Microdroplet Liquid Metal Ink Formulations And Rheology

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Ink Technology Background and Objectives

Liquid metal inks represent a revolutionary class of materials that combine the electrical conductivity of metals with the fluidity and processability of inks. The development of these materials traces back to the early 2000s when researchers began exploring gallium-based alloys as alternatives to mercury, which posed significant environmental and health concerns. The evolution of liquid metal technology has accelerated dramatically over the past decade, with particular emphasis on room-temperature liquid metals such as gallium, indium, and their alloys (e.g., eutectic gallium-indium, EGaIn).

The microdroplet formulation of liquid metal inks marks a significant advancement in this field, enabling precise deposition and patterning capabilities previously unattainable with bulk liquid metals. These formulations typically consist of liquid metal particles suspended in carrier fluids with specific additives to control surface tension, oxidation, and rheological properties. The development trajectory has moved from simple suspensions to sophisticated formulations with tailored viscosity, surface energy, and particle size distribution.

Current research focuses on overcoming the inherent challenges of liquid metal oxidation and achieving stable microdroplet dispersions with controlled rheological properties. The rapid oxidation of gallium-based alloys when exposed to air creates a thin oxide skin that significantly affects flow behavior and printing characteristics. This oxide layer paradoxically serves both as a limitation and an opportunity, providing mechanical stability while complicating fluid dynamics.

The technical objectives in this field center around several key areas: first, developing formulations that maintain stable microdroplet suspensions without coalescence or sedimentation; second, controlling the rheological properties to enable compatibility with various printing technologies including inkjet, screen printing, and direct writing; third, ensuring consistent electrical performance after deposition and curing; and fourth, expanding the range of substrate compatibility for flexible and stretchable electronics applications.

Recent breakthroughs in surfactant chemistry and sonication techniques have enabled the creation of liquid metal microdroplets with unprecedented stability and size control, typically ranging from 1-50 micrometers. These advances have opened new possibilities for high-resolution printed electronics, soft robotics, and biomedical devices. The field is now moving toward multi-functional inks that combine electrical conductivity with other properties such as thermal management, electromagnetic shielding, or self-healing capabilities.

The ultimate goal of microdroplet liquid metal ink technology is to establish a versatile platform for next-generation flexible, stretchable, and reconfigurable electronics that can withstand mechanical deformation while maintaining electrical functionality. This represents a paradigm shift from traditional rigid electronics toward truly conformable systems that can interface seamlessly with non-planar surfaces, including biological tissues.

The microdroplet formulation of liquid metal inks marks a significant advancement in this field, enabling precise deposition and patterning capabilities previously unattainable with bulk liquid metals. These formulations typically consist of liquid metal particles suspended in carrier fluids with specific additives to control surface tension, oxidation, and rheological properties. The development trajectory has moved from simple suspensions to sophisticated formulations with tailored viscosity, surface energy, and particle size distribution.

Current research focuses on overcoming the inherent challenges of liquid metal oxidation and achieving stable microdroplet dispersions with controlled rheological properties. The rapid oxidation of gallium-based alloys when exposed to air creates a thin oxide skin that significantly affects flow behavior and printing characteristics. This oxide layer paradoxically serves both as a limitation and an opportunity, providing mechanical stability while complicating fluid dynamics.

The technical objectives in this field center around several key areas: first, developing formulations that maintain stable microdroplet suspensions without coalescence or sedimentation; second, controlling the rheological properties to enable compatibility with various printing technologies including inkjet, screen printing, and direct writing; third, ensuring consistent electrical performance after deposition and curing; and fourth, expanding the range of substrate compatibility for flexible and stretchable electronics applications.

Recent breakthroughs in surfactant chemistry and sonication techniques have enabled the creation of liquid metal microdroplets with unprecedented stability and size control, typically ranging from 1-50 micrometers. These advances have opened new possibilities for high-resolution printed electronics, soft robotics, and biomedical devices. The field is now moving toward multi-functional inks that combine electrical conductivity with other properties such as thermal management, electromagnetic shielding, or self-healing capabilities.

The ultimate goal of microdroplet liquid metal ink technology is to establish a versatile platform for next-generation flexible, stretchable, and reconfigurable electronics that can withstand mechanical deformation while maintaining electrical functionality. This represents a paradigm shift from traditional rigid electronics toward truly conformable systems that can interface seamlessly with non-planar surfaces, including biological tissues.

Market Applications and Demand Analysis for Liquid Metal Inks

The liquid metal ink market is experiencing significant growth driven by the expanding applications in flexible electronics, wearable devices, and advanced manufacturing sectors. Current market analysis indicates that the global printed electronics market, which includes liquid metal inks, is projected to reach $19.8 billion by 2026, with a compound annual growth rate of approximately 13.6% from 2021. Within this broader market, liquid metal inks represent a rapidly growing segment due to their unique properties and versatility.

The healthcare sector demonstrates substantial demand for liquid metal inks, particularly in the development of biocompatible sensors, drug delivery systems, and medical monitoring devices. These applications leverage the non-toxicity and excellent conductivity of gallium-based liquid metal formulations, allowing for direct skin contact in medical wearables and implantable electronics.

Consumer electronics manufacturers are increasingly adopting liquid metal inks for next-generation flexible displays, stretchable circuits, and reconfigurable electronics. Market research indicates that approximately 27% of electronics manufacturers are exploring liquid metal technologies for future product development, representing a significant shift from traditional rigid circuit manufacturing.

The automotive industry presents another substantial market opportunity, with applications in printed sensors for autonomous vehicles, heating elements for defrosting systems, and electromagnetic interference (EMI) shielding. This sector's demand is expected to grow at 15.2% annually through 2025, outpacing the overall market growth rate.

Aerospace and defense sectors are investing in liquid metal ink technologies for lightweight, conformal antennas, radar systems, and specialized sensing applications. The high reliability requirements in these sectors drive demand for premium formulations with enhanced stability and performance characteristics.

Regional market analysis reveals that North America currently leads in liquid metal ink adoption, followed by East Asia and Europe. However, the fastest growth is observed in emerging economies in Southeast Asia, where electronics manufacturing is rapidly expanding. China represents the largest single national market, with significant government investment in advanced materials research and manufacturing capabilities.

Customer requirements analysis indicates that key purchasing factors include ink stability, consistent rheological properties, printing compatibility with existing equipment, and long-term reliability. Price sensitivity varies significantly by application, with consumer electronics manufacturers being most cost-conscious, while aerospace and medical device manufacturers prioritize performance over cost considerations.

The healthcare sector demonstrates substantial demand for liquid metal inks, particularly in the development of biocompatible sensors, drug delivery systems, and medical monitoring devices. These applications leverage the non-toxicity and excellent conductivity of gallium-based liquid metal formulations, allowing for direct skin contact in medical wearables and implantable electronics.

Consumer electronics manufacturers are increasingly adopting liquid metal inks for next-generation flexible displays, stretchable circuits, and reconfigurable electronics. Market research indicates that approximately 27% of electronics manufacturers are exploring liquid metal technologies for future product development, representing a significant shift from traditional rigid circuit manufacturing.

The automotive industry presents another substantial market opportunity, with applications in printed sensors for autonomous vehicles, heating elements for defrosting systems, and electromagnetic interference (EMI) shielding. This sector's demand is expected to grow at 15.2% annually through 2025, outpacing the overall market growth rate.

Aerospace and defense sectors are investing in liquid metal ink technologies for lightweight, conformal antennas, radar systems, and specialized sensing applications. The high reliability requirements in these sectors drive demand for premium formulations with enhanced stability and performance characteristics.

Regional market analysis reveals that North America currently leads in liquid metal ink adoption, followed by East Asia and Europe. However, the fastest growth is observed in emerging economies in Southeast Asia, where electronics manufacturing is rapidly expanding. China represents the largest single national market, with significant government investment in advanced materials research and manufacturing capabilities.

Customer requirements analysis indicates that key purchasing factors include ink stability, consistent rheological properties, printing compatibility with existing equipment, and long-term reliability. Price sensitivity varies significantly by application, with consumer electronics manufacturers being most cost-conscious, while aerospace and medical device manufacturers prioritize performance over cost considerations.

Current Challenges in Microdroplet Liquid Metal Formulations

Despite significant advancements in liquid metal microdroplet technology, several critical challenges persist in formulation development and rheological control. The primary obstacle remains achieving consistent particle size distribution in microdroplet production. Current formulations struggle to maintain uniform droplet dimensions below 10 μm, with size variations often exceeding 15% within the same batch. This inconsistency directly impacts printing resolution and electrical performance in resulting devices.

Oxidation management presents another significant hurdle. Liquid metals, particularly gallium-based alloys, rapidly form oxide layers upon exposure to oxygen. While this oxide skin provides mechanical stability, it simultaneously alters rheological properties unpredictably during printing processes. Formulations incorporating antioxidants have shown promise but often compromise electrical conductivity or introduce unwanted chemical interactions with substrate materials.

Viscosity control across temperature ranges remains problematic for industrial applications. Most current formulations exhibit dramatic rheological shifts with minor temperature fluctuations (±5°C), limiting manufacturing environments to tightly controlled conditions. This temperature sensitivity restricts widespread adoption in variable production environments and field applications where temperature control is impractical.

Substrate compatibility issues continue to challenge formulation chemists. Liquid metal microdroplets often exhibit poor adhesion to hydrophilic surfaces, while excessive wetting occurs on hydrophobic substrates. Developing formulations with tunable surface tension properties without compromising electrical performance remains an unsolved problem, particularly for flexible electronic applications where substrate deformation introduces additional complexity.

Long-term stability of microdroplet formulations presents ongoing difficulties. Current formulations typically demonstrate shelf-life limitations of 3-6 months before significant rheological changes occur, including phase separation, viscosity shifts, and particle agglomeration. These stability issues necessitate just-in-time manufacturing approaches that increase production costs and limit commercial scalability.

Toxicity concerns persist with certain liquid metal compositions, particularly those containing indium or bismuth. While gallium itself presents minimal toxicity, additives required for rheological control often introduce biocompatibility issues. This limits application in wearable electronics and biomedical devices where human contact is inevitable.

Standardization challenges further complicate the field, with inconsistent characterization methodologies making direct comparisons between research findings difficult. The absence of industry-wide standards for rheological testing specific to liquid metal microdroplets hampers collaborative progress and technology transfer between research institutions and commercial entities.

Oxidation management presents another significant hurdle. Liquid metals, particularly gallium-based alloys, rapidly form oxide layers upon exposure to oxygen. While this oxide skin provides mechanical stability, it simultaneously alters rheological properties unpredictably during printing processes. Formulations incorporating antioxidants have shown promise but often compromise electrical conductivity or introduce unwanted chemical interactions with substrate materials.

Viscosity control across temperature ranges remains problematic for industrial applications. Most current formulations exhibit dramatic rheological shifts with minor temperature fluctuations (±5°C), limiting manufacturing environments to tightly controlled conditions. This temperature sensitivity restricts widespread adoption in variable production environments and field applications where temperature control is impractical.

Substrate compatibility issues continue to challenge formulation chemists. Liquid metal microdroplets often exhibit poor adhesion to hydrophilic surfaces, while excessive wetting occurs on hydrophobic substrates. Developing formulations with tunable surface tension properties without compromising electrical performance remains an unsolved problem, particularly for flexible electronic applications where substrate deformation introduces additional complexity.

Long-term stability of microdroplet formulations presents ongoing difficulties. Current formulations typically demonstrate shelf-life limitations of 3-6 months before significant rheological changes occur, including phase separation, viscosity shifts, and particle agglomeration. These stability issues necessitate just-in-time manufacturing approaches that increase production costs and limit commercial scalability.

Toxicity concerns persist with certain liquid metal compositions, particularly those containing indium or bismuth. While gallium itself presents minimal toxicity, additives required for rheological control often introduce biocompatibility issues. This limits application in wearable electronics and biomedical devices where human contact is inevitable.

Standardization challenges further complicate the field, with inconsistent characterization methodologies making direct comparisons between research findings difficult. The absence of industry-wide standards for rheological testing specific to liquid metal microdroplets hampers collaborative progress and technology transfer between research institutions and commercial entities.

Current Microdroplet Formulation and Rheology Control Methods

01 Rheological properties of liquid metal inks

Liquid metal inks require specific rheological properties to ensure proper printing performance. These properties include viscosity, surface tension, and flow behavior which must be carefully controlled to achieve optimal printing results. The rheology can be adjusted through the addition of various additives and by controlling the particle size and distribution of the metal components. Proper rheological control enables consistent ink deposition and prevents issues such as nozzle clogging or uneven spreading.- Rheological properties of liquid metal inks: Liquid metal inks require specific rheological properties to ensure proper printing performance. These properties include viscosity, surface tension, and flow behavior which must be carefully controlled to achieve optimal printing results. The rheology of liquid metal inks affects their printability, pattern definition, and the quality of the final printed structures. Additives can be incorporated to modify these rheological properties to suit different printing methods and substrate requirements.

- Temperature-dependent rheology control: The rheological behavior of liquid metal inks can be controlled through temperature manipulation. At higher temperatures, many liquid metal formulations exhibit decreased viscosity, allowing for better flow during the printing process. Some formulations are designed to undergo phase transitions at specific temperatures, transitioning from solid to liquid states for printing and then solidifying upon cooling. This temperature-dependent behavior is crucial for applications requiring precise deposition and rapid solidification.

- Particle size and distribution effects on rheology: The size and distribution of metal particles in liquid metal inks significantly impact their rheological behavior. Smaller particles generally result in lower viscosity and better flow characteristics, while also improving stability against sedimentation. Controlled particle size distribution helps achieve optimal packing density and influences the ink's shear thinning behavior. These factors are critical for preventing nozzle clogging in printing systems and ensuring consistent deposition patterns.

- Surfactants and stabilizers for rheology modification: Surfactants and stabilizers are incorporated into liquid metal ink formulations to modify their rheological properties. These additives help control surface tension, prevent agglomeration of metal particles, and maintain consistent flow behavior. They create steric or electrostatic barriers between particles, improving dispersion stability and preventing sedimentation during storage. The selection of appropriate surfactants is crucial for achieving the desired printing performance while maintaining the electrical conductivity of the printed structures.

- Shear-dependent behavior for printing applications: Liquid metal inks often exhibit shear-dependent rheological behavior, which is advantageous for various printing technologies. Many formulations are designed to be shear-thinning, meaning their viscosity decreases under applied shear forces during printing and increases when the shear is removed. This property allows the ink to flow easily through printing nozzles but remain in place after deposition. The recovery time after shear is also important for maintaining printed pattern definition and preventing spreading or bleeding on the substrate.

02 Composition of liquid metal inks for controlling flow behavior

The composition of liquid metal inks significantly affects their rheological properties. These inks typically contain metal particles (such as gallium, indium, or alloys), solvents, binders, and rheology modifiers. The ratio and type of these components determine the ink's flow characteristics. Surfactants and dispersants are often added to prevent agglomeration of metal particles and maintain stable suspension. Polymeric additives can be incorporated to adjust viscosity and provide the desired shear-thinning behavior necessary for printing applications.Expand Specific Solutions03 Temperature effects on liquid metal ink rheology

Temperature has a significant impact on the rheological behavior of liquid metal inks. Many liquid metal formulations exhibit phase changes or dramatic viscosity shifts at specific temperature thresholds. Some compositions are designed to remain liquid at room temperature but solidify rapidly upon cooling after deposition. Others may require heating during printing to maintain optimal flow properties. Understanding and controlling these temperature-dependent rheological changes is crucial for developing effective printing processes and ensuring consistent print quality.Expand Specific Solutions04 Shear-dependent behavior of liquid metal inks

Liquid metal inks often exhibit non-Newtonian, shear-dependent flow behavior that is essential for printing applications. Many formulations are designed to be shear-thinning (pseudoplastic), meaning their viscosity decreases under applied pressure during printing but increases when pressure is removed. This property allows the ink to flow smoothly through narrow printer nozzles but then maintain its shape after deposition. Some formulations also incorporate thixotropic properties, where viscosity changes over time under constant shear, providing additional control over the printing process.Expand Specific Solutions05 Measurement and characterization techniques for liquid metal ink rheology

Various techniques are employed to measure and characterize the rheological properties of liquid metal inks. These include rotational rheometry to determine viscosity profiles, oscillatory tests to evaluate viscoelastic properties, and specialized methods to assess yield stress and thixotropy. Advanced imaging techniques may be used to observe flow behavior during printing. These measurements are crucial for quality control and for developing predictive models of ink behavior under different printing conditions. Standardized testing protocols help ensure consistency in ink formulation and performance across different batches.Expand Specific Solutions

Leading Companies and Research Institutions in Liquid Metal Inks

The microdroplet liquid metal ink formulation and rheology market is in its growth phase, characterized by increasing applications in flexible electronics, printed circuits, and advanced manufacturing. The global market size is estimated to be around $500 million, with projected annual growth of 15-20%. Technologically, the field is advancing rapidly but remains in mid-maturity, with significant R&D still underway. Key players include established printing technology companies like Seiko Epson, Canon, and Brother Industries, alongside specialized innovators such as Beijing Dream Ink Technology. Academic institutions like Xiamen University and Tianjin University are contributing fundamental research, while industrial giants including Samsung Electro-Mechanics and Mitsubishi Materials are developing commercial applications, indicating a competitive landscape balanced between established corporations and emerging specialists.

Seiko Epson Corp.

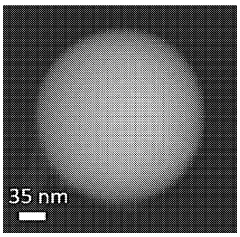

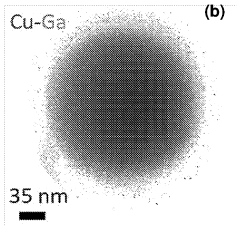

Technical Solution: Seiko Epson has developed sophisticated liquid metal ink formulations specifically engineered for precision microdroplet ejection through piezoelectric printheads. Their technology focuses on bismuth-based alloys with melting points below 150°C, enabling low-temperature processing compatible with polymer substrates. The company's formulations incorporate proprietary surfactant packages that maintain stable interfacial tension across varying shear rates, critical for consistent droplet formation. Epson's approach utilizes core-shell particle architectures where the liquid metal core remains fluid while the oxide shell provides structural stability during printing. Their research demonstrates droplet size control within ±2 μm variation across production batches, with rheological properties maintaining consistency through over 1000 thermal cycles. The formulations achieve sheet resistance values below 0.1 Ω/sq at 25 μm thickness while maintaining adhesion to various substrate materials.

Strengths: Exceptional droplet size uniformity, superior compatibility with flexible substrates, and excellent thermal cycling stability. Weaknesses: Relatively slower solidification rates compared to some competitors and higher sensitivity to ambient humidity during printing processes.

Xerox Holdings Corp.

Technical Solution: Xerox has developed advanced liquid metal ink formulations utilizing gallium-based alloys with precise microdroplet control. Their technology employs acoustic ejection methods to generate uniform microdroplets in the 10-50 μm range while maintaining stable rheological properties. The company's approach incorporates specialized surfactants and polymer additives to control surface tension and prevent oxidation during printing processes. Xerox's formulations feature temperature-responsive viscosity modifiers that enable rapid solidification after deposition while maintaining flowability during ejection. Their research has demonstrated successful integration of these inks in flexible electronics applications with conductivity reaching 3.2×10^6 S/m, approaching bulk metal values while maintaining printability through standard nozzle systems.

Strengths: Superior oxidation resistance compared to competitors, excellent conductivity retention after thermal cycling, and compatibility with existing printing infrastructure. Weaknesses: Higher production costs than conventional metallic inks and limited shelf life requiring specialized storage conditions.

Key Patents and Research on Liquid Metal Ink Rheology

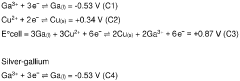

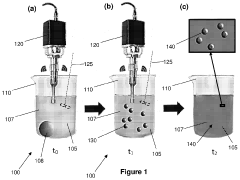

Method of synthesising microdroplets

PatentWO2024130322A1

Innovation

- A method involving high-temperature sonication of a metallic alloy in a high-temperature solvent above the melting point of the alloy and any intermetallic compounds, breaking down the alloy into microdroplets with uniform composition and morphology, using a solvent like molten acetate salts to achieve a high yield and homogeneous distribution.

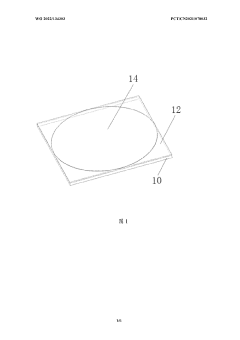

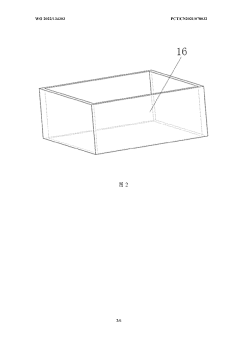

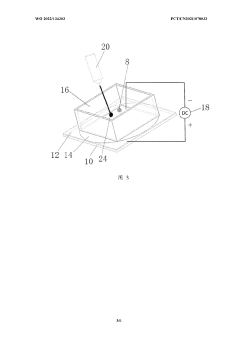

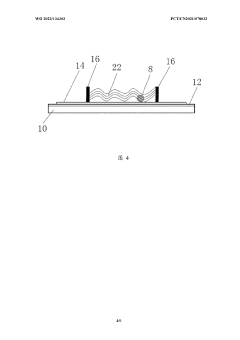

Device and method for optically driving liquid metal micro-droplet

PatentWO2022134303A1

Innovation

- Using a light-driven method, by irradiating laser light on the photosensitive film, the photosensitivity of the photosensitive film and the electric field of the conductive film are used to achieve precise control and flexible movement of liquid metal microdroplets.

Manufacturing Scalability and Process Integration

The scalability of microdroplet liquid metal ink manufacturing represents a critical challenge for industrial adoption. Current laboratory-scale production methods typically yield small quantities suitable for research purposes but face significant barriers when transitioning to mass production. The primary manufacturing challenge stems from maintaining consistent rheological properties across large batches, as liquid metal inks are highly sensitive to oxidation and environmental conditions during processing.

Integration with existing manufacturing infrastructure requires careful consideration of equipment compatibility. Conventional printing and coating equipment may require modifications to handle the unique properties of liquid metal inks, particularly their high surface tension and tendency to oxidize. Companies pioneering this technology have developed specialized dispensing systems that maintain inert atmospheres during the printing process, though these solutions add complexity and cost to production lines.

Temperature control during manufacturing emerges as another critical factor affecting scalability. Liquid metal inks exhibit temperature-dependent rheological properties that must be precisely managed throughout the production process. Industrial implementation requires robust thermal management systems to ensure consistent ink performance across large production runs, with temperature variations of even a few degrees potentially altering viscosity profiles significantly.

Material handling systems present additional integration challenges. The high density of liquid metal formulations necessitates reinforced pumping and dispensing equipment, while their reactivity with certain materials limits options for storage containers and transfer lines. Leading manufacturers have developed specialized alloy-compatible components, though these represent custom solutions rather than standardized equipment.

Cost considerations for scaled production remain substantial. Current estimates suggest that production costs for liquid metal inks exceed those of conventional conductive inks by a factor of 3-5x, primarily due to raw material costs and specialized handling requirements. However, economic modeling indicates that economies of scale could reduce this premium to approximately 1.5-2x at production volumes exceeding 1000 liters annually.

Recent advances in continuous flow processing show promise for addressing many scalability challenges. This approach minimizes exposure to oxidizing environments while enabling precise control of mixing parameters and particle size distribution. Several technology companies have demonstrated pilot-scale continuous production systems capable of producing up to 50 liters of consistent formulation per day, representing a significant step toward industrial viability.

Integration with existing manufacturing infrastructure requires careful consideration of equipment compatibility. Conventional printing and coating equipment may require modifications to handle the unique properties of liquid metal inks, particularly their high surface tension and tendency to oxidize. Companies pioneering this technology have developed specialized dispensing systems that maintain inert atmospheres during the printing process, though these solutions add complexity and cost to production lines.

Temperature control during manufacturing emerges as another critical factor affecting scalability. Liquid metal inks exhibit temperature-dependent rheological properties that must be precisely managed throughout the production process. Industrial implementation requires robust thermal management systems to ensure consistent ink performance across large production runs, with temperature variations of even a few degrees potentially altering viscosity profiles significantly.

Material handling systems present additional integration challenges. The high density of liquid metal formulations necessitates reinforced pumping and dispensing equipment, while their reactivity with certain materials limits options for storage containers and transfer lines. Leading manufacturers have developed specialized alloy-compatible components, though these represent custom solutions rather than standardized equipment.

Cost considerations for scaled production remain substantial. Current estimates suggest that production costs for liquid metal inks exceed those of conventional conductive inks by a factor of 3-5x, primarily due to raw material costs and specialized handling requirements. However, economic modeling indicates that economies of scale could reduce this premium to approximately 1.5-2x at production volumes exceeding 1000 liters annually.

Recent advances in continuous flow processing show promise for addressing many scalability challenges. This approach minimizes exposure to oxidizing environments while enabling precise control of mixing parameters and particle size distribution. Several technology companies have demonstrated pilot-scale continuous production systems capable of producing up to 50 liters of consistent formulation per day, representing a significant step toward industrial viability.

Environmental Impact and Safety Considerations

The environmental and safety implications of microdroplet liquid metal ink formulations require careful consideration as these materials gain prominence in flexible electronics, soft robotics, and biomedical applications. Liquid metal alloys, particularly gallium-based compositions such as eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), present unique environmental challenges throughout their lifecycle.

When assessing environmental impact, the extraction processes for constituent metals deserve particular attention. Gallium, though relatively abundant in the Earth's crust, is primarily obtained as a byproduct of aluminum and zinc processing, which carries significant energy costs and carbon footprint implications. The mining and refinement of indium, a critical component in many liquid metal formulations, raises additional sustainability concerns due to its relative scarcity and energy-intensive extraction methods.

The rheological additives and surfactants employed to stabilize microdroplets introduce another dimension of environmental consideration. Fluorinated surfactants, while effective for controlling liquid metal behavior, may persist in the environment and potentially bioaccumulate. Research into biodegradable alternatives such as polysaccharide-based stabilizers represents a promising direction for reducing the environmental footprint of these formulations.

Waste management presents significant challenges for liquid metal ink technologies. The oxidation behavior of gallium alloys complicates recycling efforts, as the formation of oxide layers alters the rheological properties critical to their functionality. Developing closed-loop systems for the recovery and reprocessing of these materials from end-of-life devices will be essential for sustainable implementation at scale.

From a safety perspective, the toxicological profile of liquid metal microdroplet formulations requires thorough evaluation. While bulk gallium exhibits relatively low toxicity, the behavior of micro and nano-scale particles may differ substantially. The potential for these materials to cross biological barriers when formulated at the microscale necessitates comprehensive biocompatibility studies, particularly for applications with human contact potential.

Occupational safety considerations for researchers and manufacturing personnel include exposure risks during formulation processes. The tendency of liquid metals to form aerosols under certain processing conditions requires appropriate engineering controls and personal protective equipment protocols. Additionally, the compatibility of these materials with standard waste treatment facilities must be established to prevent unintended environmental releases.

Regulatory frameworks for liquid metal inks remain in development, with significant variations across jurisdictions. Proactive engagement with regulatory bodies and the establishment of industry standards for safety testing and environmental impact assessment will facilitate responsible commercialization of these promising materials.

When assessing environmental impact, the extraction processes for constituent metals deserve particular attention. Gallium, though relatively abundant in the Earth's crust, is primarily obtained as a byproduct of aluminum and zinc processing, which carries significant energy costs and carbon footprint implications. The mining and refinement of indium, a critical component in many liquid metal formulations, raises additional sustainability concerns due to its relative scarcity and energy-intensive extraction methods.

The rheological additives and surfactants employed to stabilize microdroplets introduce another dimension of environmental consideration. Fluorinated surfactants, while effective for controlling liquid metal behavior, may persist in the environment and potentially bioaccumulate. Research into biodegradable alternatives such as polysaccharide-based stabilizers represents a promising direction for reducing the environmental footprint of these formulations.

Waste management presents significant challenges for liquid metal ink technologies. The oxidation behavior of gallium alloys complicates recycling efforts, as the formation of oxide layers alters the rheological properties critical to their functionality. Developing closed-loop systems for the recovery and reprocessing of these materials from end-of-life devices will be essential for sustainable implementation at scale.

From a safety perspective, the toxicological profile of liquid metal microdroplet formulations requires thorough evaluation. While bulk gallium exhibits relatively low toxicity, the behavior of micro and nano-scale particles may differ substantially. The potential for these materials to cross biological barriers when formulated at the microscale necessitates comprehensive biocompatibility studies, particularly for applications with human contact potential.

Occupational safety considerations for researchers and manufacturing personnel include exposure risks during formulation processes. The tendency of liquid metals to form aerosols under certain processing conditions requires appropriate engineering controls and personal protective equipment protocols. Additionally, the compatibility of these materials with standard waste treatment facilities must be established to prevent unintended environmental releases.

Regulatory frameworks for liquid metal inks remain in development, with significant variations across jurisdictions. Proactive engagement with regulatory bodies and the establishment of industry standards for safety testing and environmental impact assessment will facilitate responsible commercialization of these promising materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!