Liquid Metal For Soft Actuator Electrical Interconnects

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnects Background and Objectives

Liquid metal interconnects represent a revolutionary approach to creating flexible and stretchable electrical connections for soft robotics and wearable electronics. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to traditional rigid electronic components. Gallium-based liquid metals, particularly gallium-indium eutectic alloys (EGaIn) and gallium-indium-tin (Galinstan), emerged as promising candidates due to their unique combination of high electrical conductivity and fluidity at room temperature.

The development trajectory of liquid metal interconnects has been driven by the increasing demand for soft, deformable electronic systems that can maintain functionality under mechanical stress. Traditional copper or gold wiring systems fail under repeated bending or stretching, creating a significant technological gap that liquid metals are uniquely positioned to fill. This technology has evolved from simple proof-of-concept demonstrations to sophisticated implementations in functional soft actuators and robotic systems.

Current research objectives in this field focus on addressing several key challenges. First, improving the stability and reliability of liquid metal interconnects under extreme deformation conditions remains paramount. While liquid metals can theoretically accommodate significant strain, practical implementations often suffer from connectivity issues during repeated cycling. Second, developing scalable manufacturing techniques for liquid metal integration into soft actuators represents a critical goal for commercial viability.

Another important objective is enhancing the interface between liquid metals and other electronic components. The unique surface properties of gallium-based alloys, particularly their tendency to form oxide skins, create both challenges and opportunities for creating stable electrical connections. Researchers aim to develop standardized methods for creating reliable junctions between liquid metal interconnects and conventional electronic systems.

The long-term technological goal involves creating fully integrated soft robotic systems where liquid metal serves multiple functions beyond simple electrical connectivity. This includes exploring the potential for liquid metals to act as sensors, thermal management systems, and even as active components in soft actuator mechanisms. The vision is to develop a comprehensive technological ecosystem where liquid metals enable unprecedented levels of integration between electronic control systems and mechanical actuation in soft robotics.

Understanding the fundamental physical and chemical properties of liquid metals under various environmental and mechanical conditions represents another critical research direction. This includes investigating oxidation behaviors, wetting characteristics on different substrate materials, and long-term stability under operational conditions typical of soft robotic applications.

The development trajectory of liquid metal interconnects has been driven by the increasing demand for soft, deformable electronic systems that can maintain functionality under mechanical stress. Traditional copper or gold wiring systems fail under repeated bending or stretching, creating a significant technological gap that liquid metals are uniquely positioned to fill. This technology has evolved from simple proof-of-concept demonstrations to sophisticated implementations in functional soft actuators and robotic systems.

Current research objectives in this field focus on addressing several key challenges. First, improving the stability and reliability of liquid metal interconnects under extreme deformation conditions remains paramount. While liquid metals can theoretically accommodate significant strain, practical implementations often suffer from connectivity issues during repeated cycling. Second, developing scalable manufacturing techniques for liquid metal integration into soft actuators represents a critical goal for commercial viability.

Another important objective is enhancing the interface between liquid metals and other electronic components. The unique surface properties of gallium-based alloys, particularly their tendency to form oxide skins, create both challenges and opportunities for creating stable electrical connections. Researchers aim to develop standardized methods for creating reliable junctions between liquid metal interconnects and conventional electronic systems.

The long-term technological goal involves creating fully integrated soft robotic systems where liquid metal serves multiple functions beyond simple electrical connectivity. This includes exploring the potential for liquid metals to act as sensors, thermal management systems, and even as active components in soft actuator mechanisms. The vision is to develop a comprehensive technological ecosystem where liquid metals enable unprecedented levels of integration between electronic control systems and mechanical actuation in soft robotics.

Understanding the fundamental physical and chemical properties of liquid metals under various environmental and mechanical conditions represents another critical research direction. This includes investigating oxidation behaviors, wetting characteristics on different substrate materials, and long-term stability under operational conditions typical of soft robotic applications.

Market Analysis for Soft Robotics Applications

The soft robotics market is experiencing significant growth, with a projected market value of $3.27 billion by 2026, growing at a CAGR of 35.1% from 2021. This rapid expansion is driven by increasing demand across multiple sectors including healthcare, manufacturing, and consumer electronics. Liquid metal electrical interconnects represent a critical enabling technology within this ecosystem, addressing fundamental challenges in creating reliable electrical connections in deformable structures.

Healthcare applications currently dominate the soft robotics market, accounting for approximately 40% of total market share. Within this segment, surgical assistants, rehabilitation devices, and prosthetics represent the primary applications benefiting from liquid metal interconnect technology. The ability of liquid metals to maintain conductivity under extreme deformation makes them particularly valuable for wearable medical devices and implantable technologies where patient comfort and anatomical conformity are paramount.

Manufacturing represents the second-largest application sector, with collaborative robots (cobots) incorporating soft actuators projected to grow at 42% annually through 2025. These systems require robust electrical connections that can withstand repeated mechanical stress while maintaining consistent performance. The automotive industry has emerged as a significant adopter, integrating soft robotic components into assembly processes and human-machine interfaces.

Consumer electronics applications are expanding rapidly, with particular growth in haptic feedback devices, flexible displays, and wearable technology. Market research indicates consumer preference for devices that can conform to body contours, creating a $1.2 billion opportunity specifically for stretchable electronics incorporating liquid metal interconnects by 2025.

Geographically, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate at 41% annually, driven by significant investments in manufacturing automation and healthcare robotics in China, Japan, and South Korea.

Key market barriers include material costs, with gallium-based liquid metals currently priced at $300-500 per kilogram, limiting mass-market adoption. Additionally, manufacturing scalability remains challenging, with current production methods primarily suited for laboratory or small-batch production rather than high-volume manufacturing.

Customer adoption analysis reveals that industries with high-value applications and critical reliability requirements are the early adopters, willing to absorb premium costs for performance advantages. The technology adoption curve indicates we are currently in the early adopter phase, with crossing into the early majority expected within 24-36 months as manufacturing processes mature and material costs decrease through economies of scale.

Healthcare applications currently dominate the soft robotics market, accounting for approximately 40% of total market share. Within this segment, surgical assistants, rehabilitation devices, and prosthetics represent the primary applications benefiting from liquid metal interconnect technology. The ability of liquid metals to maintain conductivity under extreme deformation makes them particularly valuable for wearable medical devices and implantable technologies where patient comfort and anatomical conformity are paramount.

Manufacturing represents the second-largest application sector, with collaborative robots (cobots) incorporating soft actuators projected to grow at 42% annually through 2025. These systems require robust electrical connections that can withstand repeated mechanical stress while maintaining consistent performance. The automotive industry has emerged as a significant adopter, integrating soft robotic components into assembly processes and human-machine interfaces.

Consumer electronics applications are expanding rapidly, with particular growth in haptic feedback devices, flexible displays, and wearable technology. Market research indicates consumer preference for devices that can conform to body contours, creating a $1.2 billion opportunity specifically for stretchable electronics incorporating liquid metal interconnects by 2025.

Geographically, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate at 41% annually, driven by significant investments in manufacturing automation and healthcare robotics in China, Japan, and South Korea.

Key market barriers include material costs, with gallium-based liquid metals currently priced at $300-500 per kilogram, limiting mass-market adoption. Additionally, manufacturing scalability remains challenging, with current production methods primarily suited for laboratory or small-batch production rather than high-volume manufacturing.

Customer adoption analysis reveals that industries with high-value applications and critical reliability requirements are the early adopters, willing to absorb premium costs for performance advantages. The technology adoption curve indicates we are currently in the early adopter phase, with crossing into the early majority expected within 24-36 months as manufacturing processes mature and material costs decrease through economies of scale.

Technical Challenges in Liquid Metal Implementation

Despite the promising potential of liquid metal for soft actuator electrical interconnects, several significant technical challenges impede its widespread implementation. The primary obstacle lies in the inherent oxidation behavior of gallium-based liquid metals, which form a thin oxide layer upon exposure to air. This oxide skin, while providing mechanical stability, creates inconsistent electrical conductivity and complicates precise control of the liquid metal flow within microchannels.

Material compatibility presents another substantial challenge. Liquid metals, particularly gallium alloys, exhibit corrosive properties that can degrade common elastomers and polymers used in soft robotics. This corrosion effect accelerates over time, compromising the structural integrity of the soft actuator and potentially leading to electrical failures or material breakdown at the interface between the liquid metal and substrate materials.

The manufacturing processes for integrating liquid metal into soft actuators remain largely artisanal rather than industrial. Current injection and patterning techniques lack the precision and repeatability necessary for mass production. Microfluidic channel fabrication requires specialized equipment and expertise, while the viscosity and surface tension properties of liquid metals make automated dispensing systems challenging to implement effectively.

Thermal management issues also present significant hurdles. During operation, electrical current passing through liquid metal interconnects generates heat that can alter the mechanical properties of surrounding elastomers. This thermal expansion mismatch between the liquid metal and encapsulating materials can lead to delamination or rupture of microchannels during extended operation cycles.

Long-term reliability and stability concerns further complicate implementation. Environmental factors such as temperature fluctuations, mechanical stress, and humidity can affect the performance of liquid metal interconnects over time. The migration and potential leakage of liquid metal from microchannels during repeated deformation cycles remains inadequately addressed in current research.

Standardization and characterization methodologies for liquid metal electrical interconnects are notably underdeveloped. The lack of industry standards for testing mechanical durability, electrical performance, and failure modes hampers comparative analysis between different implementation approaches. This absence of standardized metrics makes it difficult for researchers and manufacturers to benchmark their innovations effectively.

Cost considerations also present barriers to widespread adoption. Current gallium-based liquid metals remain relatively expensive compared to traditional conductive materials, with limited economies of scale in production. The specialized equipment and expertise required for implementation further increase the overall cost structure, making commercial viability challenging for mass-market applications.

Material compatibility presents another substantial challenge. Liquid metals, particularly gallium alloys, exhibit corrosive properties that can degrade common elastomers and polymers used in soft robotics. This corrosion effect accelerates over time, compromising the structural integrity of the soft actuator and potentially leading to electrical failures or material breakdown at the interface between the liquid metal and substrate materials.

The manufacturing processes for integrating liquid metal into soft actuators remain largely artisanal rather than industrial. Current injection and patterning techniques lack the precision and repeatability necessary for mass production. Microfluidic channel fabrication requires specialized equipment and expertise, while the viscosity and surface tension properties of liquid metals make automated dispensing systems challenging to implement effectively.

Thermal management issues also present significant hurdles. During operation, electrical current passing through liquid metal interconnects generates heat that can alter the mechanical properties of surrounding elastomers. This thermal expansion mismatch between the liquid metal and encapsulating materials can lead to delamination or rupture of microchannels during extended operation cycles.

Long-term reliability and stability concerns further complicate implementation. Environmental factors such as temperature fluctuations, mechanical stress, and humidity can affect the performance of liquid metal interconnects over time. The migration and potential leakage of liquid metal from microchannels during repeated deformation cycles remains inadequately addressed in current research.

Standardization and characterization methodologies for liquid metal electrical interconnects are notably underdeveloped. The lack of industry standards for testing mechanical durability, electrical performance, and failure modes hampers comparative analysis between different implementation approaches. This absence of standardized metrics makes it difficult for researchers and manufacturers to benchmark their innovations effectively.

Cost considerations also present barriers to widespread adoption. Current gallium-based liquid metals remain relatively expensive compared to traditional conductive materials, with limited economies of scale in production. The specialized equipment and expertise required for implementation further increase the overall cost structure, making commercial viability challenging for mass-market applications.

Current Liquid Metal Interconnect Solutions

01 Liquid metal interconnect compositions

Liquid metal compositions are used for electrical interconnects due to their unique properties. These compositions typically include gallium-based alloys such as gallium-indium-tin (Galinstan) or other eutectic alloys that remain liquid at room temperature. These materials offer excellent electrical conductivity while maintaining flexibility, making them ideal for applications requiring both electrical performance and mechanical adaptability. The liquid nature allows for self-healing connections and conforming to irregular surfaces.- Liquid metal interconnect compositions: Liquid metal compositions are used for electrical interconnects due to their unique properties. These compositions typically include gallium-based alloys such as gallium-indium-tin (Galinstan) or other eutectic alloys that remain liquid at room temperature. These materials offer excellent electrical conductivity while maintaining flexibility. The liquid nature allows for self-healing connections and adaptation to mechanical stresses that would damage traditional solid interconnects.

- Encapsulation techniques for liquid metal interconnects: Various encapsulation methods are employed to contain liquid metal interconnects while maintaining their electrical properties. These include polymer encapsulation, microfluidic channels, and elastomeric substrates that prevent leakage while allowing controlled deformation. The encapsulation materials must be compatible with the liquid metal to prevent oxidation or degradation while maintaining electrical isolation from surrounding components.

- Flexible and stretchable electronic applications: Liquid metal interconnects are particularly valuable in flexible and stretchable electronics. These applications include wearable devices, soft robotics, and biomedical implants where traditional rigid interconnects would fail under repeated bending or stretching. The liquid metal maintains electrical connectivity even when subjected to significant deformation, enabling electronics that can conform to complex surfaces or withstand mechanical strain.

- Manufacturing and deposition methods: Various techniques have been developed for precisely depositing and patterning liquid metal interconnects. These include direct writing, microcontact printing, selective wetting, injection into microchannels, and masked deposition. Advanced manufacturing methods allow for creating complex circuit patterns with liquid metals while maintaining precise control over dimensions and electrical properties. Some approaches incorporate pressure-assisted injection or vacuum techniques to ensure void-free interconnects.

- Thermal management and reliability: Liquid metal interconnects offer excellent thermal conductivity, making them useful for heat dissipation in electronic components. Their ability to maintain contact under thermal cycling improves reliability compared to solid interconnects that may develop cracks or fatigue. Special attention is given to preventing oxidation and ensuring long-term stability of the liquid metal interfaces. Various surface treatments and alloy compositions are used to enhance wetting properties and maintain reliable electrical connections over time.

02 Encapsulation techniques for liquid metal interconnects

Various encapsulation methods are employed to contain liquid metal interconnects while maintaining their electrical properties. These techniques include using elastomeric materials, microchannels, or specialized polymers that prevent leakage while allowing controlled deformation. Encapsulation systems often incorporate stretchable or flexible materials that can accommodate movement while keeping the liquid metal properly contained, which is crucial for wearable electronics and flexible circuit applications.Expand Specific Solutions03 Manufacturing methods for liquid metal interconnects

Specialized manufacturing techniques have been developed for creating liquid metal interconnects in electronic devices. These methods include microfluidic injection, printing techniques, selective wetting, and direct writing processes. Advanced manufacturing approaches allow for precise patterning and placement of liquid metal, enabling the creation of complex interconnect structures at various scales. These techniques often involve controlling the surface tension and oxidation properties of the liquid metal to achieve desired patterns and connections.Expand Specific Solutions04 Integration with semiconductor devices

Liquid metal interconnects can be integrated with semiconductor devices to create novel electronic systems. This integration involves specialized interface designs that allow liquid metals to make reliable electrical contact with solid-state components. Techniques include creating metallized pads, using transition materials, or developing specialized bonding methods that accommodate the unique properties of liquid metals. These approaches enable the combination of conventional semiconductor technology with the flexibility and self-healing properties of liquid metal interconnects.Expand Specific Solutions05 Thermal management applications

Liquid metals are used in interconnects that serve dual purposes as both electrical conductors and thermal management solutions. These interconnects leverage the high thermal conductivity of liquid metals to dissipate heat while maintaining electrical connections. This approach is particularly valuable in high-power electronics where thermal management is critical. The liquid nature allows for improved thermal contact with surfaces and can adapt to thermal expansion and contraction while maintaining electrical continuity.Expand Specific Solutions

Leading Companies in Liquid Metal and Soft Robotics

The liquid metal soft actuator electrical interconnects market is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global market size is estimated to be relatively modest but growing rapidly, driven by expanding applications in soft robotics, wearable electronics, and biomedical devices. From a technological maturity perspective, this field is transitioning from research to early commercialization, with key players demonstrating varying levels of advancement. Intel, Samsung Electronics, and Taiwan Semiconductor are leveraging liquid metal technologies for next-generation flexible electronics, while research institutions like National University of Singapore and Cornell University are pioneering fundamental innovations. Companies such as Resonac Corp. and Sumitomo Electric Industries are developing specialized materials and manufacturing processes, positioning themselves as potential suppliers in this emerging ecosystem.

National University of Singapore

Technical Solution: National University of Singapore has developed innovative liquid metal-based soft actuator electrical interconnects using gallium-indium alloys (EGaIn). Their technology focuses on creating stretchable, self-healing circuits that maintain conductivity under extreme deformation. The university's research team has pioneered methods for patterning liquid metal within elastomeric substrates using microfluidic channels, allowing for complex circuit designs that can withstand up to 700% strain without electrical failure. They've also developed novel surface modification techniques to control the oxide skin formation on liquid metals, enabling better adhesion to various substrate materials while maintaining fluidity. Their recent advancements include embedding liquid metal networks within 3D printed soft robotic structures, creating fully integrated sensing and actuation systems with minimal external wiring requirements. The technology has been demonstrated in wearable health monitoring devices and soft robotic grippers with integrated tactile sensing capabilities.

Strengths: Exceptional stretchability and deformation tolerance while maintaining electrical conductivity; self-healing properties that automatically restore connections after mechanical damage; compatibility with various elastomeric substrates. Weaknesses: Potential for metal oxidation affecting long-term performance; challenges in precise deposition and patterning for mass production; higher cost compared to conventional rigid interconnects.

Tianjin University

Technical Solution: Tianjin University has developed a comprehensive liquid metal electrical interconnect system specifically designed for soft actuators. Their approach utilizes eutectic gallium-indium (EGaIn) alloys embedded in microchannels within silicone elastomers. The university's research team has created a novel fabrication process that allows for direct writing of liquid metal patterns using controlled pressure injection, achieving line widths as small as 10μm. Their technology incorporates a dual-layer architecture where the liquid metal serves both as electrical conductor and as an interface layer that reduces mechanical stress between rigid components and soft substrates. A key innovation is their oxygen-controlled encapsulation method that manipulates the oxide skin formation on liquid metals to enhance adhesion while maintaining electrical performance. The team has demonstrated this technology in soft pneumatic actuators with integrated sensing capabilities, where the liquid metal interconnects can withstand over 500,000 actuation cycles without performance degradation. Recent advancements include the development of self-healing interconnects that can automatically restore electrical continuity after mechanical damage through controlled liquid metal flow.

Strengths: Exceptional durability under repeated mechanical deformation; high electrical conductivity comparable to solid metals; compatibility with various soft actuator designs and manufacturing processes. Weaknesses: Challenges in preventing liquid metal leakage under extreme deformation; potential for oxidation affecting long-term stability; higher manufacturing complexity compared to traditional wiring solutions.

Key Patents in Liquid Metal Electrical Conductivity

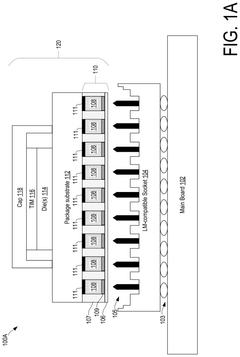

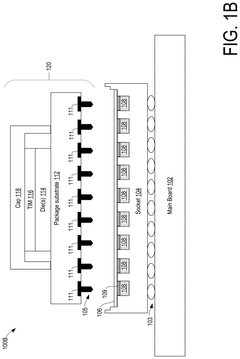

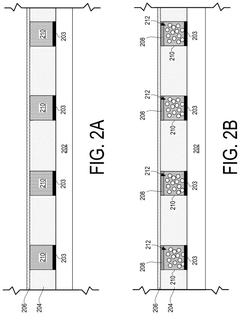

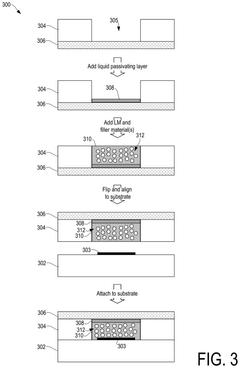

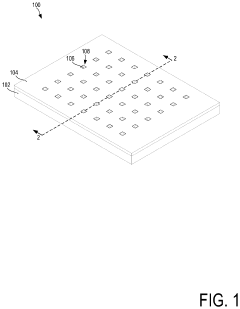

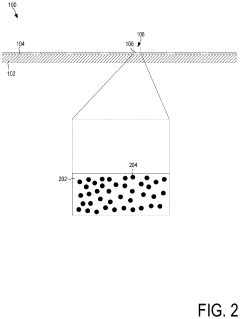

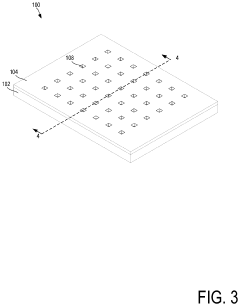

Liquid metal socket interconnects with liquid passivation layer and filler materials

PatentPendingUS20250079278A1

Innovation

- Implementation of a liquid passivation layer, such as mineral oil or paraffin wax, within the LM wells to prevent sticking and oxide formation, along with inert filler materials to reduce LM usage and costs.

Technologies for liquid metal mixtures for electrical interconnects

PatentPendingUS20230317533A1

Innovation

- A substrate with channels filled with a liquid metal mixture of gallium and fine particles, which increases viscosity and surface bonding properties, allowing for feasible screen printing and effective electrical coupling, used for creating liquid metal interconnects that can be sealed for reliable connections.

Materials Compatibility and Biocompatibility Assessment

The compatibility of liquid metals with surrounding materials is a critical consideration for soft actuator electrical interconnects. Gallium-based liquid metals, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), exhibit unique chemical properties that must be carefully evaluated when interfacing with elastomers, polymers, and other structural components. These liquid metals readily form oxide layers when exposed to oxygen, which can lead to adhesion issues with certain polymers like polydimethylsiloxane (PDMS), a commonly used material in soft robotics.

Research indicates that liquid metals demonstrate varying degrees of compatibility with different elastomers. While PDMS remains the most widely used substrate, recent studies have explored alternatives such as polyurethane, silicone rubbers, and fluoroelastomers that offer improved chemical resistance to gallium alloys. The selection of appropriate material combinations significantly impacts the long-term stability and performance of liquid metal interconnects in dynamic soft actuator applications.

Biocompatibility assessment of liquid metal interconnects reveals promising potential for biomedical applications. Gallium itself has historically been used in certain medical applications and exhibits lower toxicity compared to mercury. However, comprehensive studies on the long-term biocompatibility of gallium-based liquid metals in soft actuator contexts remain limited. Recent research has demonstrated that encapsulated liquid metal circuits within biocompatible elastomers can effectively isolate the metal from direct tissue contact, mitigating potential toxicity concerns.

The oxidation behavior of liquid metals presents both challenges and opportunities for biocompatibility. The gallium oxide skin that forms naturally provides a passivation layer that can reduce metal ion leaching into surrounding tissues. However, this same oxide layer may affect the mechanical properties and electrical performance of interconnects over time, particularly under repeated deformation cycles typical in soft actuator applications.

Environmental considerations must also factor into compatibility assessments. The potential for gallium to amalgamate with and embrittle certain metals, particularly aluminum, necessitates careful design of supporting structures and housing components. This galvanic interaction can compromise structural integrity in applications where aluminum components are present, requiring appropriate isolation strategies or alternative material selections.

Standardized testing protocols for evaluating the long-term compatibility of liquid metal systems with both structural materials and biological environments are still evolving. Current assessment methods typically combine mechanical durability testing, chemical stability evaluation, and cytotoxicity assays. The development of more comprehensive testing frameworks specific to dynamic soft actuator applications represents an important area for future research to ensure reliable performance and safety in practical implementations.

Research indicates that liquid metals demonstrate varying degrees of compatibility with different elastomers. While PDMS remains the most widely used substrate, recent studies have explored alternatives such as polyurethane, silicone rubbers, and fluoroelastomers that offer improved chemical resistance to gallium alloys. The selection of appropriate material combinations significantly impacts the long-term stability and performance of liquid metal interconnects in dynamic soft actuator applications.

Biocompatibility assessment of liquid metal interconnects reveals promising potential for biomedical applications. Gallium itself has historically been used in certain medical applications and exhibits lower toxicity compared to mercury. However, comprehensive studies on the long-term biocompatibility of gallium-based liquid metals in soft actuator contexts remain limited. Recent research has demonstrated that encapsulated liquid metal circuits within biocompatible elastomers can effectively isolate the metal from direct tissue contact, mitigating potential toxicity concerns.

The oxidation behavior of liquid metals presents both challenges and opportunities for biocompatibility. The gallium oxide skin that forms naturally provides a passivation layer that can reduce metal ion leaching into surrounding tissues. However, this same oxide layer may affect the mechanical properties and electrical performance of interconnects over time, particularly under repeated deformation cycles typical in soft actuator applications.

Environmental considerations must also factor into compatibility assessments. The potential for gallium to amalgamate with and embrittle certain metals, particularly aluminum, necessitates careful design of supporting structures and housing components. This galvanic interaction can compromise structural integrity in applications where aluminum components are present, requiring appropriate isolation strategies or alternative material selections.

Standardized testing protocols for evaluating the long-term compatibility of liquid metal systems with both structural materials and biological environments are still evolving. Current assessment methods typically combine mechanical durability testing, chemical stability evaluation, and cytotoxicity assays. The development of more comprehensive testing frameworks specific to dynamic soft actuator applications represents an important area for future research to ensure reliable performance and safety in practical implementations.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of liquid metal-based electrical interconnects for soft actuators presents significant challenges and opportunities in transitioning from laboratory prototypes to mass production. Current manufacturing processes primarily rely on manual injection or direct writing techniques, which are labor-intensive and time-consuming. These methods, while suitable for research environments, create substantial barriers to industrial-scale implementation due to their inherent inefficiency and inconsistency.

Recent advancements in automated dispensing systems and microfluidic channel fabrication have shown promise in improving production throughput. Specifically, the development of precision-controlled pneumatic dispensing equipment has increased deposition accuracy while reducing operator dependency. However, these systems still face limitations in handling the unique rheological properties of liquid metals such as gallium-indium alloys, particularly their tendency to oxidize upon exposure to air and adhere to dispensing equipment.

Cost analysis reveals that material expenses constitute a significant portion of production costs. Gallium, the primary component in most liquid metal formulations, has experienced price volatility due to its limited global supply and increasing demand across various industries. Current market prices range from $300-600 per kilogram, making it substantially more expensive than conventional conductive materials like copper ($6-8 per kilogram). This cost differential presents a major hurdle for widespread adoption, particularly in price-sensitive consumer applications.

Production yield rates present another critical economic consideration. The encapsulation process for liquid metal interconnects often suffers from defect rates of 15-25% in current manufacturing setups. These defects primarily manifest as channel leakage or inconsistent electrical performance, requiring additional quality control measures that further increase production costs. Improving yield rates through enhanced manufacturing protocols and materials engineering represents a key opportunity for cost reduction.

Economies of scale remain largely unexplored for liquid metal interconnect production. While theoretical models suggest potential cost reductions of 30-40% at high-volume production, these projections have yet to be validated in industrial settings. The development of specialized equipment for liquid metal handling and deposition could significantly reduce per-unit costs but requires substantial initial capital investment that may deter smaller manufacturers.

Environmental considerations also impact manufacturing scalability, as gallium mining and processing carry ecological footprints that must be addressed in sustainable production frameworks. Recycling pathways for liquid metal components remain underdeveloped, presenting both a challenge and an opportunity for establishing circular economy approaches in this emerging technology sector.

Recent advancements in automated dispensing systems and microfluidic channel fabrication have shown promise in improving production throughput. Specifically, the development of precision-controlled pneumatic dispensing equipment has increased deposition accuracy while reducing operator dependency. However, these systems still face limitations in handling the unique rheological properties of liquid metals such as gallium-indium alloys, particularly their tendency to oxidize upon exposure to air and adhere to dispensing equipment.

Cost analysis reveals that material expenses constitute a significant portion of production costs. Gallium, the primary component in most liquid metal formulations, has experienced price volatility due to its limited global supply and increasing demand across various industries. Current market prices range from $300-600 per kilogram, making it substantially more expensive than conventional conductive materials like copper ($6-8 per kilogram). This cost differential presents a major hurdle for widespread adoption, particularly in price-sensitive consumer applications.

Production yield rates present another critical economic consideration. The encapsulation process for liquid metal interconnects often suffers from defect rates of 15-25% in current manufacturing setups. These defects primarily manifest as channel leakage or inconsistent electrical performance, requiring additional quality control measures that further increase production costs. Improving yield rates through enhanced manufacturing protocols and materials engineering represents a key opportunity for cost reduction.

Economies of scale remain largely unexplored for liquid metal interconnect production. While theoretical models suggest potential cost reductions of 30-40% at high-volume production, these projections have yet to be validated in industrial settings. The development of specialized equipment for liquid metal handling and deposition could significantly reduce per-unit costs but requires substantial initial capital investment that may deter smaller manufacturers.

Environmental considerations also impact manufacturing scalability, as gallium mining and processing carry ecological footprints that must be addressed in sustainable production frameworks. Recycling pathways for liquid metal components remain underdeveloped, presenting both a challenge and an opportunity for establishing circular economy approaches in this emerging technology sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!