Reliability Testing Protocols For Liquid Metal Conductors

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Conductors Background and Testing Objectives

Liquid metal conductors represent a revolutionary class of materials that combine the electrical conductivity of metals with the fluidity of liquids. These materials, primarily gallium-based alloys such as Galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium), have emerged as promising alternatives to conventional rigid conductors in applications requiring flexibility, stretchability, and self-healing capabilities.

The evolution of liquid metal technology can be traced back to the mid-20th century with mercury-based applications. However, due to mercury's toxicity, research shifted toward safer alternatives in the 1990s, with gallium-based alloys gaining prominence in the early 2000s. The past decade has witnessed accelerated development in liquid metal applications, particularly in soft electronics, wearable devices, and reconfigurable circuits.

Current technological trends indicate a growing interest in addressing the inherent challenges of liquid metals, including oxidation susceptibility, poor wettability, and long-term stability concerns. The field is moving toward enhanced formulations with improved mechanical properties, controlled rheology, and better compatibility with various substrate materials.

The primary objective of reliability testing protocols for liquid metal conductors is to establish standardized methodologies for evaluating their performance under various operational conditions. These protocols aim to quantify key parameters such as electrical conductivity stability, mechanical durability during deformation cycles, resistance to environmental factors, and long-term functional reliability.

Specific testing goals include determining the maximum strain limits before electrical failure, assessing conductivity degradation over repeated mechanical cycles, evaluating oxidation rates under different environmental conditions, and measuring the self-healing efficiency after mechanical damage. Additionally, these protocols seek to establish accelerated aging methodologies that can predict the operational lifespan of liquid metal components in real-world applications.

Another critical objective is to develop comparative benchmarks against traditional conductive materials, enabling designers to make informed decisions when selecting appropriate materials for specific applications. This includes standardized metrics for comparing flexibility, stretchability, and reliability across different conductor types.

The development of these testing protocols represents a crucial step toward the commercial viability of liquid metal technologies. By establishing reliable performance metrics and predictable failure modes, these protocols will facilitate the integration of liquid metal conductors into mainstream electronic manufacturing processes and accelerate their adoption across various industries, from healthcare and consumer electronics to aerospace and automotive applications.

The evolution of liquid metal technology can be traced back to the mid-20th century with mercury-based applications. However, due to mercury's toxicity, research shifted toward safer alternatives in the 1990s, with gallium-based alloys gaining prominence in the early 2000s. The past decade has witnessed accelerated development in liquid metal applications, particularly in soft electronics, wearable devices, and reconfigurable circuits.

Current technological trends indicate a growing interest in addressing the inherent challenges of liquid metals, including oxidation susceptibility, poor wettability, and long-term stability concerns. The field is moving toward enhanced formulations with improved mechanical properties, controlled rheology, and better compatibility with various substrate materials.

The primary objective of reliability testing protocols for liquid metal conductors is to establish standardized methodologies for evaluating their performance under various operational conditions. These protocols aim to quantify key parameters such as electrical conductivity stability, mechanical durability during deformation cycles, resistance to environmental factors, and long-term functional reliability.

Specific testing goals include determining the maximum strain limits before electrical failure, assessing conductivity degradation over repeated mechanical cycles, evaluating oxidation rates under different environmental conditions, and measuring the self-healing efficiency after mechanical damage. Additionally, these protocols seek to establish accelerated aging methodologies that can predict the operational lifespan of liquid metal components in real-world applications.

Another critical objective is to develop comparative benchmarks against traditional conductive materials, enabling designers to make informed decisions when selecting appropriate materials for specific applications. This includes standardized metrics for comparing flexibility, stretchability, and reliability across different conductor types.

The development of these testing protocols represents a crucial step toward the commercial viability of liquid metal technologies. By establishing reliable performance metrics and predictable failure modes, these protocols will facilitate the integration of liquid metal conductors into mainstream electronic manufacturing processes and accelerate their adoption across various industries, from healthcare and consumer electronics to aerospace and automotive applications.

Market Demand Analysis for Reliable Liquid Metal Applications

The global market for liquid metal conductors is experiencing significant growth, driven by the increasing demand for flexible electronics, wearable devices, and advanced medical equipment. Current market projections indicate that the flexible electronics sector alone is expected to reach $42 billion by 2027, with liquid metal conductors representing a crucial enabling technology within this space. The healthcare segment, particularly for biomedical applications, shows the strongest growth potential with compound annual growth rates exceeding 20% as liquid metal solutions address critical challenges in implantable and wearable medical devices.

Industrial sectors including automotive, aerospace, and defense are increasingly adopting liquid metal technologies for their unique combination of electrical conductivity and mechanical flexibility. Market research indicates that reliability concerns represent the primary barrier to wider adoption, with 67% of potential industrial users citing uncertainty about long-term performance as their main hesitation. This underscores the critical importance of developing standardized reliability testing protocols to accelerate market penetration.

Consumer electronics manufacturers are particularly interested in liquid metal solutions that can withstand repeated mechanical deformation while maintaining consistent electrical performance. The demand for stretchable displays and conformable electronics has created a market segment estimated at $3.5 billion annually, with reliability under mechanical stress being the defining competitive factor. Companies capable of demonstrating superior reliability through rigorous testing protocols gain significant market advantage.

Geographically, North America and East Asia dominate the demand landscape, with China, South Korea, and the United States leading research and commercial applications. European markets show increasing interest, particularly in medical and automotive applications where reliability standards are exceptionally stringent. This regional variation in reliability requirements necessitates testing protocols that address diverse environmental and operational conditions.

The market increasingly values comprehensive reliability data, with 78% of surveyed technology procurement specialists indicating that detailed reliability testing results significantly influence purchasing decisions. This represents a shift from earlier market phases where novel functionality alone drove adoption. Current procurement patterns show that organizations are willing to pay premium prices (typically 15-30% higher) for liquid metal solutions with proven reliability backed by standardized testing data.

Emerging applications in soft robotics, thermal management systems, and reconfigurable electronics are creating new market opportunities estimated to reach $5.7 billion by 2030. These applications place unique demands on liquid metal conductors, including resistance to oxidation, compatibility with diverse substrate materials, and stability under varying thermal conditions - all factors that must be addressed in comprehensive reliability testing protocols.

Industrial sectors including automotive, aerospace, and defense are increasingly adopting liquid metal technologies for their unique combination of electrical conductivity and mechanical flexibility. Market research indicates that reliability concerns represent the primary barrier to wider adoption, with 67% of potential industrial users citing uncertainty about long-term performance as their main hesitation. This underscores the critical importance of developing standardized reliability testing protocols to accelerate market penetration.

Consumer electronics manufacturers are particularly interested in liquid metal solutions that can withstand repeated mechanical deformation while maintaining consistent electrical performance. The demand for stretchable displays and conformable electronics has created a market segment estimated at $3.5 billion annually, with reliability under mechanical stress being the defining competitive factor. Companies capable of demonstrating superior reliability through rigorous testing protocols gain significant market advantage.

Geographically, North America and East Asia dominate the demand landscape, with China, South Korea, and the United States leading research and commercial applications. European markets show increasing interest, particularly in medical and automotive applications where reliability standards are exceptionally stringent. This regional variation in reliability requirements necessitates testing protocols that address diverse environmental and operational conditions.

The market increasingly values comprehensive reliability data, with 78% of surveyed technology procurement specialists indicating that detailed reliability testing results significantly influence purchasing decisions. This represents a shift from earlier market phases where novel functionality alone drove adoption. Current procurement patterns show that organizations are willing to pay premium prices (typically 15-30% higher) for liquid metal solutions with proven reliability backed by standardized testing data.

Emerging applications in soft robotics, thermal management systems, and reconfigurable electronics are creating new market opportunities estimated to reach $5.7 billion by 2030. These applications place unique demands on liquid metal conductors, including resistance to oxidation, compatibility with diverse substrate materials, and stability under varying thermal conditions - all factors that must be addressed in comprehensive reliability testing protocols.

Current Testing Limitations and Technical Challenges

Despite significant advancements in liquid metal conductor technology, current reliability testing protocols face substantial limitations that impede comprehensive performance evaluation. Traditional testing methods developed for solid conductors often fail to address the unique properties of liquid metals, such as gallium-based alloys, which exhibit distinct flow dynamics, oxidation behaviors, and interface interactions. This fundamental mismatch creates significant gaps in reliability assessment frameworks.

Existing testing standards lack standardized protocols specifically designed for liquid metal conductors, resulting in inconsistent testing methodologies across research institutions and manufacturers. This inconsistency makes comparative analysis challenging and hinders industry-wide quality benchmarking. Furthermore, accelerated aging tests that accurately simulate real-world degradation mechanisms for liquid metal systems remain underdeveloped.

A critical technical challenge lies in the dynamic nature of liquid metal interfaces. Current testing equipment struggles to monitor and characterize the evolution of these interfaces during operation, particularly at the liquid metal-substrate boundary where chemical reactions and intermetallic compound formation can significantly impact long-term performance. The lack of specialized in-situ monitoring tools limits our understanding of failure mechanisms under various environmental conditions.

Temperature cycling presents another formidable challenge, as liquid metals undergo phase transitions and volume changes that can stress containment structures and connection points. Existing thermal cycling protocols fail to adequately capture these effects, particularly in applications involving extreme temperature ranges or rapid thermal fluctuations. This limitation is especially problematic for wearable and flexible electronics applications where thermal management is critical.

Mechanical reliability testing faces similar constraints, with insufficient methodologies for evaluating liquid metal behavior under various strain conditions, vibration, and impact scenarios. The self-healing properties of liquid metals, while advantageous, complicate traditional failure analysis approaches that rely on permanent deformation markers.

Environmental testing represents another significant gap, with limited protocols for assessing liquid metal conductor performance under humidity, corrosive atmospheres, or radiation exposure. The potential for galvanic corrosion when liquid metals contact dissimilar materials remains inadequately characterized in current testing frameworks.

Finally, the long-term stability testing of liquid metal systems suffers from a lack of accelerated testing methods that can reliably predict performance over extended periods. The absence of established correlation factors between accelerated tests and real-world aging significantly hampers lifetime prediction models, creating uncertainty for product development and reliability engineering.

Existing testing standards lack standardized protocols specifically designed for liquid metal conductors, resulting in inconsistent testing methodologies across research institutions and manufacturers. This inconsistency makes comparative analysis challenging and hinders industry-wide quality benchmarking. Furthermore, accelerated aging tests that accurately simulate real-world degradation mechanisms for liquid metal systems remain underdeveloped.

A critical technical challenge lies in the dynamic nature of liquid metal interfaces. Current testing equipment struggles to monitor and characterize the evolution of these interfaces during operation, particularly at the liquid metal-substrate boundary where chemical reactions and intermetallic compound formation can significantly impact long-term performance. The lack of specialized in-situ monitoring tools limits our understanding of failure mechanisms under various environmental conditions.

Temperature cycling presents another formidable challenge, as liquid metals undergo phase transitions and volume changes that can stress containment structures and connection points. Existing thermal cycling protocols fail to adequately capture these effects, particularly in applications involving extreme temperature ranges or rapid thermal fluctuations. This limitation is especially problematic for wearable and flexible electronics applications where thermal management is critical.

Mechanical reliability testing faces similar constraints, with insufficient methodologies for evaluating liquid metal behavior under various strain conditions, vibration, and impact scenarios. The self-healing properties of liquid metals, while advantageous, complicate traditional failure analysis approaches that rely on permanent deformation markers.

Environmental testing represents another significant gap, with limited protocols for assessing liquid metal conductor performance under humidity, corrosive atmospheres, or radiation exposure. The potential for galvanic corrosion when liquid metals contact dissimilar materials remains inadequately characterized in current testing frameworks.

Finally, the long-term stability testing of liquid metal systems suffers from a lack of accelerated testing methods that can reliably predict performance over extended periods. The absence of established correlation factors between accelerated tests and real-world aging significantly hampers lifetime prediction models, creating uncertainty for product development and reliability engineering.

Established Testing Protocols and Standards

01 Reliability of liquid metal interconnects in electronic devices

Liquid metal conductors are used as reliable interconnects in electronic devices due to their flexibility and conductivity. These materials maintain electrical connectivity even under mechanical stress, bending, or stretching. The liquid nature allows for self-healing properties when connections are temporarily broken. Various formulations and encapsulation methods have been developed to prevent oxidation and ensure long-term reliability in applications such as flexible electronics and wearable devices.- Gallium-based liquid metal conductors: Gallium-based liquid metal alloys offer excellent conductivity while maintaining flexibility at room temperature. These materials, including gallium-indium-tin alloys (Galinstan), provide reliable electrical connections in flexible and stretchable electronics. Their self-healing properties allow them to recover conductivity after mechanical damage, making them suitable for applications requiring durability under mechanical stress. The low melting point and high boiling point ensure stable performance across a wide temperature range.

- Encapsulation techniques for liquid metal reliability: Proper encapsulation of liquid metal conductors significantly improves their long-term reliability by preventing oxidation and leakage. Various encapsulation materials including elastomers, polymers, and microfluidic channels can be used to contain liquid metals while maintaining their electrical properties. Advanced encapsulation techniques allow for controlled deformation while preserving electrical continuity, enabling applications in wearable electronics and soft robotics. These methods also protect against environmental factors that could degrade performance over time.

- Surface treatment and oxide management: Liquid metals, particularly gallium-based alloys, form surface oxides that affect their electrical reliability. Controlled oxide formation can be beneficial for stabilizing liquid metal structures, while excessive oxidation impedes conductivity. Surface treatments using acids, bases, or alloying elements can modify oxide behavior to enhance reliability. Techniques for managing oxide formation include electrochemical methods, chemical additives, and physical barriers that prevent oxygen exposure while maintaining electrical performance under operational conditions.

- Thermal stability and temperature effects: The reliability of liquid metal conductors is significantly influenced by temperature fluctuations. Research focuses on developing alloy compositions that maintain consistent electrical properties across wide temperature ranges. Thermal cycling can cause expansion, contraction, and potential separation from contact surfaces, affecting long-term reliability. Specialized formulations and interface designs help mitigate these effects by accommodating thermal expansion while maintaining electrical contact. Temperature-stable liquid metal systems are crucial for applications in harsh environments or those experiencing frequent thermal cycling.

- Contact interface engineering: The reliability of liquid metal conductors heavily depends on their interfaces with solid conductors and substrates. Engineering these interfaces involves addressing challenges like adhesion, wetting behavior, and intermetallic compound formation. Surface treatments, specialized coatings, and interface materials can improve wetting characteristics and prevent unwanted chemical reactions that degrade performance over time. Advanced interface designs incorporate features that maintain reliable electrical contact during mechanical deformation, vibration, and thermal cycling, ensuring consistent performance in dynamic applications.

02 Temperature stability and thermal management of liquid metal conductors

Liquid metal conductors exhibit specific thermal properties that affect their reliability. These materials maintain conductivity across a wide temperature range, making them suitable for applications with thermal cycling. Proper thermal management techniques are essential to prevent degradation or phase changes that could impact performance. Formulations can be modified to adjust melting points and thermal expansion coefficients to match application requirements, enhancing long-term reliability in varying environmental conditions.Expand Specific Solutions03 Encapsulation and containment systems for liquid metal reliability

Effective encapsulation is crucial for the reliability of liquid metal conductors. Various containment systems have been developed to prevent leakage, oxidation, and contamination. These include polymer encapsulants, microchannels, and specialized housing structures. The encapsulation materials must be chemically compatible with the liquid metal to prevent degradation over time. Advanced sealing techniques ensure that the liquid metal remains properly contained while maintaining its electrical and mechanical properties throughout the device lifetime.Expand Specific Solutions04 Oxidation resistance and surface treatment of liquid metal conductors

Liquid metals often face reliability challenges due to oxidation, which can degrade conductivity. Surface treatments and alloying with specific elements can enhance oxidation resistance and maintain reliable performance over time. Protective coatings and specialized formulations prevent the formation of non-conductive oxide layers. Some approaches include creating gallium-based alloys with improved oxidation resistance or incorporating additives that form protective barriers while maintaining the beneficial properties of the liquid metal conductor.Expand Specific Solutions05 Testing and quality control methods for liquid metal conductor reliability

Specialized testing methodologies have been developed to evaluate and ensure the reliability of liquid metal conductors. These include accelerated aging tests, thermal cycling, mechanical stress testing, and electrical performance monitoring over time. Quality control processes during manufacturing focus on material purity, proper mixing of alloys, and verification of electrical properties. Advanced analytical techniques help identify potential failure modes and optimize formulations for specific applications, ensuring consistent performance throughout the intended product lifecycle.Expand Specific Solutions

Key Industry Players and Research Institutions

The liquid metal conductors reliability testing market is currently in a growth phase, with increasing adoption across semiconductor and electronics industries. Major players like TSMC, SMIC, and Samsung Electronics are driving technological advancements in this field. The market size is expanding due to growing applications in flexible electronics and high-performance computing. From a technical maturity perspective, established semiconductor equipment providers such as KLA Corp., Tokyo Electron, and FormFactor are developing sophisticated testing protocols, while research institutions like Beihang University and ITRI are contributing fundamental innovations. Companies including Micron Technology and Yangtze Memory Technologies are integrating liquid metal conductor testing into their manufacturing processes, indicating the technology's transition from experimental to commercial applications, though standardization remains a challenge.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has established sophisticated reliability testing protocols for liquid metal conductors focused on their integration into advanced semiconductor packaging. Their methodology includes high-precision electrical characterization under varying temperature conditions (-55°C to 150°C) to evaluate conductivity stability and contact resistance variations. TSMC employs specialized microfluidic test structures to assess liquid metal flow characteristics and containment reliability under thermal and mechanical stress. Their protocols feature high-frequency signal integrity testing (up to 110GHz) to evaluate performance in advanced communication applications. TSMC has developed proprietary encapsulation integrity tests that monitor for potential leakage or migration of liquid metal components over extended time periods (>5000 hours) under operational conditions. Additionally, they utilize advanced imaging techniques including X-ray microtomography and scanning acoustic microscopy to non-destructively evaluate the structural integrity of liquid metal interconnects during reliability testing.

Strengths: Exceptional precision in electrical characterization; advanced non-destructive evaluation techniques; comprehensive high-frequency performance assessment. Weaknesses: Testing infrastructure requires significant capital investment; protocols may be overly specialized for semiconductor applications with limited applicability to other domains.

KLA Corp.

Technical Solution: KLA has developed specialized reliability testing protocols for liquid metal conductors that leverage their expertise in metrology and inspection systems. Their approach centers on automated optical and electron microscopy techniques that can detect subtle changes in liquid metal morphology and distribution during reliability testing. KLA's protocols incorporate in-situ monitoring systems that track electrical performance parameters in real-time during environmental stress tests, enabling precise correlation between physical changes and electrical degradation. They employ specialized surface analysis techniques including Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) to characterize chemical interactions between liquid metals and surrounding materials at interfaces. KLA has pioneered defect classification systems specifically for liquid metal applications, using machine learning algorithms to categorize and predict failure modes based on optical signatures. Their testing methodology includes specialized corrosion testing protocols that evaluate galvanic compatibility between liquid metals and adjacent materials under various environmental conditions.

Strengths: Industry-leading metrology and inspection capabilities; advanced defect classification through machine learning; exceptional surface and interface analysis. Weaknesses: Testing approach heavily focused on detection and analysis rather than comprehensive reliability prediction; protocols may require adaptation for specific application environments.

Critical Patents and Literature on Liquid Metal Reliability

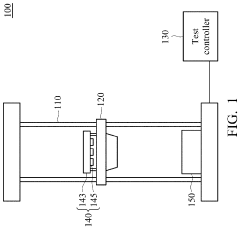

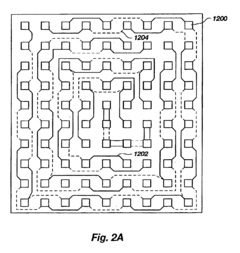

Reliability testing method and apparatus

PatentActiveUS20200088786A1

Innovation

- A drop reliability testing system that includes a test chip with metallization layers and conductive redistribution layers, where a daisy chain test circuit monitors resistance changes during a drop test, simulating the mechanical stress on the ICs and identifying potential delamination or cracking in low-k or ELK dielectric materials.

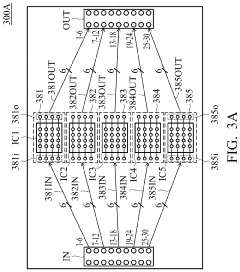

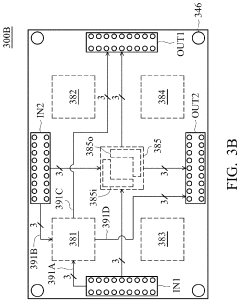

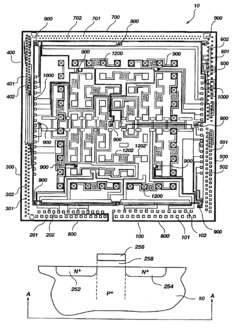

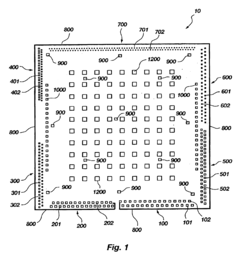

Semiconductor reliability test chip

PatentInactiveUS6770906B2

Innovation

- A semiconductor test chip with multiple integrated test functions, including bond pad pitch and size evaluation, wire bond placement accuracy, thermal impedance testing, ion mobility assessment, and flip chip application testing, featuring a square die design with varying bond pad configurations, polysilicon layers, and thermal measurement capabilities.

Environmental Impact and Safety Considerations

Liquid metal conductors, while offering remarkable electrical and thermal properties, present unique environmental and safety challenges that must be thoroughly addressed in reliability testing protocols. The toxicity profile of gallium-based liquid metals, though generally considered lower than mercury alternatives, still requires careful handling and disposal procedures. When exposed to air or moisture, these materials can form oxide layers that may leach into surrounding environments, potentially affecting soil and water systems if improperly contained.

Testing protocols must incorporate comprehensive environmental impact assessments that evaluate the full lifecycle of liquid metal components, from manufacturing through disposal. Particular attention should be paid to potential leakage scenarios during extreme operating conditions, as the mobility of liquid metals presents unique containment challenges compared to solid conductors. Accelerated weathering tests that simulate environmental exposure over extended periods are essential to understand long-term degradation patterns and potential release mechanisms.

Safety considerations for laboratory personnel conducting reliability tests must address both acute and chronic exposure risks. Direct skin contact with gallium-based alloys can cause irritation and potential metal absorption, while aerosolization during high-temperature testing may create inhalation hazards. Testing facilities should implement specialized handling protocols, including appropriate personal protective equipment and dedicated workspaces with proper ventilation systems designed specifically for liquid metal work.

The reactivity of liquid metals with certain substrate materials presents additional safety concerns that must be evaluated through compatibility testing. Gallium, for instance, can aggressively attack aluminum and certain other metals, potentially compromising structural integrity of test apparatus or final applications. Reliability testing protocols should therefore include chemical compatibility assessments across all materials that may contact the liquid metal throughout its operational lifetime.

Regulatory compliance represents another critical dimension of environmental and safety considerations. Testing protocols must align with evolving standards from organizations such as the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and international equivalents. Documentation of safety procedures, exposure monitoring data, and waste management practices should be integrated into the testing framework to ensure regulatory requirements are satisfied across different jurisdictions where liquid metal conductors may be deployed.

Waste management strategies specific to liquid metal conductors must be developed and validated as part of reliability testing. These should include procedures for recovering and recycling liquid metals from failed components, neutralizing reactive materials, and ensuring proper disposal of non-recyclable elements. The economic and environmental benefits of closed-loop recycling systems should be quantified to encourage sustainable practices in the growing liquid metal electronics sector.

Testing protocols must incorporate comprehensive environmental impact assessments that evaluate the full lifecycle of liquid metal components, from manufacturing through disposal. Particular attention should be paid to potential leakage scenarios during extreme operating conditions, as the mobility of liquid metals presents unique containment challenges compared to solid conductors. Accelerated weathering tests that simulate environmental exposure over extended periods are essential to understand long-term degradation patterns and potential release mechanisms.

Safety considerations for laboratory personnel conducting reliability tests must address both acute and chronic exposure risks. Direct skin contact with gallium-based alloys can cause irritation and potential metal absorption, while aerosolization during high-temperature testing may create inhalation hazards. Testing facilities should implement specialized handling protocols, including appropriate personal protective equipment and dedicated workspaces with proper ventilation systems designed specifically for liquid metal work.

The reactivity of liquid metals with certain substrate materials presents additional safety concerns that must be evaluated through compatibility testing. Gallium, for instance, can aggressively attack aluminum and certain other metals, potentially compromising structural integrity of test apparatus or final applications. Reliability testing protocols should therefore include chemical compatibility assessments across all materials that may contact the liquid metal throughout its operational lifetime.

Regulatory compliance represents another critical dimension of environmental and safety considerations. Testing protocols must align with evolving standards from organizations such as the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and international equivalents. Documentation of safety procedures, exposure monitoring data, and waste management practices should be integrated into the testing framework to ensure regulatory requirements are satisfied across different jurisdictions where liquid metal conductors may be deployed.

Waste management strategies specific to liquid metal conductors must be developed and validated as part of reliability testing. These should include procedures for recovering and recycling liquid metals from failed components, neutralizing reactive materials, and ensuring proper disposal of non-recyclable elements. The economic and environmental benefits of closed-loop recycling systems should be quantified to encourage sustainable practices in the growing liquid metal electronics sector.

Scalability and Manufacturing Integration Strategies

The scalability of liquid metal conductor technology represents a critical challenge for its widespread industrial adoption. Current laboratory-scale production methods typically involve manual injection or deposition techniques that are inherently limited in throughput and consistency. To achieve commercial viability, manufacturing processes must be developed that can produce liquid metal conductors at scale while maintaining their unique electrical and mechanical properties. Roll-to-roll processing shows particular promise, allowing continuous deposition of liquid metal onto flexible substrates at speeds compatible with existing electronics manufacturing lines.

Integration with conventional electronics manufacturing presents several technical hurdles. Liquid metals such as gallium-based alloys exhibit surface oxidation behaviors that can complicate automated handling and deposition. Advanced dispensing systems utilizing precise pressure control and specialized nozzle designs have demonstrated improved consistency in liquid metal patterning. These systems must be further refined to achieve the micron-level precision required for modern electronics while maintaining production speeds compatible with commercial manufacturing.

Material compatibility represents another significant consideration for manufacturing integration. Liquid metals can react with certain substrate materials or cause corrosion in processing equipment. Development of compatible material systems and protective barrier layers is essential for long-term manufacturing stability. Recent advances in surface treatment technologies have shown promise in creating stable interfaces between liquid metals and various substrate materials, potentially enabling integration with a wider range of manufacturing platforms.

Cost considerations remain paramount for successful scaling. While gallium-based liquid metals offer superior performance characteristics, their raw material costs exceed those of conventional conductors like copper. Manufacturing strategies must therefore focus on material efficiency, potentially through techniques such as selective deposition or material recovery systems. Preliminary economic analyses suggest that high-volume production could reduce per-unit costs significantly, particularly for applications where the unique properties of liquid metal conductors command premium value.

Environmental and safety protocols must be established for large-scale manufacturing operations. While gallium-based liquid metals present lower toxicity concerns than mercury, proper handling procedures and waste management systems are essential. Closed-loop manufacturing systems that capture and recycle excess liquid metal show promise for both economic and environmental sustainability. Regulatory compliance frameworks specific to liquid metal manufacturing are still evolving and will require proactive industry engagement to establish appropriate standards.

Integration with conventional electronics manufacturing presents several technical hurdles. Liquid metals such as gallium-based alloys exhibit surface oxidation behaviors that can complicate automated handling and deposition. Advanced dispensing systems utilizing precise pressure control and specialized nozzle designs have demonstrated improved consistency in liquid metal patterning. These systems must be further refined to achieve the micron-level precision required for modern electronics while maintaining production speeds compatible with commercial manufacturing.

Material compatibility represents another significant consideration for manufacturing integration. Liquid metals can react with certain substrate materials or cause corrosion in processing equipment. Development of compatible material systems and protective barrier layers is essential for long-term manufacturing stability. Recent advances in surface treatment technologies have shown promise in creating stable interfaces between liquid metals and various substrate materials, potentially enabling integration with a wider range of manufacturing platforms.

Cost considerations remain paramount for successful scaling. While gallium-based liquid metals offer superior performance characteristics, their raw material costs exceed those of conventional conductors like copper. Manufacturing strategies must therefore focus on material efficiency, potentially through techniques such as selective deposition or material recovery systems. Preliminary economic analyses suggest that high-volume production could reduce per-unit costs significantly, particularly for applications where the unique properties of liquid metal conductors command premium value.

Environmental and safety protocols must be established for large-scale manufacturing operations. While gallium-based liquid metals present lower toxicity concerns than mercury, proper handling procedures and waste management systems are essential. Closed-loop manufacturing systems that capture and recycle excess liquid metal show promise for both economic and environmental sustainability. Regulatory compliance frameworks specific to liquid metal manufacturing are still evolving and will require proactive industry engagement to establish appropriate standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!