In Situ Repair Techniques For Damaged Liquid Metal Circuits

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Circuit Repair Background and Objectives

Liquid metal circuits represent a revolutionary advancement in flexible electronics, offering unique properties such as self-healing capabilities, excellent conductivity, and mechanical flexibility. The concept of liquid metal circuits emerged in the early 2000s, with gallium-based alloys (particularly gallium-indium-tin alloys like Galinstan) becoming the primary focus due to their low toxicity and room temperature liquidity compared to mercury-based alternatives.

The evolution of liquid metal circuit technology has accelerated significantly over the past decade, transitioning from laboratory curiosities to practical applications in wearable electronics, soft robotics, and biomedical devices. This rapid development has been driven by increasing demands for flexible, stretchable, and resilient electronic systems that can withstand mechanical deformation while maintaining functionality.

Despite their self-healing properties, liquid metal circuits remain vulnerable to various forms of damage, including oxidation, leakage, and mechanical disruption that exceeds their self-recovery capabilities. As these circuits find applications in increasingly critical systems, the need for effective in situ repair techniques has become paramount to ensure operational reliability and extend service life.

The primary objective of this technical research is to comprehensively evaluate existing and emerging in situ repair techniques for damaged liquid metal circuits. We aim to identify methodologies that can be implemented without removing the circuit from its operational environment, thereby minimizing downtime and avoiding the need for component replacement.

Secondary objectives include assessing the scalability of repair techniques from laboratory settings to field applications, evaluating the long-term reliability of repaired circuits, and identifying potential integration pathways for automated repair systems. Additionally, we seek to understand how repair techniques might be tailored to specific application environments, from consumer electronics to aerospace systems.

The technical landscape for liquid metal circuit repair spans multiple disciplines, including materials science, electrical engineering, and microfluidics. Current repair approaches range from simple mechanical interventions to sophisticated chemical treatments and electromagnetic manipulation techniques. Understanding the comparative efficacy of these methods across different damage scenarios represents a critical knowledge gap that this research aims to address.

As liquid metal electronics continue to penetrate mainstream applications, establishing standardized, effective repair protocols will become increasingly important for industry adoption. This research seeks to provide a foundation for such standardization by systematically evaluating repair techniques against metrics of effectiveness, implementation complexity, and long-term reliability.

The evolution of liquid metal circuit technology has accelerated significantly over the past decade, transitioning from laboratory curiosities to practical applications in wearable electronics, soft robotics, and biomedical devices. This rapid development has been driven by increasing demands for flexible, stretchable, and resilient electronic systems that can withstand mechanical deformation while maintaining functionality.

Despite their self-healing properties, liquid metal circuits remain vulnerable to various forms of damage, including oxidation, leakage, and mechanical disruption that exceeds their self-recovery capabilities. As these circuits find applications in increasingly critical systems, the need for effective in situ repair techniques has become paramount to ensure operational reliability and extend service life.

The primary objective of this technical research is to comprehensively evaluate existing and emerging in situ repair techniques for damaged liquid metal circuits. We aim to identify methodologies that can be implemented without removing the circuit from its operational environment, thereby minimizing downtime and avoiding the need for component replacement.

Secondary objectives include assessing the scalability of repair techniques from laboratory settings to field applications, evaluating the long-term reliability of repaired circuits, and identifying potential integration pathways for automated repair systems. Additionally, we seek to understand how repair techniques might be tailored to specific application environments, from consumer electronics to aerospace systems.

The technical landscape for liquid metal circuit repair spans multiple disciplines, including materials science, electrical engineering, and microfluidics. Current repair approaches range from simple mechanical interventions to sophisticated chemical treatments and electromagnetic manipulation techniques. Understanding the comparative efficacy of these methods across different damage scenarios represents a critical knowledge gap that this research aims to address.

As liquid metal electronics continue to penetrate mainstream applications, establishing standardized, effective repair protocols will become increasingly important for industry adoption. This research seeks to provide a foundation for such standardization by systematically evaluating repair techniques against metrics of effectiveness, implementation complexity, and long-term reliability.

Market Analysis for Self-Healing Electronic Systems

The self-healing electronic systems market is experiencing significant growth driven by increasing demand for reliable and durable electronic devices across multiple industries. Current market valuations indicate that the global self-healing electronics sector is expanding at a compound annual growth rate of approximately 19% and is projected to reach substantial market value by 2028. This growth trajectory is particularly relevant for liquid metal circuit technologies, which represent a promising segment within this broader market.

Consumer electronics constitutes the largest application segment, with smartphones, wearables, and portable devices manufacturers seeking to incorporate self-healing capabilities to extend product lifecycles and reduce warranty claims. The automotive industry follows closely, with increasing integration of electronics in vehicles creating demand for resilient circuitry that can withstand vibration, temperature fluctuations, and mechanical stress.

Market research indicates that aerospace and defense sectors are willing to pay premium prices for self-healing electronic systems due to the critical nature of their applications and the high cost of system failures. Healthcare devices represent another high-value segment, particularly for implantable medical devices where repair accessibility is severely limited.

Regional analysis shows North America currently leading the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate due to expanding electronics manufacturing capabilities and increasing adoption of advanced technologies in countries like China, South Korea, and Japan.

Key market drivers include the rising complexity of electronic systems, increasing miniaturization trends, and growing concerns about electronic waste. The ability of in situ repair techniques for liquid metal circuits to address these challenges positions this technology favorably within the market landscape.

Customer surveys reveal that manufacturers prioritize three key factors when considering self-healing electronic systems: reliability improvement metrics, implementation costs, and compatibility with existing manufacturing processes. The potential for liquid metal circuits to offer advantages across these dimensions suggests strong market receptivity.

Market barriers include concerns about long-term stability of self-healing mechanisms, regulatory uncertainties regarding novel materials, and the higher initial cost compared to conventional circuits. However, total cost of ownership analyses demonstrate that self-healing systems can provide significant savings over product lifecycles through reduced maintenance and replacement costs.

Consumer electronics constitutes the largest application segment, with smartphones, wearables, and portable devices manufacturers seeking to incorporate self-healing capabilities to extend product lifecycles and reduce warranty claims. The automotive industry follows closely, with increasing integration of electronics in vehicles creating demand for resilient circuitry that can withstand vibration, temperature fluctuations, and mechanical stress.

Market research indicates that aerospace and defense sectors are willing to pay premium prices for self-healing electronic systems due to the critical nature of their applications and the high cost of system failures. Healthcare devices represent another high-value segment, particularly for implantable medical devices where repair accessibility is severely limited.

Regional analysis shows North America currently leading the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate due to expanding electronics manufacturing capabilities and increasing adoption of advanced technologies in countries like China, South Korea, and Japan.

Key market drivers include the rising complexity of electronic systems, increasing miniaturization trends, and growing concerns about electronic waste. The ability of in situ repair techniques for liquid metal circuits to address these challenges positions this technology favorably within the market landscape.

Customer surveys reveal that manufacturers prioritize three key factors when considering self-healing electronic systems: reliability improvement metrics, implementation costs, and compatibility with existing manufacturing processes. The potential for liquid metal circuits to offer advantages across these dimensions suggests strong market receptivity.

Market barriers include concerns about long-term stability of self-healing mechanisms, regulatory uncertainties regarding novel materials, and the higher initial cost compared to conventional circuits. However, total cost of ownership analyses demonstrate that self-healing systems can provide significant savings over product lifecycles through reduced maintenance and replacement costs.

Current Challenges in Liquid Metal Circuit Repair

Despite significant advancements in liquid metal circuit technology, several critical challenges persist in developing effective in situ repair techniques. The inherent fluidity of liquid metals, while advantageous for creating flexible electronics, presents unique obstacles when attempting repairs in operational environments. Current repair methods struggle with precise control of liquid metal flow during the repair process, often resulting in unintended electrical connections or shorts that compromise circuit functionality.

Oxidation remains a formidable challenge, as most liquid metal alloys rapidly form oxide layers when exposed to air. This oxidation not only impedes proper wetting and adhesion during repairs but also alters the electrical properties of the repaired section. Existing techniques have yet to develop reliable methods for managing this oxidation in field conditions where controlled atmospheres are impractical.

The interface stability between original and repair materials represents another significant hurdle. Repaired sections frequently exhibit different mechanical and electrical properties compared to the original circuit, creating potential failure points under mechanical stress or thermal cycling. This heterogeneity in material properties compromises the long-term reliability of repaired circuits, particularly in applications subject to repeated deformation or environmental fluctuations.

Temperature sensitivity further complicates repair processes, as many liquid metal alloys exhibit significant changes in viscosity and surface tension with temperature variations. This sensitivity makes standardized repair protocols difficult to establish, as environmental conditions can dramatically affect repair outcomes. Current techniques lack robust temperature compensation mechanisms necessary for consistent field repairs.

Containment of liquid metals during repair operations presents ongoing difficulties, particularly for vertical or complex three-dimensional circuit geometries. Existing encapsulation methods often fail to adequately prevent liquid metal migration post-repair, leading to progressive circuit degradation over time. The development of effective, field-applicable containment solutions remains an active research challenge.

Tool miniaturization represents a practical limitation, as current repair instruments lack the precision required for increasingly miniaturized liquid metal circuit applications. The development of specialized micro-tools capable of manipulating small volumes of liquid metals with high spatial resolution is still in its infancy, limiting repair capabilities for advanced circuit designs.

Finally, quality assessment of completed repairs presents significant challenges, as non-destructive testing methods for liquid metal circuits remain underdeveloped. Current techniques provide limited insight into the internal structure and electrical continuity of repaired sections, making reliability predictions difficult and potentially compromising safety-critical applications.

Oxidation remains a formidable challenge, as most liquid metal alloys rapidly form oxide layers when exposed to air. This oxidation not only impedes proper wetting and adhesion during repairs but also alters the electrical properties of the repaired section. Existing techniques have yet to develop reliable methods for managing this oxidation in field conditions where controlled atmospheres are impractical.

The interface stability between original and repair materials represents another significant hurdle. Repaired sections frequently exhibit different mechanical and electrical properties compared to the original circuit, creating potential failure points under mechanical stress or thermal cycling. This heterogeneity in material properties compromises the long-term reliability of repaired circuits, particularly in applications subject to repeated deformation or environmental fluctuations.

Temperature sensitivity further complicates repair processes, as many liquid metal alloys exhibit significant changes in viscosity and surface tension with temperature variations. This sensitivity makes standardized repair protocols difficult to establish, as environmental conditions can dramatically affect repair outcomes. Current techniques lack robust temperature compensation mechanisms necessary for consistent field repairs.

Containment of liquid metals during repair operations presents ongoing difficulties, particularly for vertical or complex three-dimensional circuit geometries. Existing encapsulation methods often fail to adequately prevent liquid metal migration post-repair, leading to progressive circuit degradation over time. The development of effective, field-applicable containment solutions remains an active research challenge.

Tool miniaturization represents a practical limitation, as current repair instruments lack the precision required for increasingly miniaturized liquid metal circuit applications. The development of specialized micro-tools capable of manipulating small volumes of liquid metals with high spatial resolution is still in its infancy, limiting repair capabilities for advanced circuit designs.

Finally, quality assessment of completed repairs presents significant challenges, as non-destructive testing methods for liquid metal circuits remain underdeveloped. Current techniques provide limited insight into the internal structure and electrical continuity of repaired sections, making reliability predictions difficult and potentially compromising safety-critical applications.

Existing In Situ Repair Solutions

01 Self-healing liquid metal circuits

Liquid metal circuits can be designed with self-healing properties that allow them to automatically repair when damaged. These circuits utilize the unique properties of liquid metals such as gallium alloys that remain fluid at room temperature. When a circuit is broken or damaged, the liquid metal can flow back together, restoring electrical conductivity without external intervention. This self-healing mechanism is particularly valuable for applications requiring high reliability and durability.- Self-healing liquid metal circuits: Liquid metal circuits can be designed with self-healing properties that allow them to automatically repair when damaged. These circuits utilize the fluidity and surface tension properties of liquid metals like gallium alloys to reconnect broken pathways. When a circuit is damaged, the liquid metal can flow back together, restoring electrical conductivity without external intervention. This self-healing mechanism significantly improves the durability and reliability of electronic devices, particularly in applications where physical damage is likely to occur.

- Repair methods for liquid metal interconnects: Various methods have been developed for repairing damaged liquid metal interconnects in electronic circuits. These techniques include localized heating to reflow the liquid metal, injection of additional liquid metal material to bridge gaps, and application of electric fields to guide the liquid metal back into position. Some approaches use microfluidic channels to deliver fresh liquid metal to damaged areas. These repair methods can be performed manually or through automated systems, enabling the restoration of functionality to damaged circuits without replacing entire components.

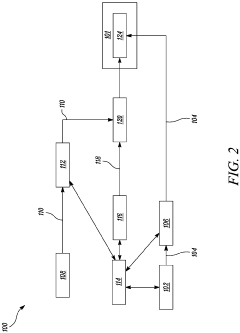

- Liquid metal circuit testing and fault detection: Advanced testing methods have been developed to identify faults in liquid metal circuits before implementing repairs. These systems use electrical resistance measurements, thermal imaging, and optical inspection techniques to precisely locate discontinuities or damage in liquid metal pathways. Some technologies incorporate real-time monitoring systems that can detect changes in circuit performance indicative of potential failures. Early detection of faults allows for preventive maintenance and targeted repairs, minimizing downtime and extending the operational life of liquid metal circuit systems.

- Encapsulation techniques for liquid metal circuit protection: Protective encapsulation methods have been developed to prevent damage to liquid metal circuits and reduce the need for repairs. These techniques involve surrounding the liquid metal pathways with flexible polymers, elastomers, or other protective materials that shield the circuits from environmental factors while maintaining their flexibility. Some encapsulation approaches incorporate self-healing polymers that work in conjunction with the liquid metal to provide multiple layers of repair capability. These protective measures significantly extend the lifespan of liquid metal circuits in harsh operating environments.

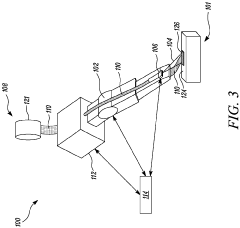

- Liquid metal circuit fabrication and repair equipment: Specialized equipment has been developed for both the fabrication and repair of liquid metal circuits. These systems include precision dispensing tools for applying liquid metal, controlled heating elements for managing viscosity during repairs, and microscopic manipulation tools for working with small-scale circuits. Some equipment incorporates computer vision and robotics to automate the repair process, ensuring consistent results. Advanced fabrication techniques also focus on creating more robust initial designs that minimize the need for future repairs by incorporating redundant pathways or reinforced junction points.

02 Repair methods for liquid metal interconnects

Various methods have been developed for repairing damaged liquid metal interconnects in electronic circuits. These techniques include localized heating to reflow the liquid metal, injection of additional liquid metal material to bridge gaps, and the use of encapsulation materials that guide the liquid metal back into position when damaged. These repair methods can be applied to flexible electronics, wearable devices, and other applications where traditional solid metal circuits would fail permanently when damaged.Expand Specific Solutions03 Liquid metal circuit fabrication and restoration

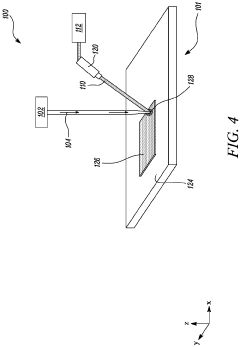

Specialized techniques for fabricating and restoring liquid metal circuits involve precise deposition methods and controlled environments. These include microfluidic approaches for creating channels that can be filled with liquid metal, patterning techniques that allow for complex circuit designs, and methods for ensuring proper adhesion to substrates. When circuits require repair, these same fabrication techniques can be adapted to restore functionality by reapplying liquid metal to damaged areas or replacing sections of the circuit.Expand Specific Solutions04 Display panel repair using liquid metal

Liquid metals are increasingly used for repairing defects in display panels and circuits. The technique involves identifying broken connections or defective pixels in display panels and using precisely controlled amounts of liquid metal to restore electrical pathways. This approach is particularly valuable for repairing high-resolution displays where conventional soldering would be impractical. The liquid metal can be injected into microscopic channels or directly applied to damaged areas to bridge disconnections.Expand Specific Solutions05 Memory and semiconductor device repair

Liquid metal technology is applied to repair defects in memory circuits and semiconductor devices. This involves using liquid metal to replace damaged interconnects or to create alternative pathways around defective components. The technique allows for post-manufacturing repair of complex integrated circuits, potentially increasing yield rates and extending the useful life of electronic devices. The repair process may involve laser-guided deposition of liquid metal or micromanipulation techniques to place the material precisely where needed.Expand Specific Solutions

Leading Companies and Research Institutions

The in situ repair of damaged liquid metal circuits is currently in an emerging phase, with the market showing significant growth potential as flexible electronics and self-healing technologies gain traction. The global market for self-healing electronic materials is expanding rapidly, estimated to reach several billion dollars by 2025. Technologically, the field remains in early maturity stages with varying approaches being developed. Leading semiconductor manufacturers like TSMC, GlobalFoundries, and IBM are investing in research for circuit repair technologies, while academic institutions including Tsinghua University and Nanjing University are advancing fundamental research. Companies like Apple and BOE Technology are exploring applications in consumer electronics. The competitive landscape features both established semiconductor giants developing proprietary solutions and specialized research institutions focusing on novel repair methodologies for liquid metal interconnects.

GLOBALFOUNDRIES, Inc.

Technical Solution: GLOBALFOUNDRIES has developed a comprehensive in situ repair system for liquid metal circuits targeting aerospace and defense applications. Their technology utilizes galinstan-based liquid metal alloys with modified surface properties to enhance flow characteristics during repair processes. The system incorporates a network of microfluidic reservoirs containing liquid metal that can be directed to damaged areas through electrochemically controlled channels. When damage is detected, the system applies localized electric fields to reduce the oxide layer on the liquid metal surface, enabling flow into fractured regions. GLOBALFOUNDRIES' approach includes integration of piezoelectric actuators that can physically manipulate liquid metal position with micrometer precision. Their research demonstrates successful repair of circuits under extreme temperature variations (-55°C to 125°C) and in high-vibration environments. The technology also incorporates redundant sensing mechanisms that can differentiate between temporary connection issues and permanent damage, optimizing when repair mechanisms are activated.

Strengths: Functions reliably in extreme environmental conditions; high precision repair capabilities; effective integration with existing semiconductor manufacturing processes. Weaknesses: Complex control systems increase power requirements; repair mechanisms add significant area overhead to circuits; limited scalability to very fine-pitch interconnects.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed an innovative in situ repair technology for liquid metal circuits focused on high-performance computing applications. Their approach utilizes a network of microscale liquid metal channels with controlled oxidation properties that enable self-healing when damage occurs. The system incorporates gallium-indium-tin alloys with precisely engineered surface tension characteristics that promote flow toward damaged areas. TSMC's technology features embedded thermal management systems that can locally heat damaged regions to reduce liquid metal viscosity, facilitating repair of severed connections. Their research demonstrates successful implementation in 3D stacked chip architectures, where traditional repair methods are impractical. The system can detect resistance changes as small as 0.1 ohm to identify potential failure points before complete circuit breakage occurs. TSMC has also developed specialized encapsulation materials that prevent liquid metal oxidation while maintaining repair capabilities throughout the device lifecycle.

Strengths: Highly responsive to minor damage before catastrophic failure; compatible with advanced packaging technologies; minimal performance impact after repairs. Weaknesses: Requires sophisticated monitoring systems; repair capability decreases over multiple damage-repair cycles; higher initial manufacturing complexity.

Key Patents and Technical Literature Review

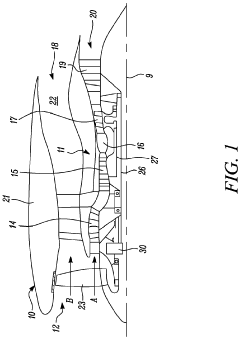

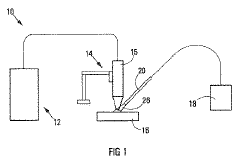

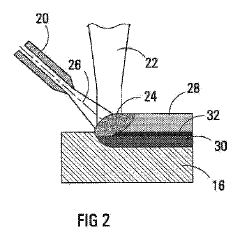

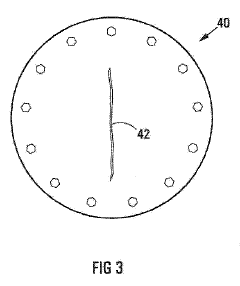

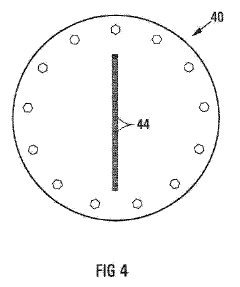

Repair system and method for in-situ repair of machine

PatentPendingEP4309840A1

Innovation

- A repair system utilizing a laser unit, galvanometer, and a continuous supply of flexible metallic mesh, which is deposited and laser-welded onto the machine surface, allowing for customizable repair patches with reduced wastage and improved efficiency, and optionally using shielding gas and ceramic coatings for enhanced performance.

How to repair metal work

PatentActiveJP2012512752A

Innovation

- A method involving cold forging to close defects followed by laser cladding with clad beads to form a continuous metal layer, allowing in-situ repair without draining the container.

Material Compatibility and Integration Issues

Material compatibility represents a critical challenge in the development and implementation of in situ repair techniques for damaged liquid metal circuits. The inherent chemical reactivity of liquid metals, particularly gallium-based alloys such as EGaIn and Galinstan, creates significant integration issues with surrounding materials. These liquid metals readily form amalgams with other metallic elements, potentially compromising the structural integrity of adjacent components. For instance, gallium-based liquid metals are known to embrittle aluminum and can penetrate grain boundaries in various metals, leading to mechanical failure over time.

Surface oxidation presents another substantial compatibility concern. When exposed to oxygen, liquid metals form a thin oxide layer that alters their surface tension and wetting properties. While this oxide skin can be beneficial for containing the liquid metal, it complicates repair processes by creating barriers to electrical connectivity and material adhesion during in situ repairs. The oxide layer's properties vary significantly with environmental conditions, making consistent repair protocols difficult to establish.

Substrate compatibility issues further complicate repair techniques. Many flexible and stretchable substrates used in advanced electronics, such as PDMS (polydimethylsiloxane) and other elastomers, may experience degradation when in prolonged contact with liquid metals. Chemical interactions between the substrate and liquid metal can lead to changes in mechanical properties, adhesion failures, or even electrical performance degradation. The permeation of liquid metal into porous substrates represents another challenge, potentially causing unintended electrical pathways or short circuits.

Temperature sensitivity creates additional integration challenges. The thermal expansion coefficient mismatch between liquid metals and surrounding materials can induce mechanical stress during temperature fluctuations, potentially compromising repaired connections. Furthermore, the phase transition temperatures of liquid metals must be considered when developing repair protocols for various operating environments, as solidification could negate the self-healing properties that make these materials valuable.

Encapsulation materials used to protect repaired circuits introduce their own compatibility concerns. These materials must maintain flexibility while preventing liquid metal leakage, remain chemically stable in contact with the liquid metal, and preserve the electrical properties of the circuit. Current encapsulation solutions often represent a compromise between these competing requirements, highlighting the need for advanced materials specifically designed for liquid metal circuit applications.

Surface oxidation presents another substantial compatibility concern. When exposed to oxygen, liquid metals form a thin oxide layer that alters their surface tension and wetting properties. While this oxide skin can be beneficial for containing the liquid metal, it complicates repair processes by creating barriers to electrical connectivity and material adhesion during in situ repairs. The oxide layer's properties vary significantly with environmental conditions, making consistent repair protocols difficult to establish.

Substrate compatibility issues further complicate repair techniques. Many flexible and stretchable substrates used in advanced electronics, such as PDMS (polydimethylsiloxane) and other elastomers, may experience degradation when in prolonged contact with liquid metals. Chemical interactions between the substrate and liquid metal can lead to changes in mechanical properties, adhesion failures, or even electrical performance degradation. The permeation of liquid metal into porous substrates represents another challenge, potentially causing unintended electrical pathways or short circuits.

Temperature sensitivity creates additional integration challenges. The thermal expansion coefficient mismatch between liquid metals and surrounding materials can induce mechanical stress during temperature fluctuations, potentially compromising repaired connections. Furthermore, the phase transition temperatures of liquid metals must be considered when developing repair protocols for various operating environments, as solidification could negate the self-healing properties that make these materials valuable.

Encapsulation materials used to protect repaired circuits introduce their own compatibility concerns. These materials must maintain flexibility while preventing liquid metal leakage, remain chemically stable in contact with the liquid metal, and preserve the electrical properties of the circuit. Current encapsulation solutions often represent a compromise between these competing requirements, highlighting the need for advanced materials specifically designed for liquid metal circuit applications.

Environmental Impact and Sustainability Considerations

The environmental implications of liquid metal circuit repair technologies represent a critical dimension of their overall viability. Traditional electronic waste management poses significant environmental challenges, with millions of tons of e-waste generated annually containing hazardous materials. In-situ repair techniques for liquid metal circuits offer promising sustainability advantages by extending device lifespans and reducing disposal frequency. This approach aligns with circular economy principles by maintaining products in use longer, thereby conserving resources and minimizing waste generation.

The composition of repair materials presents both opportunities and challenges from an environmental perspective. Gallium-based liquid metal alloys commonly used in these applications generally exhibit lower toxicity compared to mercury or lead-based alternatives. However, their environmental fate and potential bioaccumulation require further investigation, particularly as deployment scales increase. Self-healing formulations incorporating biodegradable components represent an emerging frontier that could further enhance environmental compatibility.

Energy consumption during repair processes must be considered within the sustainability framework. In-situ repair typically requires significantly less energy than manufacturing replacement components or devices, creating a favorable carbon footprint differential. Quantitative lifecycle assessments indicate potential energy savings of 60-85% when comparing repair to replacement scenarios, though these figures vary based on specific technologies and implementation methods.

Resource efficiency constitutes another environmental dimension of liquid metal circuit repair. These techniques typically utilize minimal material inputs compared to traditional manufacturing processes. Additionally, the ability to precisely target damaged areas minimizes waste generation during the repair process itself. Some advanced systems incorporate reclamation mechanisms that capture and reuse excess liquid metal, further enhancing resource efficiency.

Regulatory frameworks increasingly emphasize product repairability and environmental impact reduction. The European Union's Right to Repair initiatives and similar policies emerging globally create a favorable policy environment for in-situ repair technologies. Companies developing these solutions may gain competitive advantages through alignment with evolving environmental regulations and consumer preferences for sustainable electronics.

Future research directions should prioritize developing repair materials with enhanced biodegradability and reduced environmental persistence. Additionally, standardizing environmental impact assessment methodologies specific to liquid metal circuit repair would enable more accurate sustainability comparisons across different technological approaches. Integrating these considerations into early-stage technology development can ensure environmental sustainability becomes a fundamental design parameter rather than an afterthought.

The composition of repair materials presents both opportunities and challenges from an environmental perspective. Gallium-based liquid metal alloys commonly used in these applications generally exhibit lower toxicity compared to mercury or lead-based alternatives. However, their environmental fate and potential bioaccumulation require further investigation, particularly as deployment scales increase. Self-healing formulations incorporating biodegradable components represent an emerging frontier that could further enhance environmental compatibility.

Energy consumption during repair processes must be considered within the sustainability framework. In-situ repair typically requires significantly less energy than manufacturing replacement components or devices, creating a favorable carbon footprint differential. Quantitative lifecycle assessments indicate potential energy savings of 60-85% when comparing repair to replacement scenarios, though these figures vary based on specific technologies and implementation methods.

Resource efficiency constitutes another environmental dimension of liquid metal circuit repair. These techniques typically utilize minimal material inputs compared to traditional manufacturing processes. Additionally, the ability to precisely target damaged areas minimizes waste generation during the repair process itself. Some advanced systems incorporate reclamation mechanisms that capture and reuse excess liquid metal, further enhancing resource efficiency.

Regulatory frameworks increasingly emphasize product repairability and environmental impact reduction. The European Union's Right to Repair initiatives and similar policies emerging globally create a favorable policy environment for in-situ repair technologies. Companies developing these solutions may gain competitive advantages through alignment with evolving environmental regulations and consumer preferences for sustainable electronics.

Future research directions should prioritize developing repair materials with enhanced biodegradability and reduced environmental persistence. Additionally, standardizing environmental impact assessment methodologies specific to liquid metal circuit repair would enable more accurate sustainability comparisons across different technological approaches. Integrating these considerations into early-stage technology development can ensure environmental sustainability becomes a fundamental design parameter rather than an afterthought.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!