Material Jetting Vs SLS: Dimensional Accuracy, Surface Integrity And Porosity

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printing Evolution and Precision Goals

3D printing technology has evolved dramatically since its inception in the 1980s, transforming from simple prototyping tools to sophisticated manufacturing systems capable of producing functional end-use parts. The journey began with stereolithography (SLA), followed by the development of Fused Deposition Modeling (FDM) in the early 1990s. Material Jetting and Selective Laser Sintering (SLS) represent more advanced iterations in this evolutionary timeline, emerging as industrial-grade technologies in the late 1990s and early 2000s.

Material Jetting technology has roots in traditional inkjet printing, adapted to deposit photopolymers layer by layer and cure them with UV light. Its development has focused on multi-material capabilities and high-resolution outputs. SLS technology, conversely, evolved from powder metallurgy principles, using lasers to selectively fuse polymer powder particles. Both technologies have undergone significant refinement over the past two decades, with particular emphasis on improving dimensional accuracy, surface quality, and material properties.

The precision goals for these technologies have become increasingly demanding as applications have expanded from prototyping to functional part production. Initially, tolerances of ±0.2mm were considered acceptable for most applications. Today's industrial standards often require accuracies of ±0.05mm or better, particularly in aerospace, medical, and high-precision engineering sectors. This evolution reflects the industry's trajectory toward manufacturing-grade reliability.

Surface integrity requirements have similarly evolved, with early acceptance of visible layer lines and rough textures giving way to demands for near-injection-molding quality surfaces. The Ra (roughness average) values expected from premium 3D printing technologies have decreased from 15-20μm to 5μm or less in many applications. This progression has been driven by aesthetic considerations and functional requirements related to fluid dynamics, wear resistance, and assembly precision.

Porosity control represents perhaps the most significant technical advancement goal. Early printed parts often exhibited 5-15% internal porosity, limiting mechanical properties and reliability. Current technology targets aim for near-zero porosity in SLS parts and highly controlled, predictable microstructures in both technologies. This evolution reflects the transition of 3D printing from prototyping to end-use part production, where mechanical integrity and predictable performance are paramount.

The convergence of these precision goals has established new benchmarks for additive manufacturing technologies. Material Jetting and SLS have responded differently to these challenges, with distinct technological approaches that yield different performance characteristics across dimensional accuracy, surface integrity, and porosity control parameters.

Material Jetting technology has roots in traditional inkjet printing, adapted to deposit photopolymers layer by layer and cure them with UV light. Its development has focused on multi-material capabilities and high-resolution outputs. SLS technology, conversely, evolved from powder metallurgy principles, using lasers to selectively fuse polymer powder particles. Both technologies have undergone significant refinement over the past two decades, with particular emphasis on improving dimensional accuracy, surface quality, and material properties.

The precision goals for these technologies have become increasingly demanding as applications have expanded from prototyping to functional part production. Initially, tolerances of ±0.2mm were considered acceptable for most applications. Today's industrial standards often require accuracies of ±0.05mm or better, particularly in aerospace, medical, and high-precision engineering sectors. This evolution reflects the industry's trajectory toward manufacturing-grade reliability.

Surface integrity requirements have similarly evolved, with early acceptance of visible layer lines and rough textures giving way to demands for near-injection-molding quality surfaces. The Ra (roughness average) values expected from premium 3D printing technologies have decreased from 15-20μm to 5μm or less in many applications. This progression has been driven by aesthetic considerations and functional requirements related to fluid dynamics, wear resistance, and assembly precision.

Porosity control represents perhaps the most significant technical advancement goal. Early printed parts often exhibited 5-15% internal porosity, limiting mechanical properties and reliability. Current technology targets aim for near-zero porosity in SLS parts and highly controlled, predictable microstructures in both technologies. This evolution reflects the transition of 3D printing from prototyping to end-use part production, where mechanical integrity and predictable performance are paramount.

The convergence of these precision goals has established new benchmarks for additive manufacturing technologies. Material Jetting and SLS have responded differently to these challenges, with distinct technological approaches that yield different performance characteristics across dimensional accuracy, surface integrity, and porosity control parameters.

Market Analysis for High-Precision Additive Manufacturing

The high-precision additive manufacturing market is experiencing robust growth, driven by increasing demand across aerospace, medical, automotive, and consumer electronics sectors. Current market valuation stands at approximately 12 billion USD with a compound annual growth rate of 23% projected through 2028, significantly outpacing traditional manufacturing methods.

Material Jetting and Selective Laser Sintering (SLS) technologies represent premium segments within this market, with Material Jetting capturing about 18% market share and SLS holding 27% in high-precision applications. These technologies command premium pricing due to their superior dimensional accuracy capabilities, with Material Jetting systems typically ranging from $200,000 to $500,000 and industrial SLS systems from $150,000 to $400,000.

Customer demand analysis reveals distinct market preferences based on application requirements. Industries requiring exceptional surface finish quality and multi-material capabilities predominantly favor Material Jetting, while those prioritizing mechanical strength and functional prototyping gravitate toward SLS. The medical device sector shows particular growth for Material Jetting due to its ability to produce anatomical models with multiple material properties and colors.

Regional market distribution shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the fastest growth rate at 27% annually, driven by rapid industrialization in China, Japan, and South Korea. These countries are actively investing in high-precision manufacturing capabilities to support their electronics and automotive industries.

Market barriers include high equipment costs, material limitations, and post-processing requirements. The average return on investment period for high-precision additive manufacturing equipment ranges from 18 to 36 months, depending on utilization rates and application value. This creates significant entry barriers for small and medium enterprises.

Future market projections indicate continued segmentation between consumer/prosumer and industrial applications. The high-precision industrial segment is expected to maintain premium pricing while expanding capabilities, particularly in multi-material applications and production-scale manufacturing. Material Jetting is projected to grow at 26% annually through 2028, slightly outpacing SLS at 22%, primarily due to expanding applications in medical and consumer electronics sectors requiring exceptional dimensional accuracy and surface integrity.

Material Jetting and Selective Laser Sintering (SLS) technologies represent premium segments within this market, with Material Jetting capturing about 18% market share and SLS holding 27% in high-precision applications. These technologies command premium pricing due to their superior dimensional accuracy capabilities, with Material Jetting systems typically ranging from $200,000 to $500,000 and industrial SLS systems from $150,000 to $400,000.

Customer demand analysis reveals distinct market preferences based on application requirements. Industries requiring exceptional surface finish quality and multi-material capabilities predominantly favor Material Jetting, while those prioritizing mechanical strength and functional prototyping gravitate toward SLS. The medical device sector shows particular growth for Material Jetting due to its ability to produce anatomical models with multiple material properties and colors.

Regional market distribution shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the fastest growth rate at 27% annually, driven by rapid industrialization in China, Japan, and South Korea. These countries are actively investing in high-precision manufacturing capabilities to support their electronics and automotive industries.

Market barriers include high equipment costs, material limitations, and post-processing requirements. The average return on investment period for high-precision additive manufacturing equipment ranges from 18 to 36 months, depending on utilization rates and application value. This creates significant entry barriers for small and medium enterprises.

Future market projections indicate continued segmentation between consumer/prosumer and industrial applications. The high-precision industrial segment is expected to maintain premium pricing while expanding capabilities, particularly in multi-material applications and production-scale manufacturing. Material Jetting is projected to grow at 26% annually through 2028, slightly outpacing SLS at 22%, primarily due to expanding applications in medical and consumer electronics sectors requiring exceptional dimensional accuracy and surface integrity.

Material Jetting vs SLS: Current Capabilities and Limitations

Material Jetting and Selective Laser Sintering (SLS) represent two distinct approaches in additive manufacturing, each with specific capabilities and limitations that influence their application domains. Material Jetting, analogous to inkjet printing, deposits photopolymer droplets layer by layer, which are then cured using ultraviolet light. This technology excels in dimensional accuracy, consistently achieving tolerances of ±0.1% with a lower bound of ±0.05 mm, making it suitable for applications requiring high precision.

The surface finish of Material Jetting parts is exceptional, with Ra values typically between 1-3 μm without post-processing, resulting in parts with smooth, glossy surfaces. This characteristic eliminates the "stair-stepping" effect common in other 3D printing technologies. However, Material Jetting struggles with porosity control, as the curing process can trap air bubbles, leading to micro-voids that may compromise mechanical properties.

In contrast, SLS utilizes a high-power laser to selectively fuse polymer powder particles. SLS typically achieves dimensional accuracies of ±0.3% with a minimum of ±0.3 mm, which is less precise than Material Jetting but still adequate for many engineering applications. The layer-by-layer sintering process results in a characteristic grainy surface finish with Ra values between 7-15 μm, requiring post-processing for applications demanding smoother surfaces.

A significant advantage of SLS lies in its porosity management. The sintering process allows for controlled porosity ranging from 3% to 30%, which can be beneficial for applications requiring specific density characteristics. This controllable porosity enables the creation of parts with tailored mechanical properties, particularly valuable in aerospace and medical applications.

Material Jetting offers multi-material and multi-color capabilities within a single build, allowing for complex parts with varying material properties and visual characteristics. However, it is limited to photopolymers and waxes, restricting its application in functional prototyping and end-use parts requiring high mechanical strength or thermal resistance.

SLS, while limited to single material builds, can process a wider range of engineering-grade thermoplastics including nylon, polystyrene, and thermoplastic elastomers. This versatility makes SLS more suitable for functional prototypes and end-use parts in demanding environments. Additionally, SLS does not require support structures, enabling more complex geometries and reducing post-processing requirements.

The build volume constraints also differ significantly between these technologies. Material Jetting typically offers build volumes up to 500 × 400 × 200 mm, while SLS systems can accommodate larger builds, often exceeding 700 × 380 × 580 mm, making SLS more suitable for larger components or batch production of smaller parts.

The surface finish of Material Jetting parts is exceptional, with Ra values typically between 1-3 μm without post-processing, resulting in parts with smooth, glossy surfaces. This characteristic eliminates the "stair-stepping" effect common in other 3D printing technologies. However, Material Jetting struggles with porosity control, as the curing process can trap air bubbles, leading to micro-voids that may compromise mechanical properties.

In contrast, SLS utilizes a high-power laser to selectively fuse polymer powder particles. SLS typically achieves dimensional accuracies of ±0.3% with a minimum of ±0.3 mm, which is less precise than Material Jetting but still adequate for many engineering applications. The layer-by-layer sintering process results in a characteristic grainy surface finish with Ra values between 7-15 μm, requiring post-processing for applications demanding smoother surfaces.

A significant advantage of SLS lies in its porosity management. The sintering process allows for controlled porosity ranging from 3% to 30%, which can be beneficial for applications requiring specific density characteristics. This controllable porosity enables the creation of parts with tailored mechanical properties, particularly valuable in aerospace and medical applications.

Material Jetting offers multi-material and multi-color capabilities within a single build, allowing for complex parts with varying material properties and visual characteristics. However, it is limited to photopolymers and waxes, restricting its application in functional prototyping and end-use parts requiring high mechanical strength or thermal resistance.

SLS, while limited to single material builds, can process a wider range of engineering-grade thermoplastics including nylon, polystyrene, and thermoplastic elastomers. This versatility makes SLS more suitable for functional prototypes and end-use parts in demanding environments. Additionally, SLS does not require support structures, enabling more complex geometries and reducing post-processing requirements.

The build volume constraints also differ significantly between these technologies. Material Jetting typically offers build volumes up to 500 × 400 × 200 mm, while SLS systems can accommodate larger builds, often exceeding 700 × 380 × 580 mm, making SLS more suitable for larger components or batch production of smaller parts.

Technical Comparison of Material Jetting and SLS Methodologies

01 Dimensional accuracy optimization in Material Jetting and SLS

Various techniques can be employed to enhance dimensional accuracy in Material Jetting and Selective Laser Sintering (SLS) processes. These include precise control of process parameters such as laser power, scanning speed, and material deposition rate. Advanced calibration methods and real-time monitoring systems help maintain geometric fidelity during printing. Computational modeling and simulation tools can predict and compensate for potential dimensional variations before fabrication begins.- Dimensional accuracy optimization in Material Jetting and SLS: Various techniques can be employed to enhance dimensional accuracy in Material Jetting and SLS 3D printing processes. These include precise calibration of printing parameters, optimization of material properties, and implementation of advanced control systems. By carefully controlling factors such as layer thickness, printing speed, and thermal gradients, the dimensional accuracy of printed parts can be significantly improved, resulting in components that closely match the intended design specifications.

- Surface integrity enhancement methods: Surface integrity of 3D printed parts can be enhanced through various post-processing techniques and in-process optimizations. These include surface treatments, polishing methods, and parameter adjustments during printing. For Material Jetting and SLS technologies, controlling factors such as material deposition rate, energy distribution, and cooling profiles can significantly improve surface finish. Advanced surface treatment methods can further reduce roughness and enhance the aesthetic and functional properties of the printed components.

- Porosity control strategies: Controlling porosity in Material Jetting and SLS printed parts is crucial for achieving desired mechanical properties. Various approaches include optimizing powder characteristics, adjusting energy density parameters, and implementing specialized scanning strategies. By carefully managing the thermal history during the printing process, unwanted porosity can be minimized while intentional porosity can be precisely controlled when required for specific applications such as filtration or lightweight structures.

- Material formulation for improved print quality: Advanced material formulations play a critical role in enhancing the quality of parts produced by Material Jetting and SLS technologies. Specialized additives, particle size distributions, and rheological modifiers can significantly impact dimensional accuracy, surface finish, and porosity characteristics. By tailoring material compositions specifically for these printing processes, manufacturers can achieve superior part quality while maintaining or improving processing efficiency.

- Process monitoring and feedback control systems: Implementation of real-time monitoring and feedback control systems can significantly enhance the quality of Material Jetting and SLS printed parts. These systems utilize sensors to track critical process parameters and part characteristics during printing, allowing for immediate adjustments to maintain dimensional accuracy and surface integrity while minimizing porosity defects. Advanced algorithms and machine learning approaches enable predictive corrections that can compensate for process variations before they impact part quality.

02 Surface integrity enhancement methods

Surface integrity in 3D printed parts can be improved through various post-processing techniques and in-process optimizations. For Material Jetting, controlled droplet placement and curing parameters significantly affect surface quality. In SLS, particle size distribution and laser parameters directly impact surface roughness. Post-processing methods such as chemical treatments, mechanical polishing, and thermal treatments can further enhance surface finish. Advanced surface coating technologies can also be applied to improve functional properties while maintaining dimensional accuracy.Expand Specific Solutions03 Porosity control and management strategies

Controlling porosity in 3D printed parts is crucial for mechanical properties and functional performance. For SLS, powder characteristics, energy density, and thermal management significantly influence pore formation and distribution. In Material Jetting, droplet spacing, overlap parameters, and curing conditions affect internal structure development. Intentional porosity can be designed for specific applications like filtration or lightweight structures, while unwanted porosity can be minimized through process optimization and material formulation adjustments.Expand Specific Solutions04 Material formulation for improved print quality

Advanced material formulations play a critical role in achieving superior dimensional accuracy, surface integrity, and porosity control. For Material Jetting, optimized rheological properties ensure consistent droplet formation and placement. In SLS, powder characteristics such as particle size distribution, flowability, and thermal properties significantly impact print quality. Additives and modifiers can enhance material processability and final part properties. Novel composite materials can be designed to address specific challenges related to shrinkage, warping, and surface finish.Expand Specific Solutions05 Process monitoring and quality control systems

Real-time monitoring and quality control systems are essential for ensuring consistent dimensional accuracy, surface integrity, and porosity in 3D printed parts. Advanced sensor technologies can detect variations during the printing process, allowing for immediate adjustments. Machine learning algorithms can analyze process data to predict and prevent defects. Closed-loop control systems integrate monitoring data with process parameters to maintain optimal printing conditions. Post-build inspection methods using advanced imaging techniques provide comprehensive quality assessment of finished parts.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Additive Manufacturing

Material Jetting and SLS 3D printing technologies are currently in a mature growth phase within the additive manufacturing industry, which is projected to reach $35 billion by 2027. The competitive landscape features established players like Stratasys and voxeljet dominating Material Jetting, while EOS, Farsoon Technologies, and Solvay lead in SLS technology. Stratasys has pioneered high-precision Material Jetting solutions achieving ±0.1mm accuracy, while companies like Boeing and Jabil leverage SLS for industrial applications requiring 99.5% density parts. Research institutions including Chinese Academy of Science and University of Southern California are advancing both technologies through innovations in material science and process optimization, focusing on reducing porosity issues and improving surface finish quality for production-grade applications.

Stratasys Ltd.

Technical Solution: Stratasys has developed advanced Material Jetting technology through their PolyJet platform, which deposits photopolymer materials in ultra-thin layers (as thin as 16 microns) using multiple print heads with hundreds of tiny nozzles. Their technology enables multi-material printing with up to 14 different materials in a single build. For dimensional accuracy, Stratasys PolyJet achieves tolerances of ±0.1mm for features under 100mm, significantly better than typical SLS tolerances of ±0.3mm. Their VeroUltra material line specifically addresses surface finish quality, producing parts with layer lines virtually invisible to the naked eye and Ra values as low as 1-2μm without post-processing. Regarding porosity, PolyJet creates fully dense parts (99.8% density) compared to SLS's typical 95-97% density, eliminating the need for infiltration processes. Stratasys has also implemented adaptive slicing algorithms that automatically adjust layer thickness based on geometry complexity to optimize both accuracy and build time.

Strengths: Superior surface finish requiring minimal post-processing; exceptional dimensional accuracy for small, detailed features; ability to create fully dense parts without porosity issues; multi-material capabilities in single builds. Weaknesses: Limited mechanical properties compared to SLS parts; photopolymers can degrade over time with UV exposure; generally higher cost per part than SLS for larger production runs; build volume limitations compared to industrial SLS systems.

Xerox Holdings Corp.

Technical Solution: Xerox has leveraged its extensive expertise in 2D printing to develop advanced Material Jetting technology for 3D printing through their Liquid Metal system. While primarily focused on metal printing, their core technology principles apply to polymer materials as well. Their system achieves dimensional accuracies of ±0.05mm for features under 50mm—approximately twice the precision of typical SLS systems. For surface integrity, Xerox's proprietary print head technology delivers droplets as small as 75 picoliters with placement accuracy of 5μm, resulting in surface roughness values as low as 3-5μm Ra without post-processing. Their Direct-to-Object jetting technology incorporates real-time optical monitoring that adjusts droplet deposition based on detected surface variations, ensuring consistent layer formation. Regarding porosity, Xerox's materials are specifically formulated to achieve rapid solidification with minimal shrinkage, resulting in parts with densities exceeding 99.5%. Their patented acoustic wave ejection technology prevents nozzle clogging and ensures consistent material flow, eliminating the formation of voids that commonly occur in material jetting systems due to print head inconsistencies.

Strengths: Exceptional dimensional accuracy and surface finish quality; minimal post-processing requirements; ability to create fully dense parts with virtually no porosity; potential for multi-material and functional gradient materials in single builds. Weaknesses: Limited build volume compared to industrial SLS systems; higher material costs; more restricted material selection compared to SLS; mechanical properties generally inferior to sintered parts for structural applications.

Key Patents and Research on Dimensional Accuracy Optimization

Additive manufacturing using multiple laser beams

PatentWO2024142051A1

Innovation

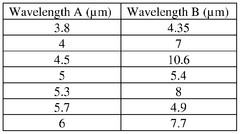

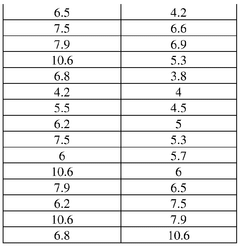

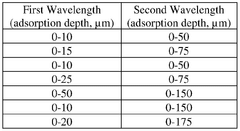

- Employing a multiwavelength laser source that generates beams of different wavelengths or characteristics, allowing for simultaneous or sequential sintering or melting at various depths within the powder bed, thereby enhancing layer adhesion and print quality by modifying absorption depths and selective melting of material components.

Macroporous metal substrates for fuel cell systems by 3D fabrication method and thereof

PatentPendingIN202141025991A

Innovation

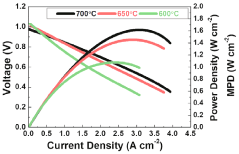

- The use of Selective Laser Sintering (SLS) 3D printing technique to fabricate stainless steel (SS) porous networks, allowing for tailored porosity and reduced density, eliminating the need for additional densification steps and enhancing mechanical properties like compressive strength.

Materials Science Advancements for 3D Printing Applications

Recent advancements in materials science have significantly expanded the capabilities and applications of 3D printing technologies. Material Jetting and Selective Laser Sintering (SLS) represent two distinct approaches to additive manufacturing, each with unique material requirements and performance characteristics that directly impact dimensional accuracy, surface integrity, and porosity control.

Material Jetting technology has benefited from the development of photopolymer resins with enhanced mechanical properties and thermal stability. These materials now incorporate nanoparticles and specialized additives that reduce shrinkage during curing, resulting in printed parts with dimensional tolerances as tight as ±0.1mm. The latest generation of UV-curable resins demonstrates improved cross-linking efficiency, minimizing internal stress formation and enhancing surface smoothness with Ra values below 0.5μm without post-processing.

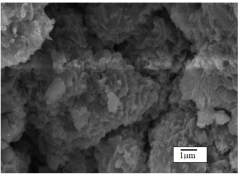

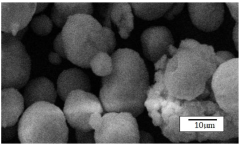

SLS technology has witnessed parallel advancements in powder materials, particularly in particle morphology optimization. Spherical particles with controlled size distribution (typically 20-80μm) now enable higher packing densities exceeding 60%, directly addressing historical porosity challenges. New polymer powders with modified melt flow characteristics facilitate more complete fusion between layers, reducing internal voids to below 2% in optimized processes.

The introduction of composite materials has been transformative for both technologies. In Material Jetting, ceramic-filled resins provide enhanced dimensional stability during thermal cycling, while maintaining the process's inherent surface quality advantages. For SLS, carbon fiber and glass-reinforced powders have expanded the technology's application range while improving thermal conductivity during the sintering process, resulting in more uniform consolidation and reduced warpage.

Surface chemistry modifications represent another critical advancement area. Material Jetting resins now incorporate surfactants that improve wetting characteristics and layer adhesion, while SLS powders feature surface treatments that enhance flowability without compromising particle fusion. These developments have narrowed the historical performance gap between the technologies, with Material Jetting maintaining superiority in surface finish (typically 30-50% smoother surfaces) while SLS has significantly improved in dimensional consistency across complex geometries.

The development of in-situ monitoring and real-time material property adjustment capabilities has further enhanced both technologies. Advanced optical and thermal sensors now enable closed-loop control systems that can detect and compensate for material variations during printing, ensuring more consistent results regardless of the specific technology employed.

Material Jetting technology has benefited from the development of photopolymer resins with enhanced mechanical properties and thermal stability. These materials now incorporate nanoparticles and specialized additives that reduce shrinkage during curing, resulting in printed parts with dimensional tolerances as tight as ±0.1mm. The latest generation of UV-curable resins demonstrates improved cross-linking efficiency, minimizing internal stress formation and enhancing surface smoothness with Ra values below 0.5μm without post-processing.

SLS technology has witnessed parallel advancements in powder materials, particularly in particle morphology optimization. Spherical particles with controlled size distribution (typically 20-80μm) now enable higher packing densities exceeding 60%, directly addressing historical porosity challenges. New polymer powders with modified melt flow characteristics facilitate more complete fusion between layers, reducing internal voids to below 2% in optimized processes.

The introduction of composite materials has been transformative for both technologies. In Material Jetting, ceramic-filled resins provide enhanced dimensional stability during thermal cycling, while maintaining the process's inherent surface quality advantages. For SLS, carbon fiber and glass-reinforced powders have expanded the technology's application range while improving thermal conductivity during the sintering process, resulting in more uniform consolidation and reduced warpage.

Surface chemistry modifications represent another critical advancement area. Material Jetting resins now incorporate surfactants that improve wetting characteristics and layer adhesion, while SLS powders feature surface treatments that enhance flowability without compromising particle fusion. These developments have narrowed the historical performance gap between the technologies, with Material Jetting maintaining superiority in surface finish (typically 30-50% smoother surfaces) while SLS has significantly improved in dimensional consistency across complex geometries.

The development of in-situ monitoring and real-time material property adjustment capabilities has further enhanced both technologies. Advanced optical and thermal sensors now enable closed-loop control systems that can detect and compensate for material variations during printing, ensuring more consistent results regardless of the specific technology employed.

Industrial Standards and Quality Assurance Protocols

The adoption of standardized quality control frameworks is essential for ensuring consistent performance in additive manufacturing processes. For Material Jetting and SLS technologies, several international standards have been established to evaluate dimensional accuracy, surface integrity, and porosity characteristics. The ISO/ASTM 52901:2017 provides general principles for AM parts, while ASTM F3091 specifically addresses powder bed fusion processes like SLS.

Material Jetting processes typically follow ISO/ASTM 52910 for design requirements and ISO 17296-3 for test methods to verify dimensional accuracy. These standards recommend measurement protocols using coordinate measuring machines (CMMs) with accuracy levels of ±0.001mm for critical features. Surface integrity assessments for Material Jetting components adhere to ISO 4287 and ISO 4288, which define parameters like Ra (average roughness) and Rz (maximum height profile).

For SLS technology, the ASTM F3049 standard provides guidelines for characterizing properties of powder feedstock materials, directly impacting final part quality. Dimensional accuracy verification follows ISO 286-1 and ISO 286-2 tolerance systems, with typical acceptance criteria ranging from ±0.1mm to ±0.3mm depending on part complexity and size. Surface integrity evaluations utilize ASTM F2971 protocols, employing optical profilometry and scanning electron microscopy techniques.

Porosity assessment protocols differ significantly between these technologies. Material Jetting quality assurance typically employs ASTM E2109 for non-destructive evaluation using micro-CT scanning with resolution capabilities of 5-10μm. SLS porosity characterization follows ASTM B311 for density measurements and ASTM E1570 for microstructural analysis, with acceptance thresholds typically set at <2% for functional components.

Industry-specific standards further refine these protocols. The aerospace sector implements AS9100D with additional requirements for process validation and material traceability. Medical device manufacturing follows ISO 13485:2016, emphasizing risk management and sterility considerations for both technologies, with Material Jetting generally requiring more stringent biocompatibility testing under ISO 10993 series.

Quality assurance documentation requirements include process parameter logs, material certification, in-process monitoring data, and post-processing verification. Material Jetting typically requires more extensive surface treatment documentation due to its multi-material capabilities, while SLS documentation focuses more heavily on powder recycling protocols and thermal history tracking to ensure consistent part properties across production batches.

Material Jetting processes typically follow ISO/ASTM 52910 for design requirements and ISO 17296-3 for test methods to verify dimensional accuracy. These standards recommend measurement protocols using coordinate measuring machines (CMMs) with accuracy levels of ±0.001mm for critical features. Surface integrity assessments for Material Jetting components adhere to ISO 4287 and ISO 4288, which define parameters like Ra (average roughness) and Rz (maximum height profile).

For SLS technology, the ASTM F3049 standard provides guidelines for characterizing properties of powder feedstock materials, directly impacting final part quality. Dimensional accuracy verification follows ISO 286-1 and ISO 286-2 tolerance systems, with typical acceptance criteria ranging from ±0.1mm to ±0.3mm depending on part complexity and size. Surface integrity evaluations utilize ASTM F2971 protocols, employing optical profilometry and scanning electron microscopy techniques.

Porosity assessment protocols differ significantly between these technologies. Material Jetting quality assurance typically employs ASTM E2109 for non-destructive evaluation using micro-CT scanning with resolution capabilities of 5-10μm. SLS porosity characterization follows ASTM B311 for density measurements and ASTM E1570 for microstructural analysis, with acceptance thresholds typically set at <2% for functional components.

Industry-specific standards further refine these protocols. The aerospace sector implements AS9100D with additional requirements for process validation and material traceability. Medical device manufacturing follows ISO 13485:2016, emphasizing risk management and sterility considerations for both technologies, with Material Jetting generally requiring more stringent biocompatibility testing under ISO 10993 series.

Quality assurance documentation requirements include process parameter logs, material certification, in-process monitoring data, and post-processing verification. Material Jetting typically requires more extensive surface treatment documentation due to its multi-material capabilities, while SLS documentation focuses more heavily on powder recycling protocols and thermal history tracking to ensure consistent part properties across production batches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!