Green Ammonia Synthesis: Industry Standards and Performance

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green Ammonia Background and Objectives

Green ammonia represents a revolutionary approach to traditional ammonia production, offering a sustainable alternative to the carbon-intensive Haber-Bosch process that has dominated the industry for over a century. The evolution of ammonia synthesis technology began with Fritz Haber's groundbreaking work in the early 1900s, which was later industrialized by Carl Bosch, creating the foundation for modern fertilizer production and global food security.

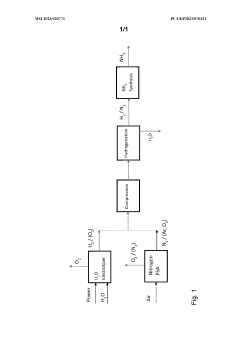

Traditional ammonia production consumes approximately 1-2% of global energy and contributes significantly to greenhouse gas emissions, releasing 1.8 tons of CO2 for each ton of ammonia produced. This environmental impact has driven the technological shift toward green ammonia, which utilizes renewable electricity to power electrolysis for hydrogen production, combined with nitrogen separation from air, to synthesize ammonia without carbon emissions.

The green ammonia technology trajectory shows accelerating development since 2010, with significant breakthroughs in electrolysis efficiency, renewable energy integration, and novel catalysts. Research institutions and industry leaders have established ambitious targets to reduce production costs from current levels of $900-1,300 per ton to below $450 per ton by 2030, making green ammonia economically competitive with conventional methods.

Key technological objectives for green ammonia development include achieving energy efficiency improvements of 20-30% in electrolysis systems, developing catalysts that can operate at lower temperatures and pressures than the traditional 400-500°C and 150-300 bar, and creating modular production systems that can be deployed alongside renewable energy installations.

Market projections indicate that green ammonia could capture 25-30% of the global ammonia market by 2040, representing a potential market value exceeding $100 billion. This growth is driven by multiple applications beyond traditional fertilizer use, including maritime fuel, energy storage, and hydrogen carrier functions.

The technical roadmap for green ammonia development focuses on three parallel paths: enhancing conventional electrolysis-based processes, developing direct electrochemical ammonia synthesis, and exploring biological nitrogen fixation methods. Each approach presents unique advantages and challenges, with varying technology readiness levels and commercialization timelines.

Industry standards for green ammonia are currently evolving, with organizations such as the International Renewable Energy Agency (IRENA), the Ammonia Energy Association, and ISO technical committees working to establish certification frameworks, safety protocols, and performance metrics that will facilitate market adoption and regulatory compliance.

Traditional ammonia production consumes approximately 1-2% of global energy and contributes significantly to greenhouse gas emissions, releasing 1.8 tons of CO2 for each ton of ammonia produced. This environmental impact has driven the technological shift toward green ammonia, which utilizes renewable electricity to power electrolysis for hydrogen production, combined with nitrogen separation from air, to synthesize ammonia without carbon emissions.

The green ammonia technology trajectory shows accelerating development since 2010, with significant breakthroughs in electrolysis efficiency, renewable energy integration, and novel catalysts. Research institutions and industry leaders have established ambitious targets to reduce production costs from current levels of $900-1,300 per ton to below $450 per ton by 2030, making green ammonia economically competitive with conventional methods.

Key technological objectives for green ammonia development include achieving energy efficiency improvements of 20-30% in electrolysis systems, developing catalysts that can operate at lower temperatures and pressures than the traditional 400-500°C and 150-300 bar, and creating modular production systems that can be deployed alongside renewable energy installations.

Market projections indicate that green ammonia could capture 25-30% of the global ammonia market by 2040, representing a potential market value exceeding $100 billion. This growth is driven by multiple applications beyond traditional fertilizer use, including maritime fuel, energy storage, and hydrogen carrier functions.

The technical roadmap for green ammonia development focuses on three parallel paths: enhancing conventional electrolysis-based processes, developing direct electrochemical ammonia synthesis, and exploring biological nitrogen fixation methods. Each approach presents unique advantages and challenges, with varying technology readiness levels and commercialization timelines.

Industry standards for green ammonia are currently evolving, with organizations such as the International Renewable Energy Agency (IRENA), the Ammonia Energy Association, and ISO technical committees working to establish certification frameworks, safety protocols, and performance metrics that will facilitate market adoption and regulatory compliance.

Market Analysis for Green Ammonia

The global green ammonia market is experiencing unprecedented growth, driven by increasing environmental concerns and the push for decarbonization across industries. Current market valuations place the green ammonia sector at approximately $72 million in 2021, with projections indicating a compound annual growth rate (CAGR) of 72.9% through 2030, potentially reaching a market size of $5.4 billion.

The demand landscape for green ammonia spans multiple sectors, with fertilizer production currently representing the largest application segment, accounting for roughly 80% of conventional ammonia usage. However, emerging applications in energy storage, maritime fuel, and power generation are expected to significantly reshape market dynamics in the coming decade.

Regional analysis reveals Europe as the current leader in green ammonia development, with countries like Germany, the Netherlands, and Denmark making substantial investments in production facilities. The Asia-Pacific region, particularly Japan, South Korea, and Australia, is rapidly accelerating development efforts, leveraging abundant renewable energy resources and strong policy support.

Market penetration faces significant barriers, primarily the cost differential between green ammonia ($650-1,300 per ton) and conventional ammonia ($200-450 per ton). This price gap is expected to narrow as renewable electricity costs continue to decline and carbon pricing mechanisms become more widespread.

Industry forecasts suggest that green ammonia will achieve price parity with conventional production in select markets by 2030, initially in regions with abundant renewable resources and supportive regulatory frameworks. The maritime sector represents a particularly promising growth avenue, with major shipping companies including Maersk and NYK Line announcing plans to adopt ammonia as a marine fuel.

Investment trends show accelerating capital flows into the sector, with over $5 billion committed to green ammonia projects globally since 2020. This includes both venture capital funding for innovative production technologies and large-scale infrastructure investments from established industrial players like CF Industries, Yara, and BASF.

Consumer sentiment analysis indicates growing willingness among end-users to pay premium prices for green alternatives, particularly in European and North American markets. This trend is reinforced by increasingly stringent environmental regulations and corporate sustainability commitments that favor low-carbon production methods.

The competitive landscape is evolving rapidly, with traditional ammonia producers facing competition from renewable energy developers, technology startups, and oil and gas majors seeking to diversify their portfolios. Strategic partnerships between these diverse stakeholders are becoming increasingly common, creating new value chain configurations and market opportunities.

The demand landscape for green ammonia spans multiple sectors, with fertilizer production currently representing the largest application segment, accounting for roughly 80% of conventional ammonia usage. However, emerging applications in energy storage, maritime fuel, and power generation are expected to significantly reshape market dynamics in the coming decade.

Regional analysis reveals Europe as the current leader in green ammonia development, with countries like Germany, the Netherlands, and Denmark making substantial investments in production facilities. The Asia-Pacific region, particularly Japan, South Korea, and Australia, is rapidly accelerating development efforts, leveraging abundant renewable energy resources and strong policy support.

Market penetration faces significant barriers, primarily the cost differential between green ammonia ($650-1,300 per ton) and conventional ammonia ($200-450 per ton). This price gap is expected to narrow as renewable electricity costs continue to decline and carbon pricing mechanisms become more widespread.

Industry forecasts suggest that green ammonia will achieve price parity with conventional production in select markets by 2030, initially in regions with abundant renewable resources and supportive regulatory frameworks. The maritime sector represents a particularly promising growth avenue, with major shipping companies including Maersk and NYK Line announcing plans to adopt ammonia as a marine fuel.

Investment trends show accelerating capital flows into the sector, with over $5 billion committed to green ammonia projects globally since 2020. This includes both venture capital funding for innovative production technologies and large-scale infrastructure investments from established industrial players like CF Industries, Yara, and BASF.

Consumer sentiment analysis indicates growing willingness among end-users to pay premium prices for green alternatives, particularly in European and North American markets. This trend is reinforced by increasingly stringent environmental regulations and corporate sustainability commitments that favor low-carbon production methods.

The competitive landscape is evolving rapidly, with traditional ammonia producers facing competition from renewable energy developers, technology startups, and oil and gas majors seeking to diversify their portfolios. Strategic partnerships between these diverse stakeholders are becoming increasingly common, creating new value chain configurations and market opportunities.

Technical Barriers and Global Development Status

Green ammonia synthesis faces significant technical barriers that have hindered its widespread commercial adoption. The conventional Haber-Bosch process, while well-established, requires high temperatures (400-500°C) and pressures (150-300 bar), consuming approximately 1-2% of global energy production. The primary technical challenge lies in developing catalysts that can operate efficiently at lower temperatures and pressures while maintaining acceptable conversion rates.

Current electrolysis-based green ammonia synthesis methods struggle with low energy efficiency, typically achieving only 50-60% efficiency compared to the theoretical maximum. This inefficiency translates directly into higher production costs, estimated at $600-1,200 per ton for green ammonia versus $200-400 per ton for conventional ammonia.

Catalyst development represents another major barrier. While ruthenium-based catalysts show promising activity at lower temperatures, they remain prohibitively expensive for large-scale deployment. Iron-based alternatives, though more economical, demonstrate significantly lower catalytic activity under milder conditions, creating a challenging cost-performance tradeoff.

Globally, green ammonia development exhibits distinct regional patterns. Europe leads in research and pilot projects, with countries like Denmark, the Netherlands, and Germany hosting significant demonstration facilities ranging from 1-10 MW. The European Union's Horizon Europe program has allocated approximately €100 million specifically for green ammonia research between 2021-2027.

Asia-Pacific, particularly Japan and Australia, has focused on green ammonia as an energy carrier, with JERA and Woodside Energy establishing a major supply chain initiative. China has rapidly expanded its research capacity, with over 200 academic papers on green ammonia synthesis published by Chinese institutions in 2022 alone, representing a 40% increase from 2020.

North America has concentrated on integrating green ammonia production with renewable energy infrastructure. The U.S. Department of Energy's ARPA-E program has invested $35 million in next-generation ammonia synthesis technologies since 2019, while Canada has leveraged its abundant hydroelectric resources for electrolysis-based production methods.

The Middle East is emerging as a potential green ammonia hub, utilizing its abundant solar resources. Saudi Arabia's NEOM project includes plans for a $5 billion green hydrogen and ammonia facility expected to produce 1.2 million tons of green ammonia annually by 2025, potentially becoming the world's largest such facility.

Despite these developments, the technology readiness level (TRL) for most green ammonia technologies remains between 5-7, indicating that significant engineering challenges must be overcome before achieving commercial-scale deployment.

Current electrolysis-based green ammonia synthesis methods struggle with low energy efficiency, typically achieving only 50-60% efficiency compared to the theoretical maximum. This inefficiency translates directly into higher production costs, estimated at $600-1,200 per ton for green ammonia versus $200-400 per ton for conventional ammonia.

Catalyst development represents another major barrier. While ruthenium-based catalysts show promising activity at lower temperatures, they remain prohibitively expensive for large-scale deployment. Iron-based alternatives, though more economical, demonstrate significantly lower catalytic activity under milder conditions, creating a challenging cost-performance tradeoff.

Globally, green ammonia development exhibits distinct regional patterns. Europe leads in research and pilot projects, with countries like Denmark, the Netherlands, and Germany hosting significant demonstration facilities ranging from 1-10 MW. The European Union's Horizon Europe program has allocated approximately €100 million specifically for green ammonia research between 2021-2027.

Asia-Pacific, particularly Japan and Australia, has focused on green ammonia as an energy carrier, with JERA and Woodside Energy establishing a major supply chain initiative. China has rapidly expanded its research capacity, with over 200 academic papers on green ammonia synthesis published by Chinese institutions in 2022 alone, representing a 40% increase from 2020.

North America has concentrated on integrating green ammonia production with renewable energy infrastructure. The U.S. Department of Energy's ARPA-E program has invested $35 million in next-generation ammonia synthesis technologies since 2019, while Canada has leveraged its abundant hydroelectric resources for electrolysis-based production methods.

The Middle East is emerging as a potential green ammonia hub, utilizing its abundant solar resources. Saudi Arabia's NEOM project includes plans for a $5 billion green hydrogen and ammonia facility expected to produce 1.2 million tons of green ammonia annually by 2025, potentially becoming the world's largest such facility.

Despite these developments, the technology readiness level (TRL) for most green ammonia technologies remains between 5-7, indicating that significant engineering challenges must be overcome before achieving commercial-scale deployment.

Current Green Ammonia Synthesis Methods

01 Catalytic systems for green ammonia synthesis

Advanced catalytic systems are being developed to improve the efficiency and sustainability of green ammonia production. These catalysts operate at lower temperatures and pressures than traditional Haber-Bosch processes, reducing energy requirements. Novel materials including transition metals, metal oxides, and nanostructured composites are being engineered to enhance reaction kinetics and selectivity. These catalytic innovations are crucial for making green ammonia production economically viable and environmentally sustainable.- Sustainable production methods for green ammonia: Various sustainable methods for producing green ammonia have been developed, focusing on renewable energy sources and environmentally friendly processes. These methods aim to reduce carbon emissions compared to traditional Haber-Bosch processes by utilizing renewable electricity, electrolysis of water for hydrogen production, and innovative catalysts. The sustainable production approaches include solar-powered synthesis, wind energy integration, and other renewable energy systems that enable carbon-neutral ammonia production.

- Performance metrics and efficiency standards for green ammonia synthesis: Specific performance metrics and efficiency standards have been established to evaluate green ammonia production systems. These include energy efficiency ratios, conversion rates, catalyst performance, and overall system yields. The standards address parameters such as electricity consumption per unit of ammonia produced, hydrogen utilization efficiency, nitrogen conversion rates, and operational stability under various conditions. These metrics help in benchmarking different green ammonia technologies and guiding further improvements in synthesis processes.

- Innovative catalyst systems for enhanced ammonia synthesis: Advanced catalyst systems have been developed to improve the efficiency and performance of green ammonia synthesis. These catalysts are designed to operate at lower temperatures and pressures than traditional systems, reducing energy requirements while maintaining or improving conversion rates. Innovations include novel metal-based catalysts, nanostructured materials, and composite catalyst systems that enhance nitrogen activation and hydrogen transfer reactions. These catalytic improvements are crucial for making green ammonia production economically viable and environmentally sustainable.

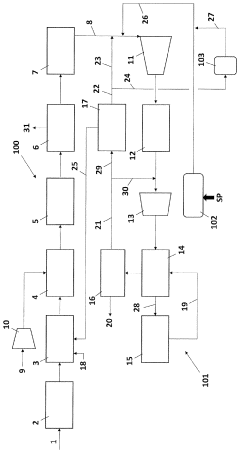

- Equipment and system design for green ammonia production: Specialized equipment and system designs have been developed specifically for green ammonia synthesis. These include modular production units, integrated renewable energy systems, advanced electrolyzers, and optimized reactor designs. The equipment focuses on scalability, efficiency, and integration with renewable energy sources. Innovations in system architecture include heat recovery systems, pressure management technologies, and automated control systems that maximize production efficiency while minimizing environmental impact and operational costs.

- Quality control and certification standards for green ammonia: Quality control protocols and certification standards have been established to ensure the consistency and purity of green ammonia products. These standards define acceptable impurity levels, physical properties, and production process requirements that qualify ammonia as 'green'. Certification systems verify that the ammonia is produced using renewable energy sources with minimal carbon footprint. The standards also address safety considerations, storage requirements, and transportation guidelines specific to green ammonia, ensuring its sustainable production and safe handling throughout the supply chain.

02 Renewable energy integration for ammonia production

Integration of renewable energy sources such as solar, wind, and hydroelectric power is essential for truly green ammonia synthesis. Systems are being designed to efficiently couple intermittent renewable energy with ammonia production processes. This includes advanced power management systems, energy storage solutions, and flexible production capabilities that can operate under variable energy inputs. These technologies enable carbon-neutral ammonia production by eliminating fossil fuel dependency in both hydrogen generation and the synthesis process.Expand Specific Solutions03 Performance metrics and efficiency standards

Standardized performance metrics are being established to evaluate and compare green ammonia production systems. These include energy efficiency ratios, carbon intensity measurements, production rates, and catalyst longevity. Industry standards are emerging to define what qualifies as 'green ammonia' based on lifecycle carbon emissions, renewable energy utilization percentage, and production efficiency. These metrics help guide research priorities and investment decisions while providing benchmarks for technological advancement in the field.Expand Specific Solutions04 Modular and distributed production systems

Modular and distributed ammonia synthesis technologies are being developed to enable localized production closer to end-use applications. These systems are designed for scalability, allowing production capacity to match local demand. Containerized and transportable units facilitate deployment in remote areas or agricultural regions where ammonia is needed for fertilizer. This distributed approach reduces transportation emissions and energy losses associated with centralized production and distribution networks, while providing flexibility in system sizing and implementation.Expand Specific Solutions05 Process optimization and control systems

Advanced process control and optimization technologies are being implemented to maximize the efficiency and reliability of green ammonia synthesis. These include AI-driven control systems, real-time monitoring of reaction parameters, and predictive maintenance capabilities. Digital twins and simulation tools help optimize operating conditions and process parameters. Innovations in heat integration, pressure management, and separation technologies further enhance overall system performance. These control systems are critical for maintaining consistent product quality while adapting to variations in renewable energy availability.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The green ammonia synthesis market is currently in a transitional growth phase, with an estimated market size of $15-20 billion and projected annual growth of 60-70% through 2030. The technology maturity varies across different synthesis approaches, with major players driving innovation at different stages. Topsoe A/S and thyssenkrupp AG lead with commercially viable electrolysis-based solutions, while Air Products & Chemicals and ACWA Power are developing large-scale implementation projects. Academic institutions like Jiangnan University and Tianjin University are advancing catalyst research, while Fortescue Future Industries and NuScale Power focus on integrating renewable energy sources. The competitive landscape shows a mix of established chemical companies pivoting to green technologies and new entrants specializing in sustainable ammonia production methods.

Topsoe A/S

Technical Solution: Topsoe has developed the Haldor Topsoe SynCOR Ammonia™ technology, a revolutionary green ammonia synthesis process that integrates renewable hydrogen production with efficient ammonia synthesis. Their system employs solid oxide electrolysis cells (SOECs) powered by renewable electricity to produce hydrogen, which is then combined with nitrogen in an optimized Haber-Bosch process. The technology features advanced catalysts that operate at lower temperatures (350-400°C) compared to conventional processes (450-500°C), reducing energy requirements by approximately 20-30%. Topsoe's dynamic load management system allows the plant to adjust production rates based on renewable energy availability, maintaining high efficiency even during fluctuating power supply. Their integrated heat recovery system captures and reuses thermal energy throughout the process, further improving overall energy efficiency by up to 15% compared to conventional systems. Topsoe has demonstrated this technology at commercial scale with their 10 MW demonstration plant in Denmark achieving ammonia production with carbon intensity below 0.1 kg CO2e/kg NH3, significantly below the industry average of 1.8-3.0 kg CO2e/kg NH3.

Strengths: Superior energy efficiency with 20-30% lower energy consumption than conventional processes; flexible operation capability allowing integration with intermittent renewable energy sources; proven technology with commercial-scale demonstrations. Weaknesses: Higher initial capital investment compared to conventional ammonia plants; requires reliable access to renewable electricity which may limit deployment in some regions; technology still has higher production costs than fossil-based ammonia in most markets without carbon pricing.

Casale SA

Technical Solution: Casale has pioneered the "Casale Green Ammonia" technology platform that integrates electrolysis-based hydrogen production with their proprietary ammonia synthesis process. Their approach features a modular design that can be scaled from small distributed plants (1,000-10,000 tons/year) to large centralized facilities (>100,000 tons/year). The technology employs advanced ruthenium-based catalysts that demonstrate 15-20% higher activity than traditional iron catalysts, enabling operation at lower pressures (70-100 bar versus conventional 150-300 bar). Casale's system incorporates a novel pressure swing adsorption (PSA) unit for hydrogen purification that achieves 99.999% purity while consuming 30% less energy than conventional purification methods. Their process control system optimizes the synthesis loop parameters in real-time based on renewable energy availability, maintaining stable operation despite fluctuating inputs. Casale has implemented this technology in several pilot projects, including a 5 MW facility in Switzerland that has demonstrated continuous operation with over 95% availability while achieving carbon intensity below 0.2 kg CO2e/kg NH3. The company has also developed specialized materials for equipment construction that resist hydrogen embrittlement, extending plant lifetime by up to 25% compared to conventional materials.

Strengths: Highly modular and scalable design allowing deployment across diverse applications and scales; advanced catalysts enabling lower pressure operation and reduced energy consumption; sophisticated control systems optimizing performance with variable renewable energy inputs. Weaknesses: Technology still has limited large-scale commercial deployment history; higher capital costs per ton of capacity for smaller-scale installations; requires integration of multiple complex subsystems which increases operational complexity.

Critical Patents and Technical Literature Review

Process for ammonia synthesis using green hydrogen

PatentPendingUS20240158247A1

Innovation

- A hybrid process that integrates conventional hydrogen from reforming with green hydrogen produced from renewable sources, utilizing recovered hydrogen from the ammonia synthesis loop to maintain high pressure and reduce compression needs, allowing for direct storage and increased renewable energy contribution.

Process for the preparation of green ammonia synthesis gas

PatentWO2023020771A1

Innovation

- The process combines hydrogen from electrolysis and nitrogen from pressure swing absorption (PSA) into a single stream, which is then pressurized and cleaned in a common catalytic hydrogenation unit to remove oxygen, reducing equipment needs and improving efficiency.

Regulatory Framework and Certification Standards

The regulatory landscape for green ammonia production is rapidly evolving as governments worldwide recognize the potential of this carbon-neutral fuel and feedstock. Currently, the International Maritime Organization (IMO) has established guidelines for ammonia as a marine fuel, focusing on safety protocols and emission standards. These regulations require specific containment systems, ventilation requirements, and emergency procedures that differ significantly from conventional fuel handling.

The European Union has taken a leading role through its Renewable Energy Directive (RED II), which includes green ammonia under renewable fuels of non-biological origin (RFNBOs). This framework mandates that green ammonia must achieve at least a 70% greenhouse gas emission reduction compared to fossil fuel alternatives to qualify for regulatory incentives. Additionally, the EU Taxonomy for Sustainable Activities provides clear criteria for hydrogen-based ammonia production to be considered environmentally sustainable.

In the United States, the Department of Energy has developed technical standards for green ammonia production facilities, while the Environmental Protection Agency regulates emissions and safety aspects. The Inflation Reduction Act of 2022 introduced significant tax credits for clean hydrogen production, which directly benefits green ammonia projects meeting specific carbon intensity thresholds.

Certification systems for green ammonia are emerging through various international bodies. The Ammonia Energy Association has proposed a certification scheme that verifies the carbon intensity of ammonia production, tracking emissions throughout the entire value chain. This system employs blockchain technology to ensure transparency and traceability of green ammonia from production to end-use.

The International Renewable Energy Agency (IRENA) has established a framework for guarantees of origin for green ammonia, which enables producers to verify and market the environmental attributes of their products. These certificates are becoming increasingly important for international trade and regulatory compliance.

Industry standards for safety and quality control in green ammonia production are primarily governed by the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards address purity requirements, contaminant limits, and testing methodologies specific to green ammonia applications in various sectors including agriculture, shipping, and power generation.

Performance benchmarks within these regulatory frameworks typically require lifecycle carbon intensity below 0.5 kg CO2e per kg of ammonia produced, with leading projects achieving even lower emissions. Water consumption, energy efficiency, and nitrogen oxide emissions during combustion are additional performance metrics increasingly incorporated into regulatory requirements.

The European Union has taken a leading role through its Renewable Energy Directive (RED II), which includes green ammonia under renewable fuels of non-biological origin (RFNBOs). This framework mandates that green ammonia must achieve at least a 70% greenhouse gas emission reduction compared to fossil fuel alternatives to qualify for regulatory incentives. Additionally, the EU Taxonomy for Sustainable Activities provides clear criteria for hydrogen-based ammonia production to be considered environmentally sustainable.

In the United States, the Department of Energy has developed technical standards for green ammonia production facilities, while the Environmental Protection Agency regulates emissions and safety aspects. The Inflation Reduction Act of 2022 introduced significant tax credits for clean hydrogen production, which directly benefits green ammonia projects meeting specific carbon intensity thresholds.

Certification systems for green ammonia are emerging through various international bodies. The Ammonia Energy Association has proposed a certification scheme that verifies the carbon intensity of ammonia production, tracking emissions throughout the entire value chain. This system employs blockchain technology to ensure transparency and traceability of green ammonia from production to end-use.

The International Renewable Energy Agency (IRENA) has established a framework for guarantees of origin for green ammonia, which enables producers to verify and market the environmental attributes of their products. These certificates are becoming increasingly important for international trade and regulatory compliance.

Industry standards for safety and quality control in green ammonia production are primarily governed by the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards address purity requirements, contaminant limits, and testing methodologies specific to green ammonia applications in various sectors including agriculture, shipping, and power generation.

Performance benchmarks within these regulatory frameworks typically require lifecycle carbon intensity below 0.5 kg CO2e per kg of ammonia produced, with leading projects achieving even lower emissions. Water consumption, energy efficiency, and nitrogen oxide emissions during combustion are additional performance metrics increasingly incorporated into regulatory requirements.

Environmental Impact Assessment and Carbon Footprint

The environmental impact assessment of green ammonia synthesis reveals significant advantages over conventional production methods. Traditional Haber-Bosch processes account for approximately 1.8% of global CO2 emissions, with each ton of ammonia produced generating 1.6-1.8 tons of carbon dioxide. In contrast, green ammonia production utilizing renewable electricity for hydrogen generation can reduce carbon emissions by up to 80-90% when compared to fossil fuel-based methods.

Life cycle assessments (LCA) of green ammonia facilities demonstrate that the carbon footprint is primarily determined by the electricity source. Facilities powered by wind or solar energy achieve carbon intensity values below 0.2 kg CO2e per kg of ammonia, while conventional natural gas-based production typically ranges between 2.0-2.5 kg CO2e per kg of ammonia. This substantial difference highlights the transformative potential of renewable-powered synthesis routes.

Water consumption represents another critical environmental parameter. Green ammonia production requires approximately 9-10 liters of purified water per kilogram of ammonia produced. While this represents a significant water footprint, advanced water recycling systems can reduce freshwater requirements by up to 60%. Additionally, coastal facilities can implement seawater desalination powered by excess renewable energy, further minimizing environmental impact in water-stressed regions.

Land use considerations vary significantly based on the renewable energy source. Solar-powered green ammonia facilities require approximately 10-15 hectares per kiloton of annual production capacity, while wind-powered facilities typically need 5-8 hectares. This land requirement must be factored into environmental impact assessments, particularly in regions with competing land use priorities.

Emerging industry standards are increasingly incorporating comprehensive environmental performance metrics. The International Fertilizer Association (IFA) has developed the "Cool Farm Tool" specifically for evaluating ammonia production, while the Ammonia Energy Association promotes the "Zero-Carbon Ammonia Certification" that requires full life-cycle carbon accounting. These standards are driving transparency and enabling meaningful comparisons between different production pathways.

Recent advancements in catalysis and electrochemical processes promise further environmental improvements. Direct electrochemical ammonia synthesis could potentially reduce energy requirements by 20-30% compared to even the most efficient green hydrogen-based processes, translating to proportional reductions in indirect environmental impacts from renewable energy infrastructure.

Life cycle assessments (LCA) of green ammonia facilities demonstrate that the carbon footprint is primarily determined by the electricity source. Facilities powered by wind or solar energy achieve carbon intensity values below 0.2 kg CO2e per kg of ammonia, while conventional natural gas-based production typically ranges between 2.0-2.5 kg CO2e per kg of ammonia. This substantial difference highlights the transformative potential of renewable-powered synthesis routes.

Water consumption represents another critical environmental parameter. Green ammonia production requires approximately 9-10 liters of purified water per kilogram of ammonia produced. While this represents a significant water footprint, advanced water recycling systems can reduce freshwater requirements by up to 60%. Additionally, coastal facilities can implement seawater desalination powered by excess renewable energy, further minimizing environmental impact in water-stressed regions.

Land use considerations vary significantly based on the renewable energy source. Solar-powered green ammonia facilities require approximately 10-15 hectares per kiloton of annual production capacity, while wind-powered facilities typically need 5-8 hectares. This land requirement must be factored into environmental impact assessments, particularly in regions with competing land use priorities.

Emerging industry standards are increasingly incorporating comprehensive environmental performance metrics. The International Fertilizer Association (IFA) has developed the "Cool Farm Tool" specifically for evaluating ammonia production, while the Ammonia Energy Association promotes the "Zero-Carbon Ammonia Certification" that requires full life-cycle carbon accounting. These standards are driving transparency and enabling meaningful comparisons between different production pathways.

Recent advancements in catalysis and electrochemical processes promise further environmental improvements. Direct electrochemical ammonia synthesis could potentially reduce energy requirements by 20-30% compared to even the most efficient green hydrogen-based processes, translating to proportional reductions in indirect environmental impacts from renewable energy infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!