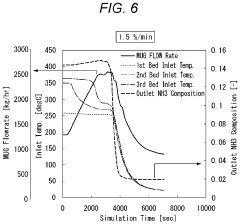

- An ammonia manufacturing apparatus and method that incorporates a heat storage unit with a heating medium to supply heat to the ammonia synthesis unit when the raw material gas supply increases, using renewable energy for hydrogen production via electrolysis and employing heat exchangers to efficiently transfer heat between the heating medium and the raw material gas or produced gas.

Environmental Impact Assessment of Ammonia Production Methods

The environmental impact of ammonia production represents a critical concern in the chemical industry, particularly as global demand continues to rise. Traditional ammonia production methods, primarily the Haber-Bosch process, are energy-intensive operations that contribute significantly to global greenhouse gas emissions. Current estimates indicate that conventional ammonia production accounts for approximately 1-2% of global carbon dioxide emissions, making it one of the most carbon-intensive industrial processes.

When examining the environmental footprint of conventional thermal processes for ammonia production, several key impact categories emerge. These include greenhouse gas emissions, primarily CO2 from natural gas reforming; nitrogen oxide emissions that contribute to air pollution and acid rain; and substantial water consumption for cooling and steam generation. The carbon intensity of traditional ammonia production typically ranges from 1.6 to 3 tons of CO2 per ton of ammonia produced, depending on the specific technology and energy source utilized.

New thermal processes for ammonia production offer promising pathways to environmental improvement. Electrified heating systems powered by renewable energy can reduce direct carbon emissions by 40-60% compared to conventional methods. Advanced catalytic systems that operate at lower temperatures not only reduce energy requirements but also minimize the formation of nitrogen oxides and other harmful byproducts.

Life cycle assessment (LCA) studies comparing conventional and emerging ammonia production technologies reveal significant differences in environmental performance. While traditional methods score poorly on climate change impact metrics, newer thermal processes demonstrate substantial improvements across multiple environmental indicators, including reduced acidification potential, lower freshwater eutrophication, and decreased photochemical ozone formation.

Regional environmental regulations increasingly influence ammonia production methods, with stricter emissions standards in Europe and North America driving innovation in cleaner production technologies. Carbon pricing mechanisms further incentivize the adoption of environmentally superior thermal processes by internalizing previously externalized environmental costs.

The transition to greener ammonia production presents both challenges and opportunities. While capital investment requirements for new thermal technologies remain high, the long-term environmental benefits and potential regulatory advantages offer compelling incentives for industry transformation. Emerging carbon capture technologies, when integrated with new thermal processes, can further reduce the environmental footprint of ammonia production, potentially achieving near-zero emissions in optimized systems.

When examining the environmental footprint of conventional thermal processes for ammonia production, several key impact categories emerge. These include greenhouse gas emissions, primarily CO2 from natural gas reforming; nitrogen oxide emissions that contribute to air pollution and acid rain; and substantial water consumption for cooling and steam generation. The carbon intensity of traditional ammonia production typically ranges from 1.6 to 3 tons of CO2 per ton of ammonia produced, depending on the specific technology and energy source utilized.

New thermal processes for ammonia production offer promising pathways to environmental improvement. Electrified heating systems powered by renewable energy can reduce direct carbon emissions by 40-60% compared to conventional methods. Advanced catalytic systems that operate at lower temperatures not only reduce energy requirements but also minimize the formation of nitrogen oxides and other harmful byproducts.

Life cycle assessment (LCA) studies comparing conventional and emerging ammonia production technologies reveal significant differences in environmental performance. While traditional methods score poorly on climate change impact metrics, newer thermal processes demonstrate substantial improvements across multiple environmental indicators, including reduced acidification potential, lower freshwater eutrophication, and decreased photochemical ozone formation.

Regional environmental regulations increasingly influence ammonia production methods, with stricter emissions standards in Europe and North America driving innovation in cleaner production technologies. Carbon pricing mechanisms further incentivize the adoption of environmentally superior thermal processes by internalizing previously externalized environmental costs.

The transition to greener ammonia production presents both challenges and opportunities. While capital investment requirements for new thermal technologies remain high, the long-term environmental benefits and potential regulatory advantages offer compelling incentives for industry transformation. Emerging carbon capture technologies, when integrated with new thermal processes, can further reduce the environmental footprint of ammonia production, potentially achieving near-zero emissions in optimized systems.

Energy Efficiency Metrics and Benchmarking for Ammonia Synthesis

Energy efficiency metrics serve as critical benchmarks for evaluating the performance and sustainability of ammonia synthesis processes. The traditional Haber-Bosch process, while revolutionary in its time, operates at energy intensities of 10-12 GJ/ton NH3, significantly above the theoretical minimum of 5.4 GJ/ton NH3. This energy gap represents both an environmental challenge and an economic opportunity for innovation in thermal processes.

Current industry benchmarks categorize ammonia plants into three efficiency tiers: conventional plants (11-13 GJ/ton), modern optimized plants (9-10.5 GJ/ton), and best-in-class facilities (8-9 GJ/ton). These metrics incorporate not only direct process energy but also upstream energy requirements for hydrogen production, which accounts for approximately 60-70% of the total energy footprint.

The energy efficiency ratio (EER), defined as the ratio of theoretical minimum energy to actual energy consumed, provides a standardized comparison across different technologies. Traditional Haber-Bosch implementations typically achieve EERs of 45-55%, while emerging thermal processes utilizing renewable energy sources and advanced catalysts demonstrate potential EERs of 65-75% in laboratory settings.

Carbon intensity metrics, measured in CO2 equivalent emissions per ton of ammonia, have become increasingly important as sustainability concerns grow. Conventional natural gas-based ammonia production generates 1.6-2.0 tons CO2e/ton NH3, while coal-based production can exceed 3.5 tons CO2e/ton NH3. New thermal processes utilizing green hydrogen and renewable heat sources aim to reduce this to below 0.5 tons CO2e/ton NH3.

Exergy efficiency analysis, which measures the maximum useful work potential of energy inputs, reveals that conventional ammonia synthesis wastes 40-50% of available work potential through irreversible processes. Advanced thermal management techniques, including heat integration, pressure optimization, and novel reactor designs, can potentially reduce these losses by 15-25%.

Benchmarking studies indicate that regional variations in energy efficiency are significant, with European and Japanese facilities typically operating 10-15% more efficiently than global averages due to stricter regulatory environments and higher energy costs driving innovation. These regional leaders provide valuable case studies for implementing best practices in thermal process optimization.

The development of standardized efficiency metrics enables meaningful comparison between conventional and emerging technologies, facilitating investment decisions and policy development that will accelerate the transition to more sustainable ammonia production methods. As new thermal processes continue to evolve, these benchmarks will need regular recalibration to accurately reflect technological progress.

Current industry benchmarks categorize ammonia plants into three efficiency tiers: conventional plants (11-13 GJ/ton), modern optimized plants (9-10.5 GJ/ton), and best-in-class facilities (8-9 GJ/ton). These metrics incorporate not only direct process energy but also upstream energy requirements for hydrogen production, which accounts for approximately 60-70% of the total energy footprint.

The energy efficiency ratio (EER), defined as the ratio of theoretical minimum energy to actual energy consumed, provides a standardized comparison across different technologies. Traditional Haber-Bosch implementations typically achieve EERs of 45-55%, while emerging thermal processes utilizing renewable energy sources and advanced catalysts demonstrate potential EERs of 65-75% in laboratory settings.

Carbon intensity metrics, measured in CO2 equivalent emissions per ton of ammonia, have become increasingly important as sustainability concerns grow. Conventional natural gas-based ammonia production generates 1.6-2.0 tons CO2e/ton NH3, while coal-based production can exceed 3.5 tons CO2e/ton NH3. New thermal processes utilizing green hydrogen and renewable heat sources aim to reduce this to below 0.5 tons CO2e/ton NH3.

Exergy efficiency analysis, which measures the maximum useful work potential of energy inputs, reveals that conventional ammonia synthesis wastes 40-50% of available work potential through irreversible processes. Advanced thermal management techniques, including heat integration, pressure optimization, and novel reactor designs, can potentially reduce these losses by 15-25%.

Benchmarking studies indicate that regional variations in energy efficiency are significant, with European and Japanese facilities typically operating 10-15% more efficiently than global averages due to stricter regulatory environments and higher energy costs driving innovation. These regional leaders provide valuable case studies for implementing best practices in thermal process optimization.

The development of standardized efficiency metrics enables meaningful comparison between conventional and emerging technologies, facilitating investment decisions and policy development that will accelerate the transition to more sustainable ammonia production methods. As new thermal processes continue to evolve, these benchmarks will need regular recalibration to accurately reflect technological progress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!