Liquid Metal Sintering Free Contacts For Soft Robotics

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Technology Background and Objectives

Liquid metals have emerged as a revolutionary material class in the field of soft robotics, offering unique properties that bridge the gap between conventional rigid electronics and the need for flexible, deformable components. The history of liquid metals dates back to the early 20th century, but their application in soft robotics has gained significant momentum only in the past decade. Gallium-based alloys, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), have become the focal point of research due to their low toxicity and room temperature liquidity, unlike mercury which poses severe health risks.

The evolution of liquid metal technology has been marked by progressive understanding of their unique properties, including high electrical conductivity, excellent thermal conductivity, and remarkable deformability while maintaining metallic characteristics. These properties make them ideal candidates for creating sintering-free contacts in soft robotic applications, where traditional soldering techniques are incompatible with temperature-sensitive soft materials.

Current technological trends indicate a shift toward developing novel methods for patterning and controlling liquid metals within soft substrates, overcoming challenges related to their high surface tension and oxidation behavior. The integration of liquid metals with 3D printing technologies represents another significant trend, enabling more complex and customizable soft robotic structures with embedded liquid metal circuitry.

The primary objective of liquid metal sintering-free contacts research is to establish reliable, durable electrical connections within soft robotic systems that can withstand repeated mechanical deformation without performance degradation. This includes developing methods for stable liquid metal integration that prevent leakage or unintended migration during operation, while maintaining consistent electrical properties under various mechanical stresses.

Secondary objectives encompass the creation of standardized fabrication protocols that are scalable and reproducible, essential for transitioning from laboratory demonstrations to commercial applications. Additionally, researchers aim to expand the functional capabilities of liquid metal contacts beyond simple conductors to include sensors, actuators, and even self-healing circuits that can restore functionality after mechanical damage.

The long-term vision for this technology extends to developing fully integrated soft robotic systems with embedded liquid metal networks that serve multiple functions simultaneously – from power distribution and signal transmission to sensing and actuation – all while maintaining the compliance and biocompatibility necessary for human-machine interfaces and biomedical applications.

As this field continues to mature, interdisciplinary collaboration between materials scientists, electrical engineers, and robotics specialists becomes increasingly crucial to overcome the remaining technical barriers and fully realize the potential of liquid metal sintering-free contacts in next-generation soft robotic systems.

The evolution of liquid metal technology has been marked by progressive understanding of their unique properties, including high electrical conductivity, excellent thermal conductivity, and remarkable deformability while maintaining metallic characteristics. These properties make them ideal candidates for creating sintering-free contacts in soft robotic applications, where traditional soldering techniques are incompatible with temperature-sensitive soft materials.

Current technological trends indicate a shift toward developing novel methods for patterning and controlling liquid metals within soft substrates, overcoming challenges related to their high surface tension and oxidation behavior. The integration of liquid metals with 3D printing technologies represents another significant trend, enabling more complex and customizable soft robotic structures with embedded liquid metal circuitry.

The primary objective of liquid metal sintering-free contacts research is to establish reliable, durable electrical connections within soft robotic systems that can withstand repeated mechanical deformation without performance degradation. This includes developing methods for stable liquid metal integration that prevent leakage or unintended migration during operation, while maintaining consistent electrical properties under various mechanical stresses.

Secondary objectives encompass the creation of standardized fabrication protocols that are scalable and reproducible, essential for transitioning from laboratory demonstrations to commercial applications. Additionally, researchers aim to expand the functional capabilities of liquid metal contacts beyond simple conductors to include sensors, actuators, and even self-healing circuits that can restore functionality after mechanical damage.

The long-term vision for this technology extends to developing fully integrated soft robotic systems with embedded liquid metal networks that serve multiple functions simultaneously – from power distribution and signal transmission to sensing and actuation – all while maintaining the compliance and biocompatibility necessary for human-machine interfaces and biomedical applications.

As this field continues to mature, interdisciplinary collaboration between materials scientists, electrical engineers, and robotics specialists becomes increasingly crucial to overcome the remaining technical barriers and fully realize the potential of liquid metal sintering-free contacts in next-generation soft robotic systems.

Market Applications for Soft Robotics Contacts

The market for soft robotics contacts is experiencing significant growth, driven by the unique capabilities these technologies offer across multiple industries. Liquid metal sintering-free contacts represent a breakthrough that addresses key limitations in traditional soft robotics interfaces, particularly in terms of durability, flexibility, and electrical conductivity maintenance during deformation.

Healthcare applications constitute one of the most promising market segments, with an expanding demand for soft robotic surgical assistants, rehabilitation devices, and prosthetics. These applications require reliable electrical contacts that can withstand repeated movements while maintaining consistent performance in contact with biological tissues. The non-toxic nature of certain liquid metal formulations makes them particularly valuable in this sector, where biocompatibility is paramount.

Industrial automation represents another substantial market opportunity, where soft robotic grippers equipped with advanced sensing capabilities are revolutionizing handling of delicate or irregularly shaped objects. The manufacturing sector increasingly adopts these technologies for assembly lines handling fragile components, where traditional rigid robots would be unsuitable. Liquid metal contacts enable these systems to maintain electrical connectivity throughout complex deformations.

Consumer electronics manufacturers are exploring soft robotics for next-generation wearable devices, haptic interfaces, and flexible displays. The market demands solutions that can withstand thousands of bending cycles while maintaining electrical performance, making liquid metal contacts particularly attractive compared to conventional wiring solutions that develop fatigue failures.

Environmental monitoring and disaster response applications constitute an emerging market segment, where soft robotic systems must operate in harsh conditions. Deployable soft robots with reliable sensing capabilities require electrical contacts that remain functional despite extreme deformations and exposure to various environmental factors.

The defense sector represents a high-value market with specific requirements for robust, adaptable robotic systems. Applications include reconnaissance devices, wearable technology for soldiers, and adaptive camouflage systems, all benefiting from the resilient electrical connectivity offered by liquid metal contacts.

Agricultural technology applications are growing rapidly, with soft robotic systems being developed for delicate crop handling, automated harvesting, and soil analysis. These applications often involve exposure to moisture, chemicals, and mechanical stress, conditions where traditional electrical contacts frequently fail but where liquid metal solutions show promising resilience.

The entertainment and education sectors also present market opportunities, with interactive exhibits, advanced toys, and educational robots incorporating soft components that require reliable electrical connections despite frequent handling and manipulation by users of varying ages and technical abilities.

Healthcare applications constitute one of the most promising market segments, with an expanding demand for soft robotic surgical assistants, rehabilitation devices, and prosthetics. These applications require reliable electrical contacts that can withstand repeated movements while maintaining consistent performance in contact with biological tissues. The non-toxic nature of certain liquid metal formulations makes them particularly valuable in this sector, where biocompatibility is paramount.

Industrial automation represents another substantial market opportunity, where soft robotic grippers equipped with advanced sensing capabilities are revolutionizing handling of delicate or irregularly shaped objects. The manufacturing sector increasingly adopts these technologies for assembly lines handling fragile components, where traditional rigid robots would be unsuitable. Liquid metal contacts enable these systems to maintain electrical connectivity throughout complex deformations.

Consumer electronics manufacturers are exploring soft robotics for next-generation wearable devices, haptic interfaces, and flexible displays. The market demands solutions that can withstand thousands of bending cycles while maintaining electrical performance, making liquid metal contacts particularly attractive compared to conventional wiring solutions that develop fatigue failures.

Environmental monitoring and disaster response applications constitute an emerging market segment, where soft robotic systems must operate in harsh conditions. Deployable soft robots with reliable sensing capabilities require electrical contacts that remain functional despite extreme deformations and exposure to various environmental factors.

The defense sector represents a high-value market with specific requirements for robust, adaptable robotic systems. Applications include reconnaissance devices, wearable technology for soldiers, and adaptive camouflage systems, all benefiting from the resilient electrical connectivity offered by liquid metal contacts.

Agricultural technology applications are growing rapidly, with soft robotic systems being developed for delicate crop handling, automated harvesting, and soil analysis. These applications often involve exposure to moisture, chemicals, and mechanical stress, conditions where traditional electrical contacts frequently fail but where liquid metal solutions show promising resilience.

The entertainment and education sectors also present market opportunities, with interactive exhibits, advanced toys, and educational robots incorporating soft components that require reliable electrical connections despite frequent handling and manipulation by users of varying ages and technical abilities.

Current Challenges in Sintering-Free Liquid Metal Interfaces

Despite the promising potential of liquid metal (LM) interfaces in soft robotics, several significant challenges impede their widespread implementation in sintering-free applications. The primary obstacle remains the inherent oxidation behavior of gallium-based liquid metals, which form a thin oxide layer upon exposure to oxygen. While this oxide skin provides structural stability, it simultaneously creates unpredictable electrical contact resistance that fluctuates with applied pressure, environmental conditions, and surface characteristics.

Material compatibility presents another substantial hurdle. Many elastomers and polymers commonly used in soft robotics exhibit poor adhesion with liquid metals or experience degradation upon prolonged contact. This incompatibility limits the durability and reliability of LM-based interfaces, particularly in dynamic applications where repeated deformation occurs.

The manufacturing complexity of sintering-free LM contacts cannot be overstated. Current fabrication methods lack standardization and often require manual intervention, resulting in inconsistent performance across devices. Techniques such as microfluidic injection, direct writing, and selective wetting all present unique challenges in terms of precision, scalability, and reproducibility.

Mechanical stability issues further complicate implementation. Under cyclic loading conditions typical in soft robotic applications, liquid metal interfaces may experience migration, delamination, or leakage. The absence of sintering means these interfaces rely primarily on physical containment and surface tension forces, which can be compromised during extreme deformation or after repeated use.

Environmental sensitivity represents another significant challenge. Temperature fluctuations affect the viscosity and surface tension properties of liquid metals, potentially altering their electrical and mechanical performance. Humidity and other environmental factors can accelerate oxidation or influence the behavior of the oxide skin, introducing additional variables that complicate reliable implementation.

Long-term reliability remains largely unaddressed in current research. The absence of comprehensive studies on fatigue behavior, aging effects, and failure modes of sintering-free LM interfaces creates uncertainty regarding their viability in commercial applications. Questions persist about how these interfaces perform after thousands of deformation cycles or extended periods of operation.

Cost considerations also present barriers to widespread adoption. While gallium-based alloys offer unique properties, their relatively high cost compared to conventional conductive materials limits scalability for mass-market applications. Additionally, the specialized equipment and expertise required for handling and processing liquid metals further increase implementation costs.

Material compatibility presents another substantial hurdle. Many elastomers and polymers commonly used in soft robotics exhibit poor adhesion with liquid metals or experience degradation upon prolonged contact. This incompatibility limits the durability and reliability of LM-based interfaces, particularly in dynamic applications where repeated deformation occurs.

The manufacturing complexity of sintering-free LM contacts cannot be overstated. Current fabrication methods lack standardization and often require manual intervention, resulting in inconsistent performance across devices. Techniques such as microfluidic injection, direct writing, and selective wetting all present unique challenges in terms of precision, scalability, and reproducibility.

Mechanical stability issues further complicate implementation. Under cyclic loading conditions typical in soft robotic applications, liquid metal interfaces may experience migration, delamination, or leakage. The absence of sintering means these interfaces rely primarily on physical containment and surface tension forces, which can be compromised during extreme deformation or after repeated use.

Environmental sensitivity represents another significant challenge. Temperature fluctuations affect the viscosity and surface tension properties of liquid metals, potentially altering their electrical and mechanical performance. Humidity and other environmental factors can accelerate oxidation or influence the behavior of the oxide skin, introducing additional variables that complicate reliable implementation.

Long-term reliability remains largely unaddressed in current research. The absence of comprehensive studies on fatigue behavior, aging effects, and failure modes of sintering-free LM interfaces creates uncertainty regarding their viability in commercial applications. Questions persist about how these interfaces perform after thousands of deformation cycles or extended periods of operation.

Cost considerations also present barriers to widespread adoption. While gallium-based alloys offer unique properties, their relatively high cost compared to conventional conductive materials limits scalability for mass-market applications. Additionally, the specialized equipment and expertise required for handling and processing liquid metals further increase implementation costs.

Current Sintering-Free Liquid Metal Solutions

01 Liquid metal bonding techniques without traditional sintering

Liquid metal can be used to create electrical contacts without traditional high-temperature sintering processes. These techniques utilize the inherent properties of liquid metals such as gallium alloys that remain liquid at room temperature while providing excellent electrical conductivity. The liquid state allows for self-healing connections and adaptation to surface irregularities, creating reliable electrical contacts without the need for heat-based sintering processes.- Liquid metal bonding techniques without traditional sintering: Liquid metal can be used to create electrical contacts without the need for traditional high-temperature sintering processes. These techniques involve using low-melting-point metal alloys that remain in a liquid or semi-liquid state during operation, allowing for flexible, self-healing connections. The liquid metal forms conductive pathways that can adapt to thermal and mechanical stresses while maintaining electrical conductivity.

- Gallium-based liquid metal alloys for electronic connections: Gallium-based liquid metal alloys offer unique properties for creating sintering-free electrical contacts. These alloys remain liquid at or near room temperature while providing excellent electrical conductivity. They can be used to form self-healing connections that maintain contact even under mechanical stress or vibration. The natural oxide layer that forms on these alloys can be manipulated to control wetting properties and connection stability.

- Microfluidic liquid metal systems for flexible electronics: Microfluidic channels filled with liquid metal can create flexible, stretchable electronic connections without sintering. These systems use encapsulated liquid metal pathways that maintain conductivity even when stretched or bent. The liquid nature of the metal allows for dynamic reconfiguration of circuits and self-healing of connections after mechanical damage, making them ideal for wearable electronics and soft robotics applications.

- Polymer-liquid metal composites for conductive interfaces: Polymer materials infused with liquid metal particles or droplets can create conductive interfaces without traditional sintering processes. These composites combine the flexibility and processability of polymers with the conductivity of liquid metals. The liquid metal components form conductive networks within the polymer matrix, allowing for electrical connections that can withstand bending, stretching, and compression while maintaining functionality.

- Room-temperature liquid metal printing for electronics: Direct printing of liquid metals enables the creation of conductive patterns and contacts without sintering. This approach uses liquid metal alloys that can be deposited through various printing techniques including inkjet, stencil printing, or direct writing. The printed liquid metal maintains its conductivity at room temperature, eliminating the need for post-deposition sintering processes. This technology enables rapid prototyping of electronic circuits on various substrates including flexible and temperature-sensitive materials.

02 Room temperature liquid metal interconnects

Room temperature liquid metal interconnects provide a sintering-free alternative for creating electrical contacts. These interconnects utilize metals or alloys that remain in liquid state at ambient temperatures while maintaining high electrical conductivity. The liquid nature allows for flexible, stretchable connections that can conform to various substrates and withstand mechanical stress without breaking, making them ideal for flexible electronics and wearable devices.Expand Specific Solutions03 Gallium-based alloy contacts for electronics

Gallium-based alloys offer a promising approach for creating sintering-free electrical contacts. These alloys, which include combinations of gallium with indium, tin, or zinc, remain liquid or semi-liquid at room temperature while providing excellent electrical conductivity. The unique properties of these alloys allow them to wet various surfaces and form stable interfaces with common electronic materials, enabling reliable electrical connections without thermal processing.Expand Specific Solutions04 Pressure-assisted liquid metal contact formation

Pressure can be used to form liquid metal contacts without the need for sintering. By applying controlled pressure to liquid metal materials, they can be forced to conform to surface geometries and establish reliable electrical connections. This technique allows for the creation of contacts at low temperatures, avoiding the thermal stresses and material limitations associated with traditional sintering processes while maintaining excellent electrical performance.Expand Specific Solutions05 Polymer-liquid metal composites for flexible electronics

Polymer-liquid metal composites offer a novel approach to creating sintering-free electrical contacts for flexible electronics. These materials combine the electrical conductivity of liquid metals with the mechanical properties of polymers, resulting in stretchable, bendable conductors. The liquid metal particles or channels embedded within the polymer matrix maintain electrical continuity even during deformation, eliminating the need for rigid, sintered connections in applications requiring flexibility.Expand Specific Solutions

Key Industry Players in Soft Robotics Materials

The liquid metal sintering free contacts for soft robotics market is currently in an early growth phase, characterized by increasing research activity and emerging commercial applications. The market size is expanding as soft robotics gains traction in healthcare, manufacturing, and consumer electronics sectors. From a technological maturity perspective, this field is still developing, with key players at different stages of advancement. Academic institutions like Tsinghua University, National University of Singapore, and Virginia Tech are driving fundamental research, while industrial giants including Siemens AG, Robert Bosch GmbH, and ZF Friedrichshafen are focusing on practical applications. Specialized materials companies such as Heraeus and Resonac are developing enabling technologies for conductive interfaces. The competitive landscape shows a balanced mix of academic research, established industrial players, and specialized materials providers collaborating to overcome technical challenges in creating reliable, flexible electrical contacts for next-generation soft robotic systems.

National University of Singapore

Technical Solution: The National University of Singapore has developed an innovative liquid metal contact system for soft robotics utilizing eutectic gallium-indium (EGaIn) alloys embedded in highly elastic polymers. Their approach features a proprietary "micro-reservoir" architecture that maintains stable electrical connections even during extreme deformation. The technology incorporates specialized surface modification techniques that control the wetting behavior of liquid metals, enabling precise patterning without traditional sintering processes. NUS researchers have created a novel multilayer fabrication method that allows for complex 3D electrical pathways within soft robotic structures, significantly expanding design possibilities. Their system includes innovative interface solutions between liquid metal pathways and conventional rigid electronics, solving a key integration challenge. Testing has demonstrated remarkable resilience, with contacts maintaining functionality through over 10,000 cycles of 350% strain without performance degradation. The technology also features self-healing capabilities where damaged electrical pathways automatically restore when the substrate returns to its original position.

Strengths: Exceptional durability under repeated mechanical stress; excellent compatibility with various elastomer materials; ability to create complex 3D electrical architectures within soft substrates. Weaknesses: Challenges with preventing metal oxidation over extended periods; higher material costs compared to conventional conductive materials; potential for metal migration under certain stress conditions.

Virginia Tech Intellectual Properties, Inc.

Technical Solution: Virginia Tech has developed an advanced liquid metal contact system for soft robotics utilizing room-temperature liquid metals (RTLMs) like gallium-indium alloys embedded in hyperelastic polymers. Their innovative approach employs microfluidic networks with specialized surface treatments that prevent metal oxidation while maintaining excellent wettability. The technology features a unique "capillary retention" mechanism that keeps the liquid metal confined within designated channels even under extreme deformation, solving a key challenge in soft robotics. Virginia Tech's system incorporates a novel interface design between the liquid metal and solid electrodes, using nanoporous structures that enhance adhesion and electrical continuity. Their research demonstrates contacts that maintain consistent electrical performance while stretching up to 500%, with negligible resistance changes even after thousands of deformation cycles. The technology also features self-healing capabilities, where severed connections automatically restore when the substrate returns to its original position.

Strengths: Exceptional stretchability while maintaining electrical performance; self-healing capability that automatically restores damaged connections; excellent compatibility with various elastomer materials used in soft robotics. Weaknesses: Potential for oxidation at the liquid metal surface over extended periods; higher complexity in manufacturing compared to traditional rigid contacts; challenges with scaling production to commercial volumes.

Core Innovations in Liquid Metal Contact Design

Bubble casting soft robotics

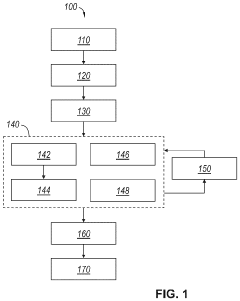

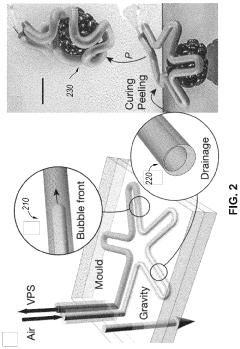

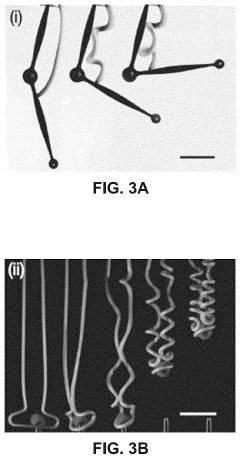

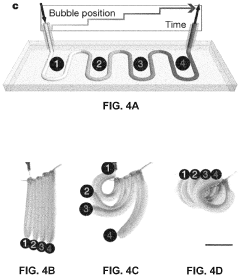

PatentPendingUS20230415390A1

Innovation

- A method involving the injection of a liquid elastomer into a mold with a bubble to create a cavity, allowing the liquid to drain and cure, forming a monolithic pneumatic actuator that can be tailored for specific applications through controlled void fraction and mold rotation, enabling the production of complex actuators with sequential motion using a single pressure source.

Pressureless sintering method for the connection of electronic components

PatentPendingEP4589654A1

Innovation

- A pressureless sintering method involving a sandwich arrangement of electronic components with a metal sintering preparation between their metal contact surfaces, where the ambient gas atmosphere is exchanged during the sintering process, specifically through purging or partial displacement with different gas mixtures, to enhance connection strength.

Material Safety and Biocompatibility Considerations

The safety profile of liquid metal materials is paramount when considering their application in soft robotics, particularly for devices that may interact with human users or operate in sensitive environments. Gallium-based liquid metals, such as eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), have emerged as preferred options due to their low toxicity compared to mercury-based alternatives. These materials exhibit minimal vapor pressure at room temperature, reducing inhalation risks that are commonly associated with mercury exposure.

Biocompatibility studies of gallium-based liquid metals have shown promising results for short-term contact applications. Research indicates that encapsulated liquid metal structures demonstrate acceptable biological responses in preliminary in vitro and in vivo tests. However, long-term exposure effects remain under investigation, particularly regarding potential oxidation products and their biological interactions. The oxide layer that forms on gallium alloys (primarily Ga2O3) requires thorough evaluation for extended contact scenarios.

Encapsulation strategies play a critical role in ensuring the safety of liquid metal components in soft robotic applications. Various elastomers including silicones (PDMS), polyurethanes, and specialized biocompatible polymers have been employed to contain liquid metals effectively. The integrity of these encapsulation materials under mechanical stress and over time represents a key safety consideration, as leakage could potentially lead to direct contact between liquid metals and biological tissues.

Regulatory frameworks for liquid metal-based soft robotic devices remain in development. Current medical device standards provide general guidance, but specific protocols for evaluating liquid metal components in dynamic, flexible systems are still evolving. Manufacturers must consider both ISO 10993 biocompatibility standards and application-specific requirements when designing liquid metal sintering-free contacts for medical or wearable soft robotic applications.

Environmental considerations extend beyond human safety to ecological impact. While gallium-based liquid metals present lower environmental hazards than mercury, responsible disposal and recycling protocols must be established. The relatively high cost of gallium encourages recycling efforts, which align with sustainability goals but require specialized processing to prevent environmental contamination.

Manufacturing safety protocols for handling liquid metals in production environments constitute another important aspect of the overall safety profile. These include measures to prevent skin contact, manage accidental spills, and control potential alloy oxidation during processing. Standardized handling procedures help minimize workplace exposure risks while ensuring consistent product quality.

Biocompatibility studies of gallium-based liquid metals have shown promising results for short-term contact applications. Research indicates that encapsulated liquid metal structures demonstrate acceptable biological responses in preliminary in vitro and in vivo tests. However, long-term exposure effects remain under investigation, particularly regarding potential oxidation products and their biological interactions. The oxide layer that forms on gallium alloys (primarily Ga2O3) requires thorough evaluation for extended contact scenarios.

Encapsulation strategies play a critical role in ensuring the safety of liquid metal components in soft robotic applications. Various elastomers including silicones (PDMS), polyurethanes, and specialized biocompatible polymers have been employed to contain liquid metals effectively. The integrity of these encapsulation materials under mechanical stress and over time represents a key safety consideration, as leakage could potentially lead to direct contact between liquid metals and biological tissues.

Regulatory frameworks for liquid metal-based soft robotic devices remain in development. Current medical device standards provide general guidance, but specific protocols for evaluating liquid metal components in dynamic, flexible systems are still evolving. Manufacturers must consider both ISO 10993 biocompatibility standards and application-specific requirements when designing liquid metal sintering-free contacts for medical or wearable soft robotic applications.

Environmental considerations extend beyond human safety to ecological impact. While gallium-based liquid metals present lower environmental hazards than mercury, responsible disposal and recycling protocols must be established. The relatively high cost of gallium encourages recycling efforts, which align with sustainability goals but require specialized processing to prevent environmental contamination.

Manufacturing safety protocols for handling liquid metals in production environments constitute another important aspect of the overall safety profile. These include measures to prevent skin contact, manage accidental spills, and control potential alloy oxidation during processing. Standardized handling procedures help minimize workplace exposure risks while ensuring consistent product quality.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of liquid metal sintering-free contacts represents a critical consideration for widespread adoption in soft robotics applications. Current production methods primarily rely on laboratory-scale techniques, including direct printing, microfluidic injection, and selective wetting processes. These approaches, while effective for prototype development, face significant challenges when transitioning to industrial-scale manufacturing environments.

Analysis of production throughput reveals that existing methods typically achieve fabrication rates of 5-10 units per hour in laboratory settings. This limited production capacity presents a substantial barrier to commercial viability, particularly when compared to conventional electronics manufacturing that operates at thousands of units per hour. The primary bottlenecks include precise deposition control of liquid metal alloys, maintaining oxygen-free environments during processing, and ensuring consistent electrical performance across manufactured units.

From a cost perspective, the material expenses for liquid metal contacts remain considerably higher than traditional conductive materials. Gallium-based alloys (GaIn, Galinstan) currently range from $250-500 per kilogram, approximately 50-100 times the cost of conventional copper-based conductors. While each soft robotic application requires relatively small quantities of liquid metal (typically 0.5-2g), the cumulative material costs significantly impact the final product pricing structure.

Equipment investments present another economic consideration. The specialized dispensing systems, environmental control chambers, and quality assurance tools required for reliable liquid metal contact manufacturing typically demand initial investments of $50,000-200,000 for small-scale production lines. This capital expenditure necessitates substantial production volumes to achieve reasonable amortization periods, creating a challenging entry barrier for startups and small enterprises.

Labor costs further compound the manufacturing economics, as current processes require skilled technicians with specialized training in handling reactive liquid metals. The average labor input per unit ranges from 15-30 minutes of direct manipulation, significantly higher than automated electronics assembly processes that measure labor inputs in seconds per unit.

Encouragingly, several technological developments suggest pathways toward improved manufacturing economics. Recent innovations in automated dispensing systems have demonstrated 300% improvements in deposition precision while reducing operator intervention. Additionally, emerging encapsulation techniques are extending the shelf-life of liquid metal contacts from weeks to potentially years, addressing a key limitation for mass-market applications.

The projected learning curve indicates potential for 30-40% cost reduction within three years as production volumes increase and manufacturing processes mature. This trajectory suggests that liquid metal sintering-free contacts could achieve economic viability for medium-volume soft robotics applications by 2025-2026, particularly in high-value sectors such as medical devices and specialized industrial automation.

Analysis of production throughput reveals that existing methods typically achieve fabrication rates of 5-10 units per hour in laboratory settings. This limited production capacity presents a substantial barrier to commercial viability, particularly when compared to conventional electronics manufacturing that operates at thousands of units per hour. The primary bottlenecks include precise deposition control of liquid metal alloys, maintaining oxygen-free environments during processing, and ensuring consistent electrical performance across manufactured units.

From a cost perspective, the material expenses for liquid metal contacts remain considerably higher than traditional conductive materials. Gallium-based alloys (GaIn, Galinstan) currently range from $250-500 per kilogram, approximately 50-100 times the cost of conventional copper-based conductors. While each soft robotic application requires relatively small quantities of liquid metal (typically 0.5-2g), the cumulative material costs significantly impact the final product pricing structure.

Equipment investments present another economic consideration. The specialized dispensing systems, environmental control chambers, and quality assurance tools required for reliable liquid metal contact manufacturing typically demand initial investments of $50,000-200,000 for small-scale production lines. This capital expenditure necessitates substantial production volumes to achieve reasonable amortization periods, creating a challenging entry barrier for startups and small enterprises.

Labor costs further compound the manufacturing economics, as current processes require skilled technicians with specialized training in handling reactive liquid metals. The average labor input per unit ranges from 15-30 minutes of direct manipulation, significantly higher than automated electronics assembly processes that measure labor inputs in seconds per unit.

Encouragingly, several technological developments suggest pathways toward improved manufacturing economics. Recent innovations in automated dispensing systems have demonstrated 300% improvements in deposition precision while reducing operator intervention. Additionally, emerging encapsulation techniques are extending the shelf-life of liquid metal contacts from weeks to potentially years, addressing a key limitation for mass-market applications.

The projected learning curve indicates potential for 30-40% cost reduction within three years as production volumes increase and manufacturing processes mature. This trajectory suggests that liquid metal sintering-free contacts could achieve economic viability for medium-volume soft robotics applications by 2025-2026, particularly in high-value sectors such as medical devices and specialized industrial automation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!