Liquid Metal Encapsulation For Washable Smart Textiles

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Technology Background and Objectives

Liquid metals have emerged as a revolutionary material in the field of smart textiles, offering unique properties that combine electrical conductivity with mechanical flexibility. The history of liquid metals dates back to the early 20th century, but their application in wearable technology has gained significant momentum only in the past decade. Gallium-based liquid metals, particularly gallium-indium alloys (EGaIn), have become the focus of research due to their low toxicity, negligible vapor pressure, and favorable melting points near room temperature.

The evolution of liquid metal technology has progressed from basic understanding of their physical properties to sophisticated applications in flexible electronics. Initially, researchers focused on overcoming oxidation issues and developing methods to pattern liquid metals. The breakthrough came with the discovery that controlled oxidation could actually be leveraged to create stable structures, leading to the development of various patterning techniques including microfluidic channels, direct writing, and stencil lithography.

The integration of liquid metals into textiles represents a convergence of materials science, electrical engineering, and textile manufacturing. This interdisciplinary approach aims to create truly wearable electronics that maintain the comfort, flexibility, and aesthetic qualities of traditional textiles while incorporating advanced electronic functionalities.

The primary technical objective in liquid metal encapsulation for washable smart textiles is to develop robust methods for incorporating liquid metal conductors into textile structures while maintaining electrical functionality through multiple washing cycles. This involves addressing several key challenges: creating durable encapsulation materials that prevent leakage, designing interconnect systems that withstand mechanical deformation, and ensuring compatibility with existing textile manufacturing processes.

Another critical objective is to achieve scalability in production methods. Current laboratory techniques for liquid metal patterning often involve manual processes that are difficult to scale for mass production. Developing automated, high-throughput methods for liquid metal deposition and encapsulation represents a significant technical goal for the industry.

Beyond washability, researchers aim to enhance the overall durability of liquid metal-embedded textiles against environmental factors such as humidity, temperature fluctuations, and UV exposure. The goal is to create smart textile systems with operational lifespans comparable to conventional electronic devices while maintaining the comfort and wearability of traditional textiles.

The long-term vision for this technology extends beyond simple conductive pathways to include fully integrated sensing, computing, and communication capabilities within everyday garments, creating a seamless interface between humans and digital systems through their clothing.

The evolution of liquid metal technology has progressed from basic understanding of their physical properties to sophisticated applications in flexible electronics. Initially, researchers focused on overcoming oxidation issues and developing methods to pattern liquid metals. The breakthrough came with the discovery that controlled oxidation could actually be leveraged to create stable structures, leading to the development of various patterning techniques including microfluidic channels, direct writing, and stencil lithography.

The integration of liquid metals into textiles represents a convergence of materials science, electrical engineering, and textile manufacturing. This interdisciplinary approach aims to create truly wearable electronics that maintain the comfort, flexibility, and aesthetic qualities of traditional textiles while incorporating advanced electronic functionalities.

The primary technical objective in liquid metal encapsulation for washable smart textiles is to develop robust methods for incorporating liquid metal conductors into textile structures while maintaining electrical functionality through multiple washing cycles. This involves addressing several key challenges: creating durable encapsulation materials that prevent leakage, designing interconnect systems that withstand mechanical deformation, and ensuring compatibility with existing textile manufacturing processes.

Another critical objective is to achieve scalability in production methods. Current laboratory techniques for liquid metal patterning often involve manual processes that are difficult to scale for mass production. Developing automated, high-throughput methods for liquid metal deposition and encapsulation represents a significant technical goal for the industry.

Beyond washability, researchers aim to enhance the overall durability of liquid metal-embedded textiles against environmental factors such as humidity, temperature fluctuations, and UV exposure. The goal is to create smart textile systems with operational lifespans comparable to conventional electronic devices while maintaining the comfort and wearability of traditional textiles.

The long-term vision for this technology extends beyond simple conductive pathways to include fully integrated sensing, computing, and communication capabilities within everyday garments, creating a seamless interface between humans and digital systems through their clothing.

Market Analysis for Washable Smart Textiles

The smart textiles market is experiencing significant growth, with the global market valued at approximately $3.6 billion in 2022 and projected to reach $13.6 billion by 2030, representing a CAGR of 26.2%. Within this sector, washable smart textiles are emerging as a critical segment due to increasing consumer demand for practical wearable technology that integrates seamlessly into daily life.

Consumer research indicates that washability is consistently ranked among the top three requirements for smart textile adoption, with 78% of potential users citing durability through washing cycles as "very important" or "essential" in purchasing decisions. This represents a significant shift from earlier generations of smart textiles, which often sacrificed practicality for functionality.

Healthcare applications represent the fastest-growing segment for washable smart textiles, with an estimated market value of $1.2 billion in 2023. Medical monitoring garments, rehabilitation supports, and elder care solutions are driving this growth, as these applications require frequent washing while maintaining electronic functionality. The sports and fitness sector follows closely, valued at approximately $980 million, with performance monitoring garments gaining popularity among both professional athletes and fitness enthusiasts.

Geographically, North America currently leads the market with a 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to expanding manufacturing capabilities and increasing consumer adoption in China, Japan, and South Korea.

A key market challenge identified in consumer surveys is price sensitivity. Current washable smart textiles command a premium of 150-300% over conventional alternatives, creating a significant barrier to mass adoption. Industry analysts predict this premium will need to decrease to below 50% to achieve mainstream market penetration.

The liquid metal encapsulation technology addresses several critical market needs, particularly the durability-flexibility paradox that has limited previous solutions. Market research indicates that technologies enabling over 100 wash cycles while maintaining full functionality could capture up to 65% of the premium smart textile market segment.

Corporate investment in washable smart textile technologies has seen a 43% year-over-year increase since 2020, with major apparel brands, technology companies, and specialized startups all competing for market share. This investment surge signals strong confidence in market growth potential and highlights the strategic importance of solving the washability challenge.

Consumer research indicates that washability is consistently ranked among the top three requirements for smart textile adoption, with 78% of potential users citing durability through washing cycles as "very important" or "essential" in purchasing decisions. This represents a significant shift from earlier generations of smart textiles, which often sacrificed practicality for functionality.

Healthcare applications represent the fastest-growing segment for washable smart textiles, with an estimated market value of $1.2 billion in 2023. Medical monitoring garments, rehabilitation supports, and elder care solutions are driving this growth, as these applications require frequent washing while maintaining electronic functionality. The sports and fitness sector follows closely, valued at approximately $980 million, with performance monitoring garments gaining popularity among both professional athletes and fitness enthusiasts.

Geographically, North America currently leads the market with a 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to expanding manufacturing capabilities and increasing consumer adoption in China, Japan, and South Korea.

A key market challenge identified in consumer surveys is price sensitivity. Current washable smart textiles command a premium of 150-300% over conventional alternatives, creating a significant barrier to mass adoption. Industry analysts predict this premium will need to decrease to below 50% to achieve mainstream market penetration.

The liquid metal encapsulation technology addresses several critical market needs, particularly the durability-flexibility paradox that has limited previous solutions. Market research indicates that technologies enabling over 100 wash cycles while maintaining full functionality could capture up to 65% of the premium smart textile market segment.

Corporate investment in washable smart textile technologies has seen a 43% year-over-year increase since 2020, with major apparel brands, technology companies, and specialized startups all competing for market share. This investment surge signals strong confidence in market growth potential and highlights the strategic importance of solving the washability challenge.

Current Challenges in Liquid Metal Encapsulation

Despite significant advancements in liquid metal technology for smart textiles, several critical challenges persist in developing effective encapsulation methods that can withstand washing conditions. The primary obstacle remains the inherent contradiction between maintaining electrical conductivity while ensuring complete waterproofing. Current encapsulation materials often compromise one attribute to enhance the other, resulting in suboptimal performance in real-world applications.

Material compatibility presents another significant challenge, as many encapsulants interact negatively with liquid metals, particularly gallium-based alloys. These interactions can lead to oxidation, degradation of the liquid metal, or compromise of the encapsulant's integrity over time. The chemical stability at the interface between liquid metal and encapsulation material remains problematic, especially under repeated mechanical stress and exposure to detergents during washing cycles.

Durability under mechanical deformation constitutes a persistent technical hurdle. Smart textiles must withstand not only washing but also regular wearing conditions involving bending, stretching, and compression. Current encapsulation solutions often crack or delaminate after repeated mechanical cycles, exposing the liquid metal and causing electrical failure or leakage. This limitation severely restricts the practical lifespan of washable smart textile products.

Manufacturing scalability represents another major challenge. Laboratory-scale encapsulation techniques often involve complex, multi-step processes that are difficult to implement in mass production environments. The precision required for uniform encapsulation thickness and complete coverage without voids or weak points demands sophisticated equipment and quality control measures that increase production costs significantly.

Environmental and health concerns also complicate liquid metal encapsulation development. Many effective encapsulants contain potentially harmful chemicals or require environmentally problematic processing methods. Regulatory compliance across different markets adds another layer of complexity, as materials approved in one region may face restrictions in others.

Temperature sensitivity remains problematic for many encapsulation systems. Washing cycles typically involve temperature variations that can cause differential expansion between the liquid metal and encapsulation material, creating mechanical stress that compromises the seal integrity. Current solutions often fail to maintain performance across the full temperature range encountered in normal use and care conditions.

Finally, the trade-off between encapsulation effectiveness and the textile's natural properties presents an ongoing challenge. Excessive encapsulation materials can compromise the fabric's breathability, flexibility, and comfort, while insufficient protection leads to premature failure. Finding the optimal balance that preserves both technical functionality and wearability continues to elude researchers and manufacturers in this field.

Material compatibility presents another significant challenge, as many encapsulants interact negatively with liquid metals, particularly gallium-based alloys. These interactions can lead to oxidation, degradation of the liquid metal, or compromise of the encapsulant's integrity over time. The chemical stability at the interface between liquid metal and encapsulation material remains problematic, especially under repeated mechanical stress and exposure to detergents during washing cycles.

Durability under mechanical deformation constitutes a persistent technical hurdle. Smart textiles must withstand not only washing but also regular wearing conditions involving bending, stretching, and compression. Current encapsulation solutions often crack or delaminate after repeated mechanical cycles, exposing the liquid metal and causing electrical failure or leakage. This limitation severely restricts the practical lifespan of washable smart textile products.

Manufacturing scalability represents another major challenge. Laboratory-scale encapsulation techniques often involve complex, multi-step processes that are difficult to implement in mass production environments. The precision required for uniform encapsulation thickness and complete coverage without voids or weak points demands sophisticated equipment and quality control measures that increase production costs significantly.

Environmental and health concerns also complicate liquid metal encapsulation development. Many effective encapsulants contain potentially harmful chemicals or require environmentally problematic processing methods. Regulatory compliance across different markets adds another layer of complexity, as materials approved in one region may face restrictions in others.

Temperature sensitivity remains problematic for many encapsulation systems. Washing cycles typically involve temperature variations that can cause differential expansion between the liquid metal and encapsulation material, creating mechanical stress that compromises the seal integrity. Current solutions often fail to maintain performance across the full temperature range encountered in normal use and care conditions.

Finally, the trade-off between encapsulation effectiveness and the textile's natural properties presents an ongoing challenge. Excessive encapsulation materials can compromise the fabric's breathability, flexibility, and comfort, while insufficient protection leads to premature failure. Finding the optimal balance that preserves both technical functionality and wearability continues to elude researchers and manufacturers in this field.

Existing Liquid Metal Encapsulation Techniques

01 Encapsulation materials for liquid metal washability

Various materials can be used to encapsulate liquid metals to improve their washability characteristics. These materials include polymers, elastomers, and specialized coatings that create a protective barrier around the liquid metal while maintaining its functional properties. The encapsulation prevents direct contact with water and detergents during washing processes, enhancing the durability and reusability of liquid metal components in applications requiring regular cleaning.- Encapsulation materials for liquid metal washability: Various materials can be used to encapsulate liquid metals to improve their washability characteristics. These materials include polymers, elastomers, and specialized coatings that create a protective barrier around the liquid metal. The encapsulation prevents direct contact with water and cleaning agents while maintaining the functional properties of the liquid metal. These materials are selected for their durability, flexibility, and resistance to common washing conditions.

- Washable electronic components with liquid metal interconnects: Electronic components incorporating liquid metal interconnects can be designed to withstand washing processes. These designs include specialized sealing techniques, protective layers, and strategic placement of liquid metal elements to prevent exposure to moisture. The washability of these components is crucial for applications in wearable technology, medical devices, and other environments where regular cleaning is necessary while maintaining electrical conductivity and performance.

- Surface treatment methods for liquid metal washability: Surface treatment methods can enhance the washability of liquid metal encapsulations. These treatments include hydrophobic coatings, chemical passivation, and surface functionalization techniques that reduce adhesion of contaminants and improve resistance to water penetration. By modifying the surface properties of the encapsulation or the liquid metal itself, these methods create barriers against moisture while allowing the encapsulated liquid metal to maintain its essential properties.

- Testing and validation of washable liquid metal encapsulations: Specific testing methodologies have been developed to validate the washability of liquid metal encapsulations. These include accelerated aging tests, repeated wash cycle testing, and environmental stress testing to simulate real-world conditions. The tests evaluate factors such as encapsulation integrity, electrical performance after washing, and long-term reliability. Standardized protocols help ensure that liquid metal encapsulations maintain their functional properties after exposure to washing agents, water, and mechanical stress.

- Applications of washable liquid metal encapsulations: Washable liquid metal encapsulations find applications in various fields including wearable electronics, medical devices, and smart textiles. These applications leverage the unique properties of liquid metals such as flexibility, conductivity, and thermal management while addressing the need for regular cleaning or sterilization. The encapsulation techniques enable integration of liquid metals into everyday items that require washing, expanding the potential use cases for liquid metal technology in consumer and specialized products.

02 Washable electronic textiles with liquid metal interconnects

Liquid metals can be incorporated into textiles to create washable electronic fabrics. These textiles feature liquid metal interconnects that maintain conductivity even after multiple washing cycles. The encapsulation techniques involve embedding the liquid metal within stretchable substrates or between protective layers that shield the conductive elements from water penetration while allowing the textile to remain flexible and comfortable for wearable applications.Expand Specific Solutions03 Semiconductor packaging with washable liquid metal thermal interfaces

Liquid metals serve as excellent thermal interface materials in semiconductor packaging due to their high thermal conductivity. Special encapsulation methods have been developed to make these liquid metal thermal interfaces washable and resistant to environmental factors. These techniques involve containing the liquid metal within sealed chambers or using specialized barrier materials that prevent leakage while allowing for effective heat transfer between components.Expand Specific Solutions04 Self-healing liquid metal encapsulation for washable electronics

Self-healing encapsulation systems for liquid metals enable electronics to maintain functionality even after washing or mechanical stress. These systems incorporate materials that can automatically repair minor damage to the encapsulation layer, preventing liquid metal leakage. The self-healing properties are achieved through reversible chemical bonds or phase-changing materials that respond to environmental triggers, ensuring the liquid metal remains properly contained throughout multiple washing cycles.Expand Specific Solutions05 Nano-coating technologies for liquid metal washability

Advanced nano-coating technologies can be applied to liquid metal surfaces to enhance their washability. These nano-coatings create an ultra-thin protective layer that repels water and prevents oxidation while maintaining the liquid metal's electrical and thermal properties. The coatings can be applied through various deposition methods and are engineered to withstand repeated exposure to cleaning agents without degradation, making them ideal for applications requiring frequent washing.Expand Specific Solutions

Key Industry Players in Smart Textile Manufacturing

The liquid metal encapsulation for washable smart textiles market is in an early growth stage, characterized by significant research activity but limited commercial deployment. The global smart textiles market is projected to reach approximately $5.5 billion by 2025, with washable applications representing a growing segment. Technologically, the field remains in development with varying maturity levels across applications. Leading players include academic institutions like Tsinghua University and Harbin Institute of Technology, which are pioneering fundamental research, while companies such as Beijing Dream Ink Technology and Exothermics are developing commercial applications. Research organizations like IMEC and Technical Institute of Physics & Chemistry CAS are bridging the gap between academic innovation and industrial implementation, focusing on scalable manufacturing processes and durability standards for these advanced textile technologies.

Technical Institute of Physics & Chemistry CAS

Technical Solution: Technical Institute of Physics & Chemistry CAS has developed an innovative liquid metal encapsulation technology for washable smart textiles using gallium-based liquid metal alloys (primarily Ga-In-Sn) with low melting points. Their approach involves micro-encapsulation of liquid metal droplets within polymer shells that maintain electrical conductivity while providing protection against water and mechanical stress. The institute has pioneered a method combining emulsification and interfacial polymerization to create liquid metal microcapsules with diameters ranging from 10-100 μm. These microcapsules can be directly printed or coated onto textile substrates using screen printing techniques, maintaining conductivity even after 50+ standard washing cycles. Their technology also incorporates self-healing properties where damaged circuits can reconnect through controlled release of liquid metal under mechanical pressure, ensuring longevity of the smart textile functionality.

Strengths: Superior washability with maintained conductivity after 50+ washing cycles; self-healing capability that extends product lifespan; excellent flexibility and stretchability up to 300% strain without performance degradation. Weaknesses: Higher production costs compared to conventional conductive materials; potential environmental concerns with gallium-based metals; limited mass production capability at current technological readiness level.

Tsinghua University

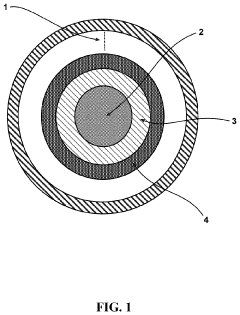

Technical Solution: Tsinghua University has developed a groundbreaking liquid metal encapsulation system for washable smart textiles using room-temperature liquid metals (RTLMs), primarily gallium-indium alloys. Their approach features a dual-layer encapsulation strategy: first encapsulating liquid metal droplets in elastic polymer microspheres, then integrating these into textile fibers through a specialized coaxial spinning process. The resulting composite fibers maintain electrical conductivity while being protected from water penetration and mechanical damage. Tsinghua's researchers have achieved remarkable stability with their encapsulated liquid metal textiles, maintaining functionality through over 100 washing cycles and 1000+ bending cycles. Their technology incorporates a unique "trigger-response" mechanism where the encapsulated liquid metal can be activated to form conductive pathways under specific stimuli (pressure, stretching), enabling dynamic circuit formation. The university has also developed specialized coating techniques that allow the liquid metal encapsulation to adhere strongly to various textile substrates including cotton, polyester, and nylon.

Strengths: Exceptional durability with functionality maintained after 100+ washing cycles; excellent mechanical properties with conductivity maintained after 1000+ bending cycles; versatile application across multiple textile types. Weaknesses: Complex manufacturing process requiring specialized equipment; higher cost compared to traditional conductive textiles; potential scalability challenges for mass production.

Critical Patents in Washable Conductive Materials

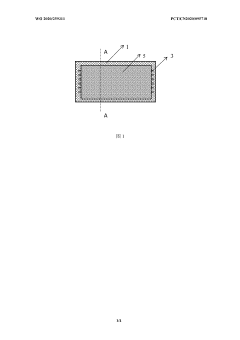

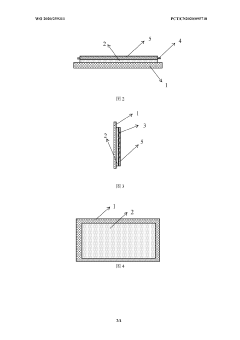

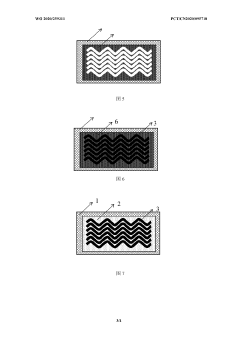

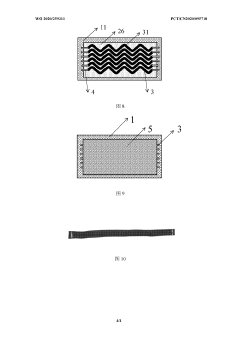

Textile material comprising liquid metal and preparation method therefor

PatentWO2020259311A1

Innovation

- The method of using a multi-layer composite structure includes preparing an insulating layer on the surface of the textile material layer. The liquid metal layer is located on the surface of the insulating layer and covers the protective layer. The liquid metal layer is prepared through hollow molds and hot pressing technology to ensure that its thickness is less than 500um, or even Less than 10um, and the preparation success rate is improved through layer-by-layer preparation.

Liquid metal encapsulates having non-native shells

PatentActiveUS20210287826A1

Innovation

- The use of a palette of materials with varied band structures and spin pairing/bond polarization for the shells of core shell liquid metal encapsulates, allowing them to respond to multiple stimuli such as electromagnetic, thermal, mechanical, photonic, and magnetic, and enhancing environmental robustness.

Durability Testing Standards for Smart Textiles

The development of durability testing standards for smart textiles incorporating liquid metal encapsulation is critical for ensuring product reliability and market acceptance. Current testing frameworks primarily focus on conventional textiles, creating a significant gap for evaluating the unique properties of washable smart textiles with embedded liquid metal components.

International standards organizations including ISO, ASTM, and AATCC have begun developing specialized protocols for smart textiles, though specific standards for liquid metal encapsulation remain in nascent stages. The IPC-8921 standard for e-textiles provides a foundation, addressing wash durability, stretch resistance, and environmental exposure, but requires adaptation for liquid metal applications.

Wash durability testing represents the most critical evaluation metric, with protocols typically requiring 20-50 standard machine wash and dry cycles to simulate real-world usage. For liquid metal encapsulated textiles, these tests must be modified to assess both electrical continuity and mechanical integrity post-washing, with particular attention to potential leakage of encapsulated materials.

Mechanical stress testing standards evaluate abrasion resistance, tensile strength, and flexural endurance. The Martindale abrasion test (ISO 12947) and Taber abraser methods require modification to incorporate electrical performance monitoring during and after mechanical stress. Specialized bend testing protocols measuring electrical performance after 1,000-10,000 flex cycles have emerged as industry benchmarks.

Environmental exposure testing standards assess performance across temperature ranges (-20°C to 60°C), humidity variations (10-95% RH), and UV exposure. For liquid metal encapsulation, these tests must verify encapsulation integrity across these conditions, with particular focus on thermal expansion coefficients between the liquid metal and encapsulation materials.

Biocompatibility and safety testing frameworks are increasingly important, with standards like ISO 10993 being adapted for wearable smart textiles. These evaluate skin sensitization, cytotoxicity, and potential leaching of materials during use and washing, with particular relevance for liquid metal components that may pose unique safety considerations.

Emerging standards are beginning to address electromagnetic performance stability, signal integrity through washing cycles, and long-term reliability modeling. Industry consortia including the Smart Textile Alliance and IEEE P2731 working group are developing comprehensive testing methodologies specifically for washable smart textiles, with increasing attention to liquid metal encapsulation technologies as they gain commercial relevance.

International standards organizations including ISO, ASTM, and AATCC have begun developing specialized protocols for smart textiles, though specific standards for liquid metal encapsulation remain in nascent stages. The IPC-8921 standard for e-textiles provides a foundation, addressing wash durability, stretch resistance, and environmental exposure, but requires adaptation for liquid metal applications.

Wash durability testing represents the most critical evaluation metric, with protocols typically requiring 20-50 standard machine wash and dry cycles to simulate real-world usage. For liquid metal encapsulated textiles, these tests must be modified to assess both electrical continuity and mechanical integrity post-washing, with particular attention to potential leakage of encapsulated materials.

Mechanical stress testing standards evaluate abrasion resistance, tensile strength, and flexural endurance. The Martindale abrasion test (ISO 12947) and Taber abraser methods require modification to incorporate electrical performance monitoring during and after mechanical stress. Specialized bend testing protocols measuring electrical performance after 1,000-10,000 flex cycles have emerged as industry benchmarks.

Environmental exposure testing standards assess performance across temperature ranges (-20°C to 60°C), humidity variations (10-95% RH), and UV exposure. For liquid metal encapsulation, these tests must verify encapsulation integrity across these conditions, with particular focus on thermal expansion coefficients between the liquid metal and encapsulation materials.

Biocompatibility and safety testing frameworks are increasingly important, with standards like ISO 10993 being adapted for wearable smart textiles. These evaluate skin sensitization, cytotoxicity, and potential leaching of materials during use and washing, with particular relevance for liquid metal components that may pose unique safety considerations.

Emerging standards are beginning to address electromagnetic performance stability, signal integrity through washing cycles, and long-term reliability modeling. Industry consortia including the Smart Textile Alliance and IEEE P2731 working group are developing comprehensive testing methodologies specifically for washable smart textiles, with increasing attention to liquid metal encapsulation technologies as they gain commercial relevance.

Environmental Impact of Liquid Metal Technologies

The environmental implications of liquid metal technologies in smart textiles represent a critical dimension requiring thorough assessment. Liquid metals, particularly gallium-based alloys used in washable smart textiles, introduce unique environmental considerations throughout their lifecycle.

Manufacturing processes for liquid metal encapsulation involve resource-intensive extraction of rare metals. Gallium, a key component in these systems, is primarily obtained as a byproduct of aluminum and zinc production, resulting in significant energy consumption and carbon emissions. The encapsulation materials, often silicone-based polymers or specialized elastomers, similarly carry substantial environmental footprints in their production phases.

During the use phase, washable smart textiles incorporating liquid metal technologies demonstrate mixed environmental impacts. On one hand, their durability through multiple wash cycles potentially extends product lifespan, reducing overall textile waste. Conversely, the washing process itself may gradually degrade encapsulation integrity, potentially releasing trace amounts of liquid metals into wastewater systems over time.

End-of-life considerations present particular challenges. The composite nature of these textiles—combining conventional fabrics with encapsulated liquid metals and electronic components—complicates recycling efforts. Current textile recycling infrastructure is largely unprepared to handle these advanced materials, potentially resulting in improper disposal or landfilling of valuable and potentially harmful substances.

Toxicity concerns vary significantly depending on the specific liquid metal formulation. While gallium itself exhibits relatively low toxicity compared to mercury or lead, certain alloy components may pose environmental risks if released. The encapsulation materials themselves, particularly if containing fluoropolymers or other persistent synthetic compounds, may contribute to microplastic pollution when degraded.

Emerging research points toward more sustainable approaches, including biodegradable encapsulation materials and closed-loop recycling systems specifically designed for smart textiles. Some manufacturers have begun implementing take-back programs to recover valuable metals and properly manage end-of-life products.

Regulatory frameworks addressing these technologies remain underdeveloped in most regions, creating uncertainty regarding environmental compliance. As liquid metal encapsulation technologies advance toward commercial scale, establishing comprehensive lifecycle assessment methodologies and appropriate regulatory guidelines will be essential to ensure their environmental sustainability.

Manufacturing processes for liquid metal encapsulation involve resource-intensive extraction of rare metals. Gallium, a key component in these systems, is primarily obtained as a byproduct of aluminum and zinc production, resulting in significant energy consumption and carbon emissions. The encapsulation materials, often silicone-based polymers or specialized elastomers, similarly carry substantial environmental footprints in their production phases.

During the use phase, washable smart textiles incorporating liquid metal technologies demonstrate mixed environmental impacts. On one hand, their durability through multiple wash cycles potentially extends product lifespan, reducing overall textile waste. Conversely, the washing process itself may gradually degrade encapsulation integrity, potentially releasing trace amounts of liquid metals into wastewater systems over time.

End-of-life considerations present particular challenges. The composite nature of these textiles—combining conventional fabrics with encapsulated liquid metals and electronic components—complicates recycling efforts. Current textile recycling infrastructure is largely unprepared to handle these advanced materials, potentially resulting in improper disposal or landfilling of valuable and potentially harmful substances.

Toxicity concerns vary significantly depending on the specific liquid metal formulation. While gallium itself exhibits relatively low toxicity compared to mercury or lead, certain alloy components may pose environmental risks if released. The encapsulation materials themselves, particularly if containing fluoropolymers or other persistent synthetic compounds, may contribute to microplastic pollution when degraded.

Emerging research points toward more sustainable approaches, including biodegradable encapsulation materials and closed-loop recycling systems specifically designed for smart textiles. Some manufacturers have begun implementing take-back programs to recover valuable metals and properly manage end-of-life products.

Regulatory frameworks addressing these technologies remain underdeveloped in most regions, creating uncertainty regarding environmental compliance. As liquid metal encapsulation technologies advance toward commercial scale, establishing comprehensive lifecycle assessment methodologies and appropriate regulatory guidelines will be essential to ensure their environmental sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!