Printable Liquid Metal Inks For Stretchable Circuitry

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Inks Background and Objectives

Liquid metal inks represent a revolutionary advancement in the field of flexible electronics, with roots dating back to the early 2000s when researchers began exploring alternatives to rigid circuit materials. The evolution of this technology has been driven by the increasing demand for wearable devices, soft robotics, and biomedical applications that require electronic components capable of withstanding mechanical deformation while maintaining electrical functionality.

The journey of liquid metal inks began with gallium-based alloys, particularly gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), which offer unique properties of low toxicity, excellent electrical conductivity, and most importantly, liquid state at room temperature. These characteristics make them ideal candidates for stretchable circuitry applications where traditional rigid metals would fail under deformation.

Over the past decade, significant advancements have been made in transforming these liquid metals into printable inks through various methods including mechanical sintering, chemical modification, and nanoparticle formulation. The technical evolution has focused on overcoming challenges related to oxidation, adhesion to substrates, and developing suitable rheological properties for various printing techniques.

Current research trends are moving toward multi-functional liquid metal inks that combine electrical conductivity with additional properties such as self-healing capabilities, thermal conductivity, and electromagnetic shielding. These developments are expanding the potential application spectrum beyond simple conductive traces to complex integrated systems.

The primary technical objectives for printable liquid metal inks include achieving stable dispersion in carrier fluids, preventing oxidation during storage and application, ensuring consistent electrical performance under repeated mechanical strain, and developing compatibility with mass-production printing technologies such as screen printing, inkjet printing, and 3D printing.

Another critical goal is to optimize the interface between liquid metal inks and other materials in electronic systems, including polymers, textiles, and biological tissues, to create truly integrated stretchable electronic devices. This includes addressing challenges related to encapsulation, interface adhesion, and long-term reliability under various environmental conditions.

The ultimate aim of research in this field is to establish liquid metal inks as a standardized material platform for next-generation flexible electronics, enabling seamless integration of computational capabilities into everyday objects and even biological systems, thus supporting the vision of ubiquitous computing and the Internet of Things (IoT).

The journey of liquid metal inks began with gallium-based alloys, particularly gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), which offer unique properties of low toxicity, excellent electrical conductivity, and most importantly, liquid state at room temperature. These characteristics make them ideal candidates for stretchable circuitry applications where traditional rigid metals would fail under deformation.

Over the past decade, significant advancements have been made in transforming these liquid metals into printable inks through various methods including mechanical sintering, chemical modification, and nanoparticle formulation. The technical evolution has focused on overcoming challenges related to oxidation, adhesion to substrates, and developing suitable rheological properties for various printing techniques.

Current research trends are moving toward multi-functional liquid metal inks that combine electrical conductivity with additional properties such as self-healing capabilities, thermal conductivity, and electromagnetic shielding. These developments are expanding the potential application spectrum beyond simple conductive traces to complex integrated systems.

The primary technical objectives for printable liquid metal inks include achieving stable dispersion in carrier fluids, preventing oxidation during storage and application, ensuring consistent electrical performance under repeated mechanical strain, and developing compatibility with mass-production printing technologies such as screen printing, inkjet printing, and 3D printing.

Another critical goal is to optimize the interface between liquid metal inks and other materials in electronic systems, including polymers, textiles, and biological tissues, to create truly integrated stretchable electronic devices. This includes addressing challenges related to encapsulation, interface adhesion, and long-term reliability under various environmental conditions.

The ultimate aim of research in this field is to establish liquid metal inks as a standardized material platform for next-generation flexible electronics, enabling seamless integration of computational capabilities into everyday objects and even biological systems, thus supporting the vision of ubiquitous computing and the Internet of Things (IoT).

Market Analysis for Stretchable Electronics

The stretchable electronics market is experiencing rapid growth, driven by increasing demand for flexible, wearable technology across multiple sectors. Current market valuations place this segment at approximately $800 million globally, with projections indicating expansion to reach $2.4 billion by 2027, representing a compound annual growth rate of 21.3% during the forecast period. This growth trajectory significantly outpaces traditional rigid electronics markets, signaling a fundamental shift in consumer and industrial preferences.

Healthcare applications currently dominate the market landscape, accounting for nearly 40% of total market share. Medical devices incorporating stretchable circuits enable continuous health monitoring with improved patient comfort and data accuracy. The consumer electronics sector follows closely, with smart clothing, fitness trackers, and flexible displays driving adoption. Industrial applications, particularly in soft robotics and human-machine interfaces, represent the fastest-growing segment with 26% year-over-year growth.

Regional analysis reveals North America currently leads market development with 38% market share, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to expanding manufacturing capabilities and increasing investment in electronics innovation hubs in China, South Korea, and Japan.

Key market drivers include miniaturization trends in electronics, growing consumer demand for unobtrusive wearable devices, and increasing healthcare focus on remote patient monitoring. The COVID-19 pandemic has accelerated adoption of telehealth solutions, creating additional demand for comfortable, reliable body-worn sensing technologies.

Market challenges primarily center around manufacturing scalability, with current production methods for liquid metal inks facing limitations in mass production environments. Cost factors also present barriers to widespread adoption, as stretchable circuit materials and manufacturing processes typically command premium pricing compared to conventional electronics.

Consumer acceptance represents another critical market factor, with concerns about durability, washing resistance (for wearable applications), and long-term reliability influencing purchasing decisions. Market research indicates consumers are willing to pay a 15-20% premium for stretchable electronics over rigid alternatives, but only when demonstrable advantages in comfort and functionality are present.

The competitive landscape features both established electronics manufacturers expanding into stretchable technologies and specialized startups focused exclusively on flexible circuit innovations. This market structure is driving rapid innovation cycles, with patent filings related to printable conductive inks increasing by 34% annually over the past three years.

Healthcare applications currently dominate the market landscape, accounting for nearly 40% of total market share. Medical devices incorporating stretchable circuits enable continuous health monitoring with improved patient comfort and data accuracy. The consumer electronics sector follows closely, with smart clothing, fitness trackers, and flexible displays driving adoption. Industrial applications, particularly in soft robotics and human-machine interfaces, represent the fastest-growing segment with 26% year-over-year growth.

Regional analysis reveals North America currently leads market development with 38% market share, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to expanding manufacturing capabilities and increasing investment in electronics innovation hubs in China, South Korea, and Japan.

Key market drivers include miniaturization trends in electronics, growing consumer demand for unobtrusive wearable devices, and increasing healthcare focus on remote patient monitoring. The COVID-19 pandemic has accelerated adoption of telehealth solutions, creating additional demand for comfortable, reliable body-worn sensing technologies.

Market challenges primarily center around manufacturing scalability, with current production methods for liquid metal inks facing limitations in mass production environments. Cost factors also present barriers to widespread adoption, as stretchable circuit materials and manufacturing processes typically command premium pricing compared to conventional electronics.

Consumer acceptance represents another critical market factor, with concerns about durability, washing resistance (for wearable applications), and long-term reliability influencing purchasing decisions. Market research indicates consumers are willing to pay a 15-20% premium for stretchable electronics over rigid alternatives, but only when demonstrable advantages in comfort and functionality are present.

The competitive landscape features both established electronics manufacturers expanding into stretchable technologies and specialized startups focused exclusively on flexible circuit innovations. This market structure is driving rapid innovation cycles, with patent filings related to printable conductive inks increasing by 34% annually over the past three years.

Technical Challenges in Printable Liquid Metal

Despite significant advancements in printable liquid metal technology for stretchable circuitry, several technical challenges persist that hinder widespread commercial adoption. The primary obstacle involves controlling the rheological properties of liquid metal inks. Gallium-based alloys such as EGaIn and Galinstan exhibit high surface tension and tend to form oxide layers when exposed to air, making consistent extrusion and patterning difficult. This oxide skin formation, while beneficial for maintaining pattern integrity, complicates the printing process by causing nozzle clogging and inconsistent flow behavior.

Adhesion issues represent another significant challenge. Liquid metals typically demonstrate poor adhesion to most substrate materials, resulting in pattern delamination during stretching or bending cycles. Current solutions involving surface treatments or adhesion promoters add complexity to manufacturing processes and may compromise the electrical performance of the printed circuits.

The oxidation behavior of liquid metal inks presents a double-edged sword. While the oxide layer helps maintain pattern stability, it also increases electrical resistance at interfaces and complicates multi-layer fabrication. Controlling oxidation during the printing process remains technically challenging, particularly in high-volume manufacturing environments where exposure to oxygen cannot be completely eliminated.

Resolution limitations constitute another technical barrier. Current printing techniques struggle to achieve fine feature sizes below 50 micrometers with liquid metal inks due to their unique fluidic properties. This resolution constraint restricts application in advanced microelectronics where miniaturization is crucial.

Long-term stability issues also plague liquid metal printed circuits. Environmental factors such as humidity, temperature fluctuations, and mechanical stress can cause performance degradation over time. The migration of liquid metal under electrical bias represents another reliability concern that has not been fully addressed.

Scalability challenges further complicate commercial implementation. Current laboratory-scale fabrication methods often involve manual steps or specialized equipment that do not translate well to high-throughput manufacturing. The development of industrial-scale printing processes that maintain precision while increasing production speed remains an ongoing challenge.

Compatibility with existing electronic components and integration into conventional manufacturing workflows presents additional hurdles. Liquid metal's unique properties require specialized handling and processing techniques that may not align with established electronics manufacturing protocols, necessitating significant adaptation of existing production lines or development of entirely new fabrication approaches.

Adhesion issues represent another significant challenge. Liquid metals typically demonstrate poor adhesion to most substrate materials, resulting in pattern delamination during stretching or bending cycles. Current solutions involving surface treatments or adhesion promoters add complexity to manufacturing processes and may compromise the electrical performance of the printed circuits.

The oxidation behavior of liquid metal inks presents a double-edged sword. While the oxide layer helps maintain pattern stability, it also increases electrical resistance at interfaces and complicates multi-layer fabrication. Controlling oxidation during the printing process remains technically challenging, particularly in high-volume manufacturing environments where exposure to oxygen cannot be completely eliminated.

Resolution limitations constitute another technical barrier. Current printing techniques struggle to achieve fine feature sizes below 50 micrometers with liquid metal inks due to their unique fluidic properties. This resolution constraint restricts application in advanced microelectronics where miniaturization is crucial.

Long-term stability issues also plague liquid metal printed circuits. Environmental factors such as humidity, temperature fluctuations, and mechanical stress can cause performance degradation over time. The migration of liquid metal under electrical bias represents another reliability concern that has not been fully addressed.

Scalability challenges further complicate commercial implementation. Current laboratory-scale fabrication methods often involve manual steps or specialized equipment that do not translate well to high-throughput manufacturing. The development of industrial-scale printing processes that maintain precision while increasing production speed remains an ongoing challenge.

Compatibility with existing electronic components and integration into conventional manufacturing workflows presents additional hurdles. Liquid metal's unique properties require specialized handling and processing techniques that may not align with established electronics manufacturing protocols, necessitating significant adaptation of existing production lines or development of entirely new fabrication approaches.

Current Printing Methods for Liquid Metal Inks

01 Liquid metal ink compositions for stretchable electronics

Liquid metal inks can be formulated with specific compositions to enhance stretchability for flexible electronic applications. These formulations typically include gallium-based alloys (such as gallium-indium or gallium-indium-tin) combined with suitable solvents and stabilizers that maintain the metallic properties while allowing the material to stretch without breaking electrical conductivity. The particle size and distribution within these inks significantly impact their stretchable performance, with nano and micro-sized particles offering different advantages for printability and elasticity.- Liquid metal ink compositions for stretchable electronics: Liquid metal inks can be formulated with specific compositions to enhance stretchability for flexible electronic applications. These compositions typically include gallium-based alloys (such as gallium-indium or gallium-indium-tin) that remain liquid at room temperature. The formulation may include additives that prevent oxidation while maintaining the metal's liquid state, allowing the ink to stretch without breaking electrical conductivity. These inks can be printed onto various substrates and maintain functionality even when subjected to significant mechanical deformation.

- Substrate materials and surface treatments for stretchable liquid metal printing: The choice of substrate material and its surface treatment significantly impacts the stretchability of printed liquid metal inks. Elastomeric substrates such as PDMS, silicone, or specialized polymers can be treated to improve adhesion and stretchability of the liquid metal ink. Surface modifications may include plasma treatment, chemical functionalization, or application of adhesion promoters that create strong interfacial bonding while allowing the substrate to stretch without delamination of the printed metal. These treatments enable the printed circuits to withstand repeated stretching cycles without performance degradation.

- Encapsulation techniques for stretchable liquid metal circuits: Encapsulation methods are crucial for protecting stretchable liquid metal circuits while maintaining their flexibility. Various elastomeric encapsulants can be applied over printed liquid metal traces to prevent oxidation, mechanical damage, and leakage during stretching. The encapsulation layer must bond well with both the substrate and the liquid metal while possessing similar mechanical properties to ensure uniform stretching. Advanced multi-layer encapsulation techniques can provide additional protection while allowing the entire system to stretch without compromising the electrical performance of the liquid metal circuits.

- Printing methods for stretchable liquid metal inks: Various printing techniques can be employed to deposit stretchable liquid metal inks, each offering different advantages for stretchability. Direct-write methods, screen printing, inkjet printing, and microcontact printing have been adapted for liquid metal deposition. The printing method affects the morphology, thickness, and pattern resolution of the liquid metal traces, which in turn influence stretchability. Some techniques incorporate pre-stretching of the substrate during printing, allowing the deposited metal to form wavy or serpentine patterns that can accommodate greater strain when the substrate returns to its relaxed state.

- Additives and fillers to enhance stretchability of liquid metal inks: Incorporating specific additives and fillers into liquid metal inks can significantly improve their stretchability. Nanomaterials such as carbon nanotubes, silver nanowires, or elastomeric particles can be dispersed within the liquid metal to create composite inks with enhanced mechanical properties. These additives can prevent the liquid metal from breaking into isolated droplets during stretching by maintaining continuous electrical pathways. Additionally, certain surfactants and polymeric binders can modify the surface tension and rheological properties of the ink, improving both printability and stretchable performance after deposition.

02 Substrate materials and surface treatments for stretchable printed circuits

The choice of substrate material and its surface treatment plays a crucial role in the stretchability of printed liquid metal circuits. Elastomeric substrates such as PDMS, silicone, or specialized polymers can be modified through plasma treatment, chemical functionalization, or mechanical patterning to improve adhesion with liquid metal inks. These treatments create micro or nano-scale surface features that enhance the mechanical interlocking between the printed metal and the substrate, allowing the entire system to withstand repeated stretching cycles without delamination or electrical failure.Expand Specific Solutions03 Encapsulation techniques for stretchable liquid metal circuits

Encapsulation methods significantly enhance the stretchability and durability of printed liquid metal circuits. By sandwiching the printed patterns between layers of elastic materials or using specialized encapsulants that bond with both the substrate and the liquid metal, the overall mechanical stability is improved. These protective layers prevent oxidation of the liquid metal, maintain electrical performance during deformation, and distribute mechanical stress more evenly across the circuit. Various encapsulation materials including silicones, polyurethanes, and specialized elastomers can be selected based on the specific application requirements.Expand Specific Solutions04 Printing methods optimized for stretchable liquid metal inks

Specialized printing techniques have been developed to optimize the deposition of liquid metal inks for maximum stretchability. These include direct writing, screen printing, inkjet printing, and micro-contact printing methods that have been modified to accommodate the unique rheological properties of liquid metals. The printing parameters such as nozzle size, printing speed, substrate temperature, and curing conditions significantly affect the morphology of the printed patterns and consequently their stretchable performance. Multi-layer printing approaches can create structures with engineered strain distribution that enhance overall stretchability.Expand Specific Solutions05 Additives and fillers for enhanced stretchability

Various additives and fillers can be incorporated into liquid metal inks to enhance their stretchability while maintaining electrical conductivity. These include elastomeric polymers, conductive nanoparticles, surfactants, and specialized binding agents that modify the mechanical properties of the printed structures. Some formulations include self-healing components that can reconnect broken circuits when stretched beyond their limits and then relaxed. The concentration and distribution of these additives must be carefully controlled to achieve the optimal balance between electrical performance and mechanical stretchability.Expand Specific Solutions

Leading Companies in Liquid Metal Ink Development

The printable liquid metal inks for stretchable circuitry market is in its growth phase, characterized by increasing adoption across flexible electronics applications. The global market is expanding rapidly, driven by demand in wearable technology, healthcare devices, and automotive sectors. Technologically, the field shows varying maturity levels with companies like Beijing Dream Ink Technology leading with specialized electronic additive manufacturing solutions, while established corporations such as Samsung SDI, Henkel, and Xerox are leveraging their manufacturing expertise to develop commercial applications. Research institutions including Karlsruher Institut für Technologie and National Center for Nanoscience & Technology are advancing fundamental innovations, while companies like Nanotech Energy and Jabil are focusing on scaling production processes. The competitive landscape features a mix of specialized startups, established electronics manufacturers, and chemical companies developing proprietary formulations.

Beijing Dream Ink Technology Co., Ltd.

Technical Solution: Beijing Dream Ink has developed a proprietary liquid metal ink formulation based on gallium-indium alloys that maintains fluidity at room temperature while offering excellent electrical conductivity. Their technology employs surface oxide engineering to stabilize liquid metal particles in various carrier solutions, enabling direct printing on multiple substrate materials. The company's process involves micro/nano-particle formation through ultrasonic dispersion and chemical modification to prevent particle aggregation, resulting in stable ink formulations with viscosity profiles optimized for different printing methods (inkjet, screen printing, and direct writing). Their inks maintain conductivity even when stretched to 300% of original length[1], with self-healing properties that allow the liquid metal particles to reconnect after mechanical deformation, restoring electrical pathways automatically. Dream Ink has also developed specialized adhesion promoters that enhance bonding between their liquid metal inks and various elastomeric substrates, addressing one of the key challenges in stretchable electronics.

Strengths: Superior stretchability while maintaining conductivity, self-healing capabilities that restore electrical connections after deformation, and compatibility with multiple printing technologies. Weaknesses: Higher cost compared to conventional conductive inks, potential oxidation issues in certain environments, and limited shelf life requiring special storage conditions.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered a liquid metal ink technology based on eutectic gallium-indium (EGaIn) alloys with proprietary additives that enhance printability and adhesion to flexible substrates. Their formulation incorporates nanoscale metal particles suspended in a polymer matrix that can be precisely deposited using modified inkjet printing systems. The company has developed a multi-layer printing approach where an initial adhesion layer is deposited, followed by the liquid metal ink, and finally a protective encapsulation layer that prevents oxidation while maintaining flexibility. This sandwich structure allows their circuits to withstand repeated stretching cycles (>10,000 cycles at 50% strain) without significant degradation in electrical performance[2]. Samsung's technology includes post-processing techniques such as selective sintering using low-temperature plasma treatment that enhances conductivity while preserving substrate integrity. Their liquid metal inks demonstrate resistance changes of less than 20% when stretched to twice their original length, making them suitable for applications in wearable electronics and biomedical devices[3].

Strengths: Excellent durability under repeated stretching cycles, sophisticated multi-layer architecture that protects the conductive material, and compatibility with existing manufacturing equipment. Weaknesses: Complex manufacturing process requiring precise control of multiple parameters, higher production costs than traditional printed electronics, and potential environmental concerns with gallium-based materials.

Key Patents in Printable Liquid Metal Technology

Optimized solvent-based liquid metal compositions and methods of using same

PatentPendingUS20240132739A1

Innovation

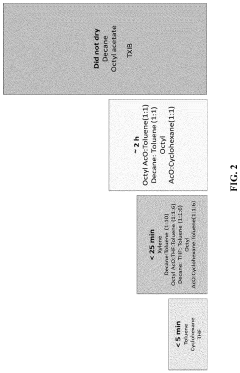

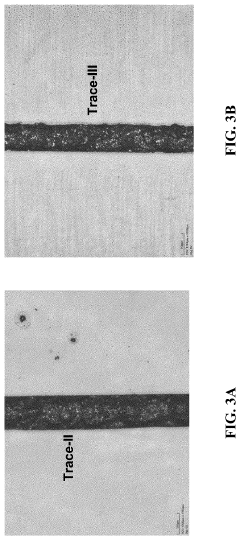

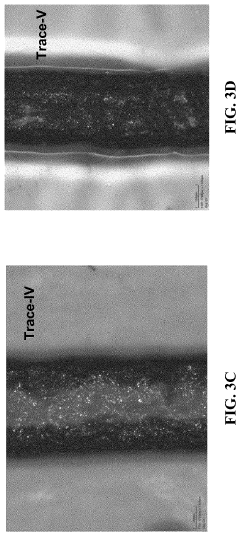

- An optimized solvent-based liquid metal composition is developed, incorporating a polymeric binder and a solvent mixture that extends decap time while maintaining electrical conductivity, including solvents like TXIB and toluene, and a metallic filler to enhance stability and conductivity.

Highly conductive, printable ink for highly stretchable soft electronics and highly conductive, ultra-stretchable conductors obtainable therefrom

PatentWO2020182408A1

Innovation

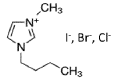

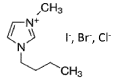

- A highly conductive, printable ink is developed using a capillary suspension phenomenon with 1.5 to 21 vol% conductive hydrophobic silver particles, a thermoplastic polyurethane (TPU) as the polymer base, and an ionic liquid secondary phase, which creates a capillary suspension that self-assembles into a percolating network, achieving high conductivity with low silver consumption and high stretchability.

Biocompatibility and Safety Considerations

The biocompatibility and safety of printable liquid metal inks represent critical considerations for their application in stretchable circuitry, particularly for wearable electronics and biomedical devices that interface directly with human skin or tissues. Gallium-based liquid metals, such as eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), have emerged as primary candidates for these applications due to their favorable electrical properties and mechanical flexibility.

Current research indicates that gallium-based liquid metals exhibit relatively low toxicity compared to traditional conductive materials like mercury. Studies have demonstrated that gallium compounds show minimal cytotoxicity in controlled laboratory environments, with limited cellular damage observed in short-term exposure scenarios. However, long-term biocompatibility studies remain insufficient, particularly regarding chronic exposure effects and potential accumulation in tissues.

The oxidation behavior of liquid metals presents both advantages and challenges from a safety perspective. The thin oxide layer that forms on the surface of gallium alloys can serve as a protective barrier, potentially reducing direct contact between the metallic core and biological tissues. This natural passivation mechanism may enhance biocompatibility, though the stability of this oxide layer under various physiological conditions requires further investigation.

Encapsulation strategies have been developed to mitigate potential safety concerns. Polymeric encapsulants such as polydimethylsiloxane (PDMS), polyurethane, and various hydrogels can effectively isolate liquid metal components from direct biological contact while maintaining the mechanical properties necessary for stretchable applications. These encapsulation methods must balance impermeability to the liquid metal with flexibility and durability under repeated deformation.

Leaching potential represents a significant safety consideration, particularly for implantable or long-term wearable applications. While gallium has limited water solubility, the potential for ion release under specific environmental conditions or mechanical stress cannot be dismissed. Recent studies have begun quantifying leaching rates under simulated physiological conditions, though standardized testing protocols remain underdeveloped.

Regulatory considerations for liquid metal inks in biomedical applications present additional challenges. Current frameworks for evaluating electronic materials in medical devices may not adequately address the unique properties of liquid metals. The FDA and equivalent international regulatory bodies have not established specific guidelines for these materials, necessitating comprehensive safety documentation for any commercial applications involving human contact.

Future research directions should focus on standardized biocompatibility testing protocols specifically designed for liquid metal systems, investigation of potential long-term immunological responses, and development of advanced encapsulation technologies that can guarantee containment while maintaining electrical and mechanical performance.

Current research indicates that gallium-based liquid metals exhibit relatively low toxicity compared to traditional conductive materials like mercury. Studies have demonstrated that gallium compounds show minimal cytotoxicity in controlled laboratory environments, with limited cellular damage observed in short-term exposure scenarios. However, long-term biocompatibility studies remain insufficient, particularly regarding chronic exposure effects and potential accumulation in tissues.

The oxidation behavior of liquid metals presents both advantages and challenges from a safety perspective. The thin oxide layer that forms on the surface of gallium alloys can serve as a protective barrier, potentially reducing direct contact between the metallic core and biological tissues. This natural passivation mechanism may enhance biocompatibility, though the stability of this oxide layer under various physiological conditions requires further investigation.

Encapsulation strategies have been developed to mitigate potential safety concerns. Polymeric encapsulants such as polydimethylsiloxane (PDMS), polyurethane, and various hydrogels can effectively isolate liquid metal components from direct biological contact while maintaining the mechanical properties necessary for stretchable applications. These encapsulation methods must balance impermeability to the liquid metal with flexibility and durability under repeated deformation.

Leaching potential represents a significant safety consideration, particularly for implantable or long-term wearable applications. While gallium has limited water solubility, the potential for ion release under specific environmental conditions or mechanical stress cannot be dismissed. Recent studies have begun quantifying leaching rates under simulated physiological conditions, though standardized testing protocols remain underdeveloped.

Regulatory considerations for liquid metal inks in biomedical applications present additional challenges. Current frameworks for evaluating electronic materials in medical devices may not adequately address the unique properties of liquid metals. The FDA and equivalent international regulatory bodies have not established specific guidelines for these materials, necessitating comprehensive safety documentation for any commercial applications involving human contact.

Future research directions should focus on standardized biocompatibility testing protocols specifically designed for liquid metal systems, investigation of potential long-term immunological responses, and development of advanced encapsulation technologies that can guarantee containment while maintaining electrical and mechanical performance.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of printable liquid metal inks for stretchable circuitry represents a critical factor in their commercial viability. Current production methods primarily operate at laboratory scale, with significant challenges in transitioning to mass production. The most common manufacturing approach involves microfluidic systems that can produce liquid metal particles with controlled size distributions, but these systems typically yield only milligram to gram quantities per hour.

Scaling up production requires addressing several technical hurdles. The oxidation sensitivity of liquid metal alloys necessitates specialized handling environments, increasing production complexity and cost. Additionally, maintaining consistent particle size distribution and preventing agglomeration during large-scale synthesis presents significant engineering challenges. Companies pioneering industrial-scale production have reported yields of up to 5kg per day, though with higher variability in quality compared to lab-scale production.

From a cost perspective, raw material expenses constitute a substantial portion of production costs. Gallium, the primary component in most liquid metal inks, has experienced price volatility, ranging from $300-600 per kilogram in recent years. This fluctuation significantly impacts the final product cost structure. The additional processing required to create stable suspensions and functionalized particles further increases production expenses by approximately 40-60% above raw material costs.

Equipment investment represents another major cost factor. Industrial-scale production facilities require specialized mixing equipment, controlled atmosphere chambers, and advanced quality control systems. Initial capital expenditure for a medium-scale production line (capable of producing 100-500kg annually) typically ranges from $2-5 million, with operational costs adding approximately $500,000-$1 million annually.

The printing process itself presents additional scalability considerations. While roll-to-roll printing offers the highest throughput potential, it requires significant optimization of ink rheology and substrate compatibility. Screen printing provides a more accessible entry point for medium-scale production but with lower throughput. Current production economics suggest a cost range of $5,000-$8,000 per kilogram for high-quality printable liquid metal inks at medium production scales.

Market analysis indicates that price points must decrease by 60-70% to enable mass adoption in consumer electronics and wearable technology applications. This cost reduction will likely require technological innovations in both materials and processing methods, as well as economies of scale. Industry projections suggest that with optimized production methods and increased demand, costs could potentially decrease by 30-40% within the next 3-5 years.

Scaling up production requires addressing several technical hurdles. The oxidation sensitivity of liquid metal alloys necessitates specialized handling environments, increasing production complexity and cost. Additionally, maintaining consistent particle size distribution and preventing agglomeration during large-scale synthesis presents significant engineering challenges. Companies pioneering industrial-scale production have reported yields of up to 5kg per day, though with higher variability in quality compared to lab-scale production.

From a cost perspective, raw material expenses constitute a substantial portion of production costs. Gallium, the primary component in most liquid metal inks, has experienced price volatility, ranging from $300-600 per kilogram in recent years. This fluctuation significantly impacts the final product cost structure. The additional processing required to create stable suspensions and functionalized particles further increases production expenses by approximately 40-60% above raw material costs.

Equipment investment represents another major cost factor. Industrial-scale production facilities require specialized mixing equipment, controlled atmosphere chambers, and advanced quality control systems. Initial capital expenditure for a medium-scale production line (capable of producing 100-500kg annually) typically ranges from $2-5 million, with operational costs adding approximately $500,000-$1 million annually.

The printing process itself presents additional scalability considerations. While roll-to-roll printing offers the highest throughput potential, it requires significant optimization of ink rheology and substrate compatibility. Screen printing provides a more accessible entry point for medium-scale production but with lower throughput. Current production economics suggest a cost range of $5,000-$8,000 per kilogram for high-quality printable liquid metal inks at medium production scales.

Market analysis indicates that price points must decrease by 60-70% to enable mass adoption in consumer electronics and wearable technology applications. This cost reduction will likely require technological innovations in both materials and processing methods, as well as economies of scale. Industry projections suggest that with optimized production methods and increased demand, costs could potentially decrease by 30-40% within the next 3-5 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!