Comparison Of Thermoelectric Generator Performance Across Semiconductor Types

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generation Background and Objectives

Thermoelectric generation represents a direct energy conversion technology that transforms thermal energy into electrical energy through the Seebeck effect, discovered by Thomas Johann Seebeck in 1821. This phenomenon occurs when a temperature gradient exists across certain semiconductor materials, causing charge carriers to diffuse from the hot side to the cold side, thereby generating an electrical potential difference. The historical development of thermoelectric technology has progressed through several significant phases, from early metallic thermocouples to modern semiconductor-based devices.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency, primarily measured by the dimensionless figure of merit ZT. Early thermoelectric generators (TEGs) utilized bismuth telluride (Bi2Te3) compounds, which dominated the field for decades with modest ZT values around 1. Recent advancements have pushed ZT values beyond 2 through innovative material engineering approaches, including nanostructuring, band engineering, and the development of complex semiconductor alloys.

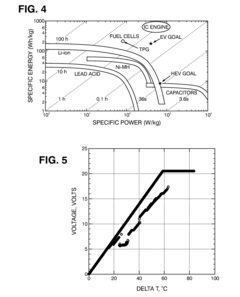

Current research trends focus on comparing performance across various semiconductor types, including traditional materials like bismuth telluride, lead telluride (PbTe), and silicon-germanium (SiGe) alloys, as well as emerging materials such as skutterudites, half-Heusler alloys, and organic semiconductors. Each material category exhibits distinct advantages in specific temperature ranges and application scenarios, necessitating comprehensive comparative analysis to optimize material selection for targeted applications.

The primary technical objective of this research is to establish a systematic framework for evaluating thermoelectric generator performance across diverse semiconductor types under standardized conditions. This includes quantifying key performance metrics such as power density, conversion efficiency, operational temperature range, long-term stability, and cost-effectiveness. Additionally, the research aims to identify optimal semiconductor materials and configurations for specific application domains, including waste heat recovery in industrial processes, automotive exhaust systems, and remote power generation.

Furthermore, this investigation seeks to address critical knowledge gaps regarding the correlation between material properties and device-level performance, particularly focusing on interface effects, contact resistance, and thermal management strategies across different semiconductor types. Understanding these relationships is essential for developing predictive models that can accelerate material discovery and device optimization processes.

The ultimate goal is to provide actionable insights that can guide research and development efforts toward achieving the U.S. Department of Energy's target of 20% conversion efficiency for thermoelectric systems, which would significantly enhance their commercial viability across numerous applications and contribute to global energy efficiency initiatives.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency, primarily measured by the dimensionless figure of merit ZT. Early thermoelectric generators (TEGs) utilized bismuth telluride (Bi2Te3) compounds, which dominated the field for decades with modest ZT values around 1. Recent advancements have pushed ZT values beyond 2 through innovative material engineering approaches, including nanostructuring, band engineering, and the development of complex semiconductor alloys.

Current research trends focus on comparing performance across various semiconductor types, including traditional materials like bismuth telluride, lead telluride (PbTe), and silicon-germanium (SiGe) alloys, as well as emerging materials such as skutterudites, half-Heusler alloys, and organic semiconductors. Each material category exhibits distinct advantages in specific temperature ranges and application scenarios, necessitating comprehensive comparative analysis to optimize material selection for targeted applications.

The primary technical objective of this research is to establish a systematic framework for evaluating thermoelectric generator performance across diverse semiconductor types under standardized conditions. This includes quantifying key performance metrics such as power density, conversion efficiency, operational temperature range, long-term stability, and cost-effectiveness. Additionally, the research aims to identify optimal semiconductor materials and configurations for specific application domains, including waste heat recovery in industrial processes, automotive exhaust systems, and remote power generation.

Furthermore, this investigation seeks to address critical knowledge gaps regarding the correlation between material properties and device-level performance, particularly focusing on interface effects, contact resistance, and thermal management strategies across different semiconductor types. Understanding these relationships is essential for developing predictive models that can accelerate material discovery and device optimization processes.

The ultimate goal is to provide actionable insights that can guide research and development efforts toward achieving the U.S. Department of Energy's target of 20% conversion efficiency for thermoelectric systems, which would significantly enhance their commercial viability across numerous applications and contribute to global energy efficiency initiatives.

Market Analysis for Thermoelectric Generator Applications

The global thermoelectric generator (TEG) market is experiencing significant growth, projected to reach $720 million by 2027, with a compound annual growth rate of 8.3% from 2022. This expansion is primarily driven by increasing demand for waste heat recovery systems across multiple industries and the growing need for reliable power sources in remote locations.

Industrial waste heat recovery represents the largest application segment, accounting for approximately 35% of the market share. Manufacturing facilities, particularly in steel, glass, and cement production, generate substantial waste heat that can be effectively converted to electricity using TEGs. The automotive sector follows closely, with TEGs being integrated into vehicle exhaust systems to improve fuel efficiency by 3-5% in conventional vehicles.

Consumer electronics applications are showing the fastest growth rate at 12.1% annually, as miniaturized TEGs are increasingly incorporated into wearable devices and IoT sensors. The aerospace and defense sectors also demonstrate strong demand, utilizing TEGs in remote sensing equipment and satellite power systems.

Geographically, North America currently leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate of 10.2% through 2027, driven by rapid industrialization in China and India, coupled with government initiatives promoting energy efficiency.

Material selection significantly impacts market dynamics, with bismuth telluride (Bi2Te3) dominating low-temperature applications (up to 250°C) with approximately 65% market share. For medium-temperature applications (250-600°C), lead telluride (PbTe) holds about 20% of the market, while silicon-germanium alloys are preferred for high-temperature applications (above 600°C).

Market challenges include the relatively high cost of TEG systems, with current prices ranging from $20-40 per watt for commercial systems, and limited conversion efficiency (typically 5-8%). These factors have restricted widespread adoption despite the environmental benefits.

Emerging opportunities exist in the renewable energy sector, where TEGs can complement solar and wind installations to enhance overall system efficiency. Additionally, the growing market for off-grid power solutions in developing regions presents significant potential, with an estimated 1.2 billion people worldwide lacking reliable electricity access.

Industrial waste heat recovery represents the largest application segment, accounting for approximately 35% of the market share. Manufacturing facilities, particularly in steel, glass, and cement production, generate substantial waste heat that can be effectively converted to electricity using TEGs. The automotive sector follows closely, with TEGs being integrated into vehicle exhaust systems to improve fuel efficiency by 3-5% in conventional vehicles.

Consumer electronics applications are showing the fastest growth rate at 12.1% annually, as miniaturized TEGs are increasingly incorporated into wearable devices and IoT sensors. The aerospace and defense sectors also demonstrate strong demand, utilizing TEGs in remote sensing equipment and satellite power systems.

Geographically, North America currently leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate of 10.2% through 2027, driven by rapid industrialization in China and India, coupled with government initiatives promoting energy efficiency.

Material selection significantly impacts market dynamics, with bismuth telluride (Bi2Te3) dominating low-temperature applications (up to 250°C) with approximately 65% market share. For medium-temperature applications (250-600°C), lead telluride (PbTe) holds about 20% of the market, while silicon-germanium alloys are preferred for high-temperature applications (above 600°C).

Market challenges include the relatively high cost of TEG systems, with current prices ranging from $20-40 per watt for commercial systems, and limited conversion efficiency (typically 5-8%). These factors have restricted widespread adoption despite the environmental benefits.

Emerging opportunities exist in the renewable energy sector, where TEGs can complement solar and wind installations to enhance overall system efficiency. Additionally, the growing market for off-grid power solutions in developing regions presents significant potential, with an estimated 1.2 billion people worldwide lacking reliable electricity access.

Current Semiconductor Materials and Technical Challenges

The thermoelectric generator (TEG) market currently relies predominantly on bismuth telluride (Bi2Te3) as the primary semiconductor material for near-room-temperature applications. This material offers a reasonable figure of merit (ZT) of approximately 1.0 at ambient temperatures, making it suitable for low-grade waste heat recovery. However, tellurium's scarcity and high cost present significant challenges for large-scale commercial deployment, limiting the widespread adoption of TEG technology.

Lead telluride (PbTe) and silicon-germanium (SiGe) alloys represent the second tier of commercially available thermoelectric materials, operating efficiently at medium (500-900K) and high (>900K) temperature ranges respectively. While these materials demonstrate good performance in specialized applications such as space power generation, their practical implementation faces obstacles including toxicity concerns with lead-based compounds and the high cost of germanium.

Recent research has focused on developing skutterudites, half-Heusler alloys, and clathrates as promising mid-temperature range materials. These complex compounds achieve enhanced ZT values through the "phonon-glass electron-crystal" concept, where thermal conductivity is reduced while maintaining good electrical properties. Despite laboratory success with ZT values exceeding 1.5 in some cases, manufacturing challenges and long-term stability issues have hindered their transition from research to commercial products.

Oxide-based thermoelectric materials, including strontium titanate and sodium cobaltite derivatives, offer advantages in stability, oxidation resistance, and environmental compatibility. However, their relatively low ZT values (typically below 0.5) have restricted their application primarily to high-temperature industrial settings where durability outweighs efficiency concerns.

Organic and polymer-based thermoelectric materials represent an emerging frontier with potential for flexible, lightweight, and low-cost applications. These materials benefit from inherently low thermal conductivity but suffer from poor electrical performance, resulting in ZT values generally below 0.2. The trade-off between flexibility and performance remains a significant technical hurdle.

Nanostructured thermoelectric materials have demonstrated theoretical potential to dramatically improve ZT values through quantum confinement effects and interface scattering of phonons. However, scalable manufacturing processes for maintaining precise nanostructures in bulk materials present formidable challenges, creating a substantial gap between laboratory demonstrations and industrial implementation.

The fundamental challenge across all material systems remains the interdependent nature of thermoelectric properties: improving one parameter (such as electrical conductivity) often adversely affects another (such as thermal conductivity), making optimization exceptionally difficult. This inherent coupling of transport properties represents the core scientific obstacle to achieving the breakthrough ZT values (>3) needed for widespread commercial viability.

Lead telluride (PbTe) and silicon-germanium (SiGe) alloys represent the second tier of commercially available thermoelectric materials, operating efficiently at medium (500-900K) and high (>900K) temperature ranges respectively. While these materials demonstrate good performance in specialized applications such as space power generation, their practical implementation faces obstacles including toxicity concerns with lead-based compounds and the high cost of germanium.

Recent research has focused on developing skutterudites, half-Heusler alloys, and clathrates as promising mid-temperature range materials. These complex compounds achieve enhanced ZT values through the "phonon-glass electron-crystal" concept, where thermal conductivity is reduced while maintaining good electrical properties. Despite laboratory success with ZT values exceeding 1.5 in some cases, manufacturing challenges and long-term stability issues have hindered their transition from research to commercial products.

Oxide-based thermoelectric materials, including strontium titanate and sodium cobaltite derivatives, offer advantages in stability, oxidation resistance, and environmental compatibility. However, their relatively low ZT values (typically below 0.5) have restricted their application primarily to high-temperature industrial settings where durability outweighs efficiency concerns.

Organic and polymer-based thermoelectric materials represent an emerging frontier with potential for flexible, lightweight, and low-cost applications. These materials benefit from inherently low thermal conductivity but suffer from poor electrical performance, resulting in ZT values generally below 0.2. The trade-off between flexibility and performance remains a significant technical hurdle.

Nanostructured thermoelectric materials have demonstrated theoretical potential to dramatically improve ZT values through quantum confinement effects and interface scattering of phonons. However, scalable manufacturing processes for maintaining precise nanostructures in bulk materials present formidable challenges, creating a substantial gap between laboratory demonstrations and industrial implementation.

The fundamental challenge across all material systems remains the interdependent nature of thermoelectric properties: improving one parameter (such as electrical conductivity) often adversely affects another (such as thermal conductivity), making optimization exceptionally difficult. This inherent coupling of transport properties represents the core scientific obstacle to achieving the breakthrough ZT values (>3) needed for widespread commercial viability.

Comparative Analysis of Semiconductor Material Performance

01 Material optimization for thermoelectric generators

Various materials can be optimized to enhance the performance of thermoelectric generators. These include advanced semiconductor materials, nanostructured materials, and composite materials that exhibit improved Seebeck coefficient, electrical conductivity, and reduced thermal conductivity. By carefully selecting and engineering these materials, the figure of merit (ZT) of thermoelectric generators can be significantly increased, leading to higher conversion efficiency and better overall performance.- Material optimization for thermoelectric generators: The performance of thermoelectric generators can be significantly improved through the optimization of thermoelectric materials. This includes developing materials with higher figure of merit (ZT), which is determined by the Seebeck coefficient, electrical conductivity, and thermal conductivity. Advanced materials such as nanostructured semiconductors, skutterudites, and bismuth telluride compounds can enhance energy conversion efficiency by reducing thermal conductivity while maintaining good electrical properties.

- Structural design improvements for thermoelectric devices: Innovative structural designs can enhance the performance of thermoelectric generators. This includes optimizing the geometry of thermoelectric elements, improving heat exchanger designs, and developing novel module configurations. Multi-stage cascaded structures, segmented legs, and advanced junction designs can maximize temperature gradients across the device, leading to higher power output and conversion efficiency.

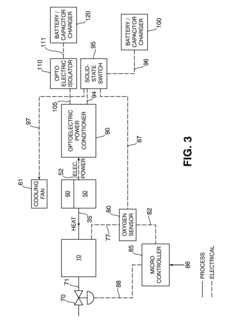

- Thermal management systems for efficiency enhancement: Effective thermal management is crucial for optimizing thermoelectric generator performance. This includes developing advanced heat sink designs, implementing efficient heat transfer mechanisms, and utilizing waste heat recovery systems. Proper thermal interface materials, heat spreading techniques, and cooling methods can maintain optimal temperature differentials across thermoelectric modules, thereby maximizing power generation and overall system efficiency.

- Integration of thermoelectric generators with other energy systems: Combining thermoelectric generators with other energy systems can create synergistic effects that improve overall performance. Hybrid systems that integrate thermoelectric generators with solar panels, fuel cells, or conventional power generation can utilize waste heat more effectively. These integrated approaches can enhance energy harvesting capabilities, increase system reliability, and improve the economic viability of thermoelectric technology.

- Testing and performance evaluation methodologies: Advanced testing and evaluation methodologies are essential for accurately assessing and improving thermoelectric generator performance. This includes developing standardized testing protocols, simulation models, and real-time monitoring systems. Precise measurement of electrical output, thermal gradients, and conversion efficiency under various operating conditions enables optimization of device parameters and validation of theoretical models, leading to more efficient thermoelectric generator designs.

02 Structural design improvements for thermoelectric devices

The structural design of thermoelectric generators plays a crucial role in their performance. Innovative designs include segmented structures, cascaded configurations, and optimized geometry that can maximize the temperature gradient across the device. Advanced heat exchanger designs and improved thermal interfaces help in efficient heat transfer, while modular arrangements allow for scalability and adaptability to different applications. These structural improvements contribute to enhanced power output and efficiency of thermoelectric generators.Expand Specific Solutions03 Testing and measurement techniques for performance evaluation

Accurate testing and measurement techniques are essential for evaluating the performance of thermoelectric generators. These include methods for measuring the Seebeck coefficient, electrical conductivity, thermal conductivity, and figure of merit (ZT). Advanced characterization tools and standardized testing protocols help in reliable performance assessment under various operating conditions. Real-time monitoring systems and data analysis techniques enable continuous performance optimization and identification of degradation mechanisms.Expand Specific Solutions04 Thermal management systems for efficiency enhancement

Effective thermal management is critical for maximizing the performance of thermoelectric generators. This includes heat sink designs, cooling systems, and thermal interface materials that optimize heat flow and temperature gradients. Advanced heat dissipation techniques help maintain optimal operating temperatures and prevent thermal degradation. By minimizing parasitic heat losses and ensuring uniform temperature distribution, thermal management systems significantly improve the conversion efficiency and reliability of thermoelectric generators.Expand Specific Solutions05 Integration with energy harvesting systems

Thermoelectric generators can be integrated with other energy harvesting systems to create hybrid solutions with enhanced performance. These integrated systems can harvest waste heat from various sources such as industrial processes, vehicle exhaust, or solar thermal systems. By combining thermoelectric generators with complementary technologies like photovoltaics or mechanical energy harvesters, the overall energy conversion efficiency can be improved. Such integrated approaches enable more effective utilization of available thermal energy and expand the application range of thermoelectric generators.Expand Specific Solutions

Leading Companies and Research Institutions in TEG Development

The thermoelectric generator (TEG) market is currently in a growth phase, with increasing applications across automotive, industrial, and consumer electronics sectors. Market size is projected to reach approximately $750 million by 2025, driven by demand for waste heat recovery systems and off-grid power solutions. Technologically, bismuth telluride remains the dominant semiconductor material for commercial applications, though companies are advancing alternative materials. Guangdong Fuxin Technology and Hangzhou Dahe Thermo-Magnetics lead in specialized TEG development in Asia, while MAHLE International and IFP Energies Nouvelles focus on automotive applications. Research institutions like University of Porto and Electronics & Telecommunications Research Institute are exploring next-generation materials, with major semiconductor players including Taiwan Semiconductor and Samsung Electronics beginning to invest in this space, signaling the technology's growing commercial potential.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed silicon-based thermoelectric materials compatible with their advanced semiconductor manufacturing processes. Their approach focuses on heavily doped silicon with engineered nano-structures that significantly reduce thermal conductivity while maintaining electrical conductivity. TSMC's proprietary process creates silicon nanowire arrays with precisely controlled dimensions and doping profiles, achieving ZT values of 0.6-0.8 at room temperature—a substantial improvement over bulk silicon's typically poor thermoelectric performance. The company has pioneered 3D integration techniques that stack n-type and p-type thermoelectric elements vertically, increasing power density by up to 300% compared to conventional planar designs. Their thermoelectric generators are fabricated using standard CMOS processes, enabling direct integration with microelectronics for self-powered sensor applications. TSMC has demonstrated working prototypes that generate 1-5 mW/cm² at temperature differences of 40-60°C, suitable for IoT and wearable device applications.

Strengths: Seamless integration with semiconductor devices; established manufacturing infrastructure; excellent scalability and reproducibility; compatible with existing microelectronics. Weaknesses: Lower absolute ZT values compared to specialized thermoelectric materials; limited high-temperature performance; higher initial development costs; primarily focused on low-power applications rather than industrial-scale energy harvesting.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicon-based thermoelectric materials that demonstrate exceptional performance-to-cost ratios. Their approach focuses on higher manganese silicides (HMS) and magnesium silicide stannide (Mg2Si1-xSnx) materials that utilize abundant, non-toxic elements. The company has pioneered nano-inclusion techniques that create phonon scattering centers within the semiconductor matrix, reducing thermal conductivity by up to 35% while maintaining electrical properties. Their manufacturing process employs spark plasma sintering (SPS) technology that enables precise control of material microstructure and grain boundaries, critical factors for optimizing the ZT figure of merit. Shin-Etsu's latest generation of n-type and p-type silicide materials achieve ZT values of 1.2-1.4 at operating temperatures of 400-600°C, making them particularly effective for automotive and industrial waste heat recovery applications.

Strengths: Uses abundant, environmentally friendly materials; excellent high-temperature performance; cost-effective manufacturing process; good thermal stability and oxidation resistance. Weaknesses: Lower ZT values at room temperature compared to bismuth telluride; requires higher temperature differentials for optimal efficiency; mechanical properties need improvement for certain applications.

Key Patents and Research in Thermoelectric Materials

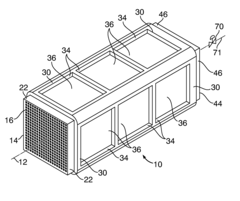

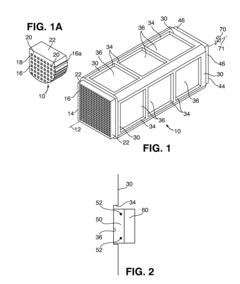

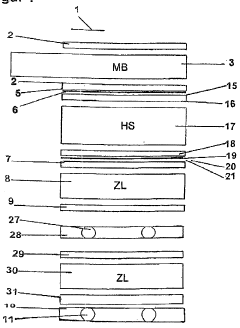

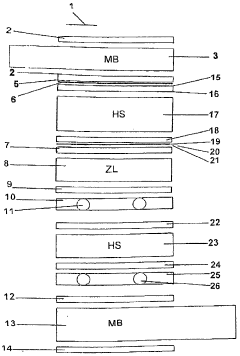

Thermoelectric generator

PatentInactiveUS8445773B2

Innovation

- A thermoelectric generator design featuring a honeycomb-shaped support coated with pyrophoric solid fuel, which ignites spontaneously in air to produce heat, integrated with a thermoelectric device and heat exchangers to generate electricity, with a shelf life extended by sealing the device when not in use.

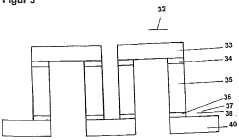

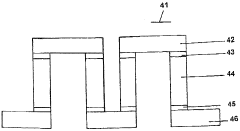

Thermoelectric generator has P-type and N-type elements that are provided at warm and cold side of generator stand over electrical and heat conducting metal bridges

PatentInactiveDE102010000660A1

Innovation

- A segmented TEG structure with metallic bridges and coatings, using light metals and specific semiconductor materials, is designed for different temperature ranges, featuring low contact resistance and efficient electrical voltage generation, with a focus on high-temperature (250°C to 400°C) and low-temperature (20°C to 250°C) applications, and a simplified manufacturing process.

Environmental Impact and Sustainability Considerations

The environmental impact of thermoelectric generators (TEGs) varies significantly across different semiconductor materials, with implications for sustainability throughout their lifecycle. Traditional bismuth telluride (Bi2Te3) based TEGs contain tellurium, which is classified as a critical raw material due to its scarcity and geopolitical supply risks. Mining and processing these materials generate substantial environmental footprints, including habitat disruption, water pollution, and energy-intensive refinement processes.

In contrast, silicon-germanium (SiGe) based TEGs offer improved environmental profiles in certain applications. While germanium remains relatively scarce, silicon is abundant, reducing overall resource depletion concerns. However, the high-temperature manufacturing processes required for SiGe TEGs result in significant energy consumption and associated carbon emissions during production.

Emerging semiconductor materials such as skutterudites, half-Heusler alloys, and organic thermoelectric materials present promising alternatives from a sustainability perspective. These materials often utilize more abundant elements and can be manufactured using less energy-intensive processes. Particularly, organic thermoelectric materials derived from carbon-based compounds offer biodegradability advantages that traditional inorganic semiconductors cannot match.

Life cycle assessment (LCA) studies indicate that the environmental impact of TEGs is predominantly determined by the manufacturing phase rather than operational or end-of-life phases. This is especially relevant when comparing different semiconductor types, as energy payback periods can vary from 1-5 years depending on the material composition and manufacturing techniques employed.

The waste management considerations also differ substantially across semiconductor types. Lead telluride (PbTe) based TEGs contain toxic lead compounds requiring specialized disposal protocols, while newer magnesium silicide (Mg2Si) based generators utilize more environmentally benign materials that pose fewer end-of-life challenges. Recovery and recycling infrastructure remains underdeveloped for most thermoelectric materials, though recent advances in hydrometallurgical techniques show promise for reclaiming rare elements from spent devices.

Carbon footprint analyses reveal that despite their manufacturing impacts, TEGs can contribute to net environmental benefits when deployed in waste heat recovery applications. By converting otherwise wasted thermal energy into useful electricity, TEGs based on high-performance semiconductors can offset their embodied carbon through operational energy generation. The magnitude of this benefit varies significantly across semiconductor types, with higher-efficiency materials like skutterudites offering superior lifetime environmental returns compared to conventional options.

In contrast, silicon-germanium (SiGe) based TEGs offer improved environmental profiles in certain applications. While germanium remains relatively scarce, silicon is abundant, reducing overall resource depletion concerns. However, the high-temperature manufacturing processes required for SiGe TEGs result in significant energy consumption and associated carbon emissions during production.

Emerging semiconductor materials such as skutterudites, half-Heusler alloys, and organic thermoelectric materials present promising alternatives from a sustainability perspective. These materials often utilize more abundant elements and can be manufactured using less energy-intensive processes. Particularly, organic thermoelectric materials derived from carbon-based compounds offer biodegradability advantages that traditional inorganic semiconductors cannot match.

Life cycle assessment (LCA) studies indicate that the environmental impact of TEGs is predominantly determined by the manufacturing phase rather than operational or end-of-life phases. This is especially relevant when comparing different semiconductor types, as energy payback periods can vary from 1-5 years depending on the material composition and manufacturing techniques employed.

The waste management considerations also differ substantially across semiconductor types. Lead telluride (PbTe) based TEGs contain toxic lead compounds requiring specialized disposal protocols, while newer magnesium silicide (Mg2Si) based generators utilize more environmentally benign materials that pose fewer end-of-life challenges. Recovery and recycling infrastructure remains underdeveloped for most thermoelectric materials, though recent advances in hydrometallurgical techniques show promise for reclaiming rare elements from spent devices.

Carbon footprint analyses reveal that despite their manufacturing impacts, TEGs can contribute to net environmental benefits when deployed in waste heat recovery applications. By converting otherwise wasted thermal energy into useful electricity, TEGs based on high-performance semiconductors can offset their embodied carbon through operational energy generation. The magnitude of this benefit varies significantly across semiconductor types, with higher-efficiency materials like skutterudites offering superior lifetime environmental returns compared to conventional options.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of thermoelectric generators (TEGs) varies significantly across different semiconductor material types, directly impacting their commercial viability. Traditional bismuth telluride (Bi2Te3) based TEGs benefit from established manufacturing processes, with production costs ranging from $5-10 per watt at moderate volumes. These materials leverage decades of industrial refinement, allowing for relatively consistent quality control and yield rates approaching 85-90% in advanced production facilities.

In contrast, newer semiconductor materials such as silicon-germanium alloys and skutterudites present greater manufacturing challenges. Current production costs for these advanced materials typically range from $15-25 per watt, primarily due to complex synthesis requirements and lower production yields (typically 60-75%). The specialized equipment needed for precise doping and nanostructuring of these materials further increases capital expenditure requirements for manufacturers.

Scale economies differ substantially between semiconductor types. Bismuth telluride benefits from production volume efficiencies, with cost reductions of approximately 15-20% when scaling from prototype to mass production. Newer materials like half-Heusler alloys currently show less favorable scaling factors, with cost reductions limited to 8-12% at comparable volume increases, reflecting their nascent manufacturing maturity.

Material availability and supply chain considerations also influence manufacturing scalability. Tellurium, essential for bismuth telluride TEGs, faces supply constraints with global production under 500 metric tons annually. This creates potential bottlenecks for large-scale deployment. Conversely, silicon-based thermoelectric materials offer superior supply chain resilience due to the semiconductor industry's established silicon infrastructure, though performance limitations currently restrict their application range.

Environmental and regulatory factors increasingly affect manufacturing cost structures. Traditional TEG materials containing tellurium, antimony, and lead face growing regulatory scrutiny, potentially necessitating costly compliance measures. Lead-free alternatives and materials with reduced toxic element content command premium pricing but may become economically advantageous as environmental regulations tighten globally.

Emerging manufacturing technologies, particularly additive manufacturing and thin-film deposition techniques, are beginning to reshape the cost landscape for certain semiconductor types. Printed thermoelectric generators using organic semiconductors, while currently limited in performance, demonstrate production cost potential below $3 per watt at scale. These approaches may eventually enable mass-market applications previously unattainable with conventional manufacturing methods, particularly for low and medium temperature differential applications where performance requirements are less stringent.

In contrast, newer semiconductor materials such as silicon-germanium alloys and skutterudites present greater manufacturing challenges. Current production costs for these advanced materials typically range from $15-25 per watt, primarily due to complex synthesis requirements and lower production yields (typically 60-75%). The specialized equipment needed for precise doping and nanostructuring of these materials further increases capital expenditure requirements for manufacturers.

Scale economies differ substantially between semiconductor types. Bismuth telluride benefits from production volume efficiencies, with cost reductions of approximately 15-20% when scaling from prototype to mass production. Newer materials like half-Heusler alloys currently show less favorable scaling factors, with cost reductions limited to 8-12% at comparable volume increases, reflecting their nascent manufacturing maturity.

Material availability and supply chain considerations also influence manufacturing scalability. Tellurium, essential for bismuth telluride TEGs, faces supply constraints with global production under 500 metric tons annually. This creates potential bottlenecks for large-scale deployment. Conversely, silicon-based thermoelectric materials offer superior supply chain resilience due to the semiconductor industry's established silicon infrastructure, though performance limitations currently restrict their application range.

Environmental and regulatory factors increasingly affect manufacturing cost structures. Traditional TEG materials containing tellurium, antimony, and lead face growing regulatory scrutiny, potentially necessitating costly compliance measures. Lead-free alternatives and materials with reduced toxic element content command premium pricing but may become economically advantageous as environmental regulations tighten globally.

Emerging manufacturing technologies, particularly additive manufacturing and thin-film deposition techniques, are beginning to reshape the cost landscape for certain semiconductor types. Printed thermoelectric generators using organic semiconductors, while currently limited in performance, demonstrate production cost potential below $3 per watt at scale. These approaches may eventually enable mass-market applications previously unattainable with conventional manufacturing methods, particularly for low and medium temperature differential applications where performance requirements are less stringent.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!