Liquid Metal Interconnects For Flexible Solar Cell Integration

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Technology Background and Integration Goals

Liquid metal technology represents a revolutionary approach in the field of flexible electronics, combining the electrical conductivity of metals with the flexibility of liquids. The history of liquid metals dates back to the early 20th century, but their application in electronics has gained significant momentum only in the past decade. Gallium-based alloys, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), have emerged as the most promising candidates due to their low toxicity, negligible vapor pressure, and liquid state at room temperature - properties that distinguish them from mercury.

The evolution of liquid metal technology has been driven by the increasing demand for flexible, stretchable, and conformable electronic devices. Traditional rigid interconnects made of copper or aluminum impose significant limitations on the flexibility of solar cells, creating stress points that lead to mechanical failure during bending or stretching. Liquid metal interconnects offer a paradigm shift by maintaining electrical connectivity even under extreme deformation conditions.

For flexible solar cell integration, liquid metal interconnects aim to solve several critical challenges. The primary goal is to maintain stable electrical connections between solar cell components while accommodating mechanical deformation without performance degradation. This includes developing interconnect systems that can withstand thousands of bending cycles while preserving low electrical resistance and minimal power loss.

Another crucial objective is to develop manufacturing processes compatible with existing solar cell production lines. This involves creating methods for precise deposition, patterning, and encapsulation of liquid metals that can be scaled to industrial production volumes while maintaining cost-effectiveness. The integration must also address challenges related to the wettability of liquid metals on various substrates used in flexible solar cells.

Environmental stability represents another significant goal, as liquid metal interconnects must maintain performance under varying temperature conditions, humidity levels, and UV exposure typical in solar applications. The technology must prevent oxidation of the liquid metal, which can compromise conductivity and adhesion to contact surfaces.

The long-term vision for liquid metal interconnects in flexible solar cells extends beyond simple replacement of rigid connections. Researchers aim to develop self-healing capabilities where damaged interconnects can autonomously restore conductivity, adaptive systems that can reconfigure connections based on mechanical deformation, and integration with energy storage components to create complete flexible power systems. These advancements would enable novel applications such as building-integrated photovoltaics, wearable solar power, and deployable space solar arrays.

The evolution of liquid metal technology has been driven by the increasing demand for flexible, stretchable, and conformable electronic devices. Traditional rigid interconnects made of copper or aluminum impose significant limitations on the flexibility of solar cells, creating stress points that lead to mechanical failure during bending or stretching. Liquid metal interconnects offer a paradigm shift by maintaining electrical connectivity even under extreme deformation conditions.

For flexible solar cell integration, liquid metal interconnects aim to solve several critical challenges. The primary goal is to maintain stable electrical connections between solar cell components while accommodating mechanical deformation without performance degradation. This includes developing interconnect systems that can withstand thousands of bending cycles while preserving low electrical resistance and minimal power loss.

Another crucial objective is to develop manufacturing processes compatible with existing solar cell production lines. This involves creating methods for precise deposition, patterning, and encapsulation of liquid metals that can be scaled to industrial production volumes while maintaining cost-effectiveness. The integration must also address challenges related to the wettability of liquid metals on various substrates used in flexible solar cells.

Environmental stability represents another significant goal, as liquid metal interconnects must maintain performance under varying temperature conditions, humidity levels, and UV exposure typical in solar applications. The technology must prevent oxidation of the liquid metal, which can compromise conductivity and adhesion to contact surfaces.

The long-term vision for liquid metal interconnects in flexible solar cells extends beyond simple replacement of rigid connections. Researchers aim to develop self-healing capabilities where damaged interconnects can autonomously restore conductivity, adaptive systems that can reconfigure connections based on mechanical deformation, and integration with energy storage components to create complete flexible power systems. These advancements would enable novel applications such as building-integrated photovoltaics, wearable solar power, and deployable space solar arrays.

Market Analysis for Flexible Solar Cell Applications

The flexible solar cell market is experiencing rapid growth, driven by increasing demand for portable and integrated power solutions across various industries. Current market projections indicate the global flexible photovoltaic market will reach approximately $10 billion by 2026, with a compound annual growth rate exceeding 15% between 2021 and 2026. This growth trajectory is significantly outpacing traditional rigid solar panel markets, highlighting the shifting preference toward adaptable energy solutions.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the flexible solar cell market. The integration of flexible solar cells into wearable devices, smartphones, and portable chargers has created substantial demand for reliable interconnect technologies that can withstand repeated bending and flexing while maintaining electrical conductivity.

Building-integrated photovoltaics (BIPV) constitutes another major market segment, with architectural applications increasingly incorporating flexible solar solutions into facades, windows, and roofing materials. This sector is projected to grow at over 20% annually as green building initiatives gain momentum globally and regulatory frameworks increasingly mandate renewable energy integration in new construction.

The automotive industry presents a particularly promising growth avenue for flexible solar technologies. Electric vehicle manufacturers are exploring solar integration into vehicle surfaces to extend range and reduce charging frequency. Market research indicates that by 2025, approximately 15% of premium electric vehicles may incorporate some form of flexible solar technology, creating a substantial market for advanced interconnect solutions.

Military and aerospace applications, while smaller in volume, offer premium pricing opportunities for high-performance flexible solar solutions. These applications demand exceptional reliability and durability from interconnect technologies, with liquid metal solutions potentially offering significant advantages over conventional methods.

Geographically, Asia-Pacific dominates the flexible solar cell market with approximately 45% market share, driven by manufacturing capabilities in China, Japan, and South Korea. North America and Europe follow with roughly 25% and 20% market shares respectively, with particularly strong growth in European markets due to aggressive renewable energy targets.

The market for interconnect technologies specifically designed for flexible solar applications is projected to grow at over 18% annually, outpacing the overall flexible solar market. This accelerated growth reflects the critical importance of reliable interconnect solutions in enabling the broader adoption of flexible solar technologies across diverse applications.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the flexible solar cell market. The integration of flexible solar cells into wearable devices, smartphones, and portable chargers has created substantial demand for reliable interconnect technologies that can withstand repeated bending and flexing while maintaining electrical conductivity.

Building-integrated photovoltaics (BIPV) constitutes another major market segment, with architectural applications increasingly incorporating flexible solar solutions into facades, windows, and roofing materials. This sector is projected to grow at over 20% annually as green building initiatives gain momentum globally and regulatory frameworks increasingly mandate renewable energy integration in new construction.

The automotive industry presents a particularly promising growth avenue for flexible solar technologies. Electric vehicle manufacturers are exploring solar integration into vehicle surfaces to extend range and reduce charging frequency. Market research indicates that by 2025, approximately 15% of premium electric vehicles may incorporate some form of flexible solar technology, creating a substantial market for advanced interconnect solutions.

Military and aerospace applications, while smaller in volume, offer premium pricing opportunities for high-performance flexible solar solutions. These applications demand exceptional reliability and durability from interconnect technologies, with liquid metal solutions potentially offering significant advantages over conventional methods.

Geographically, Asia-Pacific dominates the flexible solar cell market with approximately 45% market share, driven by manufacturing capabilities in China, Japan, and South Korea. North America and Europe follow with roughly 25% and 20% market shares respectively, with particularly strong growth in European markets due to aggressive renewable energy targets.

The market for interconnect technologies specifically designed for flexible solar applications is projected to grow at over 18% annually, outpacing the overall flexible solar market. This accelerated growth reflects the critical importance of reliable interconnect solutions in enabling the broader adoption of flexible solar technologies across diverse applications.

Current Challenges in Flexible Interconnect Technologies

The integration of flexible solar cells into various applications demands interconnect technologies that can withstand mechanical deformation while maintaining electrical performance. Current flexible interconnect solutions face significant limitations that hinder widespread adoption and optimal performance of flexible photovoltaic systems.

Traditional metallic interconnects, typically made from copper or aluminum, suffer from fatigue and fracture under repeated bending and stretching. These materials experience work hardening and develop microcracks after multiple deformation cycles, leading to increased resistance and eventual electrical failure. This fundamental limitation restricts the operational lifespan of flexible solar modules in real-world applications where constant movement is expected.

Conductive adhesives and polymer-based interconnects present an alternative approach but introduce their own challenges. While more mechanically compliant, these materials generally exhibit lower electrical conductivity compared to metals, resulting in higher resistive losses and reduced overall system efficiency. Additionally, many conductive polymers degrade when exposed to UV radiation—a significant concern for solar applications where constant sun exposure is inevitable.

Interface reliability between the interconnect and the solar cell represents another critical challenge. Thermal expansion coefficient mismatches between different materials create stress concentrations during temperature fluctuations, weakening adhesion and potentially causing delamination. This issue becomes particularly pronounced in outdoor applications where daily temperature cycles can range significantly.

Environmental stability poses a substantial hurdle for current interconnect technologies. Moisture ingress at interconnection points accelerates corrosion and degradation of contact interfaces. Conventional encapsulation methods often prove inadequate for fully flexible systems, as they either restrict movement or develop defects under repeated deformation, compromising the hermetic seal.

Manufacturing scalability remains problematic for advanced interconnect solutions. Many promising laboratory-demonstrated techniques for flexible interconnects rely on complex, multi-step processes that are difficult to implement in high-volume production environments. This manufacturing complexity translates directly to increased costs, limiting commercial viability.

The balance between mechanical compliance and electrical performance presents perhaps the most fundamental challenge. As interconnects become more flexible to accommodate mechanical deformation, their electrical resistance typically increases. Conversely, optimizing for electrical conductivity often results in more rigid structures prone to mechanical failure. This inherent trade-off necessitates careful engineering compromises that currently limit the performance envelope of flexible solar technologies.

Traditional metallic interconnects, typically made from copper or aluminum, suffer from fatigue and fracture under repeated bending and stretching. These materials experience work hardening and develop microcracks after multiple deformation cycles, leading to increased resistance and eventual electrical failure. This fundamental limitation restricts the operational lifespan of flexible solar modules in real-world applications where constant movement is expected.

Conductive adhesives and polymer-based interconnects present an alternative approach but introduce their own challenges. While more mechanically compliant, these materials generally exhibit lower electrical conductivity compared to metals, resulting in higher resistive losses and reduced overall system efficiency. Additionally, many conductive polymers degrade when exposed to UV radiation—a significant concern for solar applications where constant sun exposure is inevitable.

Interface reliability between the interconnect and the solar cell represents another critical challenge. Thermal expansion coefficient mismatches between different materials create stress concentrations during temperature fluctuations, weakening adhesion and potentially causing delamination. This issue becomes particularly pronounced in outdoor applications where daily temperature cycles can range significantly.

Environmental stability poses a substantial hurdle for current interconnect technologies. Moisture ingress at interconnection points accelerates corrosion and degradation of contact interfaces. Conventional encapsulation methods often prove inadequate for fully flexible systems, as they either restrict movement or develop defects under repeated deformation, compromising the hermetic seal.

Manufacturing scalability remains problematic for advanced interconnect solutions. Many promising laboratory-demonstrated techniques for flexible interconnects rely on complex, multi-step processes that are difficult to implement in high-volume production environments. This manufacturing complexity translates directly to increased costs, limiting commercial viability.

The balance between mechanical compliance and electrical performance presents perhaps the most fundamental challenge. As interconnects become more flexible to accommodate mechanical deformation, their electrical resistance typically increases. Conversely, optimizing for electrical conductivity often results in more rigid structures prone to mechanical failure. This inherent trade-off necessitates careful engineering compromises that currently limit the performance envelope of flexible solar technologies.

Current Liquid Metal Interconnect Implementation Methods

01 Gallium-based liquid metal interconnects

Gallium-based liquid metals offer excellent electrical conductivity while maintaining flexibility for stretchable electronics. These materials can flow and reconfigure while maintaining electrical connections, making them ideal for wearable devices and flexible circuits. The low melting point of gallium alloys allows them to remain liquid at room temperature while providing reliable electrical pathways that can withstand bending and stretching without breaking.- Gallium-based liquid metal interconnects: Gallium-based liquid metals offer excellent electrical conductivity while maintaining flexibility for electronic applications. These materials can flow and deform without breaking electrical connections, making them ideal for flexible and stretchable electronics. The low melting point of gallium alloys allows them to remain liquid at room temperature while providing reliable electrical pathways that can withstand repeated mechanical deformation.

- Encapsulation techniques for liquid metal interconnects: Various encapsulation methods protect liquid metal interconnects from oxidation and ensure containment during flexing. These techniques include using elastomeric materials, microchannels, and specialized polymers that maintain the liquid state of the metal while preventing leakage. Proper encapsulation is crucial for maintaining electrical performance and preventing contamination while allowing the necessary flexibility for the interconnects to function in dynamic applications.

- Flexible substrate integration with liquid metal: Integration of liquid metal interconnects with flexible substrates enables the creation of bendable electronic systems. These substrates, often made from polymers or thin films, provide mechanical support while accommodating the flow characteristics of liquid metals. The combination creates electronic circuits that can be folded, rolled, or stretched without losing functionality, opening possibilities for wearable devices and conformable electronics.

- Self-healing properties of liquid metal interconnects: Liquid metal interconnects exhibit self-healing capabilities when mechanical damage occurs. Unlike solid metal connections that permanently break when fractured, liquid metals can flow back together after being separated, automatically restoring electrical conductivity. This property significantly enhances the reliability and lifespan of flexible electronic devices that undergo frequent bending, stretching, or other mechanical stresses.

- Manufacturing processes for liquid metal flexible circuits: Specialized manufacturing techniques enable the precise deposition and patterning of liquid metal for flexible interconnects. These methods include microfluidic injection, direct printing, selective wetting, and masked deposition. Advanced fabrication approaches allow for creating complex circuit patterns while maintaining the unique properties of liquid metals, ensuring reliable electrical connections in flexible and stretchable electronic applications.

02 Encapsulation techniques for liquid metal interconnects

Various encapsulation methods protect liquid metal interconnects while preserving their flexibility. These techniques include using elastomeric materials, microfluidic channels, and specialized polymers that contain the liquid metal while allowing movement. Proper encapsulation prevents leakage and oxidation while maintaining the mechanical properties needed for flexible applications. These approaches enable the creation of durable, flexible electronic systems that can withstand repeated deformation.Expand Specific Solutions03 Integration of liquid metal with semiconductor devices

Techniques for integrating liquid metal interconnects with traditional semiconductor components enable flexible hybrid electronics. These methods include specialized bonding processes, interface materials, and connection architectures that accommodate the different properties of liquid metals and solid semiconductors. This integration allows for combining the processing power of conventional electronics with the flexibility of liquid metal interconnects, creating systems that can conform to complex shapes while maintaining functionality.Expand Specific Solutions04 Self-healing liquid metal interconnect systems

Self-healing properties of liquid metals enable interconnects that can automatically repair when damaged. When a connection is broken due to stretching or bending, the liquid metal can flow back together to restore electrical conductivity. This capability significantly enhances the reliability and lifespan of flexible electronic devices, allowing them to withstand mechanical stress and recover from damage that would permanently disable conventional rigid interconnects.Expand Specific Solutions05 Manufacturing processes for flexible liquid metal circuits

Advanced manufacturing techniques enable the creation of precise liquid metal interconnect patterns for flexible electronics. These processes include direct printing, selective wetting, microfluidic injection, and patterning methods that can create complex circuit designs using liquid metals. These fabrication approaches allow for mass production of flexible electronic systems with liquid metal interconnects that maintain consistent electrical performance while accommodating mechanical deformation.Expand Specific Solutions

Leading Companies in Liquid Metal and Flexible Solar Industry

The liquid metal interconnects for flexible solar cell integration market is in an early growth phase, characterized by significant R&D activity and emerging commercial applications. The global market is expanding rapidly, driven by increasing demand for flexible, lightweight solar solutions in consumer electronics, building-integrated photovoltaics, and aerospace applications. While the technology shows promising efficiency improvements, it remains in development with varying degrees of maturity across players. Leading companies like Maxeon Solar, SunPower, and Alta Devices have made substantial advances in high-efficiency flexible cell technologies, while research institutions such as Fraunhofer-Gesellschaft and Xiangtan University are pioneering novel liquid metal interconnect approaches. Traditional electronics manufacturers including Intel, Sharp, and Applied Materials are leveraging their expertise to address manufacturing scalability challenges that currently limit widespread adoption.

Maxeon Solar Pte Ltd.

Technical Solution: Maxeon has developed advanced liquid metal interconnect technology for their high-efficiency flexible solar cells. Their approach utilizes gallium-based liquid metal alloys that maintain electrical conductivity while accommodating the mechanical stress of flexing panels. The interconnects are applied through a proprietary micro-dispensing process that creates self-healing connections between solar cells. These interconnects remain liquid at operating temperatures, allowing for continuous electrical contact even when the substrate is bent or stretched. Maxeon's technology incorporates encapsulation methods that prevent oxidation of the liquid metal while maintaining flexibility. Their interconnect design features redundant connection points to ensure reliability even if individual connections fail. The company has integrated this technology into their Maxeon Air™ platform, which achieves flexibility without compromising power output or durability.

Strengths: Superior flexibility allowing for installation on curved surfaces; self-healing properties that increase longevity; higher resistance to mechanical fatigue compared to solid interconnects. Weaknesses: Higher manufacturing complexity; potential concerns about long-term containment of liquid metal; higher production costs compared to conventional interconnect technologies.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered a comprehensive liquid metal interconnect system specifically designed for flexible photovoltaics. Their technology utilizes eutectic gallium-indium (EGaIn) alloys embedded within elastomeric matrices to create stretchable, highly conductive pathways between solar cells. The company has developed specialized encapsulation techniques that prevent oxidation while maintaining the liquid state of the metal. Dow's approach includes surface modification treatments that enhance wetting and adhesion between the liquid metal and contact surfaces, ensuring reliable electrical connections. Their manufacturing process involves precision injection of the liquid metal into pre-formed microchannels within the flexible substrate, allowing for complex interconnect patterns that optimize current collection while minimizing resistance losses. The technology has been demonstrated to withstand thousands of flexing cycles without significant degradation in electrical performance, making it particularly suitable for applications requiring repeated bending or deployment.

Strengths: Excellent mechanical durability under repeated flexing; high electrical conductivity maintained during deformation; compatibility with roll-to-roll manufacturing processes. Weaknesses: Higher material costs compared to conventional solid interconnects; requires precise control of liquid metal volume and containment; potential environmental concerns regarding gallium-based alloys if not properly encapsulated.

Key Patents and Research in Liquid Metal Solar Integration

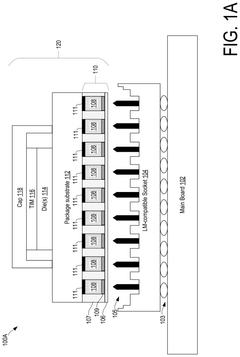

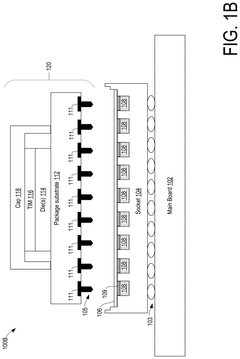

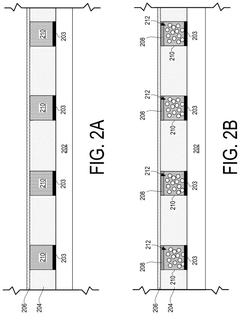

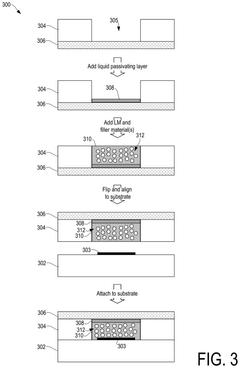

Liquid metal socket interconnects with liquid passivation layer and filler materials

PatentPendingUS20250079278A1

Innovation

- Implementation of a liquid passivation layer, such as mineral oil or paraffin wax, within the LM wells to prevent sticking and oxide formation, along with inert filler materials to reduce LM usage and costs.

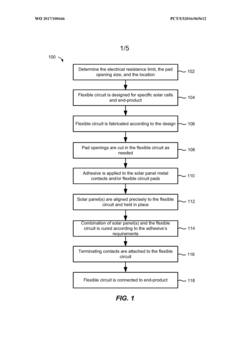

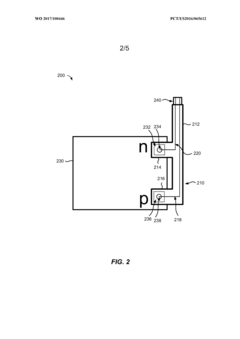

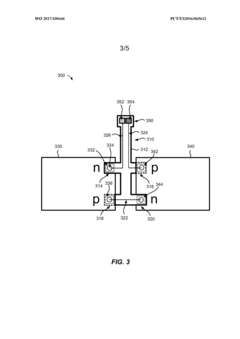

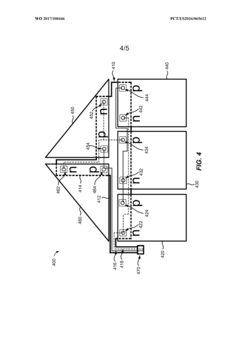

A versatile flexible circuit interconnection for flexible solar cells

PatentWO2017100446A1

Innovation

- A flexible circuit interconnection system using an insulation material with conductive wires and conductive adhesive, allowing for electrical connectivity between solar panels and devices while maintaining the intrinsic flexibility of the solar cells, and enabling arbitrary placement of electrode leads and multiple solar panels to be connected in series or parallel.

Environmental Impact and Recyclability Assessment

The environmental impact of liquid metal interconnects in flexible solar cell integration presents a complex sustainability profile that warrants thorough examination. Gallium-based liquid metal alloys, commonly used in these applications, offer significant advantages over traditional soldering materials containing lead or other toxic heavy metals. These liquid metals demonstrate lower toxicity profiles and reduced environmental persistence compared to conventional alternatives, potentially minimizing ecological damage throughout their lifecycle.

When considering manufacturing processes, liquid metal interconnects typically require lower processing temperatures than traditional soldering methods, resulting in reduced energy consumption and associated carbon emissions. This energy efficiency represents a meaningful contribution to the overall sustainability of flexible solar technology production. Additionally, the ambient temperature processing capability of many liquid metal systems eliminates the need for energy-intensive heating equipment and specialized ventilation systems.

The durability and self-healing properties of liquid metal interconnects significantly extend the operational lifespan of flexible solar installations. This longevity directly translates to reduced electronic waste generation and decreased resource consumption for replacement components, addressing a critical environmental challenge in renewable energy technology deployment.

From a recyclability perspective, gallium-based liquid metals present promising opportunities for material recovery. Unlike conventional solder joints that often require destructive mechanical separation, liquid metal interconnects can potentially be recovered through controlled thermal processes that preserve both the interconnect material and the solar cell components. The relatively high market value of gallium and other constituent elements provides economic incentives for implementing effective recycling systems.

However, challenges remain in establishing comprehensive recycling infrastructure specifically designed for liquid metal recovery from flexible electronics. Current electronic waste processing facilities may lack the specialized equipment and protocols necessary for efficient separation and purification of these materials. This gap represents an important area for future development as the technology scales commercially.

Life cycle assessment studies indicate that the environmental benefits of liquid metal interconnects are maximized when integrated into comprehensive circular economy frameworks. Designing flexible solar systems with end-of-life disassembly in mind can significantly enhance material recovery rates and reduce the environmental footprint of renewable energy technologies. This approach aligns with broader sustainability goals while supporting the economic viability of advanced solar energy systems.

When considering manufacturing processes, liquid metal interconnects typically require lower processing temperatures than traditional soldering methods, resulting in reduced energy consumption and associated carbon emissions. This energy efficiency represents a meaningful contribution to the overall sustainability of flexible solar technology production. Additionally, the ambient temperature processing capability of many liquid metal systems eliminates the need for energy-intensive heating equipment and specialized ventilation systems.

The durability and self-healing properties of liquid metal interconnects significantly extend the operational lifespan of flexible solar installations. This longevity directly translates to reduced electronic waste generation and decreased resource consumption for replacement components, addressing a critical environmental challenge in renewable energy technology deployment.

From a recyclability perspective, gallium-based liquid metals present promising opportunities for material recovery. Unlike conventional solder joints that often require destructive mechanical separation, liquid metal interconnects can potentially be recovered through controlled thermal processes that preserve both the interconnect material and the solar cell components. The relatively high market value of gallium and other constituent elements provides economic incentives for implementing effective recycling systems.

However, challenges remain in establishing comprehensive recycling infrastructure specifically designed for liquid metal recovery from flexible electronics. Current electronic waste processing facilities may lack the specialized equipment and protocols necessary for efficient separation and purification of these materials. This gap represents an important area for future development as the technology scales commercially.

Life cycle assessment studies indicate that the environmental benefits of liquid metal interconnects are maximized when integrated into comprehensive circular economy frameworks. Designing flexible solar systems with end-of-life disassembly in mind can significantly enhance material recovery rates and reduce the environmental footprint of renewable energy technologies. This approach aligns with broader sustainability goals while supporting the economic viability of advanced solar energy systems.

Scalability and Manufacturing Process Optimization

The scalability of liquid metal interconnect technology for flexible solar cell integration presents both significant opportunities and challenges for mass production. Current manufacturing processes typically involve manual or semi-automated deposition of liquid metal alloys, which creates bottlenecks when scaling to industrial volumes. Recent advancements have focused on developing continuous roll-to-roll (R2R) processing techniques that enable higher throughput while maintaining interconnect quality and reliability.

Key process optimization areas include precise control of liquid metal viscosity and wetting properties, which directly impact the uniformity and electrical performance of interconnects. Temperature management during deposition represents another critical factor, as many liquid metal alloys exhibit temperature-dependent rheological properties that affect flow characteristics and adhesion to substrate materials. Research indicates that maintaining processing temperatures within ±2°C of optimal values can reduce defect rates by up to 40%.

Material waste reduction has emerged as a significant focus area for manufacturing optimization. Traditional dispensing methods can result in material wastage exceeding 25%, whereas newer microfluidic deposition techniques have demonstrated waste reduction to below 10%. This improvement not only reduces production costs but also addresses environmental concerns associated with gallium and other metals used in these interconnects.

Encapsulation processes represent another optimization frontier, as they must be compatible with high-speed manufacturing while ensuring long-term protection of the liquid metal interconnects from environmental factors. Recent innovations in UV-curable polymers have shown promise, allowing curing times under 30 seconds while providing adequate barrier properties against oxygen and moisture penetration.

Quality control methodologies are evolving to accommodate the unique properties of liquid metal interconnects. In-line electrical testing combined with machine vision systems can detect defects in real-time, enabling immediate process adjustments. Advanced analytics applied to manufacturing data have demonstrated potential for predictive maintenance and process drift detection, further enhancing yield rates.

Cost modeling indicates that with optimized manufacturing processes, liquid metal interconnect technology could achieve cost parity with conventional soldered interconnects at production volumes exceeding 100 MW annually. This economic threshold represents a critical target for commercial viability in mainstream solar applications, particularly as the flexible photovoltaic market continues to expand at a compound annual growth rate exceeding 15%.

Key process optimization areas include precise control of liquid metal viscosity and wetting properties, which directly impact the uniformity and electrical performance of interconnects. Temperature management during deposition represents another critical factor, as many liquid metal alloys exhibit temperature-dependent rheological properties that affect flow characteristics and adhesion to substrate materials. Research indicates that maintaining processing temperatures within ±2°C of optimal values can reduce defect rates by up to 40%.

Material waste reduction has emerged as a significant focus area for manufacturing optimization. Traditional dispensing methods can result in material wastage exceeding 25%, whereas newer microfluidic deposition techniques have demonstrated waste reduction to below 10%. This improvement not only reduces production costs but also addresses environmental concerns associated with gallium and other metals used in these interconnects.

Encapsulation processes represent another optimization frontier, as they must be compatible with high-speed manufacturing while ensuring long-term protection of the liquid metal interconnects from environmental factors. Recent innovations in UV-curable polymers have shown promise, allowing curing times under 30 seconds while providing adequate barrier properties against oxygen and moisture penetration.

Quality control methodologies are evolving to accommodate the unique properties of liquid metal interconnects. In-line electrical testing combined with machine vision systems can detect defects in real-time, enabling immediate process adjustments. Advanced analytics applied to manufacturing data have demonstrated potential for predictive maintenance and process drift detection, further enhancing yield rates.

Cost modeling indicates that with optimized manufacturing processes, liquid metal interconnect technology could achieve cost parity with conventional soldered interconnects at production volumes exceeding 100 MW annually. This economic threshold represents a critical target for commercial viability in mainstream solar applications, particularly as the flexible photovoltaic market continues to expand at a compound annual growth rate exceeding 15%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!