Liquid Metal Interconnects For Flexible Power Distribution

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Technology Background and Objectives

Liquid metal technology represents a revolutionary approach to power distribution systems, combining the electrical conductivity of metals with the flexibility of liquids. The evolution of this technology can be traced back to early experiments with mercury in the 19th century, though modern applications utilize safer alternatives such as gallium-based alloys. These non-toxic liquid metals maintain their conductive properties while offering unprecedented mechanical flexibility, making them ideal candidates for next-generation flexible electronics.

The technological trajectory has accelerated significantly over the past decade, with research institutions and technology companies increasingly focusing on liquid metal applications. This surge in interest coincides with the growing demand for flexible, wearable, and stretchable electronic devices that can withstand mechanical deformation while maintaining electrical performance. The field has progressed from basic material science exploration to practical implementation in prototype devices.

Current liquid metal interconnect technology aims to overcome the limitations of traditional rigid copper wiring and brittle conductive traces. While conventional interconnects fail under bending, stretching, or twisting conditions, liquid metal interconnects can maintain conductivity even when subjected to extreme deformation, potentially revolutionizing power distribution in flexible electronics.

The primary technical objectives in this field include developing reliable encapsulation methods to contain liquid metals, creating scalable manufacturing processes for mass production, improving the electrical-mechanical interface between liquid metals and solid components, and enhancing long-term stability under various environmental conditions. Researchers are particularly focused on preventing oxidation issues that can compromise conductivity over time.

Another critical goal is to achieve comparable or superior electrical performance to conventional copper interconnects while maintaining flexibility. This includes minimizing resistance, maximizing current-carrying capacity, and ensuring consistent performance across temperature variations. The technology must also address challenges related to thermal management, as flexible power distribution systems often operate in thermally constrained environments.

Looking forward, the field is moving toward integration with emerging technologies such as printed electronics, soft robotics, and biomedical implants. The ultimate vision encompasses self-healing interconnects that can automatically restore electrical connections after mechanical damage, adaptive systems that can reconfigure their conductive pathways based on applied stress, and environmentally sustainable alternatives to traditional electronic interconnects.

The convergence of materials science, electrical engineering, and manufacturing innovation is driving this technology toward commercial viability, with potential applications spanning consumer electronics, healthcare devices, automotive systems, and aerospace components. As research continues to address current limitations, liquid metal interconnects stand poised to fundamentally transform how power is distributed in next-generation flexible electronic systems.

The technological trajectory has accelerated significantly over the past decade, with research institutions and technology companies increasingly focusing on liquid metal applications. This surge in interest coincides with the growing demand for flexible, wearable, and stretchable electronic devices that can withstand mechanical deformation while maintaining electrical performance. The field has progressed from basic material science exploration to practical implementation in prototype devices.

Current liquid metal interconnect technology aims to overcome the limitations of traditional rigid copper wiring and brittle conductive traces. While conventional interconnects fail under bending, stretching, or twisting conditions, liquid metal interconnects can maintain conductivity even when subjected to extreme deformation, potentially revolutionizing power distribution in flexible electronics.

The primary technical objectives in this field include developing reliable encapsulation methods to contain liquid metals, creating scalable manufacturing processes for mass production, improving the electrical-mechanical interface between liquid metals and solid components, and enhancing long-term stability under various environmental conditions. Researchers are particularly focused on preventing oxidation issues that can compromise conductivity over time.

Another critical goal is to achieve comparable or superior electrical performance to conventional copper interconnects while maintaining flexibility. This includes minimizing resistance, maximizing current-carrying capacity, and ensuring consistent performance across temperature variations. The technology must also address challenges related to thermal management, as flexible power distribution systems often operate in thermally constrained environments.

Looking forward, the field is moving toward integration with emerging technologies such as printed electronics, soft robotics, and biomedical implants. The ultimate vision encompasses self-healing interconnects that can automatically restore electrical connections after mechanical damage, adaptive systems that can reconfigure their conductive pathways based on applied stress, and environmentally sustainable alternatives to traditional electronic interconnects.

The convergence of materials science, electrical engineering, and manufacturing innovation is driving this technology toward commercial viability, with potential applications spanning consumer electronics, healthcare devices, automotive systems, and aerospace components. As research continues to address current limitations, liquid metal interconnects stand poised to fundamentally transform how power is distributed in next-generation flexible electronic systems.

Market Analysis for Flexible Power Distribution Solutions

The flexible power distribution market is experiencing significant growth driven by the increasing demand for wearable electronics, soft robotics, and flexible consumer devices. Current market projections indicate that the global flexible electronics market will reach approximately $42 billion by 2027, with power distribution components representing a substantial segment of this expansion. The compound annual growth rate (CAGR) for flexible power solutions specifically is estimated at 21% through 2025, outpacing many other electronics sectors.

Consumer electronics remains the dominant application sector, accounting for roughly 35% of the flexible power distribution market. This is followed by healthcare applications at 28%, automotive at 18%, and industrial applications comprising the remaining 19%. The healthcare segment, particularly in medical wearables and implantable devices, shows the highest growth potential with a projected 24% CAGR over the next five years.

Liquid metal interconnects represent a particularly promising technology within this market landscape. Traditional copper-based rigid interconnects are increasingly unable to meet the mechanical requirements of next-generation flexible devices. Liquid metal solutions offer superior elasticity, maintaining electrical conductivity even under extreme deformation conditions of up to 300% strain in some formulations, compared to conventional copper traces that typically fail beyond 2-3% strain.

Regionally, East Asia dominates manufacturing capacity with approximately 62% of global production, while North America leads in research and development investment, contributing nearly 45% of global R&D funding in this field. Europe has established a strong position in specialized applications, particularly in automotive and healthcare implementations.

Key market drivers include miniaturization demands, with devices requiring increasingly compact power distribution solutions while maintaining or improving performance characteristics. Energy efficiency has become another critical factor, with the market showing preference for solutions that minimize power loss across flexible interconnects. Additionally, biocompatibility requirements are expanding the potential applications in healthcare, creating new market opportunities for non-toxic liquid metal formulations.

Market barriers include manufacturing scalability challenges, with current production methods for liquid metal interconnects remaining largely laboratory-focused and difficult to implement in high-volume manufacturing environments. Material costs also present significant obstacles, as gallium-based liquid metals currently cost 4-8 times more than traditional copper solutions per equivalent conductive pathway. Reliability concerns persist among potential adopters, particularly regarding long-term performance stability under repeated mechanical stress.

Consumer electronics remains the dominant application sector, accounting for roughly 35% of the flexible power distribution market. This is followed by healthcare applications at 28%, automotive at 18%, and industrial applications comprising the remaining 19%. The healthcare segment, particularly in medical wearables and implantable devices, shows the highest growth potential with a projected 24% CAGR over the next five years.

Liquid metal interconnects represent a particularly promising technology within this market landscape. Traditional copper-based rigid interconnects are increasingly unable to meet the mechanical requirements of next-generation flexible devices. Liquid metal solutions offer superior elasticity, maintaining electrical conductivity even under extreme deformation conditions of up to 300% strain in some formulations, compared to conventional copper traces that typically fail beyond 2-3% strain.

Regionally, East Asia dominates manufacturing capacity with approximately 62% of global production, while North America leads in research and development investment, contributing nearly 45% of global R&D funding in this field. Europe has established a strong position in specialized applications, particularly in automotive and healthcare implementations.

Key market drivers include miniaturization demands, with devices requiring increasingly compact power distribution solutions while maintaining or improving performance characteristics. Energy efficiency has become another critical factor, with the market showing preference for solutions that minimize power loss across flexible interconnects. Additionally, biocompatibility requirements are expanding the potential applications in healthcare, creating new market opportunities for non-toxic liquid metal formulations.

Market barriers include manufacturing scalability challenges, with current production methods for liquid metal interconnects remaining largely laboratory-focused and difficult to implement in high-volume manufacturing environments. Material costs also present significant obstacles, as gallium-based liquid metals currently cost 4-8 times more than traditional copper solutions per equivalent conductive pathway. Reliability concerns persist among potential adopters, particularly regarding long-term performance stability under repeated mechanical stress.

Current Challenges in Liquid Metal Interconnect Development

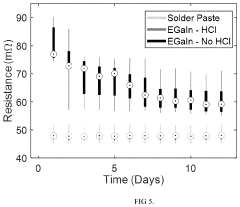

Despite the promising potential of liquid metal interconnects for flexible power distribution, several significant technical challenges impede their widespread adoption and commercialization. The primary obstacle remains the inherent oxidation tendency of gallium-based liquid metals when exposed to air, forming a thin oxide layer that affects electrical conductivity and interfacial properties. This oxidation process complicates both manufacturing processes and long-term reliability in practical applications.

Encapsulation presents another formidable challenge, as containing liquid metals within flexible substrates while maintaining their fluidic properties requires advanced materials engineering. Current encapsulation materials often struggle to balance mechanical flexibility with impermeability to liquid metals, particularly under repeated deformation cycles. The interface between liquid metals and solid conductors also presents persistent contact resistance issues that can significantly impact overall system performance.

Manufacturing scalability remains underdeveloped, with most fabrication techniques limited to laboratory-scale production. Transitioning from proof-of-concept prototypes to mass-producible components requires substantial process innovation. Existing methods such as microfluidic injection, direct printing, and selective wetting all face limitations in precision, reproducibility, and throughput when considered for industrial-scale implementation.

The mechanical stability of liquid metal interconnects under various stress conditions presents ongoing reliability concerns. While theoretically capable of withstanding significant deformation, practical implementations often suffer from issues such as metal migration, channel delamination, and performance degradation after repeated mechanical cycling. These reliability issues become particularly pronounced in applications requiring thousands of flexing cycles or operation in extreme environmental conditions.

Electrical performance consistency across temperature variations poses another significant challenge. Liquid metals exhibit temperature-dependent viscosity and electrical properties that can fluctuate in real-world operating environments. This variability complicates their integration into systems requiring precise electrical characteristics across diverse operating conditions.

Toxicity and environmental considerations also present barriers, particularly for gallium-indium alloys containing toxic elements. Developing environmentally friendly alternatives while maintaining desirable electrical and mechanical properties remains an active research area with limited breakthrough solutions to date.

Cost factors further constrain commercial viability, as gallium and indium remain relatively expensive compared to conventional conductive materials. The specialized manufacturing equipment and processes required for liquid metal integration add additional cost barriers that must be overcome for mainstream adoption in consumer electronics and power distribution applications.

Encapsulation presents another formidable challenge, as containing liquid metals within flexible substrates while maintaining their fluidic properties requires advanced materials engineering. Current encapsulation materials often struggle to balance mechanical flexibility with impermeability to liquid metals, particularly under repeated deformation cycles. The interface between liquid metals and solid conductors also presents persistent contact resistance issues that can significantly impact overall system performance.

Manufacturing scalability remains underdeveloped, with most fabrication techniques limited to laboratory-scale production. Transitioning from proof-of-concept prototypes to mass-producible components requires substantial process innovation. Existing methods such as microfluidic injection, direct printing, and selective wetting all face limitations in precision, reproducibility, and throughput when considered for industrial-scale implementation.

The mechanical stability of liquid metal interconnects under various stress conditions presents ongoing reliability concerns. While theoretically capable of withstanding significant deformation, practical implementations often suffer from issues such as metal migration, channel delamination, and performance degradation after repeated mechanical cycling. These reliability issues become particularly pronounced in applications requiring thousands of flexing cycles or operation in extreme environmental conditions.

Electrical performance consistency across temperature variations poses another significant challenge. Liquid metals exhibit temperature-dependent viscosity and electrical properties that can fluctuate in real-world operating environments. This variability complicates their integration into systems requiring precise electrical characteristics across diverse operating conditions.

Toxicity and environmental considerations also present barriers, particularly for gallium-indium alloys containing toxic elements. Developing environmentally friendly alternatives while maintaining desirable electrical and mechanical properties remains an active research area with limited breakthrough solutions to date.

Cost factors further constrain commercial viability, as gallium and indium remain relatively expensive compared to conventional conductive materials. The specialized manufacturing equipment and processes required for liquid metal integration add additional cost barriers that must be overcome for mainstream adoption in consumer electronics and power distribution applications.

Current Technical Solutions for Flexible Power Distribution

01 Gallium-based liquid metal alloys for flexible interconnects

Gallium-based liquid metal alloys, such as gallium-indium (GaIn) and gallium-indium-tin (Galinstan), are used to create flexible interconnects in electronic devices. These materials remain liquid at room temperature and can maintain electrical conductivity while being stretched or bent. The inherent fluidity of these alloys allows them to adapt to deformation without breaking, making them ideal for wearable electronics and flexible displays where traditional solid metal interconnects would fail under mechanical stress.- Gallium-based liquid metal interconnects: Gallium-based liquid metals offer excellent electrical conductivity while maintaining flexibility for stretchable electronics. These materials can flow and reconfigure under mechanical stress without losing electrical connectivity, making them ideal for flexible electronic applications. The low melting point of gallium alloys allows them to remain liquid at room temperature while providing stable electrical pathways that can withstand repeated bending and stretching.

- Encapsulation techniques for liquid metal interconnects: Various encapsulation methods are used to contain liquid metal within flexible substrates while allowing controlled deformation. These techniques include microfluidic channels, elastomeric encapsulation, and patterned structures that guide the liquid metal during stretching. Proper encapsulation prevents leakage while maintaining the mechanical advantages of liquid metals, enabling reliable performance in wearable electronics and flexible displays.

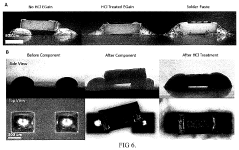

- Integration of liquid metal with semiconductor devices: Techniques for integrating liquid metal interconnects with traditional semiconductor components enable hybrid flexible-rigid electronic systems. These methods include specialized bonding processes, interface materials that accommodate the transition between solid and liquid conductors, and novel packaging approaches. The integration allows for combining the processing power of conventional electronics with the mechanical flexibility of liquid metal interconnects.

- Self-healing interconnect technologies: Self-healing properties of liquid metal interconnects allow them to automatically restore electrical connectivity after mechanical damage. When a connection is broken, the liquid nature of these metals enables them to flow back together, reforming the conductive pathway without external intervention. This capability significantly enhances the reliability and lifespan of flexible electronic devices that undergo frequent bending, folding, or stretching.

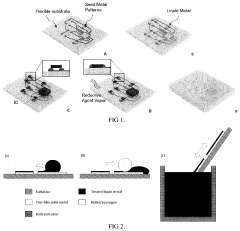

- Manufacturing processes for flexible liquid metal circuits: Advanced manufacturing techniques have been developed specifically for creating flexible liquid metal interconnects, including direct printing, selective wetting, injection molding, and laser patterning. These processes allow for precise deposition and patterning of liquid metals on flexible substrates, enabling mass production of complex flexible circuits. The manufacturing methods address challenges such as oxide formation, substrate adhesion, and dimensional control while maintaining the flexibility of the final product.

02 Encapsulation techniques for liquid metal interconnects

Various encapsulation methods are employed to contain liquid metal interconnects while maintaining their flexibility. These techniques include using elastomeric materials like PDMS (polydimethylsiloxane), microfluidic channels, and specialized polymer composites. Proper encapsulation prevents leakage of the liquid metal while allowing the interconnect to deform freely. The encapsulation material must be carefully selected to be compatible with the liquid metal, preventing oxidation while maintaining the desired mechanical properties of the overall system.Expand Specific Solutions03 Patterning and deposition methods for liquid metal circuits

Specialized techniques have been developed for patterning and depositing liquid metals to form flexible interconnects. These include direct writing, stencil printing, selective wetting, and microcontact printing. Advanced methods also incorporate laser patterning and photolithography adapted for liquid metals. These techniques allow for precise control over the geometry and placement of liquid metal interconnects, enabling complex circuit designs while maintaining flexibility and stretchability.Expand Specific Solutions04 Integration of liquid metal interconnects with rigid components

Techniques for integrating flexible liquid metal interconnects with rigid electronic components have been developed to create hybrid flexible-rigid systems. These methods include specialized bonding techniques, transition zones, and interface materials that can accommodate the mechanical mismatch between liquid interconnects and solid components. This integration is crucial for creating practical electronic devices that combine the flexibility of liquid metal interconnects with the functionality of conventional semiconductor components.Expand Specific Solutions05 Self-healing properties of liquid metal interconnects

Liquid metal interconnects exhibit self-healing properties that allow them to recover from mechanical damage. When a liquid metal interconnect is severed, the liquid nature of the material allows it to flow back together when the separated parts are brought into contact, restoring electrical conductivity. This self-healing capability significantly enhances the reliability and durability of flexible electronic systems, particularly in applications subject to repeated mechanical stress or potential damage.Expand Specific Solutions

Leading Companies in Liquid Metal Interconnect Industry

Liquid Metal Interconnects for Flexible Power Distribution technology is currently in an emerging growth phase, with the market expanding due to increasing demand for flexible electronics and power systems. The global market size is estimated to be growing at a CAGR of 15-20%, driven by applications in wearable technology, automotive electronics, and renewable energy. From a technical maturity perspective, the field shows varied development levels across key players. Intel, Qualcomm, and LG Chem are advancing commercial applications, while research institutions like Tsinghua University and Technical Institute of Physics & Chemistry CAS are pioneering fundamental breakthroughs. Companies like Beijing Dream Ink Technology and Yunnan Jujing New Material are developing specialized manufacturing processes, while established players such as Siemens and ElringKlinger are integrating liquid metal technologies into existing power distribution systems.

Technical Institute of Physics & Chemistry CAS

Technical Solution: The Technical Institute of Physics & Chemistry at the Chinese Academy of Sciences has pioneered fundamental research in liquid metal interconnect technology for flexible power distribution. Their approach utilizes low-melting-point gallium-based alloys (primarily Ga-In-Sn systems) embedded within microfluidic channels created in elastomeric substrates. The institute has developed novel surface modification techniques to control the wetting behavior of liquid metals, enabling precise patterning and stable electrical connections. Their research has yielded breakthrough methods for preventing oxidation through specialized encapsulation materials that maintain flexibility while providing an oxygen barrier. The institute has also created innovative "liquid metal composite electrodes" that combine liquid metal with conductive nanoparticles to enhance mechanical stability while preserving electrical conductivity under deformation. Recent developments include self-healing interconnect systems that can automatically restore electrical connections after mechanical damage.

Strengths: Cutting-edge fundamental research with numerous patents; excellent electrical performance (conductivity approaching bulk metals); superior mechanical flexibility and stretchability (>400% strain tolerance); innovative self-healing capabilities. Weaknesses: Technologies still primarily at laboratory scale; challenges with mass production scalability; higher costs compared to conventional interconnects; potential environmental concerns with some gallium compounds.

China Green Space Liquid Metal Technology (Jiangsu) Co., Ltd.

Technical Solution: China Green Space Liquid Metal Technology has developed advanced room-temperature liquid metal interconnects using gallium-based alloys (primarily Ga-In-Sn) for flexible power distribution systems. Their technology employs microfluidic channels embedded in elastomeric substrates, allowing the liquid metal to maintain electrical conductivity even under extreme deformation conditions. The company has pioneered encapsulation techniques that prevent oxidation and leakage while maintaining the liquid state of the metal interconnects. Their latest innovations include self-healing capabilities where severed connections can automatically restore conductivity when brought back into contact. The company has also developed specialized injection and patterning methods for precise deposition of liquid metal into complex circuit designs, enabling high-current capacity flexible interconnects that can withstand repeated mechanical stress without performance degradation.

Strengths: Exceptional flexibility and stretchability (up to 300% strain while maintaining conductivity); self-healing properties; high electrical conductivity comparable to solid metals; excellent thermal management capabilities. Weaknesses: Higher production costs compared to conventional interconnects; potential toxicity concerns with gallium compounds; challenges with long-term encapsulation integrity; limited compatibility with some electronic components.

Key Patents and Research in Liquid Metal Conductivity

Liquid metal circuits and methods of making the same

PatentPendingUS20240032189A1

Innovation

- The development of liquid metal circuits with self-healing properties, achieved through coating metallic traces with eutectic gallium-indium (EGaIn) or gallium-indium-tin (Galinstan) alloys on elastic substrates, enabling high-throughput manufacturing and integration with traditional electronics for enhanced conductivity and flexibility.

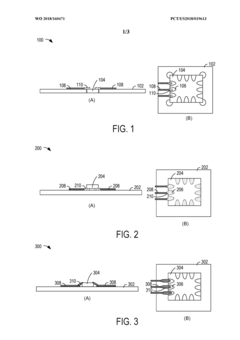

Flexible conductive bonding

PatentWO2018160471A1

Innovation

- The use of flexible interconnects, such as liquid metal or conductive polymers, that bridge between conductive traces and pads on a flexible substrate, allowing for flexible electrical pathways and self-healing characteristics, while being encapsulated with a suitable material to maintain the connection and prevent damage from stress.

Manufacturing Processes for Liquid Metal Integration

The manufacturing processes for liquid metal integration into flexible power distribution systems have evolved significantly in recent years, addressing the unique challenges posed by the fluid nature of these conductive materials. Direct printing techniques represent one of the most promising approaches, utilizing modified inkjet or extrusion printing systems specifically calibrated for the rheological properties of liquid metals. These systems typically employ precision nozzles with controlled pressure mechanisms to deposit liquid metal alloys in predefined patterns on flexible substrates, achieving line widths as fine as 10-50 micrometers depending on the specific equipment configuration.

Microfluidic channel fabrication offers another sophisticated manufacturing pathway, wherein pre-formed channels are created in elastomeric substrates using soft lithography techniques. These channels are subsequently filled with liquid metal through vacuum-assisted injection or capillary action. This approach provides excellent encapsulation and prevents oxidation issues that commonly affect exposed liquid metal surfaces, though it requires precise control of channel dimensions to ensure complete filling without void formation.

Selective wetting methods exploit the surface tension properties of liquid metals by creating patterned surfaces with alternating wettability. Typically, this involves treating substrate surfaces with oxygen plasma or chemical modifications to create hydrophilic regions that attract liquid metal alloys, while maintaining hydrophobic regions that repel them. When liquid metal is applied to these patterned surfaces, it selectively adheres to the wettable regions, forming conductive pathways without the need for physical containment structures.

Stencil-based deposition represents a more accessible manufacturing technique, utilizing laser-cut or photolithographically defined masks to control liquid metal placement. The stencil is temporarily affixed to the substrate, liquid metal is applied across the surface, and excess material is removed, leaving behind the desired pattern. While offering lower resolution than direct printing methods, this approach requires minimal specialized equipment and can be implemented in standard laboratory environments.

Post-processing techniques play a crucial role in optimizing the electrical and mechanical properties of liquid metal interconnects. These include controlled oxidation to form stable surface layers, thermal annealing to improve adhesion to substrates, and encapsulation with protective polymers to prevent leakage during flexing. Recent innovations have focused on developing self-healing capabilities, where mechanical damage to interconnects can be automatically repaired through the inherent fluidity of the liquid metal, significantly enhancing the reliability of flexible power distribution systems.

Integration with traditional electronics manufacturing workflows remains a significant challenge, requiring specialized handling protocols and equipment modifications to accommodate the unique properties of liquid metals. Hybrid manufacturing approaches that combine conventional solid conductor fabrication with strategic liquid metal integration at critical flexing points represent a promising direction for industrial implementation.

Microfluidic channel fabrication offers another sophisticated manufacturing pathway, wherein pre-formed channels are created in elastomeric substrates using soft lithography techniques. These channels are subsequently filled with liquid metal through vacuum-assisted injection or capillary action. This approach provides excellent encapsulation and prevents oxidation issues that commonly affect exposed liquid metal surfaces, though it requires precise control of channel dimensions to ensure complete filling without void formation.

Selective wetting methods exploit the surface tension properties of liquid metals by creating patterned surfaces with alternating wettability. Typically, this involves treating substrate surfaces with oxygen plasma or chemical modifications to create hydrophilic regions that attract liquid metal alloys, while maintaining hydrophobic regions that repel them. When liquid metal is applied to these patterned surfaces, it selectively adheres to the wettable regions, forming conductive pathways without the need for physical containment structures.

Stencil-based deposition represents a more accessible manufacturing technique, utilizing laser-cut or photolithographically defined masks to control liquid metal placement. The stencil is temporarily affixed to the substrate, liquid metal is applied across the surface, and excess material is removed, leaving behind the desired pattern. While offering lower resolution than direct printing methods, this approach requires minimal specialized equipment and can be implemented in standard laboratory environments.

Post-processing techniques play a crucial role in optimizing the electrical and mechanical properties of liquid metal interconnects. These include controlled oxidation to form stable surface layers, thermal annealing to improve adhesion to substrates, and encapsulation with protective polymers to prevent leakage during flexing. Recent innovations have focused on developing self-healing capabilities, where mechanical damage to interconnects can be automatically repaired through the inherent fluidity of the liquid metal, significantly enhancing the reliability of flexible power distribution systems.

Integration with traditional electronics manufacturing workflows remains a significant challenge, requiring specialized handling protocols and equipment modifications to accommodate the unique properties of liquid metals. Hybrid manufacturing approaches that combine conventional solid conductor fabrication with strategic liquid metal integration at critical flexing points represent a promising direction for industrial implementation.

Reliability and Safety Standards for Flexible Electronics

The reliability and safety standards for flexible electronics represent a critical framework for the development and deployment of liquid metal interconnects in flexible power distribution systems. These standards are evolving rapidly to address the unique challenges posed by the integration of liquid metals in flexible electronic applications.

International organizations such as IEC, IEEE, and UL have established preliminary guidelines specifically addressing the safety concerns of liquid metal components in flexible electronics. These standards focus on electrical safety, mechanical durability, and environmental impact considerations. For instance, IEC 62368-1 has been adapted to include provisions for flexible power distribution systems utilizing novel conductive materials.

Material compatibility standards are particularly important for liquid metal interconnects, as gallium-based alloys can cause embrittlement in certain metals like aluminum. ASTM F3359 provides testing methodologies for evaluating the long-term compatibility between liquid metals and substrate materials in flexible electronic applications. These standards ensure that the integration of liquid metals does not compromise the structural integrity of the entire system.

Thermal management standards address the unique heat dissipation challenges in flexible power distribution systems. The IEEE 1101.2 standard has been extended to include thermal cycling requirements for flexible electronics, ensuring that liquid metal interconnects maintain performance across varying temperature conditions without leakage or degradation.

Environmental safety standards for liquid metal interconnects focus on toxicity, recyclability, and end-of-life management. While gallium itself has low toxicity, certain liquid metal alloys may contain elements with environmental concerns. The EU's RoHS and REACH regulations have specific provisions addressing the use of metallic alloys in flexible electronics, requiring manufacturers to demonstrate compliance through rigorous testing protocols.

Mechanical reliability standards for flexible electronics have been developed to address the unique stress profiles experienced by liquid metal interconnects during bending, folding, and stretching. IPC-6013 provides guidelines for testing flexible circuits under mechanical stress, with recent amendments specifically addressing the behavior of liquid conductors under repeated deformation cycles.

Electrical performance standards ensure consistent power delivery across flexible interconnects. JEDEC JESD22-B113 has been adapted to evaluate the electrical reliability of liquid metal components under various environmental conditions, including humidity, temperature fluctuations, and mechanical stress. These standards establish minimum performance thresholds for power transmission efficiency and signal integrity in flexible distribution networks.

Emerging standards are beginning to address the unique failure modes of liquid metal systems, including oxidation prevention, encapsulation integrity, and leakage detection. Organizations like SEMI are developing specialized test methods for evaluating the long-term reliability of sealed liquid metal channels in flexible substrates under real-world operating conditions.

International organizations such as IEC, IEEE, and UL have established preliminary guidelines specifically addressing the safety concerns of liquid metal components in flexible electronics. These standards focus on electrical safety, mechanical durability, and environmental impact considerations. For instance, IEC 62368-1 has been adapted to include provisions for flexible power distribution systems utilizing novel conductive materials.

Material compatibility standards are particularly important for liquid metal interconnects, as gallium-based alloys can cause embrittlement in certain metals like aluminum. ASTM F3359 provides testing methodologies for evaluating the long-term compatibility between liquid metals and substrate materials in flexible electronic applications. These standards ensure that the integration of liquid metals does not compromise the structural integrity of the entire system.

Thermal management standards address the unique heat dissipation challenges in flexible power distribution systems. The IEEE 1101.2 standard has been extended to include thermal cycling requirements for flexible electronics, ensuring that liquid metal interconnects maintain performance across varying temperature conditions without leakage or degradation.

Environmental safety standards for liquid metal interconnects focus on toxicity, recyclability, and end-of-life management. While gallium itself has low toxicity, certain liquid metal alloys may contain elements with environmental concerns. The EU's RoHS and REACH regulations have specific provisions addressing the use of metallic alloys in flexible electronics, requiring manufacturers to demonstrate compliance through rigorous testing protocols.

Mechanical reliability standards for flexible electronics have been developed to address the unique stress profiles experienced by liquid metal interconnects during bending, folding, and stretching. IPC-6013 provides guidelines for testing flexible circuits under mechanical stress, with recent amendments specifically addressing the behavior of liquid conductors under repeated deformation cycles.

Electrical performance standards ensure consistent power delivery across flexible interconnects. JEDEC JESD22-B113 has been adapted to evaluate the electrical reliability of liquid metal components under various environmental conditions, including humidity, temperature fluctuations, and mechanical stress. These standards establish minimum performance thresholds for power transmission efficiency and signal integrity in flexible distribution networks.

Emerging standards are beginning to address the unique failure modes of liquid metal systems, including oxidation prevention, encapsulation integrity, and leakage detection. Organizations like SEMI are developing specialized test methods for evaluating the long-term reliability of sealed liquid metal channels in flexible substrates under real-world operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!