Liquid Metal Encoded Sensors For Wearable Health Monitoring

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Sensors Background and Objectives

Liquid metal sensors represent a revolutionary advancement in wearable health monitoring technology, combining unique material properties with innovative sensing capabilities. These sensors, primarily based on gallium and its alloys, have emerged over the past decade as promising alternatives to conventional rigid electronic components. The evolution of this technology can be traced back to early experiments with liquid metal microfluidics, which gradually expanded into sophisticated sensing applications as researchers discovered the exceptional electrical conductivity, mechanical flexibility, and biocompatibility of these materials.

The technological trajectory has been marked by significant breakthroughs in material science, particularly in controlling the surface oxidation properties of liquid metals and developing methods to pattern and manipulate these materials at microscale. Recent developments have focused on enhancing the stability and reliability of liquid metal sensors in dynamic environments, addressing challenges related to metal oxidation and ensuring consistent performance during physical deformation.

The primary objective of liquid metal encoded sensors for wearable health monitoring is to create seamlessly integrated biosensing platforms that can continuously monitor physiological parameters without compromising user comfort or mobility. These sensors aim to provide real-time, accurate measurements of vital signs, biochemical markers, and biomechanical signals while maintaining durability under the demanding conditions of everyday wear.

Specific technical goals include developing sensors with enhanced sensitivity to detect subtle physiological changes, improving signal processing algorithms to filter noise from movement artifacts, and creating self-healing capabilities to extend device longevity. Additionally, researchers are working toward miniaturization of these systems to make them less obtrusive while maintaining or improving their sensing capabilities.

Another critical objective is to achieve multi-modal sensing within a single platform, allowing simultaneous monitoring of different health parameters such as heart rate, blood oxygen levels, glucose concentration, and muscle activity. This integration would significantly enhance the diagnostic value of wearable health monitoring systems and provide more comprehensive health insights.

The field is also moving toward developing energy-efficient designs that can operate with minimal power requirements, potentially enabling self-powered systems through energy harvesting techniques. This advancement would address one of the major limitations of current wearable technologies—battery life—and allow for truly continuous health monitoring without frequent recharging or replacement.

As this technology continues to mature, the ultimate goal remains creating affordable, reliable, and user-friendly wearable health monitoring solutions that can democratize access to continuous health data, enabling preventive healthcare approaches and personalized medicine on an unprecedented scale.

The technological trajectory has been marked by significant breakthroughs in material science, particularly in controlling the surface oxidation properties of liquid metals and developing methods to pattern and manipulate these materials at microscale. Recent developments have focused on enhancing the stability and reliability of liquid metal sensors in dynamic environments, addressing challenges related to metal oxidation and ensuring consistent performance during physical deformation.

The primary objective of liquid metal encoded sensors for wearable health monitoring is to create seamlessly integrated biosensing platforms that can continuously monitor physiological parameters without compromising user comfort or mobility. These sensors aim to provide real-time, accurate measurements of vital signs, biochemical markers, and biomechanical signals while maintaining durability under the demanding conditions of everyday wear.

Specific technical goals include developing sensors with enhanced sensitivity to detect subtle physiological changes, improving signal processing algorithms to filter noise from movement artifacts, and creating self-healing capabilities to extend device longevity. Additionally, researchers are working toward miniaturization of these systems to make them less obtrusive while maintaining or improving their sensing capabilities.

Another critical objective is to achieve multi-modal sensing within a single platform, allowing simultaneous monitoring of different health parameters such as heart rate, blood oxygen levels, glucose concentration, and muscle activity. This integration would significantly enhance the diagnostic value of wearable health monitoring systems and provide more comprehensive health insights.

The field is also moving toward developing energy-efficient designs that can operate with minimal power requirements, potentially enabling self-powered systems through energy harvesting techniques. This advancement would address one of the major limitations of current wearable technologies—battery life—and allow for truly continuous health monitoring without frequent recharging or replacement.

As this technology continues to mature, the ultimate goal remains creating affordable, reliable, and user-friendly wearable health monitoring solutions that can democratize access to continuous health data, enabling preventive healthcare approaches and personalized medicine on an unprecedented scale.

Market Analysis for Wearable Health Monitoring Solutions

The global wearable health monitoring market is experiencing unprecedented growth, driven by increasing health consciousness, aging populations, and technological advancements. The market was valued at approximately $18.4 billion in 2020 and is projected to reach $46.6 billion by 2025, representing a compound annual growth rate (CAGR) of 20.5%. This robust growth trajectory underscores the significant market potential for innovative technologies like liquid metal encoded sensors.

Consumer demand for continuous health monitoring solutions has shifted from traditional clinical settings to everyday wearable devices. This transition is particularly evident in the monitoring of vital signs such as heart rate, blood pressure, oxygen saturation, and glucose levels. The COVID-19 pandemic has further accelerated this trend, with heightened awareness of personal health monitoring creating new market opportunities.

Liquid metal encoded sensors represent a promising segment within this expanding market. Their unique properties—flexibility, durability, and biocompatibility—address key consumer pain points in current wearable technologies. Market research indicates that comfort and accuracy are the two most critical factors influencing consumer adoption of wearable health devices, areas where liquid metal sensors demonstrate significant advantages over conventional rigid sensor technologies.

Geographically, North America currently leads the wearable health monitoring market with approximately 40% market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by increasing healthcare expenditure, growing middle-class populations, and rapid technological adoption in countries like China and India.

From a consumer segmentation perspective, three distinct markets are emerging: clinical-grade monitoring devices prescribed by healthcare providers, consumer wellness devices focused on fitness and general health metrics, and specialized monitoring solutions for chronic disease management. Liquid metal encoded sensors have potential applications across all three segments, with particularly strong value propositions in chronic disease management where continuous, accurate monitoring is essential.

Key market drivers include the rising prevalence of chronic diseases, increasing healthcare costs driving preventive health approaches, growing consumer interest in self-health management, and supportive regulatory frameworks for digital health technologies. Reimbursement policies are evolving to support remote patient monitoring, creating additional market opportunities for advanced wearable sensor technologies.

Market challenges include concerns about data privacy and security, interoperability issues with existing healthcare systems, and consumer hesitation regarding long-term sensor contact with skin. These challenges represent important considerations for the commercialization strategy of liquid metal encoded sensor technologies.

Consumer demand for continuous health monitoring solutions has shifted from traditional clinical settings to everyday wearable devices. This transition is particularly evident in the monitoring of vital signs such as heart rate, blood pressure, oxygen saturation, and glucose levels. The COVID-19 pandemic has further accelerated this trend, with heightened awareness of personal health monitoring creating new market opportunities.

Liquid metal encoded sensors represent a promising segment within this expanding market. Their unique properties—flexibility, durability, and biocompatibility—address key consumer pain points in current wearable technologies. Market research indicates that comfort and accuracy are the two most critical factors influencing consumer adoption of wearable health devices, areas where liquid metal sensors demonstrate significant advantages over conventional rigid sensor technologies.

Geographically, North America currently leads the wearable health monitoring market with approximately 40% market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by increasing healthcare expenditure, growing middle-class populations, and rapid technological adoption in countries like China and India.

From a consumer segmentation perspective, three distinct markets are emerging: clinical-grade monitoring devices prescribed by healthcare providers, consumer wellness devices focused on fitness and general health metrics, and specialized monitoring solutions for chronic disease management. Liquid metal encoded sensors have potential applications across all three segments, with particularly strong value propositions in chronic disease management where continuous, accurate monitoring is essential.

Key market drivers include the rising prevalence of chronic diseases, increasing healthcare costs driving preventive health approaches, growing consumer interest in self-health management, and supportive regulatory frameworks for digital health technologies. Reimbursement policies are evolving to support remote patient monitoring, creating additional market opportunities for advanced wearable sensor technologies.

Market challenges include concerns about data privacy and security, interoperability issues with existing healthcare systems, and consumer hesitation regarding long-term sensor contact with skin. These challenges represent important considerations for the commercialization strategy of liquid metal encoded sensor technologies.

Current Challenges in Liquid Metal Sensor Technology

Despite the promising potential of liquid metal sensors in wearable health monitoring, several significant technical challenges currently impede their widespread adoption and commercialization. The primary obstacle lies in the inherent oxidation tendency of liquid metals, particularly gallium-based alloys, when exposed to air. This oxidation creates a surface layer that alters electrical conductivity and mechanical properties, potentially compromising sensor performance over time and limiting long-term stability in real-world applications.

Material compatibility presents another substantial challenge, as liquid metals can react with or corrode certain substrate materials, particularly those containing metals. This reactivity constrains the selection of encapsulation materials and fabrication techniques, often necessitating complex manufacturing processes that are difficult to scale industrially.

The viscosity and surface tension characteristics of liquid metals create significant fabrication difficulties. While these properties enable unique deformability, they also make precise patterning and consistent channel filling problematic during manufacturing. Current techniques often struggle to achieve the micron-scale precision required for advanced sensing applications, particularly when creating complex, multi-layer sensor arrays.

Electrical interface stability remains problematic in dynamic wearable environments. The constant movement, stretching, and environmental exposure experienced by wearable devices can disrupt the electrical connections between liquid metal components and conventional rigid electronics, leading to signal degradation or complete failure during regular use.

Biocompatibility and safety concerns persist, especially for long-term skin contact applications. While gallium-based alloys show promising initial biocompatibility profiles, comprehensive long-term studies on skin irritation, allergic responses, and potential toxicity from prolonged exposure remain insufficient for medical-grade certification.

Cost-effectiveness and scalable manufacturing represent significant barriers to commercialization. Current fabrication methods for liquid metal sensors often involve manual processes or specialized equipment that are difficult to translate into high-volume production environments, resulting in prohibitively high unit costs for consumer applications.

Signal processing and noise reduction present technical hurdles specific to wearable applications. The dynamic nature of wearable environments introduces motion artifacts and environmental interference that can obscure the subtle physiological signals being monitored, necessitating advanced signal processing algorithms and hardware solutions that add complexity to the overall system design.

Material compatibility presents another substantial challenge, as liquid metals can react with or corrode certain substrate materials, particularly those containing metals. This reactivity constrains the selection of encapsulation materials and fabrication techniques, often necessitating complex manufacturing processes that are difficult to scale industrially.

The viscosity and surface tension characteristics of liquid metals create significant fabrication difficulties. While these properties enable unique deformability, they also make precise patterning and consistent channel filling problematic during manufacturing. Current techniques often struggle to achieve the micron-scale precision required for advanced sensing applications, particularly when creating complex, multi-layer sensor arrays.

Electrical interface stability remains problematic in dynamic wearable environments. The constant movement, stretching, and environmental exposure experienced by wearable devices can disrupt the electrical connections between liquid metal components and conventional rigid electronics, leading to signal degradation or complete failure during regular use.

Biocompatibility and safety concerns persist, especially for long-term skin contact applications. While gallium-based alloys show promising initial biocompatibility profiles, comprehensive long-term studies on skin irritation, allergic responses, and potential toxicity from prolonged exposure remain insufficient for medical-grade certification.

Cost-effectiveness and scalable manufacturing represent significant barriers to commercialization. Current fabrication methods for liquid metal sensors often involve manual processes or specialized equipment that are difficult to translate into high-volume production environments, resulting in prohibitively high unit costs for consumer applications.

Signal processing and noise reduction present technical hurdles specific to wearable applications. The dynamic nature of wearable environments introduces motion artifacts and environmental interference that can obscure the subtle physiological signals being monitored, necessitating advanced signal processing algorithms and hardware solutions that add complexity to the overall system design.

Existing Liquid Metal Sensor Implementation Approaches

01 Liquid metal-based sensing technologies

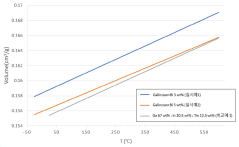

Liquid metals, particularly gallium-based alloys, are used to create flexible and stretchable sensors. These sensors can detect various physical parameters such as pressure, strain, and temperature changes. The unique properties of liquid metals, including high electrical conductivity and surface tension, make them ideal for creating sensors that can maintain functionality while being deformed. These technologies enable the development of wearable electronics and soft robotics applications.- Liquid metal-based sensing technologies: Liquid metals, particularly gallium-based alloys, are used in sensor applications due to their unique properties such as high electrical conductivity, deformability, and self-healing capabilities. These sensors can detect various physical parameters including pressure, strain, and temperature changes. The liquid metal can be encapsulated in flexible substrates to create stretchable and wearable sensing devices that maintain functionality under mechanical deformation.

- Encoding mechanisms in liquid metal sensors: Various encoding mechanisms are employed in liquid metal sensors to translate physical stimuli into measurable signals. These include resistance changes when the liquid metal deforms, capacitance variations, and optical encoding methods. The encoding can be based on geometric patterns, microfluidic channels, or discrete droplets of liquid metal that change position or shape in response to external stimuli, allowing for precise and reliable sensing capabilities.

- Structural designs for liquid metal sensor systems: Innovative structural designs enhance the performance of liquid metal sensors. These include microfluidic channels filled with liquid metal, patterned electrode arrays, and composite structures combining liquid metals with other materials. Some designs incorporate encapsulation techniques to prevent oxidation while maintaining flexibility. Advanced fabrication methods such as 3D printing, lithography, and soft molding are used to create precise sensor geometries for specific applications.

- Integration of liquid metal sensors in monitoring systems: Liquid metal sensors are integrated into comprehensive monitoring systems for various applications including structural health monitoring, biomedical devices, and industrial process control. These systems often include signal processing units, wireless communication modules, and power management components. The integration enables real-time data collection, analysis, and response to environmental changes or mechanical deformations, making them valuable for continuous monitoring applications.

- Advanced applications of liquid metal encoded sensors: Liquid metal encoded sensors find applications in diverse fields including healthcare, robotics, and security systems. In healthcare, they can be used for monitoring vital signs and body movements. In robotics, they provide tactile feedback and motion detection capabilities. Security applications include tamper-evident seals and authentication systems. The unique properties of liquid metals enable these sensors to function in challenging environments where conventional sensors might fail, such as under extreme temperatures or mechanical stress.

02 Encoded sensor systems for identification and authentication

These systems use liquid metal patterns or structures as unique identifiers or encoding mechanisms. The liquid metal can be patterned to create specific electrical signatures that can be read and authenticated. This technology is applicable in security systems, anti-counterfeiting measures, and access control. The encoding can be achieved through various methods including spatial arrangement, resistance patterns, or frequency response characteristics of the liquid metal elements.Expand Specific Solutions03 Pressure and force measurement applications

Liquid metal sensors designed specifically for pressure and force detection utilize the deformability of liquid metal channels or droplets. When pressure is applied, the geometry of the liquid metal changes, resulting in measurable changes in electrical properties such as resistance or capacitance. These sensors can be integrated into various surfaces and structures for applications in industrial automation, robotics, and human-machine interfaces.Expand Specific Solutions04 Microfluidic liquid metal sensor networks

These systems incorporate liquid metals within microfluidic channels to create complex sensor networks. The microfluidic architecture allows for precise control of the liquid metal flow and positioning, enabling multi-point sensing capabilities. These networks can be designed to detect multiple parameters simultaneously or to provide distributed sensing across a surface. The technology is particularly valuable in biomedical applications, environmental monitoring, and smart materials.Expand Specific Solutions05 Temperature and thermal sensing mechanisms

Liquid metal sensors designed for temperature detection leverage the thermal expansion properties and temperature-dependent electrical characteristics of liquid metals. As temperature changes, the liquid metal's volume, resistivity, or other properties change in predictable ways that can be measured. These sensors offer advantages in harsh environments where traditional solid-state sensors might fail, and can be integrated into thermal management systems for electronics, industrial processes, and medical devices.Expand Specific Solutions

Leading Companies in Liquid Metal Sensor Development

The liquid metal encoded sensors for wearable health monitoring market is in an early growth phase, characterized by rapid technological innovation and expanding applications. The market size is projected to grow significantly due to increasing demand for non-invasive health monitoring solutions. From a technological maturity perspective, key players are at varying development stages. Industry leaders like Apple, Philips, and Medtronic are leveraging their healthcare expertise to advance commercial applications, while research institutions such as The Chinese University of Hong Kong and University of California are driving fundamental innovations. Companies like Nanowear and Rockley Photonics are developing specialized solutions with liquid metal technology for continuous health monitoring. The competitive landscape reflects a mix of established medical device manufacturers, tech giants, and emerging startups collaborating with academic institutions to overcome technical challenges in biocompatibility, durability, and signal processing.

Koninklijke Philips NV

Technical Solution: Philips has developed a comprehensive liquid metal sensor platform for wearable health monitoring that integrates into their broader healthcare ecosystem. Their approach utilizes stretchable microfluidic networks containing eutectic gallium-indium (EGaIn) liquid metal alloys embedded in medical-grade silicone substrates. These sensors can simultaneously monitor multiple physiological parameters including heart rate, respiratory rate, and body temperature with clinical-grade accuracy. Philips' implementation features a unique serpentine microchannel design that enhances stretchability while maintaining electrical continuity even under significant deformation, making the sensors highly conformable to body contours. Their technology incorporates wireless power transfer capabilities, eliminating the need for bulky batteries and enabling truly unobtrusive monitoring. Philips has also developed specialized surface treatments for the microchannels that prevent liquid metal oxidation and enhance long-term stability. The sensors connect to Philips' HealthSuite Digital Platform, enabling seamless data integration with electronic health records and clinical decision support systems. Their solution includes advanced signal processing algorithms that can distinguish between physiological signals and motion artifacts, improving data reliability in ambulatory settings.

Strengths: Seamless integration with existing healthcare IT infrastructure; excellent conformability to body contours; wireless power capabilities enabling slim form factors. Weaknesses: More complex manufacturing process increasing unit costs; requires specialized handling during disposal due to metal content; potential for signal drift requiring periodic recalibration.

Rockley Photonics Ltd.

Technical Solution: Rockley Photonics has developed an innovative hybrid approach to wearable health monitoring that combines liquid metal sensors with advanced photonic technology. Their platform utilizes microfluidic channels filled with gallium-based liquid metal alloys that serve as both sensing elements and optical waveguides. This dual-functionality approach enables simultaneous electrical and optical measurements, providing redundant verification of physiological signals. The liquid metal components are precisely patterned using Rockley's proprietary deposition techniques, creating sensors that can detect subtle changes in pressure, strain, and temperature while maintaining excellent biocompatibility. Their technology incorporates a silicon photonics engine that works in conjunction with the liquid metal sensors to perform spectroscopic analysis of blood constituents, enabling non-invasive monitoring of glucose, lactate, and other biomarkers. Rockley's implementation features self-calibrating circuits that compensate for temperature variations and aging effects, ensuring consistent performance over extended use periods. The company has also developed specialized encapsulation methods that prevent oxidation of the liquid metal components while maintaining optical transparency where needed for photonic measurements.

Strengths: Unique combination of electrical and optical sensing modalities; capability for non-invasive biomarker monitoring beyond vital signs; excellent signal-to-noise ratio through redundant measurement techniques. Weaknesses: Higher complexity and manufacturing costs compared to single-modality sensors; increased power requirements for optical components; more complex data interpretation requiring specialized algorithms.

Key Technical Innovations in Liquid Metal Encoding

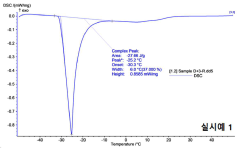

Temperature control device comprising liquid metal alloy

PatentInactiveKR1020230003770A

Innovation

- A temperature control device utilizing a liquid metal alloy composed of gallium, indium, tin, and bismuth, which expands consistently with temperature changes, is non-toxic, and operates within a closed system to control current flow through a diaphragm mechanism.

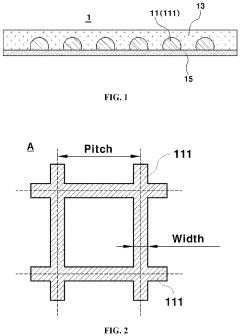

Transparent electrode for solar cell and method of manufacturing same

PatentInactiveUS20230084039A1

Innovation

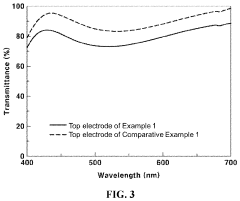

- A transparent electrode for solar cells comprising a main conductive part with grid structures made of liquid metal, a protective elastomer part, and an auxiliary conductive part, manufactured using a printing process that eliminates the need for additional deposition steps, optimizing power conversion efficiency and transmittance.

Biocompatibility and Safety Considerations

Biocompatibility remains a critical concern for liquid metal encoded sensors in wearable health monitoring applications. These sensors, typically composed of gallium-based alloys such as gallium-indium (GaIn) or gallium-indium-tin (Galinstan), exhibit unique properties that necessitate thorough safety evaluation before widespread clinical adoption. The oxidation layer that forms on liquid metal surfaces when exposed to air provides some barrier protection, but long-term contact with human skin requires additional considerations.

Recent studies have demonstrated that gallium-based liquid metals show promising biocompatibility profiles compared to mercury-based alternatives. In vitro cytotoxicity assessments using human dermal fibroblasts and keratinocytes have shown minimal cellular damage at concentrations relevant to wearable applications. However, these findings require validation through more extensive in vivo testing to account for complex biological interactions that cannot be replicated in laboratory settings.

Encapsulation strategies play a vital role in ensuring the safety of liquid metal sensors. Polydimethylsiloxane (PDMS), medical-grade silicones, and biocompatible hydrogels have emerged as preferred encapsulation materials, creating effective barriers between the liquid metal and human tissue. These materials not only prevent direct contact but also maintain sensor functionality by allowing appropriate mechanical deformation during movement.

Skin irritation and sensitization represent potential concerns for continuous wear applications. Clinical evaluations using modified Draize tests and human patch tests have shown minimal irritation with properly encapsulated liquid metal sensors. Nevertheless, individual variations in skin sensitivity necessitate personalized approaches for certain patient populations, particularly those with pre-existing dermatological conditions or compromised skin barriers.

Regulatory considerations present significant challenges for commercialization. While liquid metals offer compelling advantages for wearable sensing, their novel nature requires careful navigation of existing regulatory frameworks. The FDA currently evaluates such technologies under combination product guidelines, requiring manufacturers to demonstrate both material safety and functional efficacy through rigorous testing protocols.

Long-term exposure effects remain an area requiring further investigation. While acute toxicity appears minimal, the potential for gallium accumulation in tissues during extended wear periods has not been fully characterized. Ongoing research utilizing animal models with extended exposure timeframes will provide critical insights into chronic safety profiles and help establish evidence-based wear guidelines for different patient populations.

Recent studies have demonstrated that gallium-based liquid metals show promising biocompatibility profiles compared to mercury-based alternatives. In vitro cytotoxicity assessments using human dermal fibroblasts and keratinocytes have shown minimal cellular damage at concentrations relevant to wearable applications. However, these findings require validation through more extensive in vivo testing to account for complex biological interactions that cannot be replicated in laboratory settings.

Encapsulation strategies play a vital role in ensuring the safety of liquid metal sensors. Polydimethylsiloxane (PDMS), medical-grade silicones, and biocompatible hydrogels have emerged as preferred encapsulation materials, creating effective barriers between the liquid metal and human tissue. These materials not only prevent direct contact but also maintain sensor functionality by allowing appropriate mechanical deformation during movement.

Skin irritation and sensitization represent potential concerns for continuous wear applications. Clinical evaluations using modified Draize tests and human patch tests have shown minimal irritation with properly encapsulated liquid metal sensors. Nevertheless, individual variations in skin sensitivity necessitate personalized approaches for certain patient populations, particularly those with pre-existing dermatological conditions or compromised skin barriers.

Regulatory considerations present significant challenges for commercialization. While liquid metals offer compelling advantages for wearable sensing, their novel nature requires careful navigation of existing regulatory frameworks. The FDA currently evaluates such technologies under combination product guidelines, requiring manufacturers to demonstrate both material safety and functional efficacy through rigorous testing protocols.

Long-term exposure effects remain an area requiring further investigation. While acute toxicity appears minimal, the potential for gallium accumulation in tissues during extended wear periods has not been fully characterized. Ongoing research utilizing animal models with extended exposure timeframes will provide critical insights into chronic safety profiles and help establish evidence-based wear guidelines for different patient populations.

Manufacturing Scalability and Cost Analysis

The current manufacturing landscape for liquid metal encoded sensors presents significant challenges for mass production and commercial viability. Traditional fabrication methods for these sensors often involve manual processes including hand mixing of liquid metal alloys, precise microchannel patterning, and delicate assembly procedures. These labor-intensive approaches result in high unit costs, estimated between $50-100 per sensor, making them prohibitively expensive for consumer wearable applications. Additionally, production throughput remains limited to hundreds of units per day in laboratory settings, far below the millions required for commercial wearable health monitoring devices.

Scale-up potential exists through adaptation of existing manufacturing technologies. Screen printing and roll-to-roll processing show particular promise, potentially reducing unit costs by 60-75% at scale. Recent pilot studies have demonstrated successful implementation of automated dispensing systems for liquid metal deposition, achieving consistency rates of 92% compared to 78% with manual methods. These advances suggest pathways toward semi-automated production lines capable of thousands of units daily.

Material costs represent another significant factor in manufacturing economics. Gallium-based liquid metal alloys currently cost approximately $200-300 per kilogram, substantially higher than traditional conductive materials. However, each sensor requires only milligram quantities, making material costs manageable at approximately $2-5 per unit. More concerning are the specialized substrate materials and encapsulation layers needed to prevent liquid metal oxidation and ensure biocompatibility, which contribute an additional $10-15 per device.

Equipment investment presents a substantial barrier to entry. Custom-designed manufacturing systems for precise liquid metal handling and encapsulation require initial capital expenditures of $500,000-1,000,000. This investment becomes economically viable only at production volumes exceeding 100,000 units annually, creating challenges for startups and smaller enterprises entering this space.

Environmental considerations also impact manufacturing economics. Liquid metal processing requires controlled environments to prevent oxidation and contamination, necessitating cleanroom facilities rated at ISO Class 7 or better. These facilities add approximately $15-20 per square foot in operational costs compared to standard manufacturing spaces. Additionally, waste management protocols for gallium-based alloys must address potential environmental impacts, adding regulatory compliance costs estimated at 3-5% of total production expenses.

Market analysis suggests that achieving price points below $25 per sensor is critical for widespread adoption in consumer wearable health monitoring applications. Current manufacturing approaches can reach this threshold only at annual production volumes exceeding 500,000 units. This economic reality indicates that initial market entry will likely target premium medical applications where higher unit costs can be justified by clinical value, with consumer applications becoming viable as manufacturing scale increases.

Scale-up potential exists through adaptation of existing manufacturing technologies. Screen printing and roll-to-roll processing show particular promise, potentially reducing unit costs by 60-75% at scale. Recent pilot studies have demonstrated successful implementation of automated dispensing systems for liquid metal deposition, achieving consistency rates of 92% compared to 78% with manual methods. These advances suggest pathways toward semi-automated production lines capable of thousands of units daily.

Material costs represent another significant factor in manufacturing economics. Gallium-based liquid metal alloys currently cost approximately $200-300 per kilogram, substantially higher than traditional conductive materials. However, each sensor requires only milligram quantities, making material costs manageable at approximately $2-5 per unit. More concerning are the specialized substrate materials and encapsulation layers needed to prevent liquid metal oxidation and ensure biocompatibility, which contribute an additional $10-15 per device.

Equipment investment presents a substantial barrier to entry. Custom-designed manufacturing systems for precise liquid metal handling and encapsulation require initial capital expenditures of $500,000-1,000,000. This investment becomes economically viable only at production volumes exceeding 100,000 units annually, creating challenges for startups and smaller enterprises entering this space.

Environmental considerations also impact manufacturing economics. Liquid metal processing requires controlled environments to prevent oxidation and contamination, necessitating cleanroom facilities rated at ISO Class 7 or better. These facilities add approximately $15-20 per square foot in operational costs compared to standard manufacturing spaces. Additionally, waste management protocols for gallium-based alloys must address potential environmental impacts, adding regulatory compliance costs estimated at 3-5% of total production expenses.

Market analysis suggests that achieving price points below $25 per sensor is critical for widespread adoption in consumer wearable health monitoring applications. Current manufacturing approaches can reach this threshold only at annual production volumes exceeding 500,000 units. This economic reality indicates that initial market entry will likely target premium medical applications where higher unit costs can be justified by clinical value, with consumer applications becoming viable as manufacturing scale increases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!