Integrating Liquid Metal With Thin Film Transistor Arrays

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal-TFT Integration Background and Objectives

Liquid metal integration with thin film transistor (TFT) arrays represents a convergence of two transformative technologies that have evolved along separate trajectories until recent years. Liquid metals, particularly gallium-based alloys such as eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), have garnered significant attention due to their unique combination of metallic electrical conductivity and fluidic properties at room temperature. These materials maintain electrical conductivity comparable to conventional metals while offering unprecedented mechanical flexibility and reconfigurability.

The evolution of thin film transistor technology has been primarily driven by the display industry, with significant advancements in materials, fabrication processes, and architectural designs over the past four decades. From amorphous silicon (a-Si) to low-temperature polysilicon (LTPS) and more recently, metal oxide semiconductors such as indium-gallium-zinc oxide (IGZO), TFT technology has continuously improved in terms of performance, stability, and manufacturing scalability.

The integration of liquid metals with TFT arrays emerges from growing demands for flexible, stretchable, and reconfigurable electronics that can withstand mechanical deformation while maintaining electrical functionality. Traditional rigid electronic systems based on solid metals and semiconductors face fundamental limitations when subjected to bending, stretching, or twisting forces, creating a technological gap that liquid metal-TFT integration aims to address.

The primary objective of this technological convergence is to develop next-generation electronic systems that combine the switching capabilities and signal amplification of TFTs with the mechanical adaptability of liquid metals. Specific goals include creating deformable display technologies, wearable computing platforms, soft robotics interfaces, and biomedical devices that can conform to irregular surfaces or dynamic environments.

Another critical objective is overcoming the inherent challenges in materials compatibility between liquid metals and semiconductor materials used in TFTs. The high surface tension of liquid metals, their potential for oxidation, and concerns about metal diffusion into semiconductor layers present significant technical hurdles that require innovative solutions in materials science and device engineering.

Furthermore, this integration aims to establish new fabrication methodologies that can reliably pattern and encapsulate liquid metal components at microscale dimensions compatible with TFT manufacturing processes. The development of such techniques would enable mass production of hybrid liquid metal-TFT systems at commercially viable scales and costs.

The long-term technological trajectory points toward fully reconfigurable electronic systems where both the active semiconductor components and interconnects can dynamically adapt their electrical and mechanical properties in response to external stimuli or user commands, representing a paradigm shift from conventional rigid electronics to truly adaptive computing platforms.

The evolution of thin film transistor technology has been primarily driven by the display industry, with significant advancements in materials, fabrication processes, and architectural designs over the past four decades. From amorphous silicon (a-Si) to low-temperature polysilicon (LTPS) and more recently, metal oxide semiconductors such as indium-gallium-zinc oxide (IGZO), TFT technology has continuously improved in terms of performance, stability, and manufacturing scalability.

The integration of liquid metals with TFT arrays emerges from growing demands for flexible, stretchable, and reconfigurable electronics that can withstand mechanical deformation while maintaining electrical functionality. Traditional rigid electronic systems based on solid metals and semiconductors face fundamental limitations when subjected to bending, stretching, or twisting forces, creating a technological gap that liquid metal-TFT integration aims to address.

The primary objective of this technological convergence is to develop next-generation electronic systems that combine the switching capabilities and signal amplification of TFTs with the mechanical adaptability of liquid metals. Specific goals include creating deformable display technologies, wearable computing platforms, soft robotics interfaces, and biomedical devices that can conform to irregular surfaces or dynamic environments.

Another critical objective is overcoming the inherent challenges in materials compatibility between liquid metals and semiconductor materials used in TFTs. The high surface tension of liquid metals, their potential for oxidation, and concerns about metal diffusion into semiconductor layers present significant technical hurdles that require innovative solutions in materials science and device engineering.

Furthermore, this integration aims to establish new fabrication methodologies that can reliably pattern and encapsulate liquid metal components at microscale dimensions compatible with TFT manufacturing processes. The development of such techniques would enable mass production of hybrid liquid metal-TFT systems at commercially viable scales and costs.

The long-term technological trajectory points toward fully reconfigurable electronic systems where both the active semiconductor components and interconnects can dynamically adapt their electrical and mechanical properties in response to external stimuli or user commands, representing a paradigm shift from conventional rigid electronics to truly adaptive computing platforms.

Market Applications and Demand Analysis for Liquid Metal TFT Arrays

The integration of liquid metal with thin film transistor (TFT) arrays represents a significant technological advancement with diverse market applications across multiple industries. The flexible and conductive properties of liquid metals, particularly gallium-based alloys like Galinstan and EGaIn, have created substantial market interest due to their potential to revolutionize flexible electronics.

The healthcare sector demonstrates particularly strong demand for liquid metal TFT arrays, with the global medical wearables market projected to reach $30 billion by 2025. These technologies enable continuous health monitoring through flexible, skin-conforming devices that can track vital signs, glucose levels, and other biomarkers with unprecedented comfort and accuracy. The aging global population and increasing prevalence of chronic diseases are driving this demand, with healthcare providers seeking solutions that enable remote patient monitoring and preventive care.

Consumer electronics represents another substantial market, with flexible displays incorporating liquid metal TFT technology expected to grow at a compound annual rate of 35% through 2027. Major manufacturers are investing heavily in this technology to develop rollable smartphones, wearable devices, and next-generation displays that combine durability with novel form factors. The consumer preference for lightweight, portable, and uniquely designed electronics continues to fuel this segment's expansion.

The automotive industry has emerged as a significant adopter of liquid metal TFT arrays for advanced dashboard displays, touch controls, and sensor systems. As vehicles become increasingly autonomous and connected, the demand for flexible, reliable interface technologies has grown substantially, with the automotive display market expected to exceed $15 billion by 2026.

Defense and aerospace applications represent a premium market segment, where liquid metal TFT arrays are valued for their resilience to extreme conditions and potential for conformal integration into aircraft surfaces and military equipment. Though smaller in volume than consumer markets, this sector offers higher margins and more specialized applications.

Industrial automation and robotics applications are expanding rapidly, with liquid metal TFT arrays enabling advanced sensing capabilities and human-machine interfaces in manufacturing environments. The industrial IoT market, currently valued at approximately $77 billion, is expected to incorporate these technologies for improved equipment monitoring and process control.

Market analysis indicates that while current adoption remains primarily in high-end applications, manufacturing scale improvements and material cost reductions could drive broader market penetration within 3-5 years. The technology's unique combination of electrical conductivity, mechanical flexibility, and thermal stability positions it favorably against competing solutions like carbon nanotubes and silver nanowires in applications requiring extreme durability and performance.

The healthcare sector demonstrates particularly strong demand for liquid metal TFT arrays, with the global medical wearables market projected to reach $30 billion by 2025. These technologies enable continuous health monitoring through flexible, skin-conforming devices that can track vital signs, glucose levels, and other biomarkers with unprecedented comfort and accuracy. The aging global population and increasing prevalence of chronic diseases are driving this demand, with healthcare providers seeking solutions that enable remote patient monitoring and preventive care.

Consumer electronics represents another substantial market, with flexible displays incorporating liquid metal TFT technology expected to grow at a compound annual rate of 35% through 2027. Major manufacturers are investing heavily in this technology to develop rollable smartphones, wearable devices, and next-generation displays that combine durability with novel form factors. The consumer preference for lightweight, portable, and uniquely designed electronics continues to fuel this segment's expansion.

The automotive industry has emerged as a significant adopter of liquid metal TFT arrays for advanced dashboard displays, touch controls, and sensor systems. As vehicles become increasingly autonomous and connected, the demand for flexible, reliable interface technologies has grown substantially, with the automotive display market expected to exceed $15 billion by 2026.

Defense and aerospace applications represent a premium market segment, where liquid metal TFT arrays are valued for their resilience to extreme conditions and potential for conformal integration into aircraft surfaces and military equipment. Though smaller in volume than consumer markets, this sector offers higher margins and more specialized applications.

Industrial automation and robotics applications are expanding rapidly, with liquid metal TFT arrays enabling advanced sensing capabilities and human-machine interfaces in manufacturing environments. The industrial IoT market, currently valued at approximately $77 billion, is expected to incorporate these technologies for improved equipment monitoring and process control.

Market analysis indicates that while current adoption remains primarily in high-end applications, manufacturing scale improvements and material cost reductions could drive broader market penetration within 3-5 years. The technology's unique combination of electrical conductivity, mechanical flexibility, and thermal stability positions it favorably against competing solutions like carbon nanotubes and silver nanowires in applications requiring extreme durability and performance.

Technical Challenges in Liquid Metal-TFT Integration

The integration of liquid metal with thin film transistor (TFT) arrays presents several significant technical challenges that must be overcome for successful implementation. The primary obstacle lies in the inherent material incompatibility between conventional semiconductor fabrication processes and liquid metal handling. Liquid metals, particularly gallium-based alloys such as EGaIn (eutectic gallium-indium) and Galinstan, possess unique physical properties including high surface tension, tendency to oxidize rapidly in air, and potential for corrosion when in contact with certain metals used in TFT structures.

Temperature management represents another critical challenge. While TFT manufacturing typically involves high-temperature processes exceeding 300°C for deposition and annealing, many liquid metals have relatively low melting points. This thermal mismatch creates difficulties in process integration, as liquid metal components may become unstable during standard TFT fabrication steps, potentially causing contamination or structural damage to the transistor array.

Patterning and encapsulation of liquid metal elements within TFT structures present additional technical hurdles. Traditional photolithography techniques are not directly applicable to liquid metals due to their fluidic nature. Researchers have explored alternative approaches including microfluidic channels, soft lithography, and selective wetting techniques, but each method introduces its own set of challenges related to precision, scalability, and compatibility with existing semiconductor manufacturing infrastructure.

Interface stability between liquid metals and TFT materials constitutes a significant concern. Gallium-based liquid metals can form intermetallic compounds with commonly used electrode materials such as gold, aluminum, and copper, potentially compromising electrical connections and device performance over time. This necessitates the development of appropriate barrier layers or alternative contact materials that maintain stable interfaces while preserving electrical functionality.

Addressing oxidation issues remains paramount for successful integration. Liquid metals rapidly form oxide skins when exposed to oxygen, which can significantly alter their electrical and mechanical properties. While this oxide layer can be beneficial in some applications for stabilizing liquid metal structures, it introduces variability and potential reliability concerns in TFT integration scenarios, particularly at electrical contact points where consistent conductivity is essential.

Scaling and manufacturing considerations present perhaps the most formidable challenge. Current laboratory demonstrations of liquid metal-TFT integration typically involve manual processes or limited-scale prototypes. Translating these approaches to large-area fabrication compatible with industrial TFT manufacturing requires significant innovation in materials handling, process control, and quality assurance methodologies to ensure consistency across thousands or millions of individual devices.

Temperature management represents another critical challenge. While TFT manufacturing typically involves high-temperature processes exceeding 300°C for deposition and annealing, many liquid metals have relatively low melting points. This thermal mismatch creates difficulties in process integration, as liquid metal components may become unstable during standard TFT fabrication steps, potentially causing contamination or structural damage to the transistor array.

Patterning and encapsulation of liquid metal elements within TFT structures present additional technical hurdles. Traditional photolithography techniques are not directly applicable to liquid metals due to their fluidic nature. Researchers have explored alternative approaches including microfluidic channels, soft lithography, and selective wetting techniques, but each method introduces its own set of challenges related to precision, scalability, and compatibility with existing semiconductor manufacturing infrastructure.

Interface stability between liquid metals and TFT materials constitutes a significant concern. Gallium-based liquid metals can form intermetallic compounds with commonly used electrode materials such as gold, aluminum, and copper, potentially compromising electrical connections and device performance over time. This necessitates the development of appropriate barrier layers or alternative contact materials that maintain stable interfaces while preserving electrical functionality.

Addressing oxidation issues remains paramount for successful integration. Liquid metals rapidly form oxide skins when exposed to oxygen, which can significantly alter their electrical and mechanical properties. While this oxide layer can be beneficial in some applications for stabilizing liquid metal structures, it introduces variability and potential reliability concerns in TFT integration scenarios, particularly at electrical contact points where consistent conductivity is essential.

Scaling and manufacturing considerations present perhaps the most formidable challenge. Current laboratory demonstrations of liquid metal-TFT integration typically involve manual processes or limited-scale prototypes. Translating these approaches to large-area fabrication compatible with industrial TFT manufacturing requires significant innovation in materials handling, process control, and quality assurance methodologies to ensure consistency across thousands or millions of individual devices.

Current Integration Methods and Manufacturing Processes

01 Liquid metal integration with TFT arrays for display applications

Liquid metals can be integrated with thin film transistor (TFT) arrays to create advanced display technologies. These materials offer unique properties such as high conductivity and flexibility that enhance display performance. The combination enables the development of flexible, high-resolution displays with improved response times and durability. This technology is particularly valuable for next-generation displays that require both mechanical flexibility and high electrical performance.- Liquid metal integration in TFT arrays: Liquid metals can be integrated into thin film transistor arrays to enhance their electrical properties and flexibility. These materials offer unique advantages such as high conductivity, self-healing capabilities, and the ability to maintain electrical connections during mechanical deformation. The integration of liquid metals with TFT arrays enables the development of flexible and stretchable electronics for applications in displays, sensors, and wearable devices.

- Advanced TFT array manufacturing techniques: Various manufacturing techniques have been developed to improve the performance and yield of thin film transistor arrays. These include specialized deposition methods, patterning processes, and surface treatments that enhance the electrical characteristics and stability of the transistors. Advanced manufacturing techniques also address challenges related to large-area fabrication, uniformity, and integration with other components in display and sensing applications.

- Novel materials for TFT electrodes and channels: Research has focused on developing novel materials for TFT electrodes and channel layers to improve performance characteristics such as mobility, on/off ratio, and stability. These materials include advanced metal alloys, oxide semiconductors, and composite structures that offer advantages over conventional silicon-based transistors. The incorporation of these materials enables TFTs with enhanced switching speeds, lower power consumption, and better reliability for display and electronic applications.

- Flexible and stretchable TFT array architectures: Innovative architectures for flexible and stretchable thin film transistor arrays have been developed to enable applications in curved displays, conformable electronics, and wearable devices. These designs incorporate specialized substrate materials, interconnect structures, and device layouts that maintain functionality during bending, folding, or stretching. The resulting TFT arrays can be integrated into non-planar surfaces while maintaining their electrical performance and reliability.

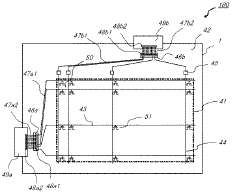

- Integration of TFT arrays with display technologies: Thin film transistor arrays have been integrated with various display technologies, including LCD, OLED, and emerging display types. These integrations involve specialized circuit designs, pixel architectures, and driving schemes that optimize display performance characteristics such as brightness, contrast, and response time. Advanced TFT array designs also address challenges related to power consumption, resolution scaling, and color reproduction in next-generation display applications.

02 Manufacturing processes for liquid metal TFT arrays

Specialized manufacturing techniques have been developed for incorporating liquid metals into thin film transistor arrays. These processes include precise deposition methods, patterning techniques, and encapsulation strategies to ensure stability of the liquid metal components. Advanced fabrication approaches allow for the creation of complex circuit structures while maintaining the unique properties of liquid metals. These manufacturing innovations enable mass production of liquid metal-based TFT arrays with consistent quality and performance.Expand Specific Solutions03 Novel materials for liquid metal and TFT integration

Research has focused on developing new materials that enhance the performance of liquid metal-based TFT arrays. These include specialized alloys with optimized melting points, conductivity, and compatibility with semiconductor processing. Novel encapsulation materials protect the liquid metal components while allowing for electrical connectivity. Additionally, interface materials have been developed to improve adhesion between liquid metals and traditional semiconductor materials, enhancing overall device reliability and performance.Expand Specific Solutions04 Flexible and stretchable TFT arrays using liquid metal interconnects

Liquid metals enable the creation of flexible and stretchable thin film transistor arrays by serving as deformable interconnects between rigid components. This approach allows for electronic devices that can bend, fold, or stretch while maintaining electrical functionality. The unique properties of liquid metals, including their ability to self-heal after deformation, make them ideal for wearable electronics, foldable displays, and medical devices that conform to the human body. These technologies represent a significant advancement in creating truly flexible electronic systems.Expand Specific Solutions05 Electrical performance optimization of liquid metal TFT arrays

Techniques have been developed to optimize the electrical performance of liquid metal-integrated thin film transistor arrays. These include methods to reduce contact resistance between liquid metals and semiconductors, strategies to minimize signal interference, and approaches to enhance switching speeds. Advanced circuit designs leverage the unique properties of liquid metals to improve power efficiency and reduce heat generation. These optimizations enable liquid metal TFT arrays to meet the demanding requirements of high-performance computing and display applications.Expand Specific Solutions

Leading Companies and Research Institutions in Flexible Electronics

The liquid metal integration with thin film transistor (TFT) arrays market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size remains relatively modest but is projected to expand significantly as applications in flexible electronics and displays gain traction. From a technical maturity perspective, major display manufacturers like Samsung Display, LG Display, BOE Technology, and Japan Display are leading development efforts, with varying degrees of progress. These companies have established expertise in TFT manufacturing and are now exploring liquid metal integration to enhance flexibility and conductivity. Research institutions like Industrial Technology Research Institute and Tsinghua University are contributing fundamental innovations, while companies like Sharp and TCL are focusing on practical applications for next-generation displays. The competitive landscape remains fluid as technical challenges in stability and mass production are addressed.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a proprietary liquid metal integration technology for TFT arrays that utilizes gallium-based alloys with low melting points (around 30°C). Their approach involves microfluidic channels embedded within the TFT substrate, allowing liquid metal to flow through predefined pathways to form reconfigurable circuits. The liquid metal is encapsulated in elastomeric materials compatible with existing TFT manufacturing processes, enabling stretchable and flexible display applications. BOE's technology incorporates surface treatment methods to overcome the native oxide formation issues typical with liquid metals, ensuring consistent electrical conductivity. Their manufacturing process includes vacuum injection techniques for precise liquid metal placement within the TFT structure, achieving channel lengths as small as 10 μm while maintaining electrical performance comparable to conventional metal interconnects.

Strengths: Superior flexibility and stretchability compared to conventional metal interconnects; self-healing capability after mechanical damage; compatibility with existing TFT manufacturing infrastructure. Weaknesses: Challenges with long-term stability of liquid metal in operational conditions; potential for metal migration under strong electric fields; higher resistance compared to solid metal interconnects.

LG Display Co., Ltd.

Technical Solution: LG Display has pioneered a hybrid liquid metal-TFT integration approach focusing on eutectic gallium-indium (EGaIn) alloys for flexible display applications. Their technology employs a dual-layer architecture where liquid metal serves as both interconnects and functional components within the TFT structure. LG's process involves creating microchannels in polymer substrates using laser ablation techniques, followed by selective wetting treatments to control liquid metal flow and adhesion. The company has developed proprietary encapsulation materials that prevent oxidation while maintaining the mechanical properties of the liquid metal. Their most recent advancements include pressure-sensitive TFT arrays where liquid metal channels change conductivity based on applied pressure, enabling new touch interface capabilities. LG has successfully demonstrated prototype flexible displays with integrated liquid metal TFT arrays that can withstand over 100,000 bending cycles without performance degradation.

Strengths: Advanced encapsulation technology preventing oxidation and leakage; excellent mechanical durability under repeated deformation; innovative pressure-sensing capabilities. Weaknesses: Higher manufacturing complexity compared to traditional TFT processes; temperature sensitivity affecting performance in extreme environments; challenges in scaling down to ultra-high resolution displays.

Key Patents and Research Breakthroughs in Liquid Metal-TFT Systems

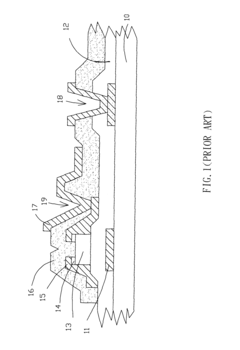

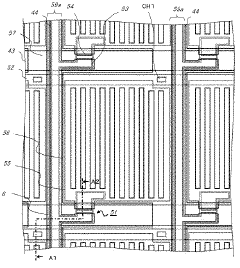

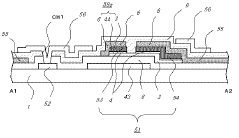

Metal contact structure and method for thin film transistor array in liquid crystal display

PatentInactiveUS6757031B2

Innovation

- A metal oxide conductive film is deposited on the source/drain electrode metal layer to protect it from plasma damage and oxide insulator formation during the contact hole etching process, using plasma dry etching with excellent controllability to form small aperture contact holes, eliminating the need for subsequent surface treatments.

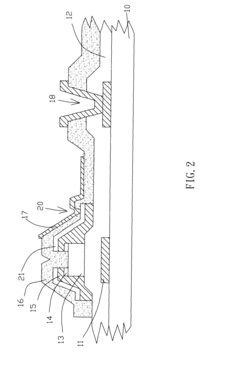

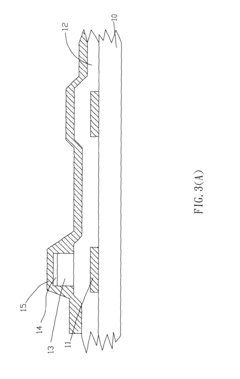

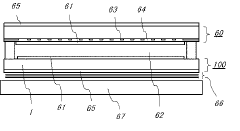

Thin film transistor array substrate, and liquid crystal display unit

PatentActiveJP2012099721A

Innovation

- A thin film transistor array substrate design where the transparent conductive film pattern directly overlaps the source or drain electrode without an intervening insulating film, and an upper insulating film is provided without covering the pattern edges, using a two-layer transparent conductive film structure to prevent film floating.

Material Compatibility and Interface Engineering Considerations

The integration of liquid metal with thin film transistor (TFT) arrays presents significant material compatibility challenges that must be addressed through careful interface engineering. Gallium-based liquid metals, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), exhibit unique properties including high electrical conductivity and fluidity at room temperature. However, these materials form native oxide layers upon exposure to oxygen, which can significantly impact their integration with semiconductor materials used in TFT fabrication.

Material compatibility issues primarily arise from the chemical reactivity of liquid metals with common TFT substrate and electrode materials. Gallium readily alloys with metals like aluminum, which is frequently used in TFT gate electrodes, potentially causing degradation of electrical properties and structural integrity. Silicon dioxide and silicon nitride, common dielectric materials in TFTs, may experience interface instability when in direct contact with liquid metals, leading to potential leakage currents and device failure.

Interface engineering solutions have emerged to address these compatibility challenges. The application of barrier layers, such as thin films of noble metals (gold, platinum) or refractory metals (tungsten, molybdenum), can effectively prevent direct contact between liquid metals and reactive TFT components. These barrier materials must maintain excellent adhesion to both the liquid metal and the underlying TFT structures while remaining chemically inert to gallium-based alloys.

Surface modification techniques represent another promising approach for enhancing compatibility. Controlled oxidation of liquid metal surfaces can create stable oxide interfaces that prevent further reaction with TFT materials. Additionally, self-assembled monolayers (SAMs) with tailored functional groups can modify the surface energy at the liquid metal-TFT interface, improving wettability and adhesion characteristics while providing a protective barrier against unwanted chemical interactions.

Thermal management considerations are crucial when engineering these interfaces, as temperature fluctuations can affect the physical state and reactivity of liquid metals. Coefficient of thermal expansion (CTE) mismatches between liquid metals and TFT materials can induce mechanical stress at interfaces during thermal cycling, potentially leading to delamination or cracking. Gradient interface designs incorporating intermediate layers with transitional CTEs have shown promise in mitigating these thermal stress issues.

Recent advances in encapsulation technologies have enabled more reliable liquid metal integration with TFTs. Microfluidic channels fabricated from chemically resistant polymers like polydimethylsiloxane (PDMS) or parylene can effectively contain liquid metals while allowing controlled electrical contact with TFT elements. These encapsulation strategies must balance hermeticity with the need for electrical connectivity and, in some applications, mechanical flexibility.

Material compatibility issues primarily arise from the chemical reactivity of liquid metals with common TFT substrate and electrode materials. Gallium readily alloys with metals like aluminum, which is frequently used in TFT gate electrodes, potentially causing degradation of electrical properties and structural integrity. Silicon dioxide and silicon nitride, common dielectric materials in TFTs, may experience interface instability when in direct contact with liquid metals, leading to potential leakage currents and device failure.

Interface engineering solutions have emerged to address these compatibility challenges. The application of barrier layers, such as thin films of noble metals (gold, platinum) or refractory metals (tungsten, molybdenum), can effectively prevent direct contact between liquid metals and reactive TFT components. These barrier materials must maintain excellent adhesion to both the liquid metal and the underlying TFT structures while remaining chemically inert to gallium-based alloys.

Surface modification techniques represent another promising approach for enhancing compatibility. Controlled oxidation of liquid metal surfaces can create stable oxide interfaces that prevent further reaction with TFT materials. Additionally, self-assembled monolayers (SAMs) with tailored functional groups can modify the surface energy at the liquid metal-TFT interface, improving wettability and adhesion characteristics while providing a protective barrier against unwanted chemical interactions.

Thermal management considerations are crucial when engineering these interfaces, as temperature fluctuations can affect the physical state and reactivity of liquid metals. Coefficient of thermal expansion (CTE) mismatches between liquid metals and TFT materials can induce mechanical stress at interfaces during thermal cycling, potentially leading to delamination or cracking. Gradient interface designs incorporating intermediate layers with transitional CTEs have shown promise in mitigating these thermal stress issues.

Recent advances in encapsulation technologies have enabled more reliable liquid metal integration with TFTs. Microfluidic channels fabricated from chemically resistant polymers like polydimethylsiloxane (PDMS) or parylene can effectively contain liquid metals while allowing controlled electrical contact with TFT elements. These encapsulation strategies must balance hermeticity with the need for electrical connectivity and, in some applications, mechanical flexibility.

Scalability and Mass Production Feasibility Assessment

The scalability of liquid metal integration with thin film transistor (TFT) arrays presents significant challenges for industrial implementation. Current laboratory-scale production methods demonstrate promising results but face substantial hurdles when transitioning to mass manufacturing environments. The primary obstacle lies in maintaining consistent liquid metal properties across large-area substrates, as variations in viscosity, surface tension, and oxidation rates can lead to performance inconsistencies in the final TFT arrays.

Manufacturing equipment for large-scale liquid metal deposition requires specialized modifications to conventional thin film processing tools. Existing physical vapor deposition (PVD) and chemical vapor deposition (CVD) systems need substantial redesign to accommodate the unique thermal and chemical properties of liquid metals. Initial cost analyses indicate that retrofitting production lines would require capital investments ranging from $5-15 million per facility, depending on desired throughput capacity.

Yield management represents another critical consideration for mass production feasibility. Current laboratory processes achieve approximately 85-90% yield rates for small-scale prototypes, but these figures are projected to decrease to 60-70% when scaled to industrial production volumes without process optimization. The primary defect modes include non-uniform liquid metal distribution, interface contamination, and oxidation-related failures during the integration process.

Material supply chain constraints further complicate scalability efforts. Gallium-based liquid metal alloys, commonly used in these applications, face potential supply limitations as global demand increases. Price volatility of constituent elements could significantly impact production costs, with recent market analyses suggesting potential 30-40% fluctuations in raw material expenses over five-year production cycles.

Process standardization presents additional challenges for quality control in mass production scenarios. The temperature-sensitive nature of liquid metal integration requires precise environmental controls throughout the manufacturing process. Variations exceeding ±2°C during critical processing steps can substantially impact device performance characteristics. Implementing such tight controls across large production facilities demands sophisticated monitoring systems and feedback mechanisms.

Despite these challenges, several technological developments show promise for improving scalability. Roll-to-roll processing adaptations for liquid metal deposition could potentially reduce manufacturing costs by 40-50% compared to traditional batch processing methods. Additionally, recent advances in microfluidic delivery systems demonstrate improved uniformity in liquid metal distribution across large substrates, potentially addressing key yield concerns.

Manufacturing equipment for large-scale liquid metal deposition requires specialized modifications to conventional thin film processing tools. Existing physical vapor deposition (PVD) and chemical vapor deposition (CVD) systems need substantial redesign to accommodate the unique thermal and chemical properties of liquid metals. Initial cost analyses indicate that retrofitting production lines would require capital investments ranging from $5-15 million per facility, depending on desired throughput capacity.

Yield management represents another critical consideration for mass production feasibility. Current laboratory processes achieve approximately 85-90% yield rates for small-scale prototypes, but these figures are projected to decrease to 60-70% when scaled to industrial production volumes without process optimization. The primary defect modes include non-uniform liquid metal distribution, interface contamination, and oxidation-related failures during the integration process.

Material supply chain constraints further complicate scalability efforts. Gallium-based liquid metal alloys, commonly used in these applications, face potential supply limitations as global demand increases. Price volatility of constituent elements could significantly impact production costs, with recent market analyses suggesting potential 30-40% fluctuations in raw material expenses over five-year production cycles.

Process standardization presents additional challenges for quality control in mass production scenarios. The temperature-sensitive nature of liquid metal integration requires precise environmental controls throughout the manufacturing process. Variations exceeding ±2°C during critical processing steps can substantially impact device performance characteristics. Implementing such tight controls across large production facilities demands sophisticated monitoring systems and feedback mechanisms.

Despite these challenges, several technological developments show promise for improving scalability. Roll-to-roll processing adaptations for liquid metal deposition could potentially reduce manufacturing costs by 40-50% compared to traditional batch processing methods. Additionally, recent advances in microfluidic delivery systems demonstrate improved uniformity in liquid metal distribution across large substrates, potentially addressing key yield concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!