Encapsulation Methods For Durable Liquid Metal Tracks On Textiles

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Textile Integration Background & Objectives

Liquid metal integration with textiles represents a significant frontier in the development of wearable electronics and smart fabrics. The evolution of this technology can be traced back to early experiments with conductive materials in textiles during the late 1990s, but has gained substantial momentum in the past decade with the discovery of room-temperature liquid metals such as gallium-based alloys. These materials offer unique advantages including excellent electrical conductivity, inherent flexibility, and self-healing properties that make them particularly suitable for wearable applications.

The technological trajectory has shifted from rigid electronic components attached to fabrics toward truly integrated, flexible systems where the electronic functionality becomes an intrinsic part of the textile structure. Liquid metals have emerged as a promising solution due to their ability to maintain conductivity under mechanical deformation, a critical requirement for wearable technology that must withstand the rigors of daily use including bending, stretching, and washing.

Current research focuses on developing reliable methods to pattern and encapsulate liquid metal traces on textile substrates while maintaining durability through multiple wear and wash cycles. The field has progressed from rudimentary proof-of-concept demonstrations to increasingly sophisticated integration techniques, including microfluidic channels, direct writing methods, and various encapsulation strategies using polymers and other protective materials.

The primary technical objectives in this domain include developing encapsulation methods that provide robust protection against environmental factors while maintaining the flexibility and comfort of the textile substrate. Researchers aim to create liquid metal tracks that can withstand at least 50 wash cycles without significant degradation in electrical performance, maintain conductivity under mechanical strain of up to 30%, and resist oxidation and corrosion in various environmental conditions including exposure to sweat and moisture.

Additionally, there is a growing emphasis on scalable manufacturing processes that can transition these technologies from laboratory demonstrations to commercial production. This includes developing printing or patterning techniques compatible with existing textile manufacturing infrastructure and identifying encapsulation materials that are both protective and environmentally sustainable.

The ultimate goal is to enable a new generation of smart textiles with seamlessly integrated electronic functionality for applications ranging from health monitoring and sports performance analysis to interactive fashion and military applications. Success in this field could fundamentally transform our relationship with both textiles and electronics, creating truly wearable systems that combine the comfort and aesthetics of traditional fabrics with advanced electronic capabilities.

The technological trajectory has shifted from rigid electronic components attached to fabrics toward truly integrated, flexible systems where the electronic functionality becomes an intrinsic part of the textile structure. Liquid metals have emerged as a promising solution due to their ability to maintain conductivity under mechanical deformation, a critical requirement for wearable technology that must withstand the rigors of daily use including bending, stretching, and washing.

Current research focuses on developing reliable methods to pattern and encapsulate liquid metal traces on textile substrates while maintaining durability through multiple wear and wash cycles. The field has progressed from rudimentary proof-of-concept demonstrations to increasingly sophisticated integration techniques, including microfluidic channels, direct writing methods, and various encapsulation strategies using polymers and other protective materials.

The primary technical objectives in this domain include developing encapsulation methods that provide robust protection against environmental factors while maintaining the flexibility and comfort of the textile substrate. Researchers aim to create liquid metal tracks that can withstand at least 50 wash cycles without significant degradation in electrical performance, maintain conductivity under mechanical strain of up to 30%, and resist oxidation and corrosion in various environmental conditions including exposure to sweat and moisture.

Additionally, there is a growing emphasis on scalable manufacturing processes that can transition these technologies from laboratory demonstrations to commercial production. This includes developing printing or patterning techniques compatible with existing textile manufacturing infrastructure and identifying encapsulation materials that are both protective and environmentally sustainable.

The ultimate goal is to enable a new generation of smart textiles with seamlessly integrated electronic functionality for applications ranging from health monitoring and sports performance analysis to interactive fashion and military applications. Success in this field could fundamentally transform our relationship with both textiles and electronics, creating truly wearable systems that combine the comfort and aesthetics of traditional fabrics with advanced electronic capabilities.

Market Analysis for Wearable E-Textile Applications

The wearable e-textile market is experiencing unprecedented growth, driven by increasing consumer demand for smart clothing and accessories that seamlessly integrate technology into daily life. The global smart textile market was valued at $3.2 billion in 2022 and is projected to reach $13.6 billion by 2027, growing at a CAGR of 26.2%. Within this sector, e-textiles incorporating liquid metal tracks represent a particularly promising segment due to their superior flexibility, durability, and conductivity compared to traditional conductive materials.

Healthcare applications currently dominate the e-textile market, accounting for approximately 32% of total revenue. Medical monitoring garments that track vital signs, temperature, and movement patterns are gaining significant traction among healthcare providers seeking remote patient monitoring solutions. The sports and fitness sector follows closely, representing 28% of the market, with performance-monitoring apparel and footwear showing strong consumer adoption rates.

Military and defense applications constitute another substantial market segment (18%), where durability requirements for liquid metal encapsulation methods are particularly stringent. These applications demand textiles that can withstand extreme environmental conditions while maintaining electrical functionality. The fashion and consumer electronics sectors collectively represent 22% of the market, with growing interest in aesthetically pleasing wearable technology that doesn't compromise on style or comfort.

Regional analysis reveals North America as the current market leader with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 29.8% over the next five years, driven by expanding manufacturing capabilities and increasing consumer adoption in China, Japan, and South Korea.

Consumer surveys indicate that durability remains the primary concern for potential e-textile adopters, with 67% of respondents citing longevity as their top consideration when purchasing smart garments. This directly relates to the critical importance of effective encapsulation methods for liquid metal tracks, as inadequate protection leads to premature product failure and poor user experience.

Price sensitivity varies significantly across market segments, with healthcare and military applications demonstrating higher willingness to pay premium prices for superior performance and reliability. Consumer applications remain more price-sensitive, suggesting that cost-effective encapsulation methods will be crucial for mass-market adoption of liquid metal e-textile technology.

Market forecasts suggest that innovations in liquid metal encapsulation technology could unlock a potential $5.8 billion sub-market within the broader e-textile industry by 2028, particularly if durability challenges can be overcome. This represents a significant opportunity for companies that can develop effective, scalable encapsulation methods that maintain conductivity while providing protection against washing, stretching, and environmental factors.

Healthcare applications currently dominate the e-textile market, accounting for approximately 32% of total revenue. Medical monitoring garments that track vital signs, temperature, and movement patterns are gaining significant traction among healthcare providers seeking remote patient monitoring solutions. The sports and fitness sector follows closely, representing 28% of the market, with performance-monitoring apparel and footwear showing strong consumer adoption rates.

Military and defense applications constitute another substantial market segment (18%), where durability requirements for liquid metal encapsulation methods are particularly stringent. These applications demand textiles that can withstand extreme environmental conditions while maintaining electrical functionality. The fashion and consumer electronics sectors collectively represent 22% of the market, with growing interest in aesthetically pleasing wearable technology that doesn't compromise on style or comfort.

Regional analysis reveals North America as the current market leader with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 29.8% over the next five years, driven by expanding manufacturing capabilities and increasing consumer adoption in China, Japan, and South Korea.

Consumer surveys indicate that durability remains the primary concern for potential e-textile adopters, with 67% of respondents citing longevity as their top consideration when purchasing smart garments. This directly relates to the critical importance of effective encapsulation methods for liquid metal tracks, as inadequate protection leads to premature product failure and poor user experience.

Price sensitivity varies significantly across market segments, with healthcare and military applications demonstrating higher willingness to pay premium prices for superior performance and reliability. Consumer applications remain more price-sensitive, suggesting that cost-effective encapsulation methods will be crucial for mass-market adoption of liquid metal e-textile technology.

Market forecasts suggest that innovations in liquid metal encapsulation technology could unlock a potential $5.8 billion sub-market within the broader e-textile industry by 2028, particularly if durability challenges can be overcome. This represents a significant opportunity for companies that can develop effective, scalable encapsulation methods that maintain conductivity while providing protection against washing, stretching, and environmental factors.

Current Encapsulation Challenges for Textile-Based Liquid Metals

Despite significant advancements in liquid metal integration with textiles, encapsulation remains one of the most critical challenges limiting widespread adoption. Current encapsulation methods face substantial durability issues when subjected to the mechanical stresses inherent in everyday textile use. Conventional polymer-based encapsulants such as PDMS (polydimethylsiloxane) and polyurethane provide initial protection but frequently develop microcracks after repeated bending, stretching, or washing cycles, leading to oxidation of the liquid metal and subsequent circuit failure.

The adhesion interface between encapsulants and textile substrates presents another significant challenge. Most encapsulation materials bond poorly with textile fibers, creating weak points where delamination occurs during mechanical deformation. This interface weakness is particularly problematic for applications requiring frequent movement, such as smart clothing or medical monitoring garments, where the constant flexing accelerates encapsulation breakdown.

Water permeability represents a third major challenge, as most current encapsulation solutions cannot maintain waterproof integrity through multiple washing cycles. Studies indicate that after just 5-10 standard machine wash cycles, over 60% of encapsulated liquid metal circuits experience performance degradation due to moisture ingress. This severely limits practical application in everyday wearable technology.

Temperature stability poses additional difficulties, with many encapsulants exhibiting significant property changes across the temperature range experienced by wearable textiles. Thermal expansion coefficient mismatches between the encapsulant, liquid metal, and textile substrate create internal stresses that compromise the protective barrier, particularly during temperature fluctuations between storage and use conditions.

Chemical compatibility issues further complicate encapsulation efforts. Many textile treatments, cleaning agents, and environmental contaminants can degrade encapsulation materials over time. Particularly problematic are interactions with common textile finishing chemicals and detergents, which can cause swelling, embrittlement, or increased permeability in the protective layers.

Manufacturing scalability remains an obstacle for many promising laboratory-scale encapsulation techniques. Methods that provide excellent protection in controlled research environments often prove difficult to implement in industrial textile production lines. Current industrial-compatible encapsulation processes typically sacrifice performance for manufacturability, resulting in compromised durability.

The balance between protective efficacy and textile comfort presents perhaps the most challenging trade-off. Highly effective barrier materials tend to be rigid and impermeable, significantly reducing the breathability, flexibility, and tactile qualities that make textiles desirable for wearable applications. This fundamental tension between protection and wearability continues to drive research toward novel encapsulation approaches that can satisfy both requirements simultaneously.

The adhesion interface between encapsulants and textile substrates presents another significant challenge. Most encapsulation materials bond poorly with textile fibers, creating weak points where delamination occurs during mechanical deformation. This interface weakness is particularly problematic for applications requiring frequent movement, such as smart clothing or medical monitoring garments, where the constant flexing accelerates encapsulation breakdown.

Water permeability represents a third major challenge, as most current encapsulation solutions cannot maintain waterproof integrity through multiple washing cycles. Studies indicate that after just 5-10 standard machine wash cycles, over 60% of encapsulated liquid metal circuits experience performance degradation due to moisture ingress. This severely limits practical application in everyday wearable technology.

Temperature stability poses additional difficulties, with many encapsulants exhibiting significant property changes across the temperature range experienced by wearable textiles. Thermal expansion coefficient mismatches between the encapsulant, liquid metal, and textile substrate create internal stresses that compromise the protective barrier, particularly during temperature fluctuations between storage and use conditions.

Chemical compatibility issues further complicate encapsulation efforts. Many textile treatments, cleaning agents, and environmental contaminants can degrade encapsulation materials over time. Particularly problematic are interactions with common textile finishing chemicals and detergents, which can cause swelling, embrittlement, or increased permeability in the protective layers.

Manufacturing scalability remains an obstacle for many promising laboratory-scale encapsulation techniques. Methods that provide excellent protection in controlled research environments often prove difficult to implement in industrial textile production lines. Current industrial-compatible encapsulation processes typically sacrifice performance for manufacturability, resulting in compromised durability.

The balance between protective efficacy and textile comfort presents perhaps the most challenging trade-off. Highly effective barrier materials tend to be rigid and impermeable, significantly reducing the breathability, flexibility, and tactile qualities that make textiles desirable for wearable applications. This fundamental tension between protection and wearability continues to drive research toward novel encapsulation approaches that can satisfy both requirements simultaneously.

State-of-the-Art Liquid Metal Encapsulation Methods

01 Protective coatings for liquid metal tracks

Various protective coatings can be applied to liquid metal tracks to enhance their durability against environmental factors. These coatings create a barrier that prevents oxidation and corrosion while maintaining electrical conductivity. The protective layers can be made from polymers, metal oxides, or composite materials that adhere well to the liquid metal surface while providing flexibility to accommodate the liquid nature of the tracks.- Protective coatings for liquid metal tracks: Various protective coatings can be applied to liquid metal tracks to enhance their durability against environmental factors. These coatings create a barrier that prevents oxidation and corrosion while maintaining electrical conductivity. The protective layers can be made from polymers, metal oxides, or composite materials that adhere well to the liquid metal surface while providing flexibility and resistance to mechanical stress.

- Self-healing mechanisms for liquid metal circuits: Self-healing technologies have been developed to improve the durability of liquid metal tracks. These mechanisms allow the liquid metal to automatically repair minor damages or breaks in the conductive path. When a track is damaged, the liquid nature of the metal enables it to flow back into position, restoring electrical connectivity. Some formulations include additives that promote this self-healing behavior under specific conditions such as heat or pressure application.

- Substrate materials and adhesion enhancement: The choice of substrate material significantly impacts the durability of liquid metal tracks. Specialized substrates with micro or nano-textured surfaces improve adhesion between the liquid metal and the base material. Surface treatments and primers can be applied to enhance wetting properties and bonding strength. Flexible substrates that can withstand repeated bending and stretching while maintaining adhesion to the liquid metal are particularly valuable for wearable and flexible electronic applications.

- Encapsulation techniques for environmental protection: Encapsulation methods protect liquid metal tracks from environmental factors that could degrade performance. These techniques involve sealing the liquid metal pathways within protective layers that prevent exposure to oxygen, moisture, and contaminants. Various encapsulation materials including elastomers, resins, and specialized polymers can be used depending on the application requirements. The encapsulation must maintain flexibility while providing a hermetic seal around the liquid metal components.

- Alloy composition for improved mechanical stability: The composition of liquid metal alloys can be engineered to enhance durability while maintaining desirable electrical properties. By adjusting the ratio of constituent metals or introducing trace elements, researchers have developed alloys with improved resistance to oxidation, better adhesion to substrates, and enhanced mechanical stability. Some alloys exhibit controlled viscosity and surface tension properties that help maintain track integrity during mechanical stress or temperature fluctuations.

02 Self-healing mechanisms for liquid metal circuits

Self-healing technologies can be incorporated into liquid metal tracks to automatically repair damage and extend durability. These mechanisms typically involve encapsulation systems that contain reserve liquid metal that can flow to damaged areas when breaches occur. Some designs include microcapsules that rupture upon damage, releasing healing agents that restore conductivity and structural integrity to the tracks, making them more resistant to mechanical stress and repeated use.Expand Specific Solutions03 Substrate materials and adhesion enhancement

The choice of substrate material significantly impacts the durability of liquid metal tracks. Specialized substrates with surface treatments can improve adhesion between the liquid metal and the base material, preventing delamination during thermal or mechanical stress. Some innovations include micro-textured surfaces that create mechanical interlocking with the liquid metal or chemical treatments that form strong bonds at the interface, enhancing overall track durability and reliability.Expand Specific Solutions04 Strain-resistant liquid metal composites

Advanced liquid metal composites incorporate supporting materials that enhance mechanical stability while maintaining electrical properties. These composites often combine liquid metals with elastomers, nanoparticles, or fiber reinforcements to create tracks that can withstand significant stretching, bending, and twisting without losing functionality. The resulting materials show improved fatigue resistance and can maintain conductivity even after thousands of deformation cycles.Expand Specific Solutions05 Environmental resistance enhancements

Specialized formulations of liquid metal alloys can be developed to resist environmental degradation factors such as humidity, temperature fluctuations, and chemical exposure. These formulations may include additives that inhibit oxidation or create passive layers on the metal surface. Some approaches involve encapsulation systems that completely isolate the liquid metal from environmental factors while still allowing the tracks to function as intended in electronic applications.Expand Specific Solutions

Leading Companies in Conductive Textile Manufacturing

The liquid metal textile encapsulation market is in its early growth phase, characterized by significant research activity but limited commercial deployment. The global smart textiles market, which encompasses this technology, is projected to reach $13 billion by 2027, with liquid metal tracks representing an emerging segment. Technical challenges in durability and washability are driving innovation across multiple sectors. Research institutions like École Polytechnique Fédérale de Lausanne, North Carolina State University, and Fraunhofer-Gesellschaft are leading fundamental research, while companies including BASF, Adidas, and IBM are exploring commercial applications. The technology sits at TRL 4-6, with industrial players like Siemens and Mitsubishi Electric focusing on integration with existing manufacturing processes to overcome scalability challenges for mass production.

École Polytechnique Fédérale de Lausanne

Technical Solution: École Polytechnique Fédérale de Lausanne (EPFL) has developed an advanced encapsulation system for liquid metal tracks on textiles using a multilayer composite approach. Their method employs a combination of vapor-phase deposition and solution processing to create hermetically sealed liquid metal pathways. The process begins with plasma treatment of textile surfaces to create reactive binding sites, followed by deposition of a thin parylene-C barrier layer (approximately 2μm thick) that serves as the primary encapsulation material[7]. Liquid metal (typically EGaIn or Galinstan) is then injected into microchannels created through laser ablation of the parylene layer. The final encapsulation step involves deposition of another parylene layer followed by a fluoropolymer coating that provides additional chemical resistance. EPFL's research has demonstrated remarkable stability with encapsulated tracks maintaining electrical performance after exposure to harsh environmental conditions including immersion in saline solutions for over 1000 hours and temperature cycling between -20°C and 80°C[8]. Their technology also incorporates specialized junction designs that maintain electrical connectivity during extreme bending and folding operations.

Strengths: Exceptional chemical resistance and environmental stability making it suitable for medical and harsh environment applications; excellent barrier properties preventing liquid metal oxidation and leakage; precise control over track dimensions enabling high-density circuit patterns. Weaknesses: Relatively high manufacturing costs due to specialized equipment requirements; limited stretchability compared to some elastomer-based approaches; challenges in scaling up production for large textile areas.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed a sophisticated encapsulation methodology for liquid metal tracks on textiles using a biomimetic approach inspired by natural vascular systems. Their technique employs a dual-layer encapsulation strategy with an inner hydrophobic elastomer layer directly contacting the liquid metal (primarily gallium-indium alloys) and an outer layer composed of a specialized fluoropolymer with self-healing properties[9]. The encapsulation process begins with creating microchannels in the textile substrate using laser ablation, followed by surface modification using plasma treatment to enhance adhesion. Liquid metal is then injected into these channels and sealed using the dual-layer approach. CNRS researchers have incorporated microcapsules containing reactive silicone agents that are released upon mechanical damage, allowing the encapsulation layer to autonomously repair minor tears and punctures[10]. Testing has demonstrated remarkable durability with encapsulated tracks maintaining conductivity after 100+ washing cycles and withstanding mechanical deformation including folding, twisting, and stretching up to 150% of original length. Their innovation also includes developing specialized textile-compatible adhesion promoters that enhance bonding between the encapsulation materials and various fabric types.

Strengths: Excellent self-healing capability that extends the functional lifespan of the electronic textiles; good washability and environmental resistance suitable for everyday wearable applications; strong adhesion to various textile substrates. Weaknesses: Complex manufacturing process requiring multiple specialized steps; potential biocompatibility concerns with some encapsulation materials limiting medical applications; relatively high material costs compared to conventional conductive textiles.

Key Patents in Textile-Compatible Liquid Metal Protection

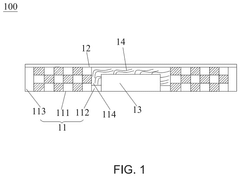

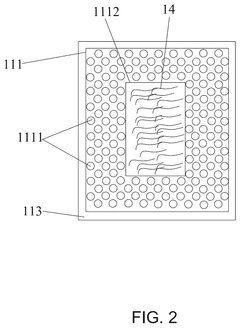

Liquid metal encapsulation device

PatentPendingUS20250201664A1

Innovation

- A liquid metal encapsulation device featuring a sealing frame with multiple holes for air discharge and compressibility to ensure uniform liquid metal distribution, combined with first and second elastic sealing rings to prevent liquid metal leakage.

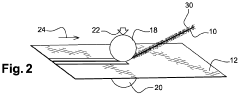

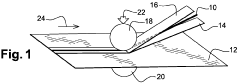

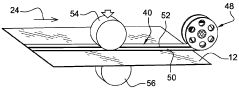

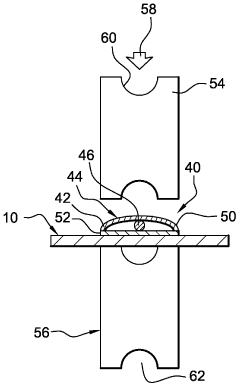

Method for attaching an element onto a fabric surface, and resulting fabric

PatentWO2011135211A1

Innovation

- A method involving encapsulating elements in heat-fusible material, applying them to the fabric surface, and using pressure and energy to melt the material, creating a protective pocket that integrates with the fabric fibers without significantly reducing flexibility.

Washability and Durability Testing Standards

The standardization of washability and durability testing for liquid metal tracks on textiles represents a critical aspect of their commercial viability. Currently, the industry employs several established testing protocols adapted from traditional electronic textiles evaluation methods. The American Association of Textile Chemists and Colorists (AATCC) Test Method 135 serves as a primary standard for evaluating dimensional changes in fabrics after repeated home laundering, which has been modified to assess the integrity of liquid metal circuits post-washing.

ISO 6330 provides comprehensive guidelines for domestic washing and drying procedures specifically designed for textile testing. For liquid metal tracks, these standards have been supplemented with electrical conductivity measurements before and after specified washing cycles, typically ranging from 5 to 50 cycles depending on the intended application. The IPC-9204 standard, originally developed for printed electronics, has been adapted to evaluate the durability of flexible conductive materials on textiles.

Mechanical durability testing follows standards such as ASTM D4966 for abrasion resistance and ASTM F1683 for flex durability. These tests simulate real-world wear conditions through controlled bending, folding, and abrasion cycles. For liquid metal tracks, specialized testing parameters include bend radii ranging from 2mm to 10mm and cycle counts up to 10,000 repetitions to simulate extended use scenarios.

Environmental durability standards incorporate temperature and humidity testing according to IEC 60068-2-14 (temperature cycling) and IEC 60068-2-78 (steady-state humidity). Liquid metal encapsulation methods must demonstrate stability across temperature ranges from -20°C to +70°C and humidity levels up to 95% RH. Additionally, sweat resistance testing following AATCC 15 has been adapted to evaluate chemical compatibility with human perspiration.

Recent developments in testing standards include the introduction of combined stress testing protocols that simultaneously evaluate multiple durability factors. The emerging ASTM WK70157 standard specifically addresses e-textiles and includes provisions for liquid metal interconnects. This standard proposes comprehensive evaluation metrics including wash durability index (WDI) and mechanical stress resistance factor (MSRF) to quantify performance across multiple stress dimensions.

Industry consensus suggests that commercial viability requires liquid metal tracks to maintain at least 90% of their initial conductivity after 20 standard washing cycles and 1,000 mechanical stress cycles. However, medical and military applications often demand higher standards, requiring performance maintenance after 50+ washing cycles and 10,000+ mechanical stress cycles, highlighting the need for application-specific testing protocols.

ISO 6330 provides comprehensive guidelines for domestic washing and drying procedures specifically designed for textile testing. For liquid metal tracks, these standards have been supplemented with electrical conductivity measurements before and after specified washing cycles, typically ranging from 5 to 50 cycles depending on the intended application. The IPC-9204 standard, originally developed for printed electronics, has been adapted to evaluate the durability of flexible conductive materials on textiles.

Mechanical durability testing follows standards such as ASTM D4966 for abrasion resistance and ASTM F1683 for flex durability. These tests simulate real-world wear conditions through controlled bending, folding, and abrasion cycles. For liquid metal tracks, specialized testing parameters include bend radii ranging from 2mm to 10mm and cycle counts up to 10,000 repetitions to simulate extended use scenarios.

Environmental durability standards incorporate temperature and humidity testing according to IEC 60068-2-14 (temperature cycling) and IEC 60068-2-78 (steady-state humidity). Liquid metal encapsulation methods must demonstrate stability across temperature ranges from -20°C to +70°C and humidity levels up to 95% RH. Additionally, sweat resistance testing following AATCC 15 has been adapted to evaluate chemical compatibility with human perspiration.

Recent developments in testing standards include the introduction of combined stress testing protocols that simultaneously evaluate multiple durability factors. The emerging ASTM WK70157 standard specifically addresses e-textiles and includes provisions for liquid metal interconnects. This standard proposes comprehensive evaluation metrics including wash durability index (WDI) and mechanical stress resistance factor (MSRF) to quantify performance across multiple stress dimensions.

Industry consensus suggests that commercial viability requires liquid metal tracks to maintain at least 90% of their initial conductivity after 20 standard washing cycles and 1,000 mechanical stress cycles. However, medical and military applications often demand higher standards, requiring performance maintenance after 50+ washing cycles and 10,000+ mechanical stress cycles, highlighting the need for application-specific testing protocols.

Environmental Impact of Liquid Metal E-Textiles

The environmental implications of liquid metal e-textiles are becoming increasingly significant as this technology advances toward commercial applications. The primary environmental concerns revolve around the toxicity and bioaccumulation potential of gallium-based liquid metals, which are commonly used in these applications. While gallium itself has relatively low toxicity compared to mercury or lead, its alloys may contain elements with varying environmental impacts. The long-term effects of these materials in ecosystems remain inadequately studied, particularly regarding their potential to leach into soil and water systems.

Waste management presents another critical environmental challenge. As liquid metal e-textiles reach end-of-life, conventional textile recycling systems are not equipped to handle these hybrid materials. The separation of liquid metal components from fabric substrates requires specialized processes that are not yet widely available. This creates a risk of improper disposal, potentially leading to contamination of landfills and water sources with metallic compounds that may persist in the environment.

Manufacturing processes for liquid metal e-textiles also contribute to their environmental footprint. The production of gallium and its alloys involves energy-intensive mining and refining operations. Additionally, encapsulation methods often utilize synthetic polymers derived from petroleum sources, further increasing the carbon footprint of these products. Some encapsulation materials, particularly fluoropolymers, have been associated with persistent environmental pollutants.

Energy consumption during the lifecycle of liquid metal e-textiles must also be considered. While the operational phase may be relatively energy-efficient, the embodied energy in materials production and processing can be substantial. The environmental trade-offs between durability and resource intensity require careful assessment to determine the net environmental benefit of these technologies.

Promising developments in green chemistry approaches to liquid metal encapsulation offer potential pathways to reduce environmental impact. Biodegradable polymers and naturally derived encapsulants are emerging as alternatives to conventional synthetic materials. Research into bio-based encapsulation methods using cellulose derivatives, chitosan, and other renewable resources shows potential for creating more environmentally compatible e-textiles.

Regulatory frameworks for managing the environmental aspects of liquid metal e-textiles are still evolving. The novelty of these materials presents challenges for existing waste electrical and electronic equipment (WEEE) directives, which may not adequately address the unique characteristics of liquid metal components embedded in textiles. Developing appropriate end-of-life management strategies will be crucial for minimizing the environmental footprint of this emerging technology.

Waste management presents another critical environmental challenge. As liquid metal e-textiles reach end-of-life, conventional textile recycling systems are not equipped to handle these hybrid materials. The separation of liquid metal components from fabric substrates requires specialized processes that are not yet widely available. This creates a risk of improper disposal, potentially leading to contamination of landfills and water sources with metallic compounds that may persist in the environment.

Manufacturing processes for liquid metal e-textiles also contribute to their environmental footprint. The production of gallium and its alloys involves energy-intensive mining and refining operations. Additionally, encapsulation methods often utilize synthetic polymers derived from petroleum sources, further increasing the carbon footprint of these products. Some encapsulation materials, particularly fluoropolymers, have been associated with persistent environmental pollutants.

Energy consumption during the lifecycle of liquid metal e-textiles must also be considered. While the operational phase may be relatively energy-efficient, the embodied energy in materials production and processing can be substantial. The environmental trade-offs between durability and resource intensity require careful assessment to determine the net environmental benefit of these technologies.

Promising developments in green chemistry approaches to liquid metal encapsulation offer potential pathways to reduce environmental impact. Biodegradable polymers and naturally derived encapsulants are emerging as alternatives to conventional synthetic materials. Research into bio-based encapsulation methods using cellulose derivatives, chitosan, and other renewable resources shows potential for creating more environmentally compatible e-textiles.

Regulatory frameworks for managing the environmental aspects of liquid metal e-textiles are still evolving. The novelty of these materials presents challenges for existing waste electrical and electronic equipment (WEEE) directives, which may not adequately address the unique characteristics of liquid metal components embedded in textiles. Developing appropriate end-of-life management strategies will be crucial for minimizing the environmental footprint of this emerging technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!