Comparison Of Thermoelectric Generators And Organic Rankine Cycle Systems

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG and ORC Technology Background and Objectives

Energy recovery systems have evolved significantly over the past decades, with thermoelectric generators (TEGs) and Organic Rankine Cycle (ORC) systems emerging as two prominent technologies for waste heat recovery. TEGs, which directly convert temperature differences into electrical energy through the Seebeck effect, have been in development since the early 19th century. However, their commercial viability only materialized in the mid-20th century with advancements in semiconductor materials.

ORC systems, on the other hand, represent an adaptation of the traditional Rankine cycle, utilizing organic working fluids instead of water to enable power generation from lower temperature heat sources. The fundamental principles of the Rankine cycle date back to the 19th century, but ORC technology gained significant traction in the 1970s and 1980s following the global energy crisis, which prompted increased interest in energy efficiency and alternative energy sources.

The technological evolution of both TEGs and ORC systems has been driven by the growing global emphasis on energy efficiency, carbon emission reduction, and sustainable energy practices. Recent advancements in material science have significantly improved the performance of TEGs, while innovations in turbine design and working fluid formulations have enhanced ORC system efficiency.

The primary technical objective in comparing these technologies is to establish comprehensive performance metrics that enable informed decision-making for specific waste heat recovery applications. This includes evaluating their respective energy conversion efficiencies across various temperature ranges, assessing their scalability from small to large installations, and determining their economic viability in different industrial contexts.

Additionally, this comparison aims to identify the optimal operational conditions for each technology, considering factors such as heat source temperature stability, space constraints, maintenance requirements, and integration complexity with existing systems. Understanding these parameters is crucial for developing hybrid systems that potentially combine both technologies to maximize overall energy recovery efficiency.

Future technological objectives include improving the power density of TEGs, enhancing the thermal-to-electrical conversion efficiency of both systems, reducing manufacturing costs through advanced production techniques, and developing more environmentally friendly materials and working fluids. The ultimate goal is to establish a clear decision framework that guides the selection between TEG and ORC technologies based on specific application requirements, thereby accelerating the adoption of waste heat recovery systems across various industries.

ORC systems, on the other hand, represent an adaptation of the traditional Rankine cycle, utilizing organic working fluids instead of water to enable power generation from lower temperature heat sources. The fundamental principles of the Rankine cycle date back to the 19th century, but ORC technology gained significant traction in the 1970s and 1980s following the global energy crisis, which prompted increased interest in energy efficiency and alternative energy sources.

The technological evolution of both TEGs and ORC systems has been driven by the growing global emphasis on energy efficiency, carbon emission reduction, and sustainable energy practices. Recent advancements in material science have significantly improved the performance of TEGs, while innovations in turbine design and working fluid formulations have enhanced ORC system efficiency.

The primary technical objective in comparing these technologies is to establish comprehensive performance metrics that enable informed decision-making for specific waste heat recovery applications. This includes evaluating their respective energy conversion efficiencies across various temperature ranges, assessing their scalability from small to large installations, and determining their economic viability in different industrial contexts.

Additionally, this comparison aims to identify the optimal operational conditions for each technology, considering factors such as heat source temperature stability, space constraints, maintenance requirements, and integration complexity with existing systems. Understanding these parameters is crucial for developing hybrid systems that potentially combine both technologies to maximize overall energy recovery efficiency.

Future technological objectives include improving the power density of TEGs, enhancing the thermal-to-electrical conversion efficiency of both systems, reducing manufacturing costs through advanced production techniques, and developing more environmentally friendly materials and working fluids. The ultimate goal is to establish a clear decision framework that guides the selection between TEG and ORC technologies based on specific application requirements, thereby accelerating the adoption of waste heat recovery systems across various industries.

Market Demand Analysis for Waste Heat Recovery Systems

The global waste heat recovery systems market is experiencing significant growth, driven by increasing energy costs and environmental regulations. The market was valued at approximately $54 billion in 2020 and is projected to reach $80 billion by 2026, growing at a CAGR of around 8.5%. This growth is primarily fueled by industrial sectors such as power generation, cement, glass, and metal processing, where substantial amounts of waste heat are generated during operations.

Thermoelectric Generators (TEGs) and Organic Rankine Cycle (ORC) systems represent two distinct approaches to waste heat recovery, each addressing different market segments. TEGs are gaining traction in applications requiring lower power output (typically under 10 kW), with particular demand in automotive, aerospace, and remote power generation sectors. The automotive industry alone represents a substantial market opportunity, with waste heat recovery systems potentially improving fuel efficiency by 3-5%.

ORC systems dominate the medium to large-scale waste heat recovery market, particularly in industrial applications where waste heat temperatures range from 80°C to 350°C. These systems are increasingly sought after in geothermal power plants, biomass facilities, and industrial processes where higher power outputs (typically above 50 kW) are required. The industrial sector accounts for approximately 67% of the total waste heat recovery systems market.

Regional analysis reveals varying adoption patterns. Europe leads the market with stringent energy efficiency regulations driving implementation, particularly in Germany, Italy, and the Nordic countries. North America follows with growing adoption in manufacturing and power generation sectors. The Asia-Pacific region, especially China and India, represents the fastest-growing market due to rapid industrialization and increasing focus on energy efficiency.

Customer requirements are evolving toward more integrated and efficient solutions. End-users increasingly demand systems with higher conversion efficiencies, lower maintenance requirements, and shorter payback periods. For TEGs, the market demands improved material performance and cost reduction, while ORC systems face pressure for more compact designs and better performance at lower temperature differentials.

The economic viability of waste heat recovery systems varies significantly based on application scale, heat source temperature, and regional energy prices. Current market analysis indicates that ORC systems typically achieve payback periods of 3-6 years for industrial applications, while TEGs offer faster returns in specialized applications despite lower overall efficiency.

Thermoelectric Generators (TEGs) and Organic Rankine Cycle (ORC) systems represent two distinct approaches to waste heat recovery, each addressing different market segments. TEGs are gaining traction in applications requiring lower power output (typically under 10 kW), with particular demand in automotive, aerospace, and remote power generation sectors. The automotive industry alone represents a substantial market opportunity, with waste heat recovery systems potentially improving fuel efficiency by 3-5%.

ORC systems dominate the medium to large-scale waste heat recovery market, particularly in industrial applications where waste heat temperatures range from 80°C to 350°C. These systems are increasingly sought after in geothermal power plants, biomass facilities, and industrial processes where higher power outputs (typically above 50 kW) are required. The industrial sector accounts for approximately 67% of the total waste heat recovery systems market.

Regional analysis reveals varying adoption patterns. Europe leads the market with stringent energy efficiency regulations driving implementation, particularly in Germany, Italy, and the Nordic countries. North America follows with growing adoption in manufacturing and power generation sectors. The Asia-Pacific region, especially China and India, represents the fastest-growing market due to rapid industrialization and increasing focus on energy efficiency.

Customer requirements are evolving toward more integrated and efficient solutions. End-users increasingly demand systems with higher conversion efficiencies, lower maintenance requirements, and shorter payback periods. For TEGs, the market demands improved material performance and cost reduction, while ORC systems face pressure for more compact designs and better performance at lower temperature differentials.

The economic viability of waste heat recovery systems varies significantly based on application scale, heat source temperature, and regional energy prices. Current market analysis indicates that ORC systems typically achieve payback periods of 3-6 years for industrial applications, while TEGs offer faster returns in specialized applications despite lower overall efficiency.

Current State and Challenges in Thermal Energy Conversion

Thermal energy conversion technologies have evolved significantly over the past decades, with Thermoelectric Generators (TEGs) and Organic Rankine Cycle (ORC) systems emerging as two prominent solutions for waste heat recovery and renewable energy applications. Currently, TEGs operate on the Seebeck effect, directly converting temperature differentials into electrical energy without moving parts, while ORC systems utilize organic working fluids with lower boiling points than water to generate electricity through conventional turbine-based power cycles.

The global landscape of thermal energy conversion shows regional disparities in technology adoption. Europe leads in ORC system deployment, particularly in geothermal and biomass applications, with Italy and Germany hosting significant installations. Meanwhile, Japan and the United States have made substantial investments in TEG research, focusing on automotive and industrial waste heat recovery applications.

A critical challenge facing TEGs is their relatively low conversion efficiency, typically ranging from 3-8% in commercial applications. This limitation stems from the inherent properties of thermoelectric materials, which struggle to simultaneously achieve high electrical conductivity and low thermal conductivity. Recent advancements in nanostructured materials and skutterudites have shown promise but remain costly for large-scale implementation.

ORC systems, while achieving higher efficiencies (typically 10-20%), face challenges related to system complexity, maintenance requirements, and working fluid selection. Environmental concerns regarding the global warming potential of certain organic fluids have prompted research into alternative working fluids. Additionally, ORC systems struggle with efficiency at lower temperature differentials (below 80°C), limiting their application in low-grade waste heat recovery scenarios.

Both technologies confront economic barriers to widespread adoption. TEGs currently have high production costs relative to their power output, with prices ranging from $5-20 per watt, significantly higher than conventional power generation. ORC systems, while more economically viable at larger scales, face challenges in miniaturization for distributed applications due to the diminishing returns in efficiency at smaller sizes.

Material science limitations represent another significant hurdle. For TEGs, the search for materials with higher ZT values (figure of merit for thermoelectric performance) continues, with current commercial materials achieving ZT values around 1-2. ORC systems face challenges in developing heat exchanger materials that can withstand thermal cycling while maintaining efficiency and cost-effectiveness.

Integration challenges persist for both technologies. TEGs require effective thermal management systems to maintain temperature differentials, while ORC systems need sophisticated control systems to optimize performance across varying heat source conditions. These integration complexities often increase implementation costs and technical barriers to adoption.

The global landscape of thermal energy conversion shows regional disparities in technology adoption. Europe leads in ORC system deployment, particularly in geothermal and biomass applications, with Italy and Germany hosting significant installations. Meanwhile, Japan and the United States have made substantial investments in TEG research, focusing on automotive and industrial waste heat recovery applications.

A critical challenge facing TEGs is their relatively low conversion efficiency, typically ranging from 3-8% in commercial applications. This limitation stems from the inherent properties of thermoelectric materials, which struggle to simultaneously achieve high electrical conductivity and low thermal conductivity. Recent advancements in nanostructured materials and skutterudites have shown promise but remain costly for large-scale implementation.

ORC systems, while achieving higher efficiencies (typically 10-20%), face challenges related to system complexity, maintenance requirements, and working fluid selection. Environmental concerns regarding the global warming potential of certain organic fluids have prompted research into alternative working fluids. Additionally, ORC systems struggle with efficiency at lower temperature differentials (below 80°C), limiting their application in low-grade waste heat recovery scenarios.

Both technologies confront economic barriers to widespread adoption. TEGs currently have high production costs relative to their power output, with prices ranging from $5-20 per watt, significantly higher than conventional power generation. ORC systems, while more economically viable at larger scales, face challenges in miniaturization for distributed applications due to the diminishing returns in efficiency at smaller sizes.

Material science limitations represent another significant hurdle. For TEGs, the search for materials with higher ZT values (figure of merit for thermoelectric performance) continues, with current commercial materials achieving ZT values around 1-2. ORC systems face challenges in developing heat exchanger materials that can withstand thermal cycling while maintaining efficiency and cost-effectiveness.

Integration challenges persist for both technologies. TEGs require effective thermal management systems to maintain temperature differentials, while ORC systems need sophisticated control systems to optimize performance across varying heat source conditions. These integration complexities often increase implementation costs and technical barriers to adoption.

Current Technical Solutions for Waste Heat Recovery

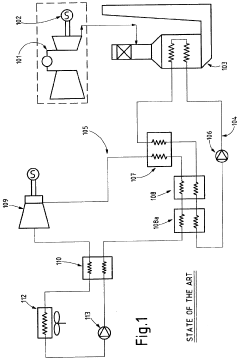

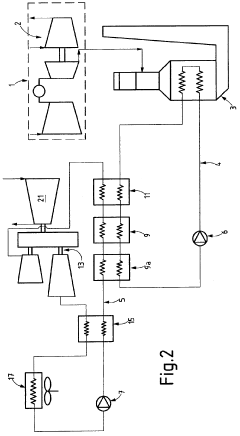

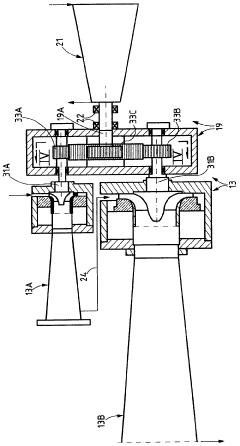

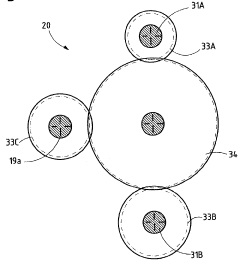

01 Integration of thermoelectric generators with organic Rankine cycle systems

Systems that combine thermoelectric generators with organic Rankine cycle technology to maximize energy recovery from waste heat sources. These integrated systems can capture heat at different temperature ranges, with thermoelectric generators typically handling higher temperatures while ORC systems utilize lower temperature waste heat. This combination improves overall system efficiency and power output compared to either technology alone.- Integration of Thermoelectric Generators with Organic Rankine Cycle Systems: Systems that combine thermoelectric generators (TEGs) with Organic Rankine Cycle (ORC) technology to maximize energy recovery from waste heat sources. These hybrid systems leverage the direct conversion of heat to electricity by TEGs alongside the mechanical power generation of ORC systems, improving overall efficiency and providing complementary operating characteristics across different temperature ranges.

- Waste Heat Recovery Applications in Vehicles: Implementation of thermoelectric generators and ORC systems in automotive and transportation applications to recover waste heat from exhaust systems and engine cooling. These systems convert thermal energy that would otherwise be lost to the environment into useful electrical power, reducing fuel consumption and emissions while providing auxiliary power for vehicle electrical systems.

- Working Fluid Selection and Optimization: Development of specialized working fluids for ORC systems that operate efficiently at various temperature ranges. Selection criteria include thermodynamic properties, environmental impact, safety, and compatibility with system components. Optimized fluid mixtures and novel compounds can significantly improve cycle efficiency and power output while meeting regulatory requirements.

- System Control and Efficiency Enhancement Techniques: Advanced control strategies and system configurations to optimize the performance of thermoelectric generators and ORC systems under varying operating conditions. These include adaptive control algorithms, variable geometry components, and innovative heat exchanger designs that maximize energy extraction and conversion efficiency while maintaining system stability and reliability.

- Industrial and Stationary Applications: Implementation of large-scale thermoelectric generators and ORC systems in industrial settings to recover waste heat from manufacturing processes, power generation, and other stationary applications. These systems can be integrated with existing industrial infrastructure to improve overall energy efficiency, reduce operating costs, and decrease environmental impact through reduced primary energy consumption.

02 Waste heat recovery applications in vehicles

Implementation of thermoelectric generators and organic Rankine cycle systems in automotive applications to recover waste heat from exhaust systems. These technologies can convert thermal energy from vehicle exhaust into electrical power to reduce fuel consumption, decrease emissions, and power auxiliary systems or hybrid vehicle batteries. Vehicle-specific designs address space constraints, weight considerations, and variable operating conditions.Expand Specific Solutions03 Working fluid selection and optimization

Selection and optimization of working fluids for organic Rankine cycle systems to improve efficiency and performance. Different working fluids are suitable for various temperature ranges and operating conditions. The choice of working fluid affects system efficiency, component sizing, environmental impact, and safety considerations. Specialized fluids can be developed for specific applications to maximize power generation.Expand Specific Solutions04 System control and efficiency enhancement techniques

Advanced control strategies and efficiency enhancement techniques for thermoelectric generators and organic Rankine cycle systems. These include variable speed operation, adaptive control algorithms, heat exchanger optimization, and expander efficiency improvements. Control systems can adjust operating parameters based on changing conditions to maintain optimal performance and maximize power output across varying heat source temperatures.Expand Specific Solutions05 Industrial waste heat recovery applications

Application of thermoelectric generators and organic Rankine cycle systems in industrial settings to recover waste heat from manufacturing processes, power generation, and other industrial operations. These systems can be scaled to accommodate large industrial heat sources and can significantly improve overall plant efficiency. Industrial implementations often feature customized designs based on specific waste heat characteristics and space availability.Expand Specific Solutions

Key Industry Players in Thermoelectric and ORC Markets

The thermoelectric generators (TEG) and Organic Rankine Cycle (ORC) systems market is in a growth phase, with increasing adoption across industrial waste heat recovery applications. The global market size is expanding rapidly, driven by energy efficiency regulations and sustainability initiatives. Technologically, ORC systems demonstrate higher maturity and efficiency for medium to large-scale applications, with companies like Turboden SpA, Orcan Energy AG, and Rondo Energy leading innovation in this segment. Meanwhile, TEG technology, though less mature for industrial-scale applications, is advancing through research at institutions like Huazhong University of Science & Technology and Korea Institute of Energy Research. Companies including Danfoss, Air Liquide, and Kraftblock are developing complementary technologies to enhance system integration and efficiency across both technologies.

Turboden SpA

Technical Solution: Turboden specializes in Organic Rankine Cycle (ORC) systems for waste heat recovery and renewable energy applications. Their technology utilizes a closed-loop thermodynamic cycle that employs organic working fluids with lower boiling points than water, enabling efficient power generation from low to medium temperature heat sources (80-300°C). Turboden's ORC systems are modular and scalable, ranging from 200kW to 20MW, and achieve electrical efficiencies of 18-24% depending on heat source temperature. Their systems incorporate proprietary turbine designs optimized for organic fluids, featuring direct drive connection between turbine and generator to minimize mechanical losses. Turboden's ORC technology includes advanced heat exchangers for efficient thermal transfer and sophisticated control systems that optimize performance across varying operating conditions, allowing for fully automated operation with minimal maintenance requirements.

Strengths: High efficiency at lower temperatures compared to conventional steam cycles; modular design allows for scalable implementation; minimal maintenance with long operational life (>20 years); environmentally friendly closed-loop system with no water consumption. Weaknesses: Higher initial capital cost compared to thermoelectric generators; requires more physical space for installation; efficiency still limited by thermodynamic constraints.

Kunming University of Science & Technology

Technical Solution: Kunming University of Science & Technology has developed innovative hybrid thermoelectric-ORC systems that combine the advantages of both technologies. Their research focuses on cascaded energy recovery systems where thermoelectric generators (TEGs) operate at higher temperature differentials (>300°C), while ORC systems harvest the remaining lower-grade waste heat. The university's approach utilizes advanced thermoelectric materials including skutterudites and half-Heusler alloys with improved figure of merit (ZT>1.5) for the TEG components. Their system architecture incorporates phase change materials as thermal buffers to stabilize temperature fluctuations, enhancing overall system efficiency. The research team has demonstrated prototype systems achieving combined conversion efficiencies of 12-18%, significantly higher than either technology alone. Their designs feature integrated heat pipe technology for efficient thermal management between the TEG and ORC components, minimizing thermal resistance and maximizing heat transfer to both conversion technologies.

Strengths: Higher overall efficiency through cascaded heat recovery; no moving parts in the TEG portion increases reliability; ability to operate effectively across wider temperature ranges; compact design suitable for distributed applications. Weaknesses: Higher system complexity increases potential failure points; advanced thermoelectric materials remain costly; optimization challenges between the two subsystems; still primarily in research/prototype stage rather than commercial deployment.

Core Patents and Innovations in TEG and ORC Technologies

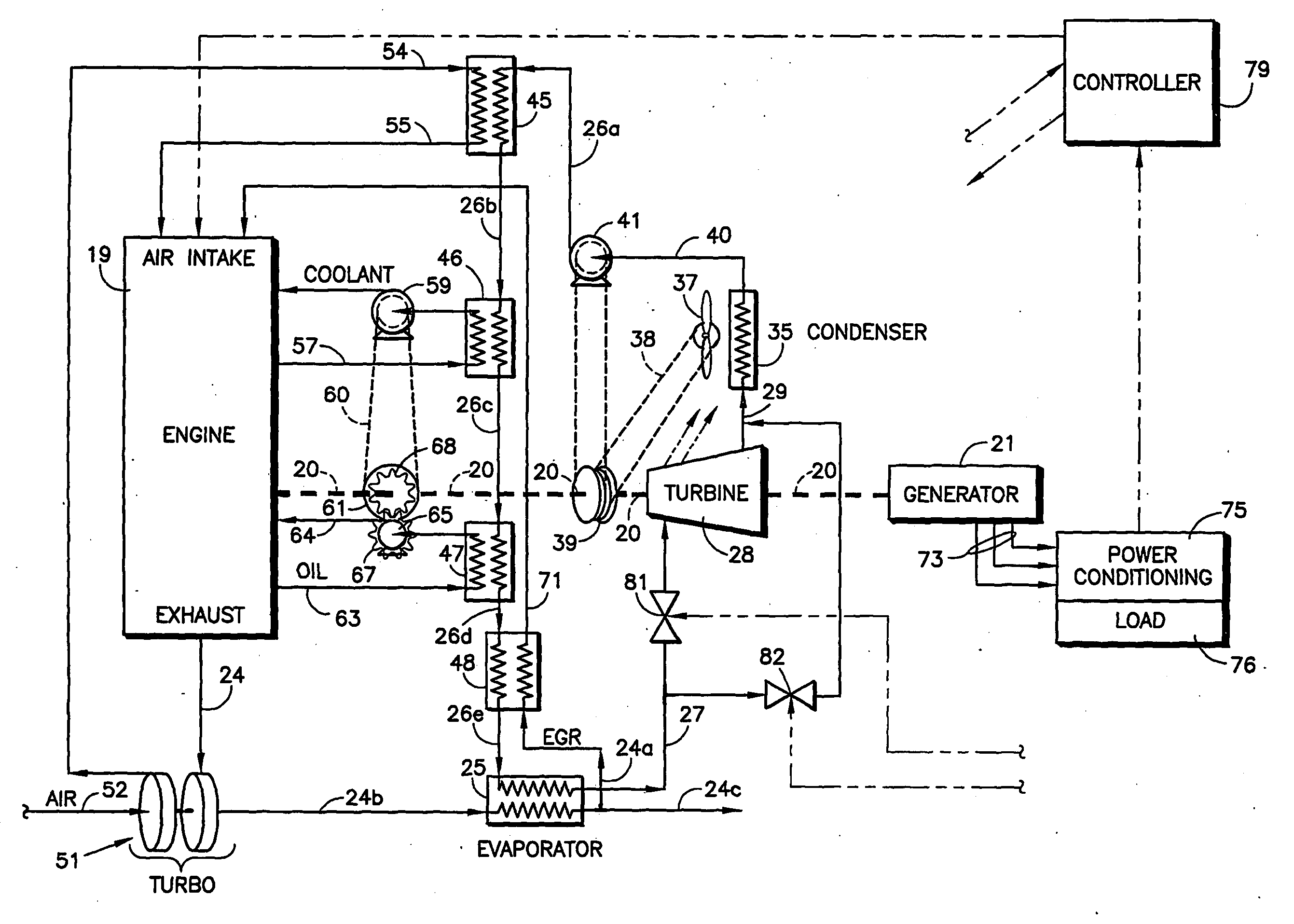

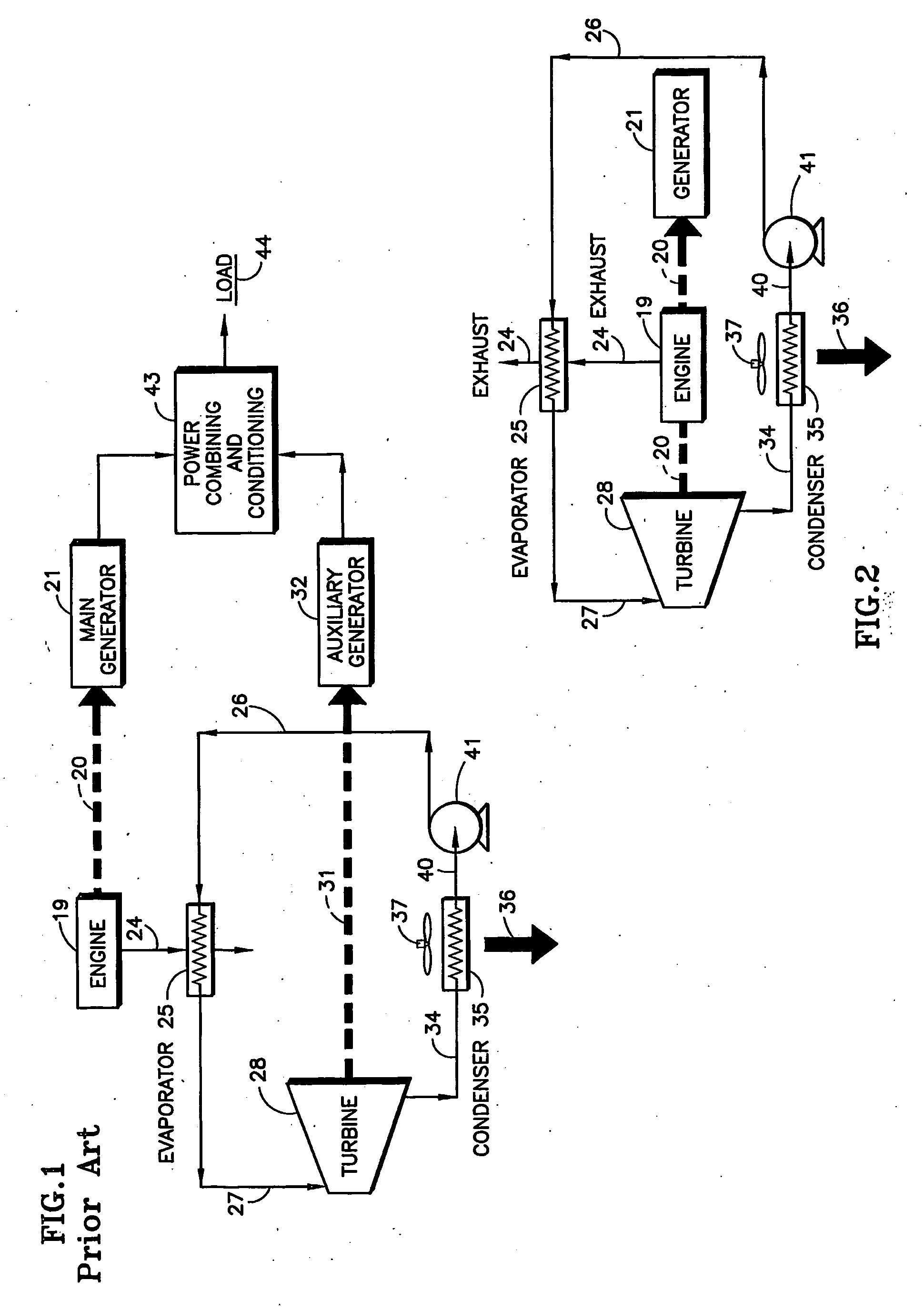

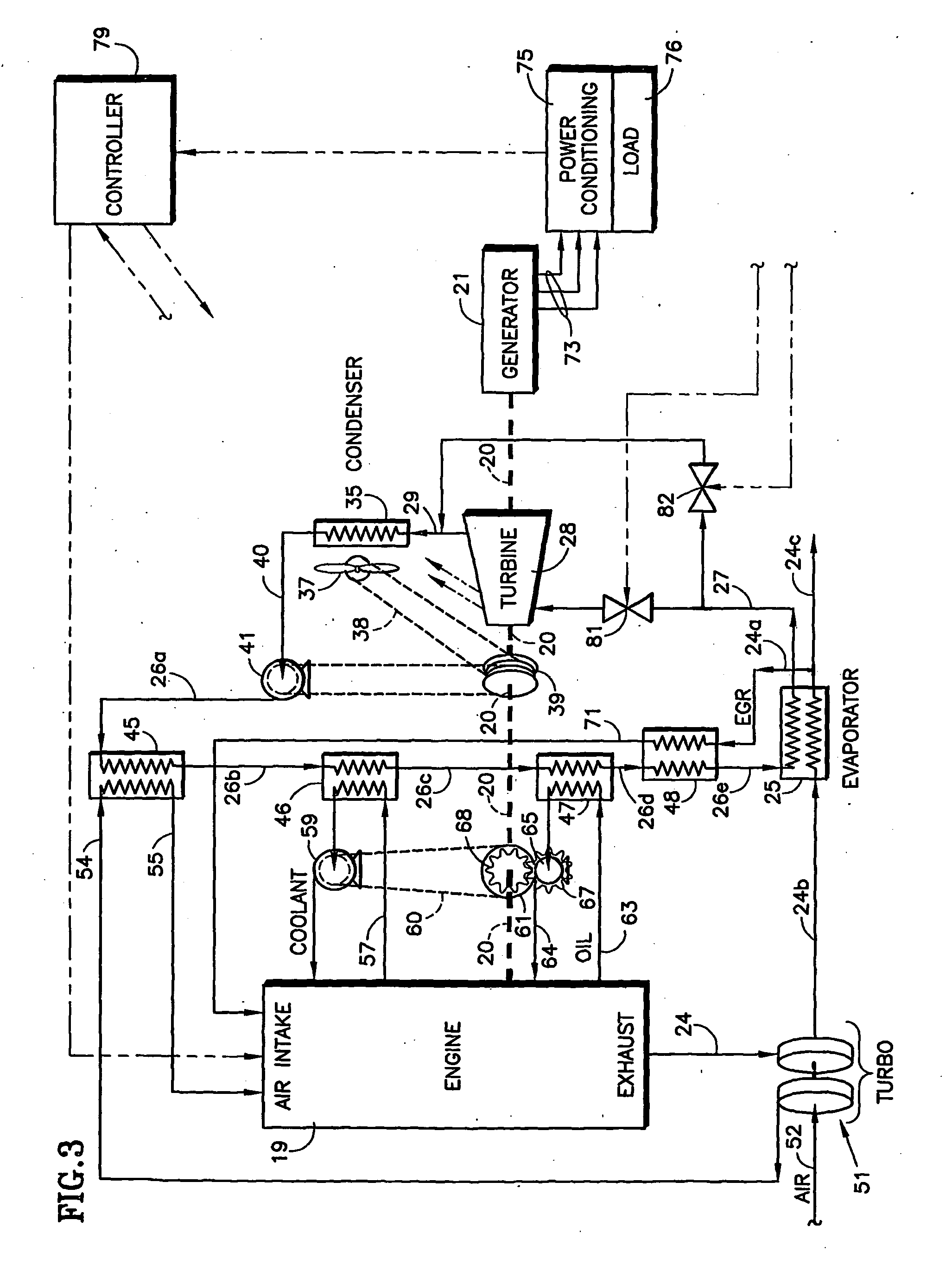

Organic Rankine Cycle Mechanically and Thermally Coupled to an Engine Driving a Common Load

PatentInactiveUS20090211253A1

Innovation

- Mechanical and thermal coupling of the engine with an organic Rankine cycle system to utilize all engine waste heat, eliminating the need for redundant generators and power combining circuitry, with shared shafts and advanced heat exchanger designs to optimize energy transfer.

An organic rankine cycle for mechanical drive applications

PatentActiveCA2828515C

Innovation

- A combined thermodynamic system integrating a gas turbine, a turbomachine, and an integrally geared multi-stage turboexpander-based organic Rankine cycle for mechanical power production, utilizing a diathermic oil and organic fluid to efficiently convert waste heat into mechanical energy, suitable for driving turbomachines without producing electric power.

Economic Viability and ROI Analysis of TEG vs ORC Systems

The economic comparison between Thermoelectric Generators (TEGs) and Organic Rankine Cycle (ORC) systems reveals significant differences in capital expenditure, operational costs, and return on investment profiles. Initial investment for TEG systems typically ranges from $2,000-$5,000 per kW, substantially higher than ORC systems which generally cost between $1,500-$3,500 per kW for medium to large-scale installations. However, this capital cost differential must be evaluated against the operational context.

TEG systems demonstrate superior economic performance in small-scale applications (under 10kW) due to their minimal maintenance requirements, estimated at 1-2% of capital costs annually compared to 3-5% for ORC systems. The absence of moving parts in TEGs translates to longer operational lifespans of 15-20 years versus 10-15 years for ORC systems, significantly impacting lifetime economic calculations.

Payback periods vary considerably based on application scenarios. TEGs typically achieve ROI within 4-7 years in remote applications where maintenance access is challenging and expensive. Conversely, ORC systems reach payback within 3-5 years in industrial waste heat recovery applications where economies of scale can be leveraged effectively.

Recent market analyses indicate that TEG systems become increasingly competitive when factoring in carbon pricing mechanisms. With carbon prices ranging from $30-$50 per ton in developed markets, TEG installations can accelerate ROI by 15-20% in regions with progressive environmental policies.

Sensitivity analysis reveals that TEG economic viability is highly dependent on material costs, particularly semiconductor materials which constitute approximately 40% of system costs. Technological advancements in material science could potentially reduce TEG costs by 30-35% over the next decade, significantly altering the comparative economic equation.

ORC systems demonstrate superior economic performance in applications exceeding 50kW, with efficiency advantages translating to 20-25% better lifetime revenue generation compared to equivalent TEG installations. This advantage diminishes in smaller applications where the simplicity and reliability of TEGs offset their efficiency disadvantages.

Hybrid systems combining both technologies are emerging as economically viable solutions in specific contexts, potentially offering 10-15% better ROI than single-technology approaches by optimizing the temperature ranges where each technology performs most efficiently.

TEG systems demonstrate superior economic performance in small-scale applications (under 10kW) due to their minimal maintenance requirements, estimated at 1-2% of capital costs annually compared to 3-5% for ORC systems. The absence of moving parts in TEGs translates to longer operational lifespans of 15-20 years versus 10-15 years for ORC systems, significantly impacting lifetime economic calculations.

Payback periods vary considerably based on application scenarios. TEGs typically achieve ROI within 4-7 years in remote applications where maintenance access is challenging and expensive. Conversely, ORC systems reach payback within 3-5 years in industrial waste heat recovery applications where economies of scale can be leveraged effectively.

Recent market analyses indicate that TEG systems become increasingly competitive when factoring in carbon pricing mechanisms. With carbon prices ranging from $30-$50 per ton in developed markets, TEG installations can accelerate ROI by 15-20% in regions with progressive environmental policies.

Sensitivity analysis reveals that TEG economic viability is highly dependent on material costs, particularly semiconductor materials which constitute approximately 40% of system costs. Technological advancements in material science could potentially reduce TEG costs by 30-35% over the next decade, significantly altering the comparative economic equation.

ORC systems demonstrate superior economic performance in applications exceeding 50kW, with efficiency advantages translating to 20-25% better lifetime revenue generation compared to equivalent TEG installations. This advantage diminishes in smaller applications where the simplicity and reliability of TEGs offset their efficiency disadvantages.

Hybrid systems combining both technologies are emerging as economically viable solutions in specific contexts, potentially offering 10-15% better ROI than single-technology approaches by optimizing the temperature ranges where each technology performs most efficiently.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of energy conversion systems have become increasingly critical in the context of global climate change and resource depletion. When comparing Thermoelectric Generators (TEGs) and Organic Rankine Cycle (ORC) systems, their environmental footprints differ significantly across multiple dimensions.

TEGs offer notable environmental advantages due to their solid-state operation with no moving parts. This characteristic eliminates the need for lubricants and working fluids that could potentially leak and cause environmental contamination. Additionally, TEGs produce zero direct emissions during operation, making them particularly suitable for environmentally sensitive applications. Their long operational lifespan, often exceeding 100,000 hours with minimal degradation, reduces replacement frequency and associated manufacturing impacts.

In contrast, ORC systems utilize organic working fluids that present varying degrees of environmental concern. Traditional working fluids like hydrofluorocarbons (HFCs) have significant global warming potential (GWP), though the industry has been transitioning toward more environmentally benign alternatives such as hydrocarbons, siloxanes, and newer refrigerants with lower GWP values. The potential for working fluid leakage remains an environmental risk factor for ORC implementations.

From a life cycle assessment perspective, TEGs typically require energy-intensive manufacturing processes and utilize some rare or precious metals like tellurium, bismuth, and antimony. The extraction and processing of these materials carry substantial environmental burdens. Conversely, ORC systems primarily use more conventional materials but require more components and complex manufacturing processes.

Regarding resource efficiency, ORC systems generally demonstrate higher thermal efficiency (typically 10-20%) compared to TEGs (usually 5-8%), allowing them to extract more useful energy from the same heat source. This efficiency advantage can translate to reduced primary resource consumption when viewed from a system perspective.

End-of-life considerations also differ markedly between these technologies. TEG materials, particularly semiconductor elements, present recycling challenges but also opportunities for material recovery due to the presence of valuable elements. ORC systems contain more conventional materials that fit into established recycling streams, though their working fluids require specialized handling and disposal protocols.

The sustainability profile of both technologies improves significantly when deployed in waste heat recovery applications, as they convert otherwise wasted energy into useful power without additional fuel consumption. This application represents perhaps their greatest contribution to environmental sustainability, potentially offsetting primary energy use and associated emissions across various industrial sectors.

TEGs offer notable environmental advantages due to their solid-state operation with no moving parts. This characteristic eliminates the need for lubricants and working fluids that could potentially leak and cause environmental contamination. Additionally, TEGs produce zero direct emissions during operation, making them particularly suitable for environmentally sensitive applications. Their long operational lifespan, often exceeding 100,000 hours with minimal degradation, reduces replacement frequency and associated manufacturing impacts.

In contrast, ORC systems utilize organic working fluids that present varying degrees of environmental concern. Traditional working fluids like hydrofluorocarbons (HFCs) have significant global warming potential (GWP), though the industry has been transitioning toward more environmentally benign alternatives such as hydrocarbons, siloxanes, and newer refrigerants with lower GWP values. The potential for working fluid leakage remains an environmental risk factor for ORC implementations.

From a life cycle assessment perspective, TEGs typically require energy-intensive manufacturing processes and utilize some rare or precious metals like tellurium, bismuth, and antimony. The extraction and processing of these materials carry substantial environmental burdens. Conversely, ORC systems primarily use more conventional materials but require more components and complex manufacturing processes.

Regarding resource efficiency, ORC systems generally demonstrate higher thermal efficiency (typically 10-20%) compared to TEGs (usually 5-8%), allowing them to extract more useful energy from the same heat source. This efficiency advantage can translate to reduced primary resource consumption when viewed from a system perspective.

End-of-life considerations also differ markedly between these technologies. TEG materials, particularly semiconductor elements, present recycling challenges but also opportunities for material recovery due to the presence of valuable elements. ORC systems contain more conventional materials that fit into established recycling streams, though their working fluids require specialized handling and disposal protocols.

The sustainability profile of both technologies improves significantly when deployed in waste heat recovery applications, as they convert otherwise wasted energy into useful power without additional fuel consumption. This application represents perhaps their greatest contribution to environmental sustainability, potentially offsetting primary energy use and associated emissions across various industrial sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!