Conductive Liquid Metal Composites With Conducting Particles

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Composites Background and Objectives

Liquid metal composites represent a revolutionary class of materials that combine the unique properties of liquid metals with various conducting particles to create highly functional conductive systems. The history of liquid metal research dates back to the early 20th century, but significant advancements in liquid metal composites have primarily emerged in the past two decades. These materials have evolved from simple mercury-based conductors to sophisticated gallium-based alloys that offer remarkable electrical conductivity while maintaining fluidic properties.

The technological evolution trajectory shows a clear shift from toxic mercury-based systems toward environmentally friendly alternatives, particularly gallium-indium-tin (Galinstan) and eutectic gallium-indium (EGaIn) alloys. These modern liquid metal systems have overcome critical limitations of traditional rigid conductors, offering unprecedented combinations of electrical conductivity, mechanical flexibility, and thermal stability. Recent research has focused on enhancing these properties through strategic incorporation of conducting particles such as silver, copper, carbon nanotubes, and graphene.

The primary objective in this field is to develop liquid metal composites that maintain high electrical conductivity while offering superior mechanical properties, including stretchability, self-healing capabilities, and stability under various environmental conditions. Researchers aim to overcome the inherent limitations of pure liquid metals, such as high surface tension, oxidation susceptibility, and limited mechanical strength, through innovative composite formulations.

Another critical goal is to establish scalable manufacturing processes that can transition these materials from laboratory curiosities to commercially viable products. This includes developing methods for precise control of particle distribution, interface engineering between liquid metals and conducting particles, and encapsulation techniques to prevent leakage and oxidation.

The field is currently experiencing a convergence of materials science, electrical engineering, and soft robotics, driving interdisciplinary research efforts. Technological objectives extend beyond simply creating conductive materials to developing programmable, stimuli-responsive systems that can adapt their properties in response to external triggers such as temperature, pressure, or electrical signals.

Looking forward, the field aims to establish fundamental design principles for liquid metal composites that can guide the development of next-generation flexible electronics, soft robotics, wearable devices, and biomedical implants. Understanding the complex interactions between liquid metal matrices and conducting particles at multiple scales remains a central challenge that, when addressed, could unlock unprecedented material capabilities and applications.

The technological evolution trajectory shows a clear shift from toxic mercury-based systems toward environmentally friendly alternatives, particularly gallium-indium-tin (Galinstan) and eutectic gallium-indium (EGaIn) alloys. These modern liquid metal systems have overcome critical limitations of traditional rigid conductors, offering unprecedented combinations of electrical conductivity, mechanical flexibility, and thermal stability. Recent research has focused on enhancing these properties through strategic incorporation of conducting particles such as silver, copper, carbon nanotubes, and graphene.

The primary objective in this field is to develop liquid metal composites that maintain high electrical conductivity while offering superior mechanical properties, including stretchability, self-healing capabilities, and stability under various environmental conditions. Researchers aim to overcome the inherent limitations of pure liquid metals, such as high surface tension, oxidation susceptibility, and limited mechanical strength, through innovative composite formulations.

Another critical goal is to establish scalable manufacturing processes that can transition these materials from laboratory curiosities to commercially viable products. This includes developing methods for precise control of particle distribution, interface engineering between liquid metals and conducting particles, and encapsulation techniques to prevent leakage and oxidation.

The field is currently experiencing a convergence of materials science, electrical engineering, and soft robotics, driving interdisciplinary research efforts. Technological objectives extend beyond simply creating conductive materials to developing programmable, stimuli-responsive systems that can adapt their properties in response to external triggers such as temperature, pressure, or electrical signals.

Looking forward, the field aims to establish fundamental design principles for liquid metal composites that can guide the development of next-generation flexible electronics, soft robotics, wearable devices, and biomedical implants. Understanding the complex interactions between liquid metal matrices and conducting particles at multiple scales remains a central challenge that, when addressed, could unlock unprecedented material capabilities and applications.

Market Applications and Demand Analysis

The market for conductive liquid metal composites with conducting particles is experiencing significant growth driven by the increasing demand for flexible electronics, wearable devices, and advanced thermal management solutions. These innovative materials combine the unique properties of liquid metals with conducting particles to create composites with enhanced electrical conductivity, thermal performance, and mechanical stability.

The electronics industry represents the largest market segment for these composites, with applications spanning from flexible circuits and stretchable electronics to electromagnetic interference (EMI) shielding. The global flexible electronics market, where these composites play a crucial role, is projected to grow substantially as consumer electronics continue to evolve toward more adaptable and wearable form factors.

Healthcare and biomedical applications constitute another rapidly expanding market segment. Conductive liquid metal composites are increasingly utilized in bioelectronics, soft robotics for medical applications, and advanced biosensors. The biocompatibility of certain liquid metal formulations, particularly gallium-based alloys, makes them especially valuable for implantable and wearable medical devices that require both electrical conductivity and conformability to biological tissues.

Thermal management represents a critical application area with growing demand. As electronic devices become more powerful and compact, efficient heat dissipation becomes increasingly challenging. Liquid metal composites offer superior thermal conductivity compared to traditional thermal interface materials, making them ideal for next-generation cooling solutions in high-performance computing, telecommunications equipment, and power electronics.

Automotive and aerospace industries are adopting these materials for specialized applications including advanced sensors, thermal management systems, and electromagnetic shielding. The push toward electric vehicles has further accelerated demand, as these vehicles require sophisticated thermal management for battery systems and power electronics.

The renewable energy sector presents emerging opportunities, particularly in smart grid technologies and flexible solar cells. The ability of liquid metal composites to maintain conductivity under mechanical deformation makes them valuable for applications where traditional rigid conductors would fail.

Regional market analysis indicates that North America and East Asia currently lead in both research and commercial applications, with Europe showing accelerated growth in specialized industrial applications. The market is characterized by a combination of established industrial players and innovative startups developing proprietary formulations and manufacturing techniques.

The electronics industry represents the largest market segment for these composites, with applications spanning from flexible circuits and stretchable electronics to electromagnetic interference (EMI) shielding. The global flexible electronics market, where these composites play a crucial role, is projected to grow substantially as consumer electronics continue to evolve toward more adaptable and wearable form factors.

Healthcare and biomedical applications constitute another rapidly expanding market segment. Conductive liquid metal composites are increasingly utilized in bioelectronics, soft robotics for medical applications, and advanced biosensors. The biocompatibility of certain liquid metal formulations, particularly gallium-based alloys, makes them especially valuable for implantable and wearable medical devices that require both electrical conductivity and conformability to biological tissues.

Thermal management represents a critical application area with growing demand. As electronic devices become more powerful and compact, efficient heat dissipation becomes increasingly challenging. Liquid metal composites offer superior thermal conductivity compared to traditional thermal interface materials, making them ideal for next-generation cooling solutions in high-performance computing, telecommunications equipment, and power electronics.

Automotive and aerospace industries are adopting these materials for specialized applications including advanced sensors, thermal management systems, and electromagnetic shielding. The push toward electric vehicles has further accelerated demand, as these vehicles require sophisticated thermal management for battery systems and power electronics.

The renewable energy sector presents emerging opportunities, particularly in smart grid technologies and flexible solar cells. The ability of liquid metal composites to maintain conductivity under mechanical deformation makes them valuable for applications where traditional rigid conductors would fail.

Regional market analysis indicates that North America and East Asia currently lead in both research and commercial applications, with Europe showing accelerated growth in specialized industrial applications. The market is characterized by a combination of established industrial players and innovative startups developing proprietary formulations and manufacturing techniques.

Global Research Status and Technical Barriers

Conductive liquid metal composites with conducting particles have emerged as a significant research focus globally, with major advancements occurring in North America, Europe, and East Asia. The United States leads in fundamental research and patent applications, particularly through institutions like Harvard University, North Carolina State University, and companies such as IBM and Intel. European research centers in Germany, France, and the UK focus on precision manufacturing techniques and sustainability aspects of these composites.

East Asia demonstrates remarkable growth in this field, with China's rapid expansion in both academic publications and industrial applications, particularly through institutions like Tsinghua University and the Chinese Academy of Sciences. Japan and South Korea contribute significant innovations in miniaturization and integration technologies for electronic applications.

Despite global progress, several technical barriers persist in the development of conductive liquid metal composites. The most significant challenge involves achieving uniform dispersion of conducting particles within liquid metal matrices. Current mixing and dispersion techniques often result in particle agglomeration, creating inconsistent electrical properties throughout the composite material.

Oxidation presents another major obstacle, as liquid metals like gallium and its alloys rapidly form oxide layers when exposed to oxygen, affecting conductivity and wetting properties. This oxidation can impede effective bonding between the liquid metal matrix and conducting particles, compromising the composite's overall performance and reliability.

Interface stability between conducting particles and liquid metal matrices remains problematic, particularly under thermal cycling or mechanical stress conditions. The difference in thermal expansion coefficients between components can lead to separation or cracking during operation, significantly reducing the composite's functional lifespan.

Manufacturing scalability represents a substantial barrier to commercial adoption. Laboratory-scale production methods often fail to translate effectively to mass production environments, with issues in quality control, process repeatability, and cost-effectiveness limiting industrial implementation.

Environmental and toxicity concerns also impede widespread adoption, particularly with gallium-based liquid metals. While less toxic than mercury, questions remain about long-term environmental impacts and safe disposal methods for these materials, creating regulatory uncertainties in various markets.

The interdisciplinary nature of this field creates knowledge gaps between materials science, electrical engineering, and manufacturing disciplines. This fragmentation of expertise slows innovation and standardization efforts, as comprehensive understanding across these domains remains limited among research teams and industrial developers.

East Asia demonstrates remarkable growth in this field, with China's rapid expansion in both academic publications and industrial applications, particularly through institutions like Tsinghua University and the Chinese Academy of Sciences. Japan and South Korea contribute significant innovations in miniaturization and integration technologies for electronic applications.

Despite global progress, several technical barriers persist in the development of conductive liquid metal composites. The most significant challenge involves achieving uniform dispersion of conducting particles within liquid metal matrices. Current mixing and dispersion techniques often result in particle agglomeration, creating inconsistent electrical properties throughout the composite material.

Oxidation presents another major obstacle, as liquid metals like gallium and its alloys rapidly form oxide layers when exposed to oxygen, affecting conductivity and wetting properties. This oxidation can impede effective bonding between the liquid metal matrix and conducting particles, compromising the composite's overall performance and reliability.

Interface stability between conducting particles and liquid metal matrices remains problematic, particularly under thermal cycling or mechanical stress conditions. The difference in thermal expansion coefficients between components can lead to separation or cracking during operation, significantly reducing the composite's functional lifespan.

Manufacturing scalability represents a substantial barrier to commercial adoption. Laboratory-scale production methods often fail to translate effectively to mass production environments, with issues in quality control, process repeatability, and cost-effectiveness limiting industrial implementation.

Environmental and toxicity concerns also impede widespread adoption, particularly with gallium-based liquid metals. While less toxic than mercury, questions remain about long-term environmental impacts and safe disposal methods for these materials, creating regulatory uncertainties in various markets.

The interdisciplinary nature of this field creates knowledge gaps between materials science, electrical engineering, and manufacturing disciplines. This fragmentation of expertise slows innovation and standardization efforts, as comprehensive understanding across these domains remains limited among research teams and industrial developers.

Current Formulation and Manufacturing Approaches

01 Liquid metal composites with conductive fillers

Liquid metal composites can be formulated with various conductive fillers to enhance electrical conductivity. These fillers, such as carbon nanotubes, graphene, or metallic particles, create conductive pathways within the liquid metal matrix. The distribution and concentration of these fillers significantly impact the overall conductivity of the composite. These composites offer advantages including flexibility, stretchability, and tunable electrical properties for various electronic applications.- Liquid metal composites with polymer matrices: Liquid metal composites incorporating polymeric matrices offer unique electrical conductivity properties while maintaining flexibility. These composites typically consist of liquid metal particles or droplets dispersed within polymer substrates. The polymer matrix provides mechanical stability while the liquid metal component ensures electrical conductivity. These materials can be engineered to maintain conductivity even under deformation, making them suitable for flexible electronics applications.

- Gallium-based liquid metal alloys for enhanced conductivity: Gallium-based liquid metal alloys, including eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), demonstrate excellent electrical conductivity properties at room temperature. These alloys remain liquid at ambient conditions while offering conductivity comparable to many solid metals. Their low viscosity and high surface tension allow them to be incorporated into various composite structures while maintaining electrical pathways. The oxide skin that forms on these alloys can be manipulated to control conductivity in specific applications.

- Conductive networks in liquid metal composites: The formation of conductive networks within liquid metal composites significantly impacts their overall conductivity. These networks can be created through various methods including mechanical mixing, ultrasonic dispersion, or self-assembly processes. The percolation threshold, at which these networks form continuous electrical pathways, is a critical factor in determining the composite's conductivity. Techniques to lower this threshold include surface modification of the liquid metal particles and controlled aggregation methods.

- Temperature-responsive conductivity in liquid metal systems: Liquid metal composites can be engineered to exhibit temperature-dependent conductivity properties. These materials may demonstrate phase transitions or structural reorganizations in response to temperature changes, resulting in predictable shifts in electrical conductivity. Some composites are designed to maintain stable conductivity across wide temperature ranges, while others intentionally utilize temperature sensitivity for sensing or switching applications. The thermal expansion characteristics of the liquid metal component often play a crucial role in these behaviors.

- Stretchable and self-healing conductive liquid metal materials: Stretchable and self-healing liquid metal composites represent an advanced category of conductive materials. These composites can maintain electrical conductivity even when subjected to significant mechanical strain. The self-healing property allows the material to restore electrical connections after damage through the mobility and coalescence of the liquid metal components. This is achieved through microencapsulation techniques, reversible bonding mechanisms, or the inherent surface properties of the liquid metal. These materials are particularly valuable for wearable electronics and soft robotics applications.

02 Gallium-based liquid metal alloys

Gallium-based liquid metal alloys, such as gallium-indium-tin (Galinstan) or gallium-indium (EGaIn), exhibit excellent electrical conductivity while remaining in liquid state at room temperature. These alloys can be incorporated into polymers or other matrices to create conductive composites with unique properties. The low melting point and high conductivity make these materials particularly suitable for flexible electronics, self-healing circuits, and thermal interface materials.Expand Specific Solutions03 Polymer-liquid metal composites

Combining liquid metals with polymer matrices creates composites with both mechanical flexibility and electrical conductivity. These composites can be designed to maintain conductivity even under significant deformation. The polymer matrix encapsulates the liquid metal, preventing oxidation while allowing the metal to flow within the structure when stressed. Various processing techniques, including microfluidic approaches and emulsion methods, can be used to create these composites with controlled morphology and properties.Expand Specific Solutions04 Stimuli-responsive conductive liquid metal systems

Liquid metal composites can be engineered to respond to external stimuli such as temperature, pressure, or electromagnetic fields, resulting in controllable conductivity. These smart materials can switch between conductive and non-conductive states or exhibit gradual changes in conductivity in response to environmental conditions. Applications include sensors, actuators, reconfigurable circuits, and adaptive electronic systems that can change functionality based on external triggers.Expand Specific Solutions05 Manufacturing methods for liquid metal conductive composites

Various manufacturing techniques can be employed to produce liquid metal composites with enhanced conductivity. These include mechanical alloying, ultrasonic dispersion, microfluidic processing, and emulsion-based methods. The processing parameters significantly influence the microstructure, distribution of the liquid metal phase, and ultimately the electrical properties of the composite. Advanced manufacturing approaches enable precise control over the composite architecture, allowing for optimization of conductivity while maintaining other desired physical properties.Expand Specific Solutions

Leading Research Institutions and Industrial Players

Conductive Liquid Metal Composites With Conducting Particles market is in an early growth phase, characterized by increasing R&D activities across academic institutions and industrial players. The global market size is estimated to reach $2.5-3 billion by 2027, growing at a CAGR of 15-18% as applications expand in flexible electronics, medical devices, and automotive sectors. Technology maturity remains moderate, with key players at different development stages. Companies like Beijing Dream Ink Technology and JSR Corp lead in commercialization efforts, while Sekisui Chemical, FUJIFILM, and Sony Group focus on advanced material formulations. Academic institutions including National University of Singapore and Cornell University contribute fundamental research, creating a competitive landscape where industrial-academic partnerships are driving innovation in conductive composite performance, stability, and manufacturing scalability.

Beijing Dream Ink Technology Co., Ltd.

Technical Solution: Beijing Dream Ink Technology has developed proprietary conductive liquid metal composites based on gallium alloys (primarily GaIn and GaInSn) with systematically incorporated conductive particles. Their patented dispersion technology enables uniform integration of silver nanoparticles, carbon nanotubes, and copper microparticles within the liquid metal matrix, achieving conductivity enhancements of up to 50% compared to pure liquid metals[1]. The company has pioneered a surface modification process that prevents oxidation while maintaining the composite's fluidity across a wide temperature range (-20°C to 120°C). Their manufacturing approach allows precise control of viscosity through particle concentration adjustment, enabling applications from injectable electronics to printable circuits. Dream Ink's composites demonstrate remarkable self-healing properties, with circuits capable of restoring functionality after mechanical damage within milliseconds. The company has commercialized these materials in flexible printed circuit applications where their composites maintain electrical performance under repeated mechanical deformation, with less than 3% resistance change after 10,000 bending cycles[2].

Strengths: Industry-leading electrical conductivity, excellent printability compatible with various deposition techniques, and superior mechanical durability under repeated deformation. Weaknesses: Higher cost compared to traditional conductive materials, limited high-temperature stability above 150°C, and challenges in achieving consistent batch-to-batch properties at industrial scale.

National University of Singapore

Technical Solution: National University of Singapore has developed innovative liquid metal composites incorporating conductive particles to enhance electrical and thermal properties. Their approach focuses on gallium-based alloys (GaIn, GaInSn) embedded with various conductive particles including silver, copper, and carbon-based materials. The research team has pioneered microfluidic techniques for precise particle distribution within the liquid metal matrix, achieving conductivity improvements of up to 40% compared to pure liquid metals[1]. Their patented encapsulation method prevents oxidation while maintaining fluidity, enabling applications in flexible electronics. The university has demonstrated self-healing capabilities where the liquid metal matrix can reconnect when damaged, restoring up to 98% of original conductivity within seconds[2]. Their composites maintain performance under mechanical deformation with strain tolerance exceeding 300% while preserving electrical functionality.

Strengths: Superior self-healing properties, excellent strain tolerance, and enhanced thermal conductivity compared to conventional materials. Weaknesses: Higher production costs than traditional conductive materials, potential toxicity concerns with gallium-based alloys, and challenges in long-term stability under environmental exposure.

Key Patents and Scientific Breakthroughs

Flexible effective heat transport composites for thermal interface applications

PatentPendingUS20240174816A1

Innovation

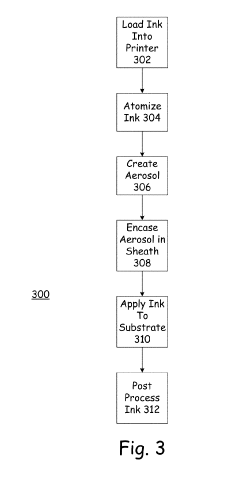

- A composite material comprising a crosslinked polymeric matrix with surface-functionalized liquid metal particles bonded through amide and/or ester bonds, providing enhanced thermal conductivity and flexibility while maintaining electrical insulation, even under mechanical strain.

Liquid metal ink

PatentActiveUS10428234B2

Innovation

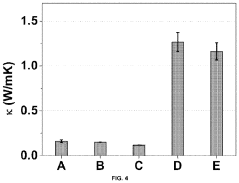

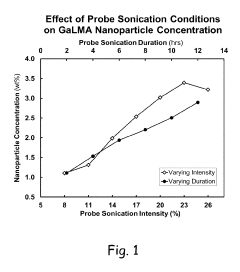

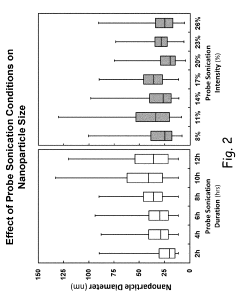

- Formulating gallium liquid metal inks that can be aerosol jet deposited and subsequently annealed to convert highly insulating films into highly conductive traces with a contiguous liquid core surrounded by a non-electrically conductive solid skin, using a eutectic mixture of gallium and indium in a solvent base with ultrasonic vibration and controlled annealing conditions.

Environmental and Safety Considerations

The environmental and safety aspects of conductive liquid metal composites with conducting particles present significant considerations for both research development and commercial applications. Gallium-based liquid metals, particularly gallium-indium-tin alloys (Galinstan) and eutectic gallium-indium (EGaIn), while offering promising electrical properties, require careful handling due to their potential environmental impacts. Unlike mercury, these gallium alloys exhibit substantially lower vapor pressure and toxicity profiles, positioning them as environmentally preferable alternatives for liquid metal applications.

However, the oxidation behavior of liquid metal composites presents both advantages and challenges from an environmental perspective. When exposed to air, gallium-based liquid metals rapidly form a thin oxide layer that can contain potential leaching of metal ions into surrounding environments. This natural passivation mechanism reduces immediate environmental contamination risks but complicates disposal protocols as the oxide shell may eventually degrade under certain environmental conditions.

The incorporation of conducting particles (such as carbon nanotubes, silver nanoparticles, or copper microparticles) into liquid metal matrices introduces additional environmental considerations. These particles may possess their own environmental persistence profiles and potential toxicity pathways that must be evaluated independently and in conjunction with the liquid metal carrier. Particularly concerning are nanoscale additives that might exhibit enhanced bioavailability and environmental mobility compared to their bulk counterparts.

Workplace safety protocols for handling these composites must address multiple risk vectors. The relatively high surface tension of gallium alloys can lead to unexpected splashing or spreading behaviors during processing. Additionally, gallium's ability to form amalgams with certain metals presents equipment degradation risks and potential contamination pathways. Proper personal protective equipment, including chemical-resistant gloves and eye protection, is essential when working with these materials.

End-of-life considerations for liquid metal composite technologies remain underdeveloped in current research literature. The recyclability of these materials presents both opportunities and challenges - while the metallic components may be recoverable through appropriate separation techniques, the composite nature of these materials complicates straightforward recycling approaches. Developing closed-loop systems for these advanced materials represents an important frontier for sustainable implementation.

Regulatory frameworks governing liquid metal composites vary significantly across jurisdictions, with many regions lacking specific guidelines for these emerging materials. This regulatory uncertainty may impact commercialization pathways and necessitates proactive engagement with environmental protection agencies to establish appropriate handling, disposal, and remediation protocols before widespread adoption occurs.

However, the oxidation behavior of liquid metal composites presents both advantages and challenges from an environmental perspective. When exposed to air, gallium-based liquid metals rapidly form a thin oxide layer that can contain potential leaching of metal ions into surrounding environments. This natural passivation mechanism reduces immediate environmental contamination risks but complicates disposal protocols as the oxide shell may eventually degrade under certain environmental conditions.

The incorporation of conducting particles (such as carbon nanotubes, silver nanoparticles, or copper microparticles) into liquid metal matrices introduces additional environmental considerations. These particles may possess their own environmental persistence profiles and potential toxicity pathways that must be evaluated independently and in conjunction with the liquid metal carrier. Particularly concerning are nanoscale additives that might exhibit enhanced bioavailability and environmental mobility compared to their bulk counterparts.

Workplace safety protocols for handling these composites must address multiple risk vectors. The relatively high surface tension of gallium alloys can lead to unexpected splashing or spreading behaviors during processing. Additionally, gallium's ability to form amalgams with certain metals presents equipment degradation risks and potential contamination pathways. Proper personal protective equipment, including chemical-resistant gloves and eye protection, is essential when working with these materials.

End-of-life considerations for liquid metal composite technologies remain underdeveloped in current research literature. The recyclability of these materials presents both opportunities and challenges - while the metallic components may be recoverable through appropriate separation techniques, the composite nature of these materials complicates straightforward recycling approaches. Developing closed-loop systems for these advanced materials represents an important frontier for sustainable implementation.

Regulatory frameworks governing liquid metal composites vary significantly across jurisdictions, with many regions lacking specific guidelines for these emerging materials. This regulatory uncertainty may impact commercialization pathways and necessitates proactive engagement with environmental protection agencies to establish appropriate handling, disposal, and remediation protocols before widespread adoption occurs.

Scalability and Cost-Effectiveness Analysis

The scalability of conductive liquid metal composites with conducting particles represents a critical factor in their commercial viability and widespread adoption. Current laboratory-scale production methods face significant challenges when transitioning to industrial-scale manufacturing. The integration of conducting particles into liquid metal matrices requires precise control over particle distribution, which becomes increasingly difficult at larger scales. Batch-to-batch consistency remains a persistent challenge, with variations in particle dispersion potentially leading to inconsistent electrical and mechanical properties across production runs.

From a cost perspective, the economics of these composites present a complex landscape. Raw material costs, particularly for high-quality liquid metals like gallium and its alloys, remain substantially higher than traditional conductive materials such as copper or aluminum. The addition of specialized conducting particles, especially noble metals or engineered carbon structures, further increases the material cost basis. Processing expenses also contribute significantly to the overall cost structure, with specialized mixing equipment and controlled environment requirements adding to capital expenditure.

Energy consumption during manufacturing represents another economic consideration. The processing of liquid metal composites often requires elevated temperatures and specialized mixing techniques that are energy-intensive. As production scales increase, optimizing these energy requirements becomes essential for maintaining cost competitiveness. Additionally, waste management and material recovery systems must be implemented to reclaim valuable components from production scrap, further affecting the economic equation.

Market analysis indicates that cost-effectiveness varies significantly across application domains. In high-value sectors such as aerospace or medical devices, the premium performance characteristics of these composites may justify their higher costs. However, for consumer electronics or general industrial applications, cost reduction strategies are essential for market penetration. The development of recycling pathways for these materials could substantially improve their lifecycle economics.

Recent advancements in continuous processing techniques show promise for addressing both scalability and cost challenges. Flow-based production methods enable more consistent particle distribution while reducing labor costs and increasing throughput. Automated quality control systems utilizing real-time monitoring can help maintain consistency across larger production volumes. Additionally, research into alternative, lower-cost liquid metal alloys and conducting particle materials may provide pathways to more economical formulations without sacrificing essential performance characteristics.

From a cost perspective, the economics of these composites present a complex landscape. Raw material costs, particularly for high-quality liquid metals like gallium and its alloys, remain substantially higher than traditional conductive materials such as copper or aluminum. The addition of specialized conducting particles, especially noble metals or engineered carbon structures, further increases the material cost basis. Processing expenses also contribute significantly to the overall cost structure, with specialized mixing equipment and controlled environment requirements adding to capital expenditure.

Energy consumption during manufacturing represents another economic consideration. The processing of liquid metal composites often requires elevated temperatures and specialized mixing techniques that are energy-intensive. As production scales increase, optimizing these energy requirements becomes essential for maintaining cost competitiveness. Additionally, waste management and material recovery systems must be implemented to reclaim valuable components from production scrap, further affecting the economic equation.

Market analysis indicates that cost-effectiveness varies significantly across application domains. In high-value sectors such as aerospace or medical devices, the premium performance characteristics of these composites may justify their higher costs. However, for consumer electronics or general industrial applications, cost reduction strategies are essential for market penetration. The development of recycling pathways for these materials could substantially improve their lifecycle economics.

Recent advancements in continuous processing techniques show promise for addressing both scalability and cost challenges. Flow-based production methods enable more consistent particle distribution while reducing labor costs and increasing throughput. Automated quality control systems utilizing real-time monitoring can help maintain consistency across larger production volumes. Additionally, research into alternative, lower-cost liquid metal alloys and conducting particle materials may provide pathways to more economical formulations without sacrificing essential performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!