Lithium Bromide vs Calcium Chloride: Cooling Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Absorption Cooling Technology Background and Objectives

Absorption cooling technology represents a significant advancement in refrigeration systems that operate without conventional vapor compression mechanisms. The technology dates back to the 1850s when Ferdinand Carré developed the first ammonia-water absorption refrigeration system. Over subsequent decades, this technology evolved from primarily industrial applications to becoming a viable alternative in commercial and residential cooling systems, particularly in regions where electricity supply is limited or expensive.

The fundamental principle of absorption cooling relies on a thermochemical process where a refrigerant is absorbed into an absorbent, creating a solution that can be pumped to a generator where heat separates the components. This cycle enables cooling without the mechanical compression required in conventional systems, significantly reducing electricity consumption while utilizing thermal energy sources.

In the evolution of absorption cooling technology, two working pairs have emerged as predominant solutions: lithium bromide-water and water-ammonia systems. Since the 1950s, lithium bromide (LiBr) has gained prominence due to its excellent absorption properties and relative safety compared to ammonia-based systems. Concurrently, calcium chloride (CaCl₂) has emerged as a potential alternative absorbent, offering cost advantages though with different performance characteristics.

The technological trajectory has been shaped by increasing demands for energy efficiency, environmental sustainability, and cost-effectiveness. Modern research focuses on enhancing coefficient of performance (COP), reducing system size, and minimizing environmental impact through improved working fluids and system designs.

The primary objective of comparing LiBr and CaCl₂ for cooling efficiency is to determine the optimal absorbent for specific applications based on comprehensive performance metrics. This comparison aims to evaluate thermal efficiency, operational stability, corrosion tendencies, crystallization risks, and economic viability across various operating conditions and system scales.

Additional objectives include identifying potential hybrid systems that might leverage the strengths of both chemicals, exploring opportunities for performance enhancement through additives or modified system configurations, and assessing environmental impacts throughout the lifecycle of these systems.

This technological assessment occurs against the backdrop of increasing global cooling demands, stricter environmental regulations regarding refrigerants, and rising energy costs. The findings will contribute to the development of more sustainable cooling solutions that align with international climate commitments while meeting growing cooling needs in both developed and developing regions.

The fundamental principle of absorption cooling relies on a thermochemical process where a refrigerant is absorbed into an absorbent, creating a solution that can be pumped to a generator where heat separates the components. This cycle enables cooling without the mechanical compression required in conventional systems, significantly reducing electricity consumption while utilizing thermal energy sources.

In the evolution of absorption cooling technology, two working pairs have emerged as predominant solutions: lithium bromide-water and water-ammonia systems. Since the 1950s, lithium bromide (LiBr) has gained prominence due to its excellent absorption properties and relative safety compared to ammonia-based systems. Concurrently, calcium chloride (CaCl₂) has emerged as a potential alternative absorbent, offering cost advantages though with different performance characteristics.

The technological trajectory has been shaped by increasing demands for energy efficiency, environmental sustainability, and cost-effectiveness. Modern research focuses on enhancing coefficient of performance (COP), reducing system size, and minimizing environmental impact through improved working fluids and system designs.

The primary objective of comparing LiBr and CaCl₂ for cooling efficiency is to determine the optimal absorbent for specific applications based on comprehensive performance metrics. This comparison aims to evaluate thermal efficiency, operational stability, corrosion tendencies, crystallization risks, and economic viability across various operating conditions and system scales.

Additional objectives include identifying potential hybrid systems that might leverage the strengths of both chemicals, exploring opportunities for performance enhancement through additives or modified system configurations, and assessing environmental impacts throughout the lifecycle of these systems.

This technological assessment occurs against the backdrop of increasing global cooling demands, stricter environmental regulations regarding refrigerants, and rising energy costs. The findings will contribute to the development of more sustainable cooling solutions that align with international climate commitments while meeting growing cooling needs in both developed and developing regions.

Market Analysis of Industrial Cooling Solutions

The global industrial cooling solutions market has been experiencing steady growth, valued at approximately $25.6 billion in 2022 and projected to reach $35.7 billion by 2028, with a CAGR of 5.7%. This growth is primarily driven by increasing industrialization, particularly in developing economies, stringent regulations regarding energy efficiency, and the rising demand for sustainable cooling technologies.

The industrial cooling sector can be segmented into various applications including HVAC systems, refrigeration, process cooling, and absorption cooling systems. Within absorption cooling systems, which represent about 12% of the total market, lithium bromide and calcium chloride solutions are two prominent working fluids that have gained significant attention due to their efficiency and environmental benefits.

Regionally, Asia-Pacific dominates the industrial cooling market with a 38% share, followed by North America (27%) and Europe (22%). China and India are experiencing the fastest growth rates due to rapid industrialization and infrastructure development. The Middle East, despite its smaller market size, shows increasing adoption of absorption cooling technologies due to high cooling demands and energy costs.

End-user industries driving demand include manufacturing (32%), food and beverage processing (18%), chemical and pharmaceutical (15%), data centers (14%), and others (21%). The data center segment is experiencing the fastest growth at 9.3% annually, creating new opportunities for efficient cooling solutions like lithium bromide and calcium chloride-based systems.

Market trends indicate a significant shift toward energy-efficient and environmentally friendly cooling solutions. Absorption chillers using lithium bromide or calcium chloride can utilize waste heat or solar energy, reducing operational costs by up to 40% compared to conventional cooling systems. This aligns with global sustainability initiatives and carbon reduction targets.

Customer preferences are increasingly favoring solutions with lower environmental impact and reduced energy consumption. Lithium bromide systems currently hold approximately 65% of the absorption chiller market, while calcium chloride solutions account for about 20%, with the remainder comprising other working fluids.

Price sensitivity varies by region and industry, with initial investment costs being a significant barrier for adoption in developing markets. However, the total cost of ownership analysis increasingly favors absorption cooling technologies due to their lower operational expenses and longer service life, typically 20-25 years compared to 15 years for conventional systems.

The industrial cooling sector can be segmented into various applications including HVAC systems, refrigeration, process cooling, and absorption cooling systems. Within absorption cooling systems, which represent about 12% of the total market, lithium bromide and calcium chloride solutions are two prominent working fluids that have gained significant attention due to their efficiency and environmental benefits.

Regionally, Asia-Pacific dominates the industrial cooling market with a 38% share, followed by North America (27%) and Europe (22%). China and India are experiencing the fastest growth rates due to rapid industrialization and infrastructure development. The Middle East, despite its smaller market size, shows increasing adoption of absorption cooling technologies due to high cooling demands and energy costs.

End-user industries driving demand include manufacturing (32%), food and beverage processing (18%), chemical and pharmaceutical (15%), data centers (14%), and others (21%). The data center segment is experiencing the fastest growth at 9.3% annually, creating new opportunities for efficient cooling solutions like lithium bromide and calcium chloride-based systems.

Market trends indicate a significant shift toward energy-efficient and environmentally friendly cooling solutions. Absorption chillers using lithium bromide or calcium chloride can utilize waste heat or solar energy, reducing operational costs by up to 40% compared to conventional cooling systems. This aligns with global sustainability initiatives and carbon reduction targets.

Customer preferences are increasingly favoring solutions with lower environmental impact and reduced energy consumption. Lithium bromide systems currently hold approximately 65% of the absorption chiller market, while calcium chloride solutions account for about 20%, with the remainder comprising other working fluids.

Price sensitivity varies by region and industry, with initial investment costs being a significant barrier for adoption in developing markets. However, the total cost of ownership analysis increasingly favors absorption cooling technologies due to their lower operational expenses and longer service life, typically 20-25 years compared to 15 years for conventional systems.

Current State and Challenges in Absorption Refrigeration

Absorption refrigeration technology has evolved significantly over the past decades, with lithium bromide (LiBr) and calcium chloride (CaCl₂) emerging as prominent working pairs with water as refrigerant. Currently, LiBr-water systems dominate commercial applications, particularly in large-scale air conditioning and industrial cooling, due to their superior coefficient of performance (COP) ranging from 0.7 to 1.2 under optimal conditions. Meanwhile, CaCl₂-water systems, though less widespread, have gained attention for their lower cost and reduced corrosivity.

The global absorption refrigeration market is experiencing steady growth, projected at a CAGR of approximately 7.5% through 2028, driven primarily by increasing energy costs and environmental regulations limiting conventional refrigerants. LiBr systems currently hold approximately 65% market share in absorption cooling technologies, while CaCl₂ systems represent about 15%, with the remainder comprising alternative working pairs.

Despite technological advancements, absorption refrigeration faces several significant challenges. Crystallization remains a critical issue, particularly in LiBr systems where solution concentration exceeding 65% can lead to salt precipitation and system failure. CaCl₂ systems exhibit higher crystallization resistance but at the cost of lower efficiency. This crystallization-efficiency trade-off represents one of the field's fundamental technical dilemmas.

Corrosion presents another major challenge, especially in LiBr systems where the highly corrosive nature of concentrated bromide solutions necessitates expensive corrosion-resistant materials and inhibitors. While CaCl₂ demonstrates lower corrosivity, it still requires specialized materials for long-term operation, impacting system cost and lifespan.

Energy efficiency limitations constitute a persistent obstacle. Even optimized LiBr systems typically achieve COPs below 1.2, significantly lower than vapor-compression alternatives (3.0-5.0). CaCl₂ systems generally exhibit even lower efficiency, with COPs rarely exceeding 0.7 under comparable conditions. This efficiency gap remains the primary barrier to wider adoption.

Size and weight constraints also hinder market penetration, as absorption systems require substantially larger heat exchangers and solution pumps compared to conventional cooling technologies. LiBr systems typically require 2.5-3 times the physical footprint of equivalent vapor-compression systems, while CaCl₂ systems may require even larger dimensions due to lower heat transfer coefficients.

Geographically, absorption cooling technology development centers primarily in Japan, the United States, and increasingly China, with Japanese manufacturers holding approximately 40% of global patents related to LiBr absorption systems. Research into CaCl₂ systems is more distributed, with significant contributions from European research institutions seeking lower-cost alternatives to LiBr technology.

The global absorption refrigeration market is experiencing steady growth, projected at a CAGR of approximately 7.5% through 2028, driven primarily by increasing energy costs and environmental regulations limiting conventional refrigerants. LiBr systems currently hold approximately 65% market share in absorption cooling technologies, while CaCl₂ systems represent about 15%, with the remainder comprising alternative working pairs.

Despite technological advancements, absorption refrigeration faces several significant challenges. Crystallization remains a critical issue, particularly in LiBr systems where solution concentration exceeding 65% can lead to salt precipitation and system failure. CaCl₂ systems exhibit higher crystallization resistance but at the cost of lower efficiency. This crystallization-efficiency trade-off represents one of the field's fundamental technical dilemmas.

Corrosion presents another major challenge, especially in LiBr systems where the highly corrosive nature of concentrated bromide solutions necessitates expensive corrosion-resistant materials and inhibitors. While CaCl₂ demonstrates lower corrosivity, it still requires specialized materials for long-term operation, impacting system cost and lifespan.

Energy efficiency limitations constitute a persistent obstacle. Even optimized LiBr systems typically achieve COPs below 1.2, significantly lower than vapor-compression alternatives (3.0-5.0). CaCl₂ systems generally exhibit even lower efficiency, with COPs rarely exceeding 0.7 under comparable conditions. This efficiency gap remains the primary barrier to wider adoption.

Size and weight constraints also hinder market penetration, as absorption systems require substantially larger heat exchangers and solution pumps compared to conventional cooling technologies. LiBr systems typically require 2.5-3 times the physical footprint of equivalent vapor-compression systems, while CaCl₂ systems may require even larger dimensions due to lower heat transfer coefficients.

Geographically, absorption cooling technology development centers primarily in Japan, the United States, and increasingly China, with Japanese manufacturers holding approximately 40% of global patents related to LiBr absorption systems. Research into CaCl₂ systems is more distributed, with significant contributions from European research institutions seeking lower-cost alternatives to LiBr technology.

Technical Comparison of LiBr and CaCl2 Cooling Systems

01 Absorption refrigeration systems using lithium bromide

Lithium bromide is widely used as an absorbent in absorption refrigeration systems due to its high affinity for water vapor. These systems utilize the ability of lithium bromide solution to absorb water vapor, creating a cooling effect. The efficiency of lithium bromide-based cooling systems depends on the concentration of the solution and operating conditions. These systems are commonly used in industrial and commercial applications where waste heat is available as an energy source.- Absorption refrigeration systems using lithium bromide: Lithium bromide is widely used as an absorbent in absorption refrigeration systems due to its high affinity for water vapor. These systems operate by using lithium bromide solution to absorb water vapor from an evaporator, creating a cooling effect. The efficiency of lithium bromide-based cooling systems depends on the concentration of the solution and operating conditions. These systems are particularly effective for air conditioning and industrial cooling applications where waste heat is available as an energy source.

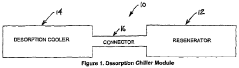

- Calcium chloride as an alternative refrigerant in cooling systems: Calcium chloride serves as a cost-effective alternative to lithium bromide in certain absorption cooling applications. It functions as an absorbent for water or other refrigerants, creating cooling through the absorption cycle. Calcium chloride-based systems typically have lower efficiency than lithium bromide systems but offer advantages in terms of cost, availability, and reduced corrosivity. These systems are particularly suitable for small to medium-scale cooling applications where initial cost is a primary concern.

- Hybrid systems combining lithium bromide and calcium chloride: Hybrid cooling systems that combine lithium bromide and calcium chloride can achieve improved efficiency and cost-effectiveness. By leveraging the high absorption capacity of lithium bromide and the economic benefits of calcium chloride, these hybrid systems optimize the overall cooling performance. The combination can reduce crystallization issues common in single-salt systems and extend the operating temperature range. Such hybrid systems represent an innovative approach to balancing efficiency and cost in absorption cooling technology.

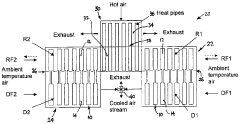

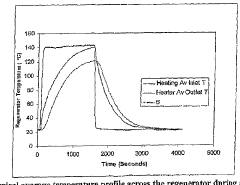

- System design improvements for enhanced cooling efficiency: Various design improvements can enhance the cooling efficiency of systems using lithium bromide or calcium chloride. These include multi-stage absorption cycles, heat recovery mechanisms, advanced heat exchangers, and optimized solution circulation methods. Improved system configurations can reduce energy consumption, minimize heat losses, and enhance the coefficient of performance (COP). Modern designs also incorporate automation and control systems to maintain optimal operating conditions under varying loads and ambient temperatures.

- Additives and solution treatments to improve performance: Various additives and solution treatments can significantly improve the performance of lithium bromide and calcium chloride cooling systems. Corrosion inhibitors protect system components and extend equipment life. Anti-crystallization agents prevent salt precipitation at high concentrations. Heat transfer enhancers improve thermal conductivity of the working solutions. Surface-active agents can enhance the absorption process by improving wetting characteristics. These chemical modifications can substantially increase system efficiency, reliability, and operational range.

02 Calcium chloride as an alternative refrigerant

Calcium chloride serves as an alternative absorbent in absorption cooling systems. It offers advantages such as lower cost compared to lithium bromide and good absorption capacity. Calcium chloride-based cooling systems operate on similar principles to lithium bromide systems but may have different efficiency characteristics and operating parameters. These systems are particularly suitable for applications where cost considerations are important and moderate cooling efficiency is acceptable.Expand Specific Solutions03 Comparative efficiency of lithium bromide and calcium chloride systems

Studies comparing the cooling efficiency of lithium bromide and calcium chloride systems show that lithium bromide generally provides higher coefficient of performance (COP) under similar operating conditions. However, calcium chloride systems may be more economical in certain applications despite lower efficiency. Factors affecting comparative performance include operating temperatures, concentration levels, system design, and heat exchanger efficiency. The selection between these refrigerants depends on specific application requirements and available energy sources.Expand Specific Solutions04 Enhanced cooling efficiency through system modifications

Various modifications can enhance the cooling efficiency of both lithium bromide and calcium chloride systems. These include multi-stage absorption cycles, heat recovery systems, improved heat exchangers, and advanced control strategies. Adding certain additives to the working solutions can also improve heat and mass transfer characteristics. System optimization techniques such as variable flow control and temperature management can significantly increase the coefficient of performance while reducing energy consumption.Expand Specific Solutions05 Hybrid and combined cooling systems

Hybrid systems combining lithium bromide and calcium chloride or integrating these absorbents with other cooling technologies can achieve improved efficiency and operational flexibility. These systems may utilize multiple temperature stages or cascade configurations to maximize performance. Combined cooling, heating, and power systems incorporating absorption cooling with lithium bromide or calcium chloride can significantly increase overall energy utilization efficiency. Such integrated approaches are particularly valuable in applications requiring both cooling and heating capabilities.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The cooling efficiency market comparing Lithium Bromide vs Calcium Chloride is in a growth phase, with increasing demand for energy-efficient cooling solutions driving a global market expected to reach $20 billion by 2027. Technology maturity varies significantly among key players. Industry leaders like Carrier Corp. and DuPont demonstrate advanced commercial applications, while companies such as Shuangliang Eco-Energy and Shanghai Disen Energy Technology are rapidly innovating in absorption cooling technologies. Academic institutions including Xi'an Jiaotong University and Qingdao University of Science & Technology are contributing significant research advancements, particularly in improving cycle efficiency and reducing environmental impact, creating a competitive landscape balanced between established corporations and emerging technology providers.

YAZAKI Corp.

Technical Solution: YAZAKI Corporation has pioneered water-lithium bromide absorption chillers specifically designed for solar cooling and waste heat recovery applications. Their WFC-SC series utilizes a single-effect absorption cycle with lithium bromide as the absorbent and water as the refrigerant. The system operates at low generator temperatures (70-95°C), making it ideal for integration with solar thermal collectors and industrial waste heat sources. YAZAKI's proprietary internal solution distribution system enhances heat and mass transfer efficiency, while their vacuum maintenance technology ensures long-term stable operation. Their chillers incorporate advanced controls that automatically adjust concentration levels to prevent crystallization issues. The company has also developed compact designs with reduced footprint, achieving cooling capacities from 10kW to 175kW while maintaining COPs of approximately 0.7. Recent innovations include improved solution heat exchangers that increase thermal efficiency by up to 15%.

Strengths: Excellent integration with low-temperature heat sources (70-95°C); compact design suitable for distributed applications; reliable operation with minimal maintenance; good part-load performance. Weaknesses: Lower COP (typically 0.7) compared to multi-effect LiBr systems; requires cooling tower for heat rejection; sensitive to ambient conditions; limited capacity range compared to industrial-scale systems.

Carrier Corp.

Technical Solution: Carrier Corporation has developed advanced absorption chiller systems utilizing lithium bromide (LiBr) as the primary working fluid. Their technology employs a vacuum-sealed system where LiBr serves as the absorbent and water as the refrigerant. The process involves water evaporation at low pressure, creating a cooling effect, while the LiBr solution absorbs water vapor, maintaining the cycle. Carrier's systems incorporate multi-stage generators and advanced heat exchangers to improve efficiency, achieving Coefficient of Performance (COP) values of 0.7-1.2 for single-effect and up to 1.5 for double-effect systems. Their patented crystallization prevention mechanisms and solution distribution techniques ensure reliable operation even under varying load conditions. Carrier has also developed hybrid systems that can utilize waste heat sources, reducing primary energy consumption by up to 30% compared to conventional cooling systems.

Strengths: Higher efficiency with COPs reaching up to 1.5 for double-effect systems; excellent performance at medium temperature ranges (80-120°C); non-toxic working fluid; utilizes waste heat effectively. Weaknesses: Risk of crystallization at high concentrations; corrosive to certain metals requiring special materials; vacuum conditions must be maintained; higher initial cost compared to conventional systems.

Key Patents and Research in Absorption Refrigerants

Operating medium for an absorption refrigeration device

PatentInactiveEP2510069A1

Innovation

- A working medium comprising 5-30% water and 65-95% lithium bromide with an ionic liquid, in a weight ratio of 0.5:1 to 5:1, which reduces friction and prevents crystallization, allowing for a single-phase solution and reduced mechanical energy consumption.

Apparatus and method for transferring heat

PatentInactiveUS8256235B2

Innovation

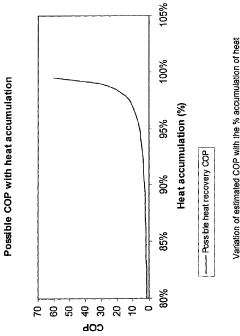

- The apparatus comprises first and second heat transfer units with a thermally connected heat exchanger, allowing for heat accumulation and simultaneous adsorption/desorption in both units, eliminating the need for additional heat exchangers and pumps, and enhancing thermal isolation between adsorbent materials to achieve a COP of up to 12.

Environmental Impact and Sustainability Assessment

The environmental impact of cooling systems utilizing lithium bromide (LiBr) and calcium chloride (CaCl₂) presents significant considerations for sustainable development in HVAC technologies. LiBr-based absorption chillers demonstrate notable advantages in terms of reduced direct greenhouse gas emissions compared to conventional vapor compression systems, as they do not rely on hydrofluorocarbons (HFCs) or other high-global warming potential refrigerants. However, the production of lithium compounds involves substantial water consumption and potential habitat disruption in lithium-rich regions such as the Lithium Triangle in South America.

Calcium chloride systems, while less common in commercial cooling applications, offer certain environmental benefits through their abundance and lower extraction impact. CaCl₂ is often a byproduct of industrial processes, potentially allowing for circular economy applications that reduce overall environmental footprint. The production energy requirements for CaCl₂ are generally lower than those for LiBr, contributing to reduced embodied carbon in system manufacturing.

Water consumption patterns differ significantly between these technologies. LiBr systems typically require more water for operation, particularly in open-loop configurations, whereas CaCl₂ systems can be designed with lower water requirements. This distinction becomes increasingly important in water-stressed regions where cooling demand is often highest.

End-of-life considerations reveal that LiBr poses greater challenges for disposal and recycling due to its potential toxicity and specialized handling requirements. Calcium chloride, being less hazardous, presents fewer disposal complications and higher potential for material recovery and reuse in various applications beyond cooling systems.

Energy efficiency metrics indicate that well-designed LiBr absorption systems can achieve higher Coefficients of Performance (COP) when powered by waste heat or renewable thermal energy, potentially offsetting their manufacturing impacts through operational efficiency. This advantage becomes particularly relevant when considering life cycle assessment (LCA) methodologies that account for both embodied and operational environmental impacts.

Recent sustainability certifications and regulatory frameworks increasingly favor systems with lower life-cycle environmental impacts. While LiBr systems may score better on operational efficiency and direct emissions, CaCl₂ alternatives often perform better on material sourcing, manufacturing impact, and end-of-life management criteria. This complex balance of environmental factors necessitates case-specific assessment based on installation location, available energy sources, and regional environmental priorities.

Calcium chloride systems, while less common in commercial cooling applications, offer certain environmental benefits through their abundance and lower extraction impact. CaCl₂ is often a byproduct of industrial processes, potentially allowing for circular economy applications that reduce overall environmental footprint. The production energy requirements for CaCl₂ are generally lower than those for LiBr, contributing to reduced embodied carbon in system manufacturing.

Water consumption patterns differ significantly between these technologies. LiBr systems typically require more water for operation, particularly in open-loop configurations, whereas CaCl₂ systems can be designed with lower water requirements. This distinction becomes increasingly important in water-stressed regions where cooling demand is often highest.

End-of-life considerations reveal that LiBr poses greater challenges for disposal and recycling due to its potential toxicity and specialized handling requirements. Calcium chloride, being less hazardous, presents fewer disposal complications and higher potential for material recovery and reuse in various applications beyond cooling systems.

Energy efficiency metrics indicate that well-designed LiBr absorption systems can achieve higher Coefficients of Performance (COP) when powered by waste heat or renewable thermal energy, potentially offsetting their manufacturing impacts through operational efficiency. This advantage becomes particularly relevant when considering life cycle assessment (LCA) methodologies that account for both embodied and operational environmental impacts.

Recent sustainability certifications and regulatory frameworks increasingly favor systems with lower life-cycle environmental impacts. While LiBr systems may score better on operational efficiency and direct emissions, CaCl₂ alternatives often perform better on material sourcing, manufacturing impact, and end-of-life management criteria. This complex balance of environmental factors necessitates case-specific assessment based on installation location, available energy sources, and regional environmental priorities.

Cost-Benefit Analysis of Competing Refrigerant Solutions

When evaluating refrigerant solutions for cooling systems, cost-benefit analysis provides critical insights for decision-makers. Lithium bromide and calcium chloride represent two competing options with distinct economic profiles across their lifecycle.

Initial investment costs differ significantly between these refrigerants. Lithium bromide systems typically require higher capital expenditure, with absorption chillers costing 20-30% more than comparable calcium chloride systems. This price premium stems from lithium bromide's specialized handling requirements and the more complex equipment needed for its implementation. However, calcium chloride systems often necessitate additional corrosion-resistant components, partially offsetting their lower initial cost advantage.

Operational efficiency translates directly to economic performance. Lithium bromide demonstrates superior cooling efficiency with a coefficient of performance (COP) ranging from 0.7-1.2 compared to calcium chloride's typical 0.5-0.8 COP. This efficiency differential results in approximately 15-25% lower energy consumption for lithium bromide systems, generating substantial cost savings over time, particularly in regions with high electricity prices.

Maintenance requirements present another significant cost factor. Calcium chloride's corrosive properties necessitate more frequent component replacement and system servicing, increasing maintenance costs by an estimated 30-40% compared to lithium bromide systems. Conversely, lithium bromide's higher market price means that refrigerant replacement or top-up costs exceed those of calcium chloride by approximately 3-4 times per unit volume.

Longevity considerations favor lithium bromide installations, which typically maintain optimal performance for 15-20 years versus 10-15 years for calcium chloride systems. This extended service life improves the return on investment despite higher upfront costs.

Environmental compliance costs increasingly impact total ownership expenses. Lithium bromide's lower environmental impact results in reduced compliance costs and potential eligibility for green incentives in many jurisdictions. Calcium chloride systems may face additional disposal fees and environmental mitigation requirements, adding 5-10% to lifetime operational costs.

Market analysis indicates that the payback period for the premium paid for lithium bromide systems typically ranges from 3-5 years in high-usage scenarios, making it economically advantageous for long-term installations despite higher initial investment. Calcium chloride remains financially competitive for shorter-term applications or in regions with lower energy costs.

Risk assessment reveals that lithium bromide systems offer greater price stability, as calcium chloride costs have shown higher volatility (±15% annual price fluctuations versus ±7% for lithium bromide) over the past decade, introducing additional financial uncertainty for long-term planning.

Initial investment costs differ significantly between these refrigerants. Lithium bromide systems typically require higher capital expenditure, with absorption chillers costing 20-30% more than comparable calcium chloride systems. This price premium stems from lithium bromide's specialized handling requirements and the more complex equipment needed for its implementation. However, calcium chloride systems often necessitate additional corrosion-resistant components, partially offsetting their lower initial cost advantage.

Operational efficiency translates directly to economic performance. Lithium bromide demonstrates superior cooling efficiency with a coefficient of performance (COP) ranging from 0.7-1.2 compared to calcium chloride's typical 0.5-0.8 COP. This efficiency differential results in approximately 15-25% lower energy consumption for lithium bromide systems, generating substantial cost savings over time, particularly in regions with high electricity prices.

Maintenance requirements present another significant cost factor. Calcium chloride's corrosive properties necessitate more frequent component replacement and system servicing, increasing maintenance costs by an estimated 30-40% compared to lithium bromide systems. Conversely, lithium bromide's higher market price means that refrigerant replacement or top-up costs exceed those of calcium chloride by approximately 3-4 times per unit volume.

Longevity considerations favor lithium bromide installations, which typically maintain optimal performance for 15-20 years versus 10-15 years for calcium chloride systems. This extended service life improves the return on investment despite higher upfront costs.

Environmental compliance costs increasingly impact total ownership expenses. Lithium bromide's lower environmental impact results in reduced compliance costs and potential eligibility for green incentives in many jurisdictions. Calcium chloride systems may face additional disposal fees and environmental mitigation requirements, adding 5-10% to lifetime operational costs.

Market analysis indicates that the payback period for the premium paid for lithium bromide systems typically ranges from 3-5 years in high-usage scenarios, making it economically advantageous for long-term installations despite higher initial investment. Calcium chloride remains financially competitive for shorter-term applications or in regions with lower energy costs.

Risk assessment reveals that lithium bromide systems offer greater price stability, as calcium chloride costs have shown higher volatility (±15% annual price fluctuations versus ±7% for lithium bromide) over the past decade, introducing additional financial uncertainty for long-term planning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!