Liquid Metal Microfluidic Channels For Reconfigurable Circuits

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Microfluidics Background and Objectives

Liquid metal microfluidics represents a revolutionary frontier in the development of reconfigurable electronic systems. The field has evolved from early explorations of mercury-based devices in the 1950s to today's advanced gallium-based liquid metal alloys that offer unprecedented opportunities for creating dynamically reconfigurable circuits. This technological evolution has been driven by the increasing demand for flexible, adaptable electronic systems that can transform their functionality in real-time.

The historical trajectory of liquid metal applications in electronics began with mercury switches and expanded through the discovery of room-temperature liquid metals like eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan) alloys in the late 20th century. These materials presented significant advantages over mercury, including lower toxicity and superior electrical conductivity, while maintaining the crucial property of remaining liquid at room temperature.

Recent advancements in microfluidic technologies have created a convergence point where liquid metals can be precisely manipulated within microscale channels, enabling the creation of circuits that can be reconfigured on demand. This represents a paradigm shift from traditional solid-state electronics, where circuit pathways are permanently defined during manufacturing.

The primary objective of liquid metal microfluidic channel research for reconfigurable circuits is to develop systems that can dynamically alter their electrical properties, connectivity patterns, and functional characteristics in response to external stimuli or programmed instructions. This capability would enable a single hardware platform to perform multiple functions sequentially or simultaneously, dramatically expanding the versatility of electronic devices.

Secondary objectives include overcoming the current limitations of liquid metal systems, such as oxidation challenges, channel wetting issues, and precise control mechanisms for the metal flow. Researchers aim to develop robust methods for manipulating liquid metal within microfluidic networks, ensuring reliable electrical connections and preventing undesired metal movement or leakage.

The field is trending toward integration with other emerging technologies, including soft robotics, wearable computing, and adaptive communication systems. The vision is to create fully reconfigurable electronic platforms that can self-optimize their circuit architecture based on operational requirements, environmental conditions, or user needs.

Long-term technological goals include the development of self-healing circuits that can automatically restore broken connections, programmable antennas that can dynamically alter their radiation patterns, and shape-shifting electronic interfaces that can physically reconfigure to provide optimal user interaction. These advances would fundamentally transform how we design and utilize electronic systems across numerous industries, from consumer electronics to aerospace applications.

The historical trajectory of liquid metal applications in electronics began with mercury switches and expanded through the discovery of room-temperature liquid metals like eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan) alloys in the late 20th century. These materials presented significant advantages over mercury, including lower toxicity and superior electrical conductivity, while maintaining the crucial property of remaining liquid at room temperature.

Recent advancements in microfluidic technologies have created a convergence point where liquid metals can be precisely manipulated within microscale channels, enabling the creation of circuits that can be reconfigured on demand. This represents a paradigm shift from traditional solid-state electronics, where circuit pathways are permanently defined during manufacturing.

The primary objective of liquid metal microfluidic channel research for reconfigurable circuits is to develop systems that can dynamically alter their electrical properties, connectivity patterns, and functional characteristics in response to external stimuli or programmed instructions. This capability would enable a single hardware platform to perform multiple functions sequentially or simultaneously, dramatically expanding the versatility of electronic devices.

Secondary objectives include overcoming the current limitations of liquid metal systems, such as oxidation challenges, channel wetting issues, and precise control mechanisms for the metal flow. Researchers aim to develop robust methods for manipulating liquid metal within microfluidic networks, ensuring reliable electrical connections and preventing undesired metal movement or leakage.

The field is trending toward integration with other emerging technologies, including soft robotics, wearable computing, and adaptive communication systems. The vision is to create fully reconfigurable electronic platforms that can self-optimize their circuit architecture based on operational requirements, environmental conditions, or user needs.

Long-term technological goals include the development of self-healing circuits that can automatically restore broken connections, programmable antennas that can dynamically alter their radiation patterns, and shape-shifting electronic interfaces that can physically reconfigure to provide optimal user interaction. These advances would fundamentally transform how we design and utilize electronic systems across numerous industries, from consumer electronics to aerospace applications.

Market Applications for Reconfigurable Circuit Technologies

Reconfigurable circuit technologies are experiencing significant market growth across multiple sectors due to their adaptability and efficiency advantages. The integration of liquid metal microfluidic channels represents a revolutionary approach that enables dynamic reconfiguration of circuit pathways through controlled movement of conductive liquid metals within microchannels. This technology addresses limitations of traditional reconfigurable systems like FPGAs, which rely on pre-designed switching elements.

The consumer electronics market presents a primary application area, with smartphones and wearable devices benefiting from reconfigurable circuits that can adapt to changing user requirements and environmental conditions. These technologies enable devices to optimize power consumption by reconfiguring circuits based on active applications, potentially extending battery life by 15-30% compared to static circuit designs.

Aerospace and defense sectors show strong interest in reconfigurable technologies due to their radiation resistance and ability to self-heal through liquid metal redistribution. Space systems particularly benefit from this resilience, as circuits can be reconfigured remotely to adapt to mission changes or compensate for radiation-induced failures without physical intervention.

Medical device manufacturers are exploring liquid metal reconfigurable circuits for implantable and wearable health monitoring systems. The technology's biocompatibility and ability to create soft, flexible interfaces with biological tissues represents a significant advancement over rigid electronic systems. Applications include neural interfaces, smart prosthetics, and adaptive diagnostic equipment that can reconfigure sensing parameters based on patient conditions.

The automotive industry is incorporating reconfigurable circuit technologies in advanced driver assistance systems and autonomous vehicles. These systems require adaptive processing capabilities to handle varying computational loads and sensor configurations across different driving scenarios. Liquid metal-based circuits offer the potential for hardware that can dynamically allocate resources to critical functions as needed.

Edge computing and IoT applications represent another growth market, where devices must balance processing capabilities with power constraints. Reconfigurable circuits allow for dynamic hardware optimization based on workload, potentially reducing energy consumption by 20-40% compared to fixed-architecture solutions.

Telecommunications infrastructure, particularly in 5G and future 6G networks, benefits from reconfigurable RF circuits that can adapt to changing bandwidth requirements and frequency allocations. Liquid metal-based reconfigurable antennas and filters enable dynamic spectrum utilization and improved signal processing efficiency across varying network conditions.

The consumer electronics market presents a primary application area, with smartphones and wearable devices benefiting from reconfigurable circuits that can adapt to changing user requirements and environmental conditions. These technologies enable devices to optimize power consumption by reconfiguring circuits based on active applications, potentially extending battery life by 15-30% compared to static circuit designs.

Aerospace and defense sectors show strong interest in reconfigurable technologies due to their radiation resistance and ability to self-heal through liquid metal redistribution. Space systems particularly benefit from this resilience, as circuits can be reconfigured remotely to adapt to mission changes or compensate for radiation-induced failures without physical intervention.

Medical device manufacturers are exploring liquid metal reconfigurable circuits for implantable and wearable health monitoring systems. The technology's biocompatibility and ability to create soft, flexible interfaces with biological tissues represents a significant advancement over rigid electronic systems. Applications include neural interfaces, smart prosthetics, and adaptive diagnostic equipment that can reconfigure sensing parameters based on patient conditions.

The automotive industry is incorporating reconfigurable circuit technologies in advanced driver assistance systems and autonomous vehicles. These systems require adaptive processing capabilities to handle varying computational loads and sensor configurations across different driving scenarios. Liquid metal-based circuits offer the potential for hardware that can dynamically allocate resources to critical functions as needed.

Edge computing and IoT applications represent another growth market, where devices must balance processing capabilities with power constraints. Reconfigurable circuits allow for dynamic hardware optimization based on workload, potentially reducing energy consumption by 20-40% compared to fixed-architecture solutions.

Telecommunications infrastructure, particularly in 5G and future 6G networks, benefits from reconfigurable RF circuits that can adapt to changing bandwidth requirements and frequency allocations. Liquid metal-based reconfigurable antennas and filters enable dynamic spectrum utilization and improved signal processing efficiency across varying network conditions.

Technical Challenges in Liquid Metal Microfluidic Systems

Despite the promising potential of liquid metal microfluidic systems for reconfigurable circuits, several significant technical challenges impede their widespread implementation and commercial viability. The primary obstacle lies in controlling the surface properties of liquid metals, particularly gallium-based alloys like EGaIn and Galinstan. These materials form a thin oxide layer upon exposure to oxygen, which dramatically alters their surface tension and wetting behavior. This oxide skin creates inconsistent flow characteristics within microchannels, making precise control and repeatability difficult to achieve.

Channel design presents another substantial challenge. Creating microfluidic pathways that maintain consistent liquid metal flow while preventing unwanted adhesion to channel walls requires sophisticated surface engineering. Researchers have explored various surface treatments including hydrophobic coatings and electrowetting techniques, but achieving uniform performance across complex circuit geometries remains problematic.

The integration of control systems for dynamic reconfiguration represents a significant hurdle. Effective manipulation of liquid metal within microchannels requires precise actuation mechanisms, which may include electrowetting, pneumatic pressure, or magnetic manipulation. Each approach introduces its own set of complications regarding response time, power requirements, and integration complexity with conventional electronic systems.

Stability and reliability issues further complicate development efforts. Liquid metal circuits must maintain consistent electrical properties over extended periods and through numerous reconfiguration cycles. Oxidation processes, material degradation, and potential leakage all threaten long-term performance. Additionally, the interface between liquid metal components and solid-state electronics creates connection challenges that must be addressed for practical applications.

Manufacturing scalability presents perhaps the most significant barrier to commercialization. Current fabrication techniques for liquid metal microfluidic systems often involve complex, multi-step processes that are difficult to scale for mass production. The precision required for microchannel fabrication, combined with the challenges of liquid metal handling during assembly, creates substantial manufacturing hurdles.

Thermal management also emerges as a critical concern, particularly for high-power applications. Liquid metals offer excellent thermal conductivity, but managing heat distribution within reconfigurable circuits requires careful design considerations to prevent localized hotspots and ensure consistent performance across operating temperature ranges.

Addressing these technical challenges requires interdisciplinary approaches combining expertise from materials science, microfluidics, electrical engineering, and manufacturing. Recent research has shown promising advances in surface modification techniques and control systems, but significant work remains before liquid metal microfluidic channels can achieve their full potential in reconfigurable circuit applications.

Channel design presents another substantial challenge. Creating microfluidic pathways that maintain consistent liquid metal flow while preventing unwanted adhesion to channel walls requires sophisticated surface engineering. Researchers have explored various surface treatments including hydrophobic coatings and electrowetting techniques, but achieving uniform performance across complex circuit geometries remains problematic.

The integration of control systems for dynamic reconfiguration represents a significant hurdle. Effective manipulation of liquid metal within microchannels requires precise actuation mechanisms, which may include electrowetting, pneumatic pressure, or magnetic manipulation. Each approach introduces its own set of complications regarding response time, power requirements, and integration complexity with conventional electronic systems.

Stability and reliability issues further complicate development efforts. Liquid metal circuits must maintain consistent electrical properties over extended periods and through numerous reconfiguration cycles. Oxidation processes, material degradation, and potential leakage all threaten long-term performance. Additionally, the interface between liquid metal components and solid-state electronics creates connection challenges that must be addressed for practical applications.

Manufacturing scalability presents perhaps the most significant barrier to commercialization. Current fabrication techniques for liquid metal microfluidic systems often involve complex, multi-step processes that are difficult to scale for mass production. The precision required for microchannel fabrication, combined with the challenges of liquid metal handling during assembly, creates substantial manufacturing hurdles.

Thermal management also emerges as a critical concern, particularly for high-power applications. Liquid metals offer excellent thermal conductivity, but managing heat distribution within reconfigurable circuits requires careful design considerations to prevent localized hotspots and ensure consistent performance across operating temperature ranges.

Addressing these technical challenges requires interdisciplinary approaches combining expertise from materials science, microfluidics, electrical engineering, and manufacturing. Recent research has shown promising advances in surface modification techniques and control systems, but significant work remains before liquid metal microfluidic channels can achieve their full potential in reconfigurable circuit applications.

Current Liquid Metal Channel Fabrication Methods

01 Liquid metal-based reconfigurable microfluidic channels

Liquid metals, particularly gallium-based alloys, can be used to create reconfigurable microfluidic channels. These channels can be dynamically altered by controlling the flow and position of the liquid metal within microfluidic devices. The reconfigurability is achieved through various stimuli such as electrical, thermal, or mechanical forces that manipulate the liquid metal to form, break, or redirect flow paths. This technology enables adaptive microfluidic systems that can change their configuration during operation.- Liquid metal-based reconfigurable microfluidic channels: Liquid metals, particularly gallium-based alloys, can be used to create reconfigurable microfluidic channels. These channels can be dynamically altered by manipulating the liquid metal through various stimuli such as electrical, thermal, or mechanical forces. The reconfigurability allows for adaptive fluidic pathways that can be modified on-demand for different applications, offering flexibility not possible with traditional rigid microfluidic systems.

- Electrical control methods for liquid metal manipulation: Electrical control methods enable precise manipulation of liquid metals within microfluidic channels through techniques such as electrowetting, continuous electrowetting, and electrochemical control. By applying voltage differentials, the surface tension and oxidation state of liquid metals can be altered, allowing for controlled movement, splitting, merging, and reshaping of liquid metal segments. This electrical control enables rapid reconfiguration of microfluidic pathways without mechanical components.

- Thermal and mechanical actuation of liquid metal microfluidics: Thermal and mechanical methods can be employed to reconfigure liquid metal microfluidic channels. Temperature changes affect the viscosity and surface properties of liquid metals, enabling flow control. Mechanical actuation through pressure differentials, vibration, or direct physical manipulation can reshape liquid metal structures. These approaches offer alternative control mechanisms that can be combined with electrical methods for enhanced reconfigurability of microfluidic systems.

- Liquid metal-based soft electronics and sensors: Reconfigurable liquid metal microfluidic channels can be integrated into soft electronics and sensors. The deformable nature of liquid metals allows for stretchable, bendable electronic components that maintain conductivity under mechanical strain. These systems can be used for wearable devices, soft robotics, and biomedical applications where traditional rigid electronics are unsuitable. The reconfigurability enables adaptive sensing capabilities and self-healing electronic pathways.

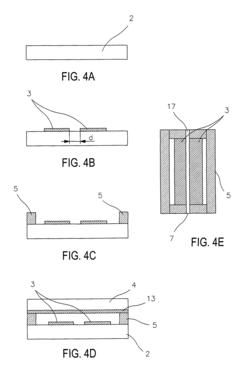

- Fabrication techniques for liquid metal microfluidic systems: Various fabrication techniques have been developed for creating reconfigurable liquid metal microfluidic systems. These include soft lithography, 3D printing, laser patterning, and injection molding to create channels and reservoirs for liquid metals. Surface treatment methods are employed to control the wetting behavior of liquid metals within channels. Encapsulation techniques prevent oxidation and ensure long-term stability of the liquid metal components while maintaining their reconfigurability.

02 Electrically controlled liquid metal actuation for channel reconfiguration

Electric fields can be used to control the movement and shape of liquid metals in microfluidic systems. By applying voltage across specific regions, liquid metal can be manipulated through electrowetting or continuous electrowetting effects, allowing for precise control over channel formation and reconfiguration. This approach enables rapid switching between different microfluidic pathways and can be used to create valves, pumps, and other functional elements within the microfluidic system.Expand Specific Solutions03 Thermal manipulation of liquid metal for adaptive microfluidics

Temperature changes can be utilized to control the behavior of liquid metals in microfluidic channels. By selectively heating or cooling regions of the device, the viscosity, surface tension, and oxidation state of the liquid metal can be altered, enabling controlled movement and reconfiguration of channels. Thermal gradients can drive the flow of liquid metal or cause phase transitions that result in channel formation or closure, providing another mechanism for achieving reconfigurable microfluidic systems.Expand Specific Solutions04 Surface modification techniques for liquid metal channel control

Surface chemistry and topography play crucial roles in controlling liquid metal behavior in microfluidic channels. By modifying surfaces with specific patterns, chemical treatments, or structured geometries, the wetting and movement of liquid metals can be precisely controlled. These modifications can create preferential pathways for liquid metal flow, enable selective adhesion or repulsion, and facilitate channel reconfiguration through controlled spreading or retraction of the liquid metal.Expand Specific Solutions05 Integration of liquid metal reconfigurable channels in flexible electronics

Liquid metal microfluidic channels can be integrated into flexible and stretchable substrates to create reconfigurable electronic systems. These systems combine the electrical conductivity of liquid metals with the ability to change channel configurations, enabling adaptive electronic circuits and sensors. The flexibility allows the devices to conform to various surfaces while maintaining functionality, and the reconfigurability enables dynamic adjustment of electrical pathways in response to mechanical deformation or other stimuli.Expand Specific Solutions

Leading Research Groups and Industry Players

The liquid metal microfluidic channels for reconfigurable circuits market is in its early growth stage, characterized by intensive research and development activities. This emerging technology combines the flexibility of liquid metals with microfluidic precision to create adaptive electronic systems. The global market size remains relatively small but is expanding rapidly, driven by applications in flexible electronics, biomedical devices, and reconfigurable computing. From a technical maturity perspective, key players demonstrate varying levels of advancement. Research institutions like PARC, Fraunhofer-Gesellschaft, and California Institute of Technology lead fundamental innovation, while commercial entities including Agilent Technologies, Analog Devices, and Beijing Dream Ink Technology are developing practical applications. Chinese universities (Peking University, Harbin Institute of Technology) are making significant contributions to material science aspects, while corporate players like HP Development and Siemens Medical Solutions focus on specialized industrial implementations.

President & Fellows of Harvard College

Technical Solution: Harvard's approach to liquid metal microfluidic channels focuses on using gallium-based liquid metals (primarily EGaIn and Galinstan) to create reconfigurable electronic circuits. Their technology employs microfluidic channels fabricated in elastomeric substrates like PDMS, where liquid metal can be injected, withdrawn, or redirected to dynamically alter circuit configurations. Harvard researchers have developed methods to overcome the oxide skin formation challenge by using acid environments or mechanical actuation to break the oxide layer. They've demonstrated applications including stretchable electronics that maintain conductivity under deformation, self-healing circuits that can restore functionality after damage, and tunable RF components with adjustable resonance frequencies. Their approach enables circuits that can be reconfigured in real-time without fabricating new hardware, offering unprecedented flexibility for adaptive electronics.

Strengths: Superior electrical conductivity compared to conductive polymers; exceptional mechanical compliance allowing for stretching up to 800% without conductivity loss; ability to self-heal after mechanical damage; real-time reconfigurability without hardware replacement. Weaknesses: Oxide skin formation on liquid metals can impede flow in microchannels; potential for metal embrittlement in certain substrate materials; challenges in precise control of liquid metal movement in complex channel networks.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed sophisticated liquid metal microfluidic platforms for reconfigurable electronics. Their approach centers on eutectic gallium-indium (EGaIn) and galinstan alloys manipulated within precisely engineered microchannels. A*STAR's innovation lies in their development of surface chemistry modifications that control liquid metal wetting behaviors, allowing selective patterning and movement. They've created microfluidic chips with integrated pneumatic control systems that enable digital addressing of liquid metal segments, facilitating complex circuit reconfiguration. Their technology incorporates impedance-matched microchannels designed specifically for RF applications, enabling reconfigurable antennas and filters with minimal signal loss. A*STAR researchers have also pioneered hybrid systems that combine solid-state components with liquid metal interconnects, creating adaptable electronic systems that blend the reliability of conventional electronics with the reconfigurability of liquid metals. Applications include software-defined radio systems, reconfigurable sensor arrays, and adaptive computing architectures.

Strengths: Advanced surface chemistry enables precise control of liquid metal behavior; integrated pneumatic systems allow digital addressing without electrical interference; RF-optimized channel designs minimize signal losses; hybrid integration with conventional electronics expands application potential. Weaknesses: Complex fabrication process increases production costs; pneumatic control systems add bulk to overall device; challenges in maintaining consistent performance across temperature variations.

Key Patents in Reconfigurable Microfluidic Circuits

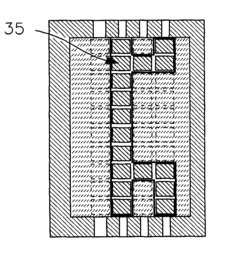

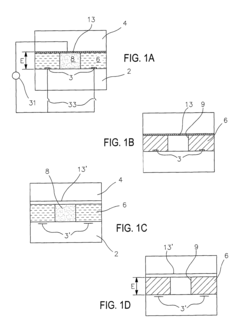

Method for producing reconfigurable microchannels

PatentInactiveUS20110104025A1

Innovation

- A method to create a reconfigurable microfluidic network using immiscible fluids between two plates with electrodes, where the shape of the first fluid is controlled by electrical forces and then solidified, allowing for the formation of reusable channels with varying geometries without the need for clean room equipment.

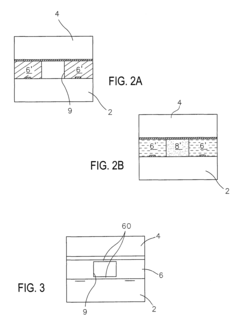

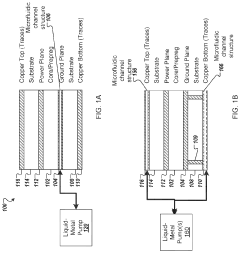

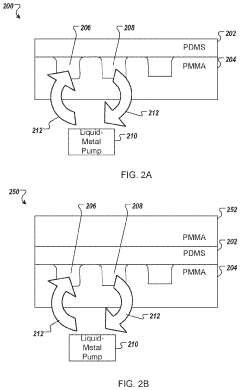

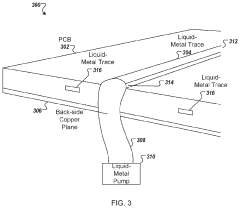

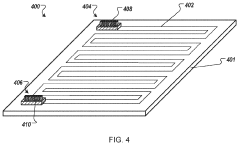

Microfluidic channels and pumps for active cooling of circuit boards

PatentActiveUS10660199B1

Innovation

- The implementation of microfluidic channels filled with liquid metal on circuit boards and cables, where a pump actively moves the liquid metal through these channels to enhance heat transfer and distribution, allowing for targeted cooling and reducing the need for oversized heatsinks.

Materials Science Considerations for Liquid Metal Compatibility

The compatibility between liquid metals and surrounding materials represents a critical factor in the development of reliable and durable reconfigurable circuits using microfluidic channels. Gallium-based liquid metals, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), exhibit unique chemical properties that must be carefully considered when selecting channel materials and designing microfluidic systems.

Primary consideration must be given to the oxidation behavior of liquid metals. When exposed to oxygen, gallium-based alloys rapidly form a thin oxide skin that significantly alters their surface tension and wetting characteristics. This oxide layer can adhere to channel walls, causing residue buildup and potential channel blockage over time. Materials with low surface energy, such as perfluorinated polymers (PTFE, PFPE) and silicones (PDMS), demonstrate superior resistance to this adhesion phenomenon.

Chemical compatibility presents another crucial dimension. Gallium is notably reactive with certain metals, particularly aluminum, where it causes catastrophic embrittlement through grain boundary penetration. Similar degradation occurs with copper, zinc, and many other common circuit metals. Therefore, channel materials must provide an effective barrier against such interactions, especially in hybrid systems where liquid metal interfaces with solid-state components.

Temperature stability constitutes a third vital consideration. While gallium-based alloys remain liquid at room temperature (melting points: EGaIn ~15.5°C, Galinstan ~-19°C), thermal cycling can induce expansion/contraction that stresses containment materials. Selected materials must maintain dimensional stability and chemical inertness across the operational temperature range, typically -20°C to 100°C for most applications.

Mechanical properties of channel materials significantly impact system performance. Elastomeric materials like PDMS offer advantages in reconfigurable systems through their flexibility and self-healing characteristics. However, they may suffer from permeability issues and mechanical degradation over time. Rigid materials like glass and certain ceramics provide excellent chemical resistance but limit reconfigurability options.

Manufacturing compatibility represents the final key consideration. Materials must be amenable to precise microfabrication techniques, including photolithography, soft lithography, or 3D printing. The integration of electrodes, sensors, and actuation mechanisms necessitates materials that can undergo multiple processing steps without degradation or contamination.

Recent advances in composite materials and surface treatments have expanded the range of compatible materials. Parylene coatings, oxide layers, and specialized polymer blends can modify surface properties to enhance liquid metal compatibility while maintaining other desirable material characteristics.

Primary consideration must be given to the oxidation behavior of liquid metals. When exposed to oxygen, gallium-based alloys rapidly form a thin oxide skin that significantly alters their surface tension and wetting characteristics. This oxide layer can adhere to channel walls, causing residue buildup and potential channel blockage over time. Materials with low surface energy, such as perfluorinated polymers (PTFE, PFPE) and silicones (PDMS), demonstrate superior resistance to this adhesion phenomenon.

Chemical compatibility presents another crucial dimension. Gallium is notably reactive with certain metals, particularly aluminum, where it causes catastrophic embrittlement through grain boundary penetration. Similar degradation occurs with copper, zinc, and many other common circuit metals. Therefore, channel materials must provide an effective barrier against such interactions, especially in hybrid systems where liquid metal interfaces with solid-state components.

Temperature stability constitutes a third vital consideration. While gallium-based alloys remain liquid at room temperature (melting points: EGaIn ~15.5°C, Galinstan ~-19°C), thermal cycling can induce expansion/contraction that stresses containment materials. Selected materials must maintain dimensional stability and chemical inertness across the operational temperature range, typically -20°C to 100°C for most applications.

Mechanical properties of channel materials significantly impact system performance. Elastomeric materials like PDMS offer advantages in reconfigurable systems through their flexibility and self-healing characteristics. However, they may suffer from permeability issues and mechanical degradation over time. Rigid materials like glass and certain ceramics provide excellent chemical resistance but limit reconfigurability options.

Manufacturing compatibility represents the final key consideration. Materials must be amenable to precise microfabrication techniques, including photolithography, soft lithography, or 3D printing. The integration of electrodes, sensors, and actuation mechanisms necessitates materials that can undergo multiple processing steps without degradation or contamination.

Recent advances in composite materials and surface treatments have expanded the range of compatible materials. Parylene coatings, oxide layers, and specialized polymer blends can modify surface properties to enhance liquid metal compatibility while maintaining other desirable material characteristics.

Energy Efficiency and Sustainability Aspects

Liquid metal-based reconfigurable circuits represent a significant advancement in sustainable electronics design, offering notable energy efficiency advantages over traditional solid-state alternatives. The inherent properties of gallium-based liquid metals, particularly their low melting points and excellent electrical conductivity, contribute to reduced power consumption during reconfiguration processes. Unlike conventional electronic switches that require continuous power to maintain states, liquid metal microfluidic channels can maintain their configuration with minimal or zero energy input once positioned, creating an inherently energy-efficient "set-and-forget" paradigm.

The manufacturing processes for liquid metal microfluidic systems generally demand fewer energy-intensive steps compared to traditional semiconductor fabrication. Conventional integrated circuits require high-temperature processing, vacuum systems, and multiple chemical etching stages that consume substantial energy. In contrast, liquid metal systems can often be fabricated using lower-temperature processes and simpler equipment setups, resulting in a reduced carbon footprint during production.

From a lifecycle perspective, liquid metal-based reconfigurable circuits offer promising sustainability benefits. The primary materials used—gallium and its alloys—are more abundant than rare earth elements required for many conventional electronics. Additionally, these systems demonstrate potential for extended operational lifespans through their reconfigurability, which allows for functional updates without hardware replacement. This characteristic directly addresses the growing electronic waste crisis by extending product lifecycles.

The recyclability aspect presents another sustainability advantage. When properly designed, liquid metal components can be more easily separated and recovered at end-of-life compared to conventional integrated circuits, where material recovery often proves challenging and energy-intensive. Research indicates that gallium can be reclaimed from these systems with relatively straightforward processes, supporting circular economy principles.

Energy storage integration represents an emerging opportunity for these systems. Recent studies demonstrate that liquid metal microfluidic channels can potentially serve dual purposes—functioning as both circuit elements and energy storage components. This integration could eliminate the need for separate battery systems in certain applications, reducing overall material requirements and improving system-level energy efficiency.

However, challenges remain in optimizing the energy required for actuation mechanisms that control liquid metal movement within microchannels. Current pneumatic, thermal, or electrical actuation methods still consume more energy than ideal. Ongoing research focuses on developing ultra-low-power actuation techniques that would further enhance the overall energy efficiency proposition of these systems.

The manufacturing processes for liquid metal microfluidic systems generally demand fewer energy-intensive steps compared to traditional semiconductor fabrication. Conventional integrated circuits require high-temperature processing, vacuum systems, and multiple chemical etching stages that consume substantial energy. In contrast, liquid metal systems can often be fabricated using lower-temperature processes and simpler equipment setups, resulting in a reduced carbon footprint during production.

From a lifecycle perspective, liquid metal-based reconfigurable circuits offer promising sustainability benefits. The primary materials used—gallium and its alloys—are more abundant than rare earth elements required for many conventional electronics. Additionally, these systems demonstrate potential for extended operational lifespans through their reconfigurability, which allows for functional updates without hardware replacement. This characteristic directly addresses the growing electronic waste crisis by extending product lifecycles.

The recyclability aspect presents another sustainability advantage. When properly designed, liquid metal components can be more easily separated and recovered at end-of-life compared to conventional integrated circuits, where material recovery often proves challenging and energy-intensive. Research indicates that gallium can be reclaimed from these systems with relatively straightforward processes, supporting circular economy principles.

Energy storage integration represents an emerging opportunity for these systems. Recent studies demonstrate that liquid metal microfluidic channels can potentially serve dual purposes—functioning as both circuit elements and energy storage components. This integration could eliminate the need for separate battery systems in certain applications, reducing overall material requirements and improving system-level energy efficiency.

However, challenges remain in optimizing the energy required for actuation mechanisms that control liquid metal movement within microchannels. Current pneumatic, thermal, or electrical actuation methods still consume more energy than ideal. Ongoing research focuses on developing ultra-low-power actuation techniques that would further enhance the overall energy efficiency proposition of these systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!