Flexible Electronics Vs Fiberglass Sections: Mechanical Robustness

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics vs Fiberglass: Evolution and Objectives

The evolution of flexible electronics represents a significant paradigm shift in the field of electronic systems, moving away from traditional rigid circuit boards toward malleable, adaptable platforms. This technological trajectory began in the 1960s with the introduction of flexible printed circuit boards (PCBs), but has accelerated dramatically in the past two decades with advancements in materials science and manufacturing techniques. The development has been driven by increasing demands for wearable technology, biomedical devices, and space-constrained applications where traditional rigid electronics prove inadequate.

Fiberglass sections, conversely, have a longer industrial history dating back to the 1930s when fiberglass was first commercialized. These composite materials, typically consisting of glass fibers embedded in a polymer matrix, have evolved from simple structural components to sophisticated engineered materials with tailored mechanical properties. The evolution of fiberglass has been characterized by improvements in fiber composition, resin systems, and manufacturing processes, resulting in materials with exceptional strength-to-weight ratios.

The convergence of these two technological paths presents both opportunities and challenges. While flexible electronics offer unprecedented form factors and adaptability, their mechanical robustness has traditionally been a limiting factor. Fiberglass sections, with their established mechanical resilience, provide a contrasting benchmark against which to evaluate the durability of flexible electronic systems.

The primary objective of comparing mechanical robustness between these technologies is to identify the performance gaps and potential synergies. Specifically, this investigation aims to quantify differences in tensile strength, fatigue resistance, impact tolerance, and environmental stability between flexible electronic substrates and fiberglass composites. Understanding these differences is crucial for applications where both electrical functionality and mechanical integrity are essential requirements.

Furthermore, this comparison seeks to explore how the mechanical properties of flexible electronics might be enhanced through integration with fiberglass elements or by adopting design principles from composite materials. The goal is not merely to document current performance disparities but to chart a path toward flexible electronic systems with mechanical robustness approaching or exceeding that of traditional fiberglass composites.

This technological assessment also aims to identify critical inflection points in the development timeline where significant advances in mechanical performance occurred, providing insights into potential future breakthroughs. By examining the evolutionary trajectories of both technologies, we can better anticipate how their respective strengths might be combined in next-generation applications requiring both flexibility and durability.

Fiberglass sections, conversely, have a longer industrial history dating back to the 1930s when fiberglass was first commercialized. These composite materials, typically consisting of glass fibers embedded in a polymer matrix, have evolved from simple structural components to sophisticated engineered materials with tailored mechanical properties. The evolution of fiberglass has been characterized by improvements in fiber composition, resin systems, and manufacturing processes, resulting in materials with exceptional strength-to-weight ratios.

The convergence of these two technological paths presents both opportunities and challenges. While flexible electronics offer unprecedented form factors and adaptability, their mechanical robustness has traditionally been a limiting factor. Fiberglass sections, with their established mechanical resilience, provide a contrasting benchmark against which to evaluate the durability of flexible electronic systems.

The primary objective of comparing mechanical robustness between these technologies is to identify the performance gaps and potential synergies. Specifically, this investigation aims to quantify differences in tensile strength, fatigue resistance, impact tolerance, and environmental stability between flexible electronic substrates and fiberglass composites. Understanding these differences is crucial for applications where both electrical functionality and mechanical integrity are essential requirements.

Furthermore, this comparison seeks to explore how the mechanical properties of flexible electronics might be enhanced through integration with fiberglass elements or by adopting design principles from composite materials. The goal is not merely to document current performance disparities but to chart a path toward flexible electronic systems with mechanical robustness approaching or exceeding that of traditional fiberglass composites.

This technological assessment also aims to identify critical inflection points in the development timeline where significant advances in mechanical performance occurred, providing insights into potential future breakthroughs. By examining the evolutionary trajectories of both technologies, we can better anticipate how their respective strengths might be combined in next-generation applications requiring both flexibility and durability.

Market Demand Analysis for Mechanically Robust Materials

The global market for mechanically robust materials has witnessed significant growth in recent years, driven by increasing demand across various industries including aerospace, automotive, consumer electronics, and healthcare. Flexible electronics and fiberglass sections represent two distinct yet competitive solutions in this expanding market landscape, each addressing specific needs for durability and performance under mechanical stress.

Market research indicates that the flexible electronics sector is experiencing rapid expansion, with a projected compound annual growth rate exceeding 15% through 2028. This growth is primarily fueled by consumer electronics applications, wearable technology, and medical devices where conformability and resilience against repeated bending are essential requirements. The ability of flexible electronics to maintain functionality while being subjected to mechanical deformation represents a key value proposition driving market adoption.

Conversely, the fiberglass composites market demonstrates steady growth, particularly in structural applications requiring high strength-to-weight ratios. Industries such as construction, transportation, and renewable energy continue to drive demand for fiberglass sections due to their exceptional mechanical properties, corrosion resistance, and cost-effectiveness compared to traditional materials like steel and aluminum.

Regional analysis reveals distinct market preferences, with Asia-Pacific leading in flexible electronics manufacturing and adoption, while North America and Europe maintain strong positions in advanced fiberglass composite development and implementation. This geographic distribution reflects both industrial capabilities and end-user requirements across different economic regions.

Customer demand patterns indicate evolving requirements for mechanically robust materials. End-users increasingly prioritize materials that can withstand extreme environmental conditions while maintaining structural integrity and functional performance. This trend is particularly evident in automotive and aerospace sectors, where weight reduction without compromising mechanical robustness represents a critical competitive advantage.

Market surveys highlight that flexible electronics are gaining traction in applications requiring adaptability to dynamic mechanical environments, while fiberglass sections maintain dominance in static load-bearing applications. The intersection of these markets occurs in emerging fields such as smart infrastructure and advanced transportation systems, where both mechanical stability and electronic functionality are essential.

Industry forecasts suggest that materials combining the mechanical advantages of both technologies will likely capture premium market segments. Hybrid solutions incorporating fiberglass reinforcement within flexible electronic substrates represent an emerging opportunity, potentially addressing limitations of each individual technology while capitalizing on their respective strengths.

Market research indicates that the flexible electronics sector is experiencing rapid expansion, with a projected compound annual growth rate exceeding 15% through 2028. This growth is primarily fueled by consumer electronics applications, wearable technology, and medical devices where conformability and resilience against repeated bending are essential requirements. The ability of flexible electronics to maintain functionality while being subjected to mechanical deformation represents a key value proposition driving market adoption.

Conversely, the fiberglass composites market demonstrates steady growth, particularly in structural applications requiring high strength-to-weight ratios. Industries such as construction, transportation, and renewable energy continue to drive demand for fiberglass sections due to their exceptional mechanical properties, corrosion resistance, and cost-effectiveness compared to traditional materials like steel and aluminum.

Regional analysis reveals distinct market preferences, with Asia-Pacific leading in flexible electronics manufacturing and adoption, while North America and Europe maintain strong positions in advanced fiberglass composite development and implementation. This geographic distribution reflects both industrial capabilities and end-user requirements across different economic regions.

Customer demand patterns indicate evolving requirements for mechanically robust materials. End-users increasingly prioritize materials that can withstand extreme environmental conditions while maintaining structural integrity and functional performance. This trend is particularly evident in automotive and aerospace sectors, where weight reduction without compromising mechanical robustness represents a critical competitive advantage.

Market surveys highlight that flexible electronics are gaining traction in applications requiring adaptability to dynamic mechanical environments, while fiberglass sections maintain dominance in static load-bearing applications. The intersection of these markets occurs in emerging fields such as smart infrastructure and advanced transportation systems, where both mechanical stability and electronic functionality are essential.

Industry forecasts suggest that materials combining the mechanical advantages of both technologies will likely capture premium market segments. Hybrid solutions incorporating fiberglass reinforcement within flexible electronic substrates represent an emerging opportunity, potentially addressing limitations of each individual technology while capitalizing on their respective strengths.

Current Mechanical Robustness Challenges and Limitations

Despite significant advancements in flexible electronics technology, several critical mechanical robustness challenges persist when compared to traditional fiberglass sections. The fundamental limitation stems from the inherent material properties of flexible substrates, which typically exhibit lower tensile strength and tear resistance than fiberglass composites. While fiberglass sections can withstand tensile forces of 1500-3000 MPa, most flexible electronic substrates demonstrate maximum tensile strengths of only 300-500 MPa, creating a significant performance gap in high-stress applications.

Cyclic bending fatigue represents another major challenge for flexible electronics. Current flexible substrates experience performance degradation after 10,000-100,000 bending cycles, whereas fiberglass maintains structural integrity for millions of cycles under similar conditions. This limitation severely restricts the deployment of flexible electronics in applications requiring repeated mechanical deformation over extended periods.

Delamination between conductive layers and flexible substrates remains problematic, particularly at interface boundaries where stress concentration occurs. The adhesion strength between these layers typically measures 1.5-4.5 N/mm, substantially lower than the interlayer bonding strength of fiberglass composites (8-12 N/mm). This weakness becomes especially pronounced during thermal cycling, where differential expansion coefficients exacerbate interfacial stress.

Environmental stability presents additional challenges for flexible electronics. Unlike fiberglass sections, which maintain consistent mechanical properties across temperatures from -40°C to 120°C, flexible electronic substrates often experience significant modulus changes and dimensional instability across this range. Furthermore, moisture absorption rates in flexible polymeric substrates (0.5-2% by weight) exceed those of properly sealed fiberglass (0.1-0.3%), leading to accelerated degradation in humid environments.

Impact resistance represents a critical limitation, with flexible electronics typically withstanding impact energies of only 1-5 J/cm², while fiberglass sections can absorb 15-25 J/cm² before structural failure. This disparity creates significant design constraints for applications in harsh or unpredictable environments where impact events are common.

Manufacturing consistency also remains challenging for flexible electronics. Current production processes exhibit 10-15% variation in mechanical properties across batches, compared to the 3-5% variation typical in fiberglass manufacturing. This inconsistency complicates reliability predictions and quality assurance protocols, particularly for mission-critical applications requiring precise mechanical performance parameters.

Recent research has identified promising approaches to address these limitations, including nanocomposite reinforcement, strain-engineered architectures, and novel encapsulation techniques. However, significant gaps remain between laboratory demonstrations and commercially viable solutions that can match the established mechanical robustness of fiberglass sections across all performance metrics.

Cyclic bending fatigue represents another major challenge for flexible electronics. Current flexible substrates experience performance degradation after 10,000-100,000 bending cycles, whereas fiberglass maintains structural integrity for millions of cycles under similar conditions. This limitation severely restricts the deployment of flexible electronics in applications requiring repeated mechanical deformation over extended periods.

Delamination between conductive layers and flexible substrates remains problematic, particularly at interface boundaries where stress concentration occurs. The adhesion strength between these layers typically measures 1.5-4.5 N/mm, substantially lower than the interlayer bonding strength of fiberglass composites (8-12 N/mm). This weakness becomes especially pronounced during thermal cycling, where differential expansion coefficients exacerbate interfacial stress.

Environmental stability presents additional challenges for flexible electronics. Unlike fiberglass sections, which maintain consistent mechanical properties across temperatures from -40°C to 120°C, flexible electronic substrates often experience significant modulus changes and dimensional instability across this range. Furthermore, moisture absorption rates in flexible polymeric substrates (0.5-2% by weight) exceed those of properly sealed fiberglass (0.1-0.3%), leading to accelerated degradation in humid environments.

Impact resistance represents a critical limitation, with flexible electronics typically withstanding impact energies of only 1-5 J/cm², while fiberglass sections can absorb 15-25 J/cm² before structural failure. This disparity creates significant design constraints for applications in harsh or unpredictable environments where impact events are common.

Manufacturing consistency also remains challenging for flexible electronics. Current production processes exhibit 10-15% variation in mechanical properties across batches, compared to the 3-5% variation typical in fiberglass manufacturing. This inconsistency complicates reliability predictions and quality assurance protocols, particularly for mission-critical applications requiring precise mechanical performance parameters.

Recent research has identified promising approaches to address these limitations, including nanocomposite reinforcement, strain-engineered architectures, and novel encapsulation techniques. However, significant gaps remain between laboratory demonstrations and commercially viable solutions that can match the established mechanical robustness of fiberglass sections across all performance metrics.

Comparative Analysis of Current Robustness Solutions

01 Fiberglass reinforcement for mechanical robustness

Fiberglass sections can be incorporated into flexible electronic structures to enhance mechanical robustness while maintaining flexibility. The fiberglass reinforcement provides structural integrity and impact resistance, allowing the electronic components to withstand physical stress and environmental factors. This combination creates a durable yet flexible system that can be used in various applications requiring both strength and adaptability.- Flexible electronic circuits with fiberglass reinforcement: Flexible electronic circuits can be reinforced with fiberglass sections to improve mechanical robustness while maintaining flexibility. The fiberglass reinforcement provides structural support and protects the electronic components from mechanical stress and environmental factors. This combination allows for the development of durable electronic devices that can withstand bending, folding, and other physical deformations while maintaining functionality.

- Composite structures using fiberglass for enhanced durability: Composite structures incorporating fiberglass sections offer superior mechanical robustness for flexible electronic applications. These structures typically combine fiberglass with other materials such as polymers or resins to create a strong yet flexible framework. The resulting composites provide improved impact resistance, tensile strength, and dimensional stability while accommodating the integration of electronic components.

- Protective enclosures with fiberglass for electronic devices: Protective enclosures made with fiberglass sections can significantly enhance the mechanical robustness of flexible electronics. These enclosures are designed to shield sensitive electronic components from physical damage, moisture, and temperature variations. The fiberglass material provides excellent structural integrity while being lightweight and allowing for customized shapes to accommodate various electronic configurations.

- Manufacturing techniques for integrating electronics with fiberglass: Specialized manufacturing techniques have been developed for integrating flexible electronics with fiberglass sections to maximize mechanical robustness. These techniques include lamination processes, adhesive bonding methods, and embedding electronic components directly within fiberglass matrices. Advanced fabrication approaches ensure proper alignment, connection integrity, and protection of electronic elements while maintaining the structural advantages of fiberglass.

- Testing and validation methods for mechanical robustness: Various testing and validation methods have been established to evaluate the mechanical robustness of flexible electronics with fiberglass sections. These methods include bend testing, impact resistance assessment, environmental stress testing, and accelerated aging protocols. Such testing ensures that the integrated systems can withstand real-world conditions and maintain functionality throughout their intended lifecycle, validating the effectiveness of the fiberglass reinforcement in protecting electronic components.

02 Flexible electronic circuit design and protection

Specialized design approaches for flexible electronic circuits enhance their mechanical robustness. These include strategic placement of components, use of stretchable interconnects, and protective encapsulation layers. The designs accommodate bending and twisting motions without compromising electrical performance, while protective elements shield sensitive components from environmental damage and mechanical stress.Expand Specific Solutions03 Composite materials for flexible electronics

Advanced composite materials combining fiberglass with polymers or other flexible substrates create platforms for robust flexible electronics. These composites offer a balance of mechanical strength, flexibility, and electrical properties. The integration of different material layers with varying properties allows for customized performance characteristics, including improved impact resistance, thermal stability, and dimensional stability while maintaining necessary flexibility.Expand Specific Solutions04 Structural design for impact and stress resistance

Innovative structural designs enhance the mechanical robustness of flexible electronics with fiberglass sections. These include sandwich structures, strategic reinforcement at stress points, and modular designs that isolate sensitive components from mechanical forces. The structural approaches distribute impact forces and prevent stress concentration, allowing the flexible electronic systems to withstand drops, bending, and other physical challenges.Expand Specific Solutions05 Testing and simulation methods for mechanical robustness

Specialized testing protocols and simulation methods have been developed to evaluate and predict the mechanical robustness of flexible electronics with fiberglass sections. These include cyclic bend testing, impact resistance evaluation, environmental stress testing, and computational modeling of mechanical behavior. These methods help optimize designs before manufacturing and ensure that the final products meet durability requirements for their intended applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The flexible electronics market is currently in a growth phase, with increasing adoption across consumer electronics, healthcare, and automotive sectors. The market size is projected to reach significant value due to rising demand for bendable, lightweight devices. Technologically, flexible electronics are advancing rapidly but still face challenges in mechanical robustness compared to traditional fiberglass sections. Leading players like Samsung Electronics and Samsung Display are pioneering innovations in flexible display technologies, while Corning brings expertise in durable glass solutions. Research institutions such as CEA, ITRI, and Huazhong University are advancing fundamental technologies. Companies like Murata, Infineon, and Nokia are developing specialized components, while manufacturers including GlobalFoundries and AT&S are improving production processes for enhanced durability and reliability in flexible electronic systems.

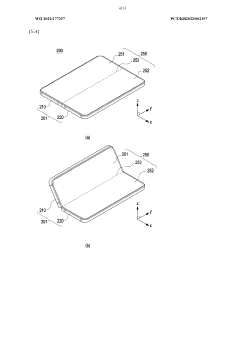

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed advanced flexible electronics technologies that focus on enhancing mechanical robustness through multi-layered composite structures. Their approach combines ultra-thin flexible substrates with specialized protective coatings that distribute mechanical stress. Samsung's proprietary Flexible OLED technology incorporates a neutral mechanical plane design that positions sensitive electronic components at points of minimal strain during bending. Their research shows that these flexible displays can withstand over 200,000 folding cycles without performance degradation, significantly outperforming traditional rigid electronics. Samsung has also pioneered a unique encapsulation technology that uses alternating inorganic and organic layers to create a flexible yet highly durable barrier against environmental factors while maintaining flexibility.

Strengths: Superior bend radius capabilities (as small as 1.4mm without damage), excellent fatigue resistance under repeated flexing, and compatibility with mass production processes. Weaknesses: Higher production costs compared to fiberglass solutions, temperature sensitivity limitations, and potential for pixel degradation at extreme folding points over extended use periods.

Corning, Inc.

Technical Solution: Corning has pioneered advanced fiberglass composite technologies specifically designed for high mechanical robustness applications. Their Willow Glass technology represents a breakthrough in ultra-thin, flexible glass that combines the thermal stability and optical clarity of traditional glass with unprecedented flexibility. With thicknesses between 100-200 micrometers, this specialized fiberglass can bend to a radius of 2-3mm without fracturing. Corning's proprietary fusion draw process creates atomically smooth surfaces with minimal defects, significantly enhancing mechanical strength. Their comparative studies demonstrate that their fiberglass solutions maintain structural integrity under mechanical stress conditions that would cause permanent deformation in most flexible electronics. Additionally, Corning has developed specialized edge treatment technologies that increase edge strength by up to 5x compared to untreated fiberglass, addressing a traditional weakness of glass-based materials.

Strengths: Superior thermal stability (withstanding processing temperatures up to 600°C), exceptional chemical resistance, superior optical transparency, and dimensional stability under environmental fluctuations. Weaknesses: Less flexibility than polymer-based electronics, higher weight per unit area, and requires specialized handling during manufacturing to prevent microfractures that can propagate under stress.

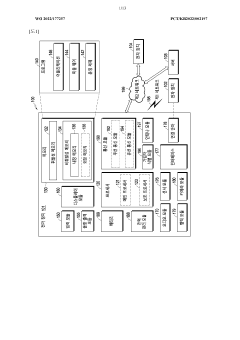

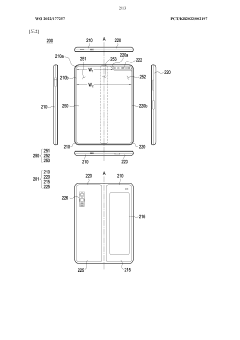

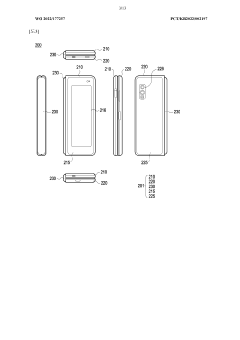

Critical Patents and Research in Mechanical Durability

Electronic device comprising glass having differential edge shape

PatentWO2022177257A2

Innovation

- The implementation of a window member with a non-uniform thickness profile, where the edge region is thinner than the non-bending parts, and specialized polishing to remove cracks and etching marks, enhancing bending performance while maintaining impact resistance.

Electronic component and method for producing an electronic component

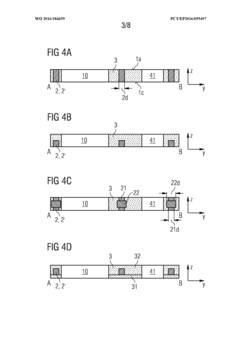

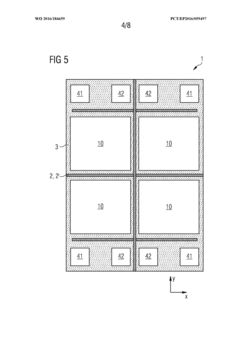

PatentWO2016184659A1

Innovation

- Incorporating mechanically stiffening reinforcement structures made of materials with higher breaking strength and modulus of elasticity, such as metal, fiberglass, or carbon fibers, into a molded body that encloses a semiconductor chip, enhancing the component's structural integrity without compromising electrical functionality.

Material Testing Methodologies and Standards

The standardization of testing methodologies is crucial for accurate comparison between flexible electronics and fiberglass sections. ASTM D790 and ISO 178 provide foundational frameworks for flexural testing, while ASTM D638 and ISO 527 establish protocols for tensile strength evaluation. These standards ensure consistent measurement of mechanical properties across different material systems, enabling meaningful comparisons between the inherently different structures of flexible electronics and fiberglass composites.

For flexible electronics specifically, IEC 62715-6-1 addresses the mechanical durability of flexible display devices, while IPC-6013 focuses on flexible and rigid-flexible printed boards. These standards incorporate specialized testing parameters that account for the unique characteristics of thin-film electronic structures, including bend radius limitations and cyclic fatigue resistance. The development of ASTM F3301 for determining critical mechanical properties of flexible barrier films represents significant progress in standardizing testing for next-generation electronic materials.

Fiberglass testing methodologies are more established, with ASTM D2344 for short-beam strength and ASTM D3039 for tensile properties of fiber-reinforced composites providing comprehensive evaluation frameworks. These standards account for the anisotropic nature of fiberglass materials and their composite structures, allowing for directional strength characterization that is essential when comparing with the typically more isotropic flexible electronic substrates.

Dynamic mechanical analysis (DMA) offers valuable insights for both material categories, measuring viscoelastic properties across temperature ranges and frequencies. This technique is particularly valuable for understanding how mechanical properties of flexible electronics and fiberglass sections change under varying environmental conditions, with ASTM D4065 providing standardized procedures for such analyses.

Environmental conditioning protocols, including ASTM D5229 for moisture absorption and ASTM D1183 for resistance to accelerated weathering, are essential components of comprehensive testing regimes. These standards help predict long-term performance degradation under real-world conditions, addressing a critical concern for both flexible electronics and fiberglass applications in demanding environments.

Recent developments in testing methodologies have focused on miniaturized specimen testing and in-situ characterization techniques. Nanoindentation (ISO 14577) and microtensile testing enable evaluation of localized mechanical properties at scales relevant to thin-film electronic structures, while digital image correlation provides non-contact strain mapping during mechanical loading. These advanced techniques bridge the gap between traditional bulk material testing and the microscale mechanics relevant to flexible electronic systems.

For flexible electronics specifically, IEC 62715-6-1 addresses the mechanical durability of flexible display devices, while IPC-6013 focuses on flexible and rigid-flexible printed boards. These standards incorporate specialized testing parameters that account for the unique characteristics of thin-film electronic structures, including bend radius limitations and cyclic fatigue resistance. The development of ASTM F3301 for determining critical mechanical properties of flexible barrier films represents significant progress in standardizing testing for next-generation electronic materials.

Fiberglass testing methodologies are more established, with ASTM D2344 for short-beam strength and ASTM D3039 for tensile properties of fiber-reinforced composites providing comprehensive evaluation frameworks. These standards account for the anisotropic nature of fiberglass materials and their composite structures, allowing for directional strength characterization that is essential when comparing with the typically more isotropic flexible electronic substrates.

Dynamic mechanical analysis (DMA) offers valuable insights for both material categories, measuring viscoelastic properties across temperature ranges and frequencies. This technique is particularly valuable for understanding how mechanical properties of flexible electronics and fiberglass sections change under varying environmental conditions, with ASTM D4065 providing standardized procedures for such analyses.

Environmental conditioning protocols, including ASTM D5229 for moisture absorption and ASTM D1183 for resistance to accelerated weathering, are essential components of comprehensive testing regimes. These standards help predict long-term performance degradation under real-world conditions, addressing a critical concern for both flexible electronics and fiberglass applications in demanding environments.

Recent developments in testing methodologies have focused on miniaturized specimen testing and in-situ characterization techniques. Nanoindentation (ISO 14577) and microtensile testing enable evaluation of localized mechanical properties at scales relevant to thin-film electronic structures, while digital image correlation provides non-contact strain mapping during mechanical loading. These advanced techniques bridge the gap between traditional bulk material testing and the microscale mechanics relevant to flexible electronic systems.

Environmental Impact and Sustainability Considerations

The environmental impact of flexible electronics compared to fiberglass sections represents a critical consideration in sustainable technology development. Flexible electronics typically utilize thin polymer substrates and minimal metallic components, resulting in significantly reduced material consumption compared to traditional fiberglass composites. This material efficiency translates to lower resource extraction requirements and diminished environmental footprint during the manufacturing phase.

Production processes for flexible electronics generally consume less energy than fiberglass manufacturing, which requires energy-intensive heating and curing processes. Studies indicate that flexible electronic production can reduce energy consumption by 30-45% compared to equivalent fiberglass component manufacturing. This energy efficiency contributes substantially to reduced carbon emissions throughout the product lifecycle.

End-of-life considerations reveal notable differences between these technologies. Fiberglass presents significant recycling challenges due to its composite nature, with most discarded fiberglass ultimately contributing to landfill waste. In contrast, flexible electronics offer improved recyclability potential, particularly when designed with disassembly and material recovery in mind. Advanced flexible electronic designs increasingly incorporate biodegradable substrates and water-soluble components that minimize persistent environmental impact.

Chemical usage patterns differ substantially between these technologies. Fiberglass production involves potentially hazardous compounds including formaldehyde-based resins and various hardeners that pose environmental risks if improperly managed. Flexible electronics manufacturing has traditionally relied on solvents and etching chemicals, though recent innovations have introduced water-based processing alternatives that significantly reduce toxicity concerns.

Durability factors into sustainability calculations through product lifespan considerations. While fiberglass sections typically demonstrate superior longevity in harsh environments, this advantage may be offset by the repairability of flexible electronics. Damaged flexible circuits can often be partially replaced or repaired, whereas fiberglass components frequently require complete replacement when structural integrity is compromised.

Transportation efficiency favors flexible electronics due to their lightweight nature and compact form factor. The reduced mass and volume translate to lower fuel consumption and emissions during distribution. Additionally, the mechanical flexibility enables more efficient packaging configurations that optimize shipping density compared to rigid fiberglass sections.

Future sustainability improvements for both technologies are emerging through materials innovation. Bio-based polymers and natural fiber reinforcements are being developed for fiberglass alternatives, while flexible electronics research focuses on fully biodegradable substrates and non-toxic conductive materials. These parallel development paths suggest that environmental performance will remain a key competitive factor in determining which technology prevails in specific applications.

Production processes for flexible electronics generally consume less energy than fiberglass manufacturing, which requires energy-intensive heating and curing processes. Studies indicate that flexible electronic production can reduce energy consumption by 30-45% compared to equivalent fiberglass component manufacturing. This energy efficiency contributes substantially to reduced carbon emissions throughout the product lifecycle.

End-of-life considerations reveal notable differences between these technologies. Fiberglass presents significant recycling challenges due to its composite nature, with most discarded fiberglass ultimately contributing to landfill waste. In contrast, flexible electronics offer improved recyclability potential, particularly when designed with disassembly and material recovery in mind. Advanced flexible electronic designs increasingly incorporate biodegradable substrates and water-soluble components that minimize persistent environmental impact.

Chemical usage patterns differ substantially between these technologies. Fiberglass production involves potentially hazardous compounds including formaldehyde-based resins and various hardeners that pose environmental risks if improperly managed. Flexible electronics manufacturing has traditionally relied on solvents and etching chemicals, though recent innovations have introduced water-based processing alternatives that significantly reduce toxicity concerns.

Durability factors into sustainability calculations through product lifespan considerations. While fiberglass sections typically demonstrate superior longevity in harsh environments, this advantage may be offset by the repairability of flexible electronics. Damaged flexible circuits can often be partially replaced or repaired, whereas fiberglass components frequently require complete replacement when structural integrity is compromised.

Transportation efficiency favors flexible electronics due to their lightweight nature and compact form factor. The reduced mass and volume translate to lower fuel consumption and emissions during distribution. Additionally, the mechanical flexibility enables more efficient packaging configurations that optimize shipping density compared to rigid fiberglass sections.

Future sustainability improvements for both technologies are emerging through materials innovation. Bio-based polymers and natural fiber reinforcements are being developed for fiberglass alternatives, while flexible electronics research focuses on fully biodegradable substrates and non-toxic conductive materials. These parallel development paths suggest that environmental performance will remain a key competitive factor in determining which technology prevails in specific applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!