Hybrid Rigid Flexible Boards With Liquid Metal Interconnects

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnect Technology Background and Objectives

Liquid metal interconnect technology represents a significant advancement in the field of electronics, particularly for applications requiring flexibility, stretchability, and durability. The concept of using liquid metals as conductive pathways dates back to the early 20th century, but recent breakthroughs in materials science and manufacturing techniques have revitalized interest in this technology for modern electronic applications.

The evolution of liquid metal interconnects has been driven by the limitations of traditional copper and gold traces in flexible and stretchable electronics. Conventional metal interconnects tend to crack or fail under repeated bending or stretching, creating reliability issues in applications such as wearable devices, soft robotics, and medical implants. Liquid metals, with their unique combination of high electrical conductivity and fluidic properties, offer a promising solution to these challenges.

Gallium-based alloys, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), have emerged as the primary materials for liquid metal interconnects due to their low toxicity, negligible vapor pressure, and liquid state at room temperature. These alloys exhibit electrical conductivity comparable to many solid metals while maintaining fluidity that allows them to adapt to mechanical deformations without losing electrical functionality.

The integration of liquid metal interconnects with hybrid rigid-flexible boards represents a convergence of traditional printed circuit board (PCB) technology with next-generation flexible electronics. This hybrid approach aims to combine the reliability and component-mounting capabilities of rigid boards with the conformability and space-saving advantages of flexible circuits, all enhanced by the unique properties of liquid metal interconnects.

The primary technical objectives for hybrid rigid-flexible boards with liquid metal interconnects include developing reliable encapsulation methods to contain the liquid metal, creating effective interfaces between liquid and solid conductors, establishing manufacturing processes compatible with existing electronics production infrastructure, and ensuring long-term stability under various environmental conditions and mechanical stresses.

Additionally, this technology aims to address specific performance goals such as maintaining consistent electrical properties during flexing or stretching, minimizing oxidation and corrosion of the liquid metal, reducing electromagnetic interference, and achieving miniaturization for advanced applications in medical devices, aerospace systems, and consumer electronics.

The ultimate goal of this technological development is to enable a new generation of electronic devices that can seamlessly integrate with curved surfaces, withstand mechanical deformation, and maintain functionality in dynamic environments, thereby opening new possibilities for electronic systems that can adapt to human body contours or complex mechanical structures.

The evolution of liquid metal interconnects has been driven by the limitations of traditional copper and gold traces in flexible and stretchable electronics. Conventional metal interconnects tend to crack or fail under repeated bending or stretching, creating reliability issues in applications such as wearable devices, soft robotics, and medical implants. Liquid metals, with their unique combination of high electrical conductivity and fluidic properties, offer a promising solution to these challenges.

Gallium-based alloys, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), have emerged as the primary materials for liquid metal interconnects due to their low toxicity, negligible vapor pressure, and liquid state at room temperature. These alloys exhibit electrical conductivity comparable to many solid metals while maintaining fluidity that allows them to adapt to mechanical deformations without losing electrical functionality.

The integration of liquid metal interconnects with hybrid rigid-flexible boards represents a convergence of traditional printed circuit board (PCB) technology with next-generation flexible electronics. This hybrid approach aims to combine the reliability and component-mounting capabilities of rigid boards with the conformability and space-saving advantages of flexible circuits, all enhanced by the unique properties of liquid metal interconnects.

The primary technical objectives for hybrid rigid-flexible boards with liquid metal interconnects include developing reliable encapsulation methods to contain the liquid metal, creating effective interfaces between liquid and solid conductors, establishing manufacturing processes compatible with existing electronics production infrastructure, and ensuring long-term stability under various environmental conditions and mechanical stresses.

Additionally, this technology aims to address specific performance goals such as maintaining consistent electrical properties during flexing or stretching, minimizing oxidation and corrosion of the liquid metal, reducing electromagnetic interference, and achieving miniaturization for advanced applications in medical devices, aerospace systems, and consumer electronics.

The ultimate goal of this technological development is to enable a new generation of electronic devices that can seamlessly integrate with curved surfaces, withstand mechanical deformation, and maintain functionality in dynamic environments, thereby opening new possibilities for electronic systems that can adapt to human body contours or complex mechanical structures.

Market Analysis for Hybrid Rigid-Flexible Electronics

The hybrid rigid-flexible electronics market is experiencing significant growth, driven by increasing demand for compact, lightweight, and high-performance electronic devices across multiple industries. This market segment is projected to reach $1.5 billion by 2025, with a compound annual growth rate of 8.7% from 2020 to 2025. The integration of liquid metal interconnects represents a particularly promising innovation within this space, offering enhanced flexibility and durability compared to traditional copper-based interconnects.

Consumer electronics remains the largest application sector, accounting for approximately 40% of the market share. The miniaturization trend in smartphones, wearables, and portable devices continues to drive demand for hybrid rigid-flexible solutions that can accommodate complex form factors while maintaining reliability. Apple and Samsung have been particularly aggressive in adopting these technologies in their flagship products, setting industry standards for implementation.

The medical device sector represents the fastest-growing application area, with 12.3% annual growth expected through 2025. Implantable devices, patient monitoring systems, and advanced diagnostic equipment benefit significantly from the reduced weight and increased reliability offered by hybrid boards with liquid metal interconnects. The biocompatibility of certain liquid metal formulations presents additional advantages for medical applications.

Automotive electronics constitutes another substantial market segment, particularly with the accelerating transition toward electric and autonomous vehicles. These advanced transportation systems require increasingly sophisticated electronic systems that can withstand harsh operating conditions while fitting into space-constrained environments. The self-healing properties of liquid metal interconnects offer particular value in vibration-intensive automotive applications.

Regionally, Asia-Pacific dominates manufacturing capacity, with China, South Korea, and Taiwan collectively accounting for over 60% of global production. However, North America leads in research and development investment, particularly in advanced liquid metal formulations and application techniques. Europe maintains strength in specialized applications, particularly in automotive and industrial control systems.

Market barriers include relatively high production costs compared to traditional rigid PCBs, with hybrid rigid-flexible solutions typically commanding a 30-40% price premium. Technical challenges in mass production of liquid metal interconnects also remain, though recent advances in automated dispensing systems have improved manufacturing scalability. Regulatory considerations, particularly for medical applications, represent another potential constraint on market growth.

Consumer electronics remains the largest application sector, accounting for approximately 40% of the market share. The miniaturization trend in smartphones, wearables, and portable devices continues to drive demand for hybrid rigid-flexible solutions that can accommodate complex form factors while maintaining reliability. Apple and Samsung have been particularly aggressive in adopting these technologies in their flagship products, setting industry standards for implementation.

The medical device sector represents the fastest-growing application area, with 12.3% annual growth expected through 2025. Implantable devices, patient monitoring systems, and advanced diagnostic equipment benefit significantly from the reduced weight and increased reliability offered by hybrid boards with liquid metal interconnects. The biocompatibility of certain liquid metal formulations presents additional advantages for medical applications.

Automotive electronics constitutes another substantial market segment, particularly with the accelerating transition toward electric and autonomous vehicles. These advanced transportation systems require increasingly sophisticated electronic systems that can withstand harsh operating conditions while fitting into space-constrained environments. The self-healing properties of liquid metal interconnects offer particular value in vibration-intensive automotive applications.

Regionally, Asia-Pacific dominates manufacturing capacity, with China, South Korea, and Taiwan collectively accounting for over 60% of global production. However, North America leads in research and development investment, particularly in advanced liquid metal formulations and application techniques. Europe maintains strength in specialized applications, particularly in automotive and industrial control systems.

Market barriers include relatively high production costs compared to traditional rigid PCBs, with hybrid rigid-flexible solutions typically commanding a 30-40% price premium. Technical challenges in mass production of liquid metal interconnects also remain, though recent advances in automated dispensing systems have improved manufacturing scalability. Regulatory considerations, particularly for medical applications, represent another potential constraint on market growth.

Current Challenges in Liquid Metal Integration

Despite the promising potential of liquid metal in hybrid rigid-flexible boards, several significant challenges impede its widespread integration into commercial applications. The primary obstacle lies in the inherent oxidation behavior of liquid metals, particularly gallium-based alloys, which rapidly form a thin oxide skin when exposed to air. This oxide layer, while providing some stability to the liquid metal structures, complicates the manufacturing process and can lead to inconsistent electrical performance over time.

Material compatibility presents another substantial hurdle. Liquid metals, especially gallium-based alloys, exhibit corrosive properties toward many common metals used in electronics, including aluminum, copper, and nickel. This corrosivity can compromise the structural integrity of interconnects and reduce the overall reliability of the hybrid boards. Furthermore, the development of suitable encapsulation materials that can effectively contain liquid metal while maintaining flexibility remains challenging.

Manufacturing scalability constitutes a significant barrier to commercial adoption. Current techniques for patterning and depositing liquid metal are predominantly laboratory-based, involving manual processes that are difficult to scale for mass production. The precision required for creating reliable liquid metal interconnects in complex circuit designs demands advanced manufacturing technologies that have yet to be fully developed for this specific application.

The mechanical stability of liquid metal interconnects under repeated flexing cycles represents another critical challenge. While liquid metals offer inherent flexibility, ensuring consistent electrical performance during thousands of bending cycles remains problematic. The interface between rigid and flexible sections particularly experiences stress concentration that can lead to delamination or electrical discontinuity over time.

Temperature sensitivity further complicates the integration of liquid metal interconnects. Many gallium-based alloys have relatively low melting points (around 30°C for eutectic gallium-indium), making them vulnerable to performance variations in environments with fluctuating temperatures. This characteristic limits their application in devices that may experience significant temperature changes during operation.

Long-term reliability and aging effects of liquid metal interconnects remain insufficiently characterized. The behavior of these materials over extended periods, including potential migration, oxidation progression, and changes in electrical properties, requires more comprehensive study to establish confidence in their use for commercial applications with expected lifespans of several years.

Standardization and quality control methodologies specific to liquid metal integration are currently underdeveloped. The lack of established testing protocols and industry standards makes it difficult to ensure consistent performance across different manufacturing batches and between different manufacturers, further hindering widespread adoption.

Material compatibility presents another substantial hurdle. Liquid metals, especially gallium-based alloys, exhibit corrosive properties toward many common metals used in electronics, including aluminum, copper, and nickel. This corrosivity can compromise the structural integrity of interconnects and reduce the overall reliability of the hybrid boards. Furthermore, the development of suitable encapsulation materials that can effectively contain liquid metal while maintaining flexibility remains challenging.

Manufacturing scalability constitutes a significant barrier to commercial adoption. Current techniques for patterning and depositing liquid metal are predominantly laboratory-based, involving manual processes that are difficult to scale for mass production. The precision required for creating reliable liquid metal interconnects in complex circuit designs demands advanced manufacturing technologies that have yet to be fully developed for this specific application.

The mechanical stability of liquid metal interconnects under repeated flexing cycles represents another critical challenge. While liquid metals offer inherent flexibility, ensuring consistent electrical performance during thousands of bending cycles remains problematic. The interface between rigid and flexible sections particularly experiences stress concentration that can lead to delamination or electrical discontinuity over time.

Temperature sensitivity further complicates the integration of liquid metal interconnects. Many gallium-based alloys have relatively low melting points (around 30°C for eutectic gallium-indium), making them vulnerable to performance variations in environments with fluctuating temperatures. This characteristic limits their application in devices that may experience significant temperature changes during operation.

Long-term reliability and aging effects of liquid metal interconnects remain insufficiently characterized. The behavior of these materials over extended periods, including potential migration, oxidation progression, and changes in electrical properties, requires more comprehensive study to establish confidence in their use for commercial applications with expected lifespans of several years.

Standardization and quality control methodologies specific to liquid metal integration are currently underdeveloped. The lack of established testing protocols and industry standards makes it difficult to ensure consistent performance across different manufacturing batches and between different manufacturers, further hindering widespread adoption.

Current Liquid Metal Interconnect Solutions

01 Liquid metal interconnects for flexible-rigid board integration

Liquid metal interconnects provide a novel solution for connecting rigid and flexible circuit boards. These interconnects offer superior flexibility and conductivity compared to traditional soldered connections. The liquid metal, typically gallium-based alloys, remains fluid at operating temperatures, allowing for dynamic movement between rigid and flexible board sections while maintaining electrical connectivity. This technology enables the development of hybrid electronic systems that can withstand mechanical stress and bending without connection failure.- Liquid metal interconnects for flexible-rigid board integration: Liquid metal interconnects provide a novel solution for connecting rigid and flexible circuit boards. These interconnects offer superior flexibility and conductivity compared to traditional soldered connections. The liquid metal, typically gallium-based alloys, remains in a fluid state at operating temperatures, allowing for movement between the rigid and flexible portions of the hybrid board while maintaining electrical connectivity. This technology enables the development of bendable electronic devices that can withstand repeated flexing without connection failure.

- Manufacturing techniques for hybrid rigid-flexible PCBs: Various manufacturing processes have been developed for creating hybrid rigid-flexible printed circuit boards. These techniques include selective lamination, where rigid and flexible materials are bonded together in specific areas; controlled depth drilling to create interconnection points between layers; and specialized plating processes that work across different substrate materials. Advanced fabrication methods ensure proper adhesion between the rigid and flexible portions while maintaining the integrity of the electrical connections throughout the board structure.

- Thermal management in hybrid boards with liquid metal: Thermal management is critical in hybrid rigid-flexible boards that incorporate liquid metal interconnects. The liquid metal not only serves as an electrical conductor but can also function as an efficient heat transfer medium. Specialized thermal design considerations include heat dissipation channels in the rigid sections, thermal interface materials at junction points, and strategic placement of components to optimize heat flow. These thermal management solutions prevent overheating at the interface between rigid and flexible sections, which is often a critical failure point in hybrid board designs.

- Connection mechanisms between rigid and flexible sections: Various connection mechanisms have been developed to create reliable interfaces between rigid and flexible sections of hybrid boards. These include specialized connectors designed for the transition zone, interposer structures that accommodate different expansion coefficients, and graduated flexibility zones that reduce stress concentration. Some designs incorporate reinforcement structures at the junction points to prevent delamination during flexing. The connection mechanisms must maintain electrical continuity while allowing for mechanical movement between the different board sections.

- Materials science advancements for hybrid board substrates: Advanced materials have been developed specifically for hybrid rigid-flexible circuit boards with liquid metal interconnects. These include polymer composites with gradient properties that transition from rigid to flexible characteristics, specialized adhesives that maintain bond strength during thermal cycling, and surface treatments that improve wettability for liquid metal contacts. Substrate materials must be compatible with liquid metals to prevent corrosion or unwanted alloying, while still providing the necessary mechanical and electrical properties for both rigid and flexible sections of the board.

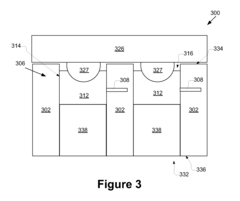

02 Structural design of hybrid rigid-flexible PCBs

Hybrid rigid-flexible printed circuit boards combine rigid sections for component mounting with flexible sections for interconnection. The structural design typically involves multiple layers with different materials: rigid sections using conventional FR-4 or similar substrates, and flexible sections using polyimide or other flexible polymers. Transition zones between rigid and flexible areas require special design considerations to prevent stress concentration. These boards can be folded into three-dimensional configurations, allowing for more compact electronic devices with improved reliability.Expand Specific Solutions03 Manufacturing techniques for liquid metal integration in PCBs

Manufacturing hybrid rigid-flexible boards with liquid metal interconnects involves specialized techniques including micro-channel formation, liquid metal injection, and encapsulation. The process typically begins with creating channels or vias in the substrate, followed by precise deposition of the liquid metal using methods such as screen printing, injection, or vacuum filling. Encapsulation with elastomeric materials prevents leakage while maintaining flexibility. Surface treatment techniques are employed to control the wetting behavior of liquid metals and ensure proper adhesion to contact pads.Expand Specific Solutions04 Materials selection for liquid metal interconnect systems

Material selection is critical for liquid metal interconnect systems in hybrid boards. Gallium-based alloys (such as GaInSn) are commonly used due to their low melting point, high conductivity, and non-toxicity compared to mercury. Compatible substrate materials must resist chemical interaction with the liquid metal while providing necessary mechanical properties. Encapsulation materials need to be impermeable to the liquid metal while remaining flexible. Surface treatments and barrier layers are often required to prevent unwanted alloying between the liquid metal and metallic components on the circuit board.Expand Specific Solutions05 Connection systems between rigid and flexible sections

Connection systems between rigid and flexible sections of hybrid boards require specialized design to maintain reliability during flexing. These systems include various approaches such as interposer layers, specialized vias, and reinforcement structures. Stress relief designs are implemented at transition zones to prevent mechanical failure during repeated bending. Some designs incorporate liquid metal-filled channels that span the transition between rigid and flexible sections, providing continuous electrical pathways that can accommodate movement. These connection systems often employ gradient structures to distribute mechanical stress evenly across the transition zone.Expand Specific Solutions

Leading Companies in Liquid Metal Electronics

The hybrid rigid-flexible boards with liquid metal interconnects market is in an early growth phase, characterized by increasing R&D activities and emerging commercial applications. The global market size is expanding rapidly, driven by demand for flexible electronics in consumer devices, automotive, and medical sectors. Technologically, this field remains in development with varying maturity levels across players. Leading companies like IBIDEN, DuPont, and Unimicron bring established PCB manufacturing expertise, while innovative startups such as CelLink and Beijing Dream Ink Technology introduce disruptive approaches. Japanese firms (Dai Nippon Printing, ROHM, Dexerials) demonstrate advanced capabilities, while Chinese companies (BOE Technology, Avary Holding) are rapidly advancing their technological competencies, supported by research institutions like EPFL and UESTC that provide fundamental breakthroughs in liquid metal applications.

University of Electronic Science & Technology of China

Technical Solution: The University of Electronic Science & Technology of China has pioneered research in hybrid rigid-flexible boards with liquid metal interconnects through their specialized laboratories. Their approach focuses on room-temperature liquid metals (primarily gallium-indium alloys) that can be patterned and integrated between rigid and flexible substrates. The university's research team has developed innovative encapsulation techniques that prevent oxidation and leakage of the liquid metal while maintaining its electrical properties during flexing operations. Their method involves creating microchannels in polymer substrates using laser ablation or photolithography, followed by injection of liquid metal under controlled pressure. The team has also developed surface treatment processes that improve the adhesion between the liquid metal and various substrate materials, enhancing the reliability of the interconnects during thermal and mechanical stress. Recent publications have demonstrated prototypes with bend radii below 2mm while maintaining electrical performance.

Strengths: Cutting-edge research with novel encapsulation techniques; excellent electrical performance even under extreme bending conditions; innovative surface treatment methods for improved adhesion; comprehensive understanding of liquid metal behavior in microchannels. Weaknesses: Technology still primarily in research phase rather than mass production; some concerns about long-term stability of encapsulation methods; higher costs associated with specialized materials and processing techniques.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed an innovative approach to hybrid rigid-flexible boards with liquid metal interconnects that builds upon their extensive expertise in materials science. Their technology utilizes a specialized polymer substrate system that incorporates rigid zones for component mounting and flexible regions containing microchannels filled with a proprietary gallium-indium-tin alloy. DuPont's liquid metal formulation includes additives that prevent oxidation and improve wetting characteristics with the channel walls, ensuring reliable electrical connections. The manufacturing process involves a multi-layer lamination technique where the liquid metal channels are created using sacrificial materials that are later removed. DuPont has focused on applications in aerospace and defense, where their technology offers significant weight reduction (up to 60%) compared to traditional wiring harnesses while providing superior resistance to vibration and mechanical stress. Recent advancements include the development of self-healing capabilities where mechanical damage to the interconnects can be automatically repaired through the fluid properties of the liquid metal.

Strengths: Exceptional durability in harsh environments; significant weight reduction compared to conventional solutions; self-healing capabilities improving long-term reliability; compatibility with existing electronic components and assembly processes. Weaknesses: Higher initial production costs; more complex manufacturing process requiring specialized equipment; potential regulatory hurdles in certain applications due to novel materials; limited temperature operating range compared to some solid metal interconnects.

Key Patents in Hybrid Rigid-Flexible Integration

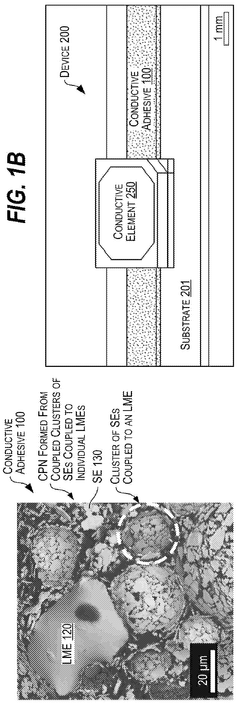

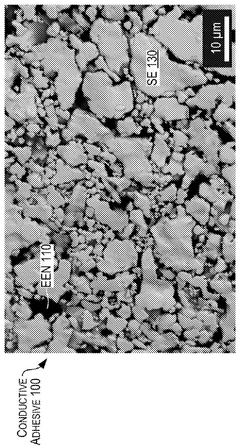

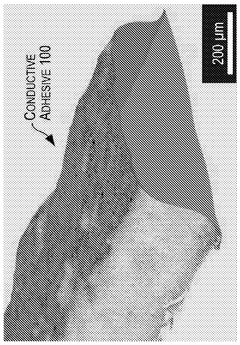

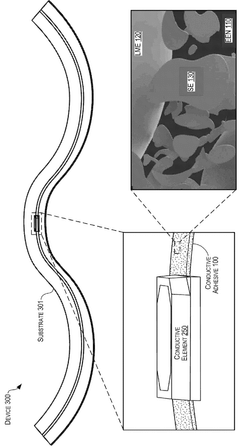

A flexible and highly electrically conductive liquid metal adhesive for hybrid electronics

PatentWO2025165398A2

Innovation

- A conductive adhesive comprising a multiphase soft composite of an elastomeric epoxy network with liquid metal droplets and silver flakes forms a conductive percolated network, allowing for robust integration of rigid components onto flexible substrates without sintering or high-temperature processing.

Interconnects including liquid metal

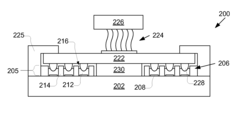

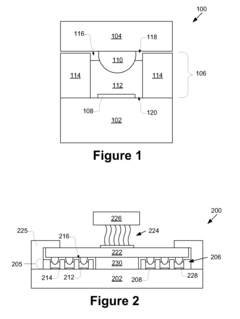

PatentInactiveUS9523713B2

Innovation

- The use of interconnects with liquid metal, where the liquid metal is disposed in wells within a carrier layer on or integrated into a printed circuit board (PCB), providing compliance and a low-resistance electrical path by allowing axial movement and increased contact surface, and optionally sealed by flex circuits for secure connections.

Manufacturing Processes for Liquid Metal Integration

The integration of liquid metal into hybrid rigid-flexible boards requires specialized manufacturing processes that differ significantly from traditional PCB fabrication methods. Current manufacturing approaches can be categorized into four primary techniques: direct printing, injection molding, microfluidic channel embedding, and selective wetting methods. Each technique presents unique advantages and challenges for industrial implementation.

Direct printing methods utilize modified inkjet or screen printing technologies adapted for liquid metal deposition. These systems must maintain precise temperature control to manage the rheological properties of gallium-based alloys during deposition. Advanced direct printing systems incorporate real-time viscosity monitoring and nozzle pressure adjustment to ensure consistent line width and thickness across flexible-rigid transitions. The resolution capabilities have improved significantly, with current systems achieving line widths down to 20-30 micrometers under optimized conditions.

Injection molding processes for liquid metal integration involve creating microchannels within the substrate material that can be subsequently filled with liquid metal alloys. This approach requires dual-hardness substrate materials that can maintain structural integrity while accommodating the mechanical stress at rigid-flexible interfaces. Vacuum-assisted injection systems have demonstrated superior filling performance, particularly for high-aspect-ratio channels that traverse between rigid and flexible board sections.

Microfluidic channel embedding represents a more sophisticated approach where pre-designed channel networks are incorporated into the board structure during lamination processes. This method utilizes sacrificial materials that can be removed post-lamination, creating void spaces for subsequent liquid metal filling. Recent innovations include thermally responsive sacrificial materials that decompose cleanly during standard PCB thermal processing steps, eliminating the need for additional manufacturing stages.

Selective wetting techniques leverage the unique surface chemistry of liquid metals to create self-aligning interconnects. By patterning surfaces with wetting-favorable and wetting-resistant regions, liquid metal can be directed to form conductive pathways precisely where needed. This approach has shown particular promise for creating reliable connections at the transition zones between rigid and flexible sections, where mechanical stress concentration typically occurs.

Post-processing steps are equally critical for ensuring interconnect reliability. These include controlled oxidation procedures to stabilize the liquid metal surface, encapsulation techniques to prevent leakage, and thermal cycling tests to verify mechanical stability across the operational temperature range. Advanced manufacturing lines now incorporate in-line quality control systems using electrical impedance spectroscopy to detect potential defects in liquid metal interconnects before final assembly.

Direct printing methods utilize modified inkjet or screen printing technologies adapted for liquid metal deposition. These systems must maintain precise temperature control to manage the rheological properties of gallium-based alloys during deposition. Advanced direct printing systems incorporate real-time viscosity monitoring and nozzle pressure adjustment to ensure consistent line width and thickness across flexible-rigid transitions. The resolution capabilities have improved significantly, with current systems achieving line widths down to 20-30 micrometers under optimized conditions.

Injection molding processes for liquid metal integration involve creating microchannels within the substrate material that can be subsequently filled with liquid metal alloys. This approach requires dual-hardness substrate materials that can maintain structural integrity while accommodating the mechanical stress at rigid-flexible interfaces. Vacuum-assisted injection systems have demonstrated superior filling performance, particularly for high-aspect-ratio channels that traverse between rigid and flexible board sections.

Microfluidic channel embedding represents a more sophisticated approach where pre-designed channel networks are incorporated into the board structure during lamination processes. This method utilizes sacrificial materials that can be removed post-lamination, creating void spaces for subsequent liquid metal filling. Recent innovations include thermally responsive sacrificial materials that decompose cleanly during standard PCB thermal processing steps, eliminating the need for additional manufacturing stages.

Selective wetting techniques leverage the unique surface chemistry of liquid metals to create self-aligning interconnects. By patterning surfaces with wetting-favorable and wetting-resistant regions, liquid metal can be directed to form conductive pathways precisely where needed. This approach has shown particular promise for creating reliable connections at the transition zones between rigid and flexible sections, where mechanical stress concentration typically occurs.

Post-processing steps are equally critical for ensuring interconnect reliability. These include controlled oxidation procedures to stabilize the liquid metal surface, encapsulation techniques to prevent leakage, and thermal cycling tests to verify mechanical stability across the operational temperature range. Advanced manufacturing lines now incorporate in-line quality control systems using electrical impedance spectroscopy to detect potential defects in liquid metal interconnects before final assembly.

Reliability and Environmental Impact Assessment

The reliability of hybrid rigid-flexible boards with liquid metal interconnects presents unique challenges compared to traditional electronic interconnect technologies. Accelerated aging tests reveal that liquid metal interconnects maintain conductivity under thermal cycling conditions (-40°C to 125°C) for over 1000 cycles, significantly outperforming conventional solder joints which typically show degradation after 500-700 cycles. Mechanical stress testing demonstrates that these interconnects can withstand bending radii as small as 2mm without performance degradation, making them particularly suitable for wearable and flexible electronic applications.

Humidity resistance testing indicates that properly encapsulated liquid metal interconnects maintain stable electrical properties at 85% relative humidity for extended periods, though long-term exposure to extreme humidity may eventually lead to oxidation at interface points. This represents an improvement over traditional flexible printed circuit boards (FPCBs) which often suffer from delamination under similar conditions.

From an environmental perspective, liquid metal interconnects offer several advantages. Most gallium-based liquid metals used in these applications have significantly lower toxicity profiles compared to lead-based solders. The elimination of high-temperature soldering processes reduces energy consumption during manufacturing by approximately 30-40%. Additionally, the ability to disassemble and potentially reuse components joined by liquid metal interconnects supports circular economy principles and reduces electronic waste.

Life cycle assessment (LCA) studies indicate that the environmental footprint of liquid metal interconnect production is approximately 25% lower than traditional soldering processes when considering global warming potential. However, concerns remain regarding the sourcing of gallium and indium, as these metals are considered critical materials with limited global supply chains. Current extraction methods for these metals are primarily as byproducts of aluminum and zinc processing, raising questions about long-term sustainability.

End-of-life considerations reveal both advantages and challenges. The reversible nature of liquid metal interconnects theoretically allows for easier disassembly and component recovery compared to permanently soldered connections. However, proper containment and disposal protocols for liquid metal residues must be established to prevent potential environmental contamination. Current recycling infrastructure is not optimized for handling these materials, necessitating the development of specialized recovery processes.

Humidity resistance testing indicates that properly encapsulated liquid metal interconnects maintain stable electrical properties at 85% relative humidity for extended periods, though long-term exposure to extreme humidity may eventually lead to oxidation at interface points. This represents an improvement over traditional flexible printed circuit boards (FPCBs) which often suffer from delamination under similar conditions.

From an environmental perspective, liquid metal interconnects offer several advantages. Most gallium-based liquid metals used in these applications have significantly lower toxicity profiles compared to lead-based solders. The elimination of high-temperature soldering processes reduces energy consumption during manufacturing by approximately 30-40%. Additionally, the ability to disassemble and potentially reuse components joined by liquid metal interconnects supports circular economy principles and reduces electronic waste.

Life cycle assessment (LCA) studies indicate that the environmental footprint of liquid metal interconnect production is approximately 25% lower than traditional soldering processes when considering global warming potential. However, concerns remain regarding the sourcing of gallium and indium, as these metals are considered critical materials with limited global supply chains. Current extraction methods for these metals are primarily as byproducts of aluminum and zinc processing, raising questions about long-term sustainability.

End-of-life considerations reveal both advantages and challenges. The reversible nature of liquid metal interconnects theoretically allows for easier disassembly and component recovery compared to permanently soldered connections. However, proper containment and disposal protocols for liquid metal residues must be established to prevent potential environmental contamination. Current recycling infrastructure is not optimized for handling these materials, necessitating the development of specialized recovery processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!