Cost-Benefit Analysis of Lithium Iron Phosphate Battery Deployment

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution and Objectives

Lithium Iron Phosphate (LFP) batteries have emerged as a significant player in the energy storage landscape, particularly in the context of electric vehicles and renewable energy systems. The evolution of LFP technology can be traced back to the late 1990s when it was first developed as a safer and more stable alternative to traditional lithium-ion batteries. Since then, LFP batteries have undergone substantial improvements in performance, cost-effectiveness, and manufacturing processes.

The primary objectives driving the development of LFP batteries include enhancing energy density, improving cycle life, reducing production costs, and maintaining high safety standards. These goals align with the broader aims of the electric vehicle and renewable energy sectors to create more efficient, affordable, and sustainable energy storage solutions.

Over the past two decades, LFP battery technology has seen significant advancements. Early iterations faced challenges related to low energy density and limited power output. However, continuous research and development efforts have led to substantial improvements in these areas. The introduction of nano-scale materials and advanced manufacturing techniques has played a crucial role in enhancing the performance characteristics of LFP batteries.

One of the key milestones in LFP battery evolution was the development of carbon-coated LFP particles, which significantly improved the material's electrical conductivity. This innovation, coupled with advancements in electrode design and electrolyte formulations, has resulted in LFP batteries with higher energy density, faster charging capabilities, and extended cycle life.

The objectives for future LFP battery development are multifaceted. Researchers and manufacturers are focusing on further increasing energy density to compete more effectively with other lithium-ion chemistries. Additionally, there is a strong emphasis on reducing production costs through economies of scale and improved manufacturing processes. Enhancing the low-temperature performance of LFP batteries is another critical objective, as this has been a traditional weakness of the technology.

Environmental considerations are also shaping the evolution of LFP batteries. The abundance of iron and phosphate in nature, combined with the absence of cobalt and nickel in the cathode material, positions LFP as a more sustainable and ethically sourced battery technology. Future objectives include further improving the recyclability of LFP batteries and reducing the environmental impact of their production processes.

As the demand for electric vehicles and renewable energy storage continues to grow, the development of LFP batteries is expected to accelerate. The technology's inherent safety advantages and improving performance characteristics make it an attractive option for a wide range of applications. The ongoing evolution of LFP batteries aims to address the critical balance between cost, performance, and sustainability, driving innovation in the broader field of energy storage solutions.

The primary objectives driving the development of LFP batteries include enhancing energy density, improving cycle life, reducing production costs, and maintaining high safety standards. These goals align with the broader aims of the electric vehicle and renewable energy sectors to create more efficient, affordable, and sustainable energy storage solutions.

Over the past two decades, LFP battery technology has seen significant advancements. Early iterations faced challenges related to low energy density and limited power output. However, continuous research and development efforts have led to substantial improvements in these areas. The introduction of nano-scale materials and advanced manufacturing techniques has played a crucial role in enhancing the performance characteristics of LFP batteries.

One of the key milestones in LFP battery evolution was the development of carbon-coated LFP particles, which significantly improved the material's electrical conductivity. This innovation, coupled with advancements in electrode design and electrolyte formulations, has resulted in LFP batteries with higher energy density, faster charging capabilities, and extended cycle life.

The objectives for future LFP battery development are multifaceted. Researchers and manufacturers are focusing on further increasing energy density to compete more effectively with other lithium-ion chemistries. Additionally, there is a strong emphasis on reducing production costs through economies of scale and improved manufacturing processes. Enhancing the low-temperature performance of LFP batteries is another critical objective, as this has been a traditional weakness of the technology.

Environmental considerations are also shaping the evolution of LFP batteries. The abundance of iron and phosphate in nature, combined with the absence of cobalt and nickel in the cathode material, positions LFP as a more sustainable and ethically sourced battery technology. Future objectives include further improving the recyclability of LFP batteries and reducing the environmental impact of their production processes.

As the demand for electric vehicles and renewable energy storage continues to grow, the development of LFP batteries is expected to accelerate. The technology's inherent safety advantages and improving performance characteristics make it an attractive option for a wide range of applications. The ongoing evolution of LFP batteries aims to address the critical balance between cost, performance, and sustainability, driving innovation in the broader field of energy storage solutions.

Market Demand for LFP Batteries

The market demand for Lithium Iron Phosphate (LFP) batteries has been experiencing significant growth in recent years, driven by several key factors. The electric vehicle (EV) industry stands as the primary driver of this demand, with automakers increasingly adopting LFP batteries due to their cost-effectiveness and safety features. This trend is particularly pronounced in China, where LFP batteries have become the dominant chemistry for electric vehicles.

The energy storage sector represents another substantial market for LFP batteries. Grid-scale energy storage systems and residential battery installations are increasingly utilizing LFP technology due to its long cycle life and thermal stability. This application is expected to grow as countries worldwide push for greater renewable energy integration and grid resilience.

Consumer electronics manufacturers are also showing interest in LFP batteries, albeit to a lesser extent than the EV and energy storage sectors. The improved safety characteristics of LFP batteries make them attractive for devices where safety is a paramount concern.

Market analysts project the global LFP battery market to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is underpinned by the expanding EV market, particularly in China and increasingly in other regions as automakers seek to reduce costs and improve safety profiles of their electric vehicles.

The demand for LFP batteries is also being bolstered by government policies and regulations. Many countries have implemented stricter emissions standards and are offering incentives for EV adoption, indirectly boosting the demand for LFP batteries. Additionally, safety regulations in various industries are becoming more stringent, favoring the adoption of LFP technology due to its inherent safety advantages.

Raw material considerations are playing a crucial role in shaping market demand. LFP batteries do not require cobalt or nickel, which are subject to supply chain concerns and price volatility. This factor is particularly appealing to manufacturers looking to reduce dependency on these materials and mitigate associated risks.

However, the market demand for LFP batteries is not without challenges. The lower energy density compared to other lithium-ion chemistries remains a limitation, particularly for applications where weight and space are critical factors. This constraint is less significant in stationary energy storage applications but can be a consideration in the EV sector, especially for high-end vehicles where range is a key selling point.

The energy storage sector represents another substantial market for LFP batteries. Grid-scale energy storage systems and residential battery installations are increasingly utilizing LFP technology due to its long cycle life and thermal stability. This application is expected to grow as countries worldwide push for greater renewable energy integration and grid resilience.

Consumer electronics manufacturers are also showing interest in LFP batteries, albeit to a lesser extent than the EV and energy storage sectors. The improved safety characteristics of LFP batteries make them attractive for devices where safety is a paramount concern.

Market analysts project the global LFP battery market to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is underpinned by the expanding EV market, particularly in China and increasingly in other regions as automakers seek to reduce costs and improve safety profiles of their electric vehicles.

The demand for LFP batteries is also being bolstered by government policies and regulations. Many countries have implemented stricter emissions standards and are offering incentives for EV adoption, indirectly boosting the demand for LFP batteries. Additionally, safety regulations in various industries are becoming more stringent, favoring the adoption of LFP technology due to its inherent safety advantages.

Raw material considerations are playing a crucial role in shaping market demand. LFP batteries do not require cobalt or nickel, which are subject to supply chain concerns and price volatility. This factor is particularly appealing to manufacturers looking to reduce dependency on these materials and mitigate associated risks.

However, the market demand for LFP batteries is not without challenges. The lower energy density compared to other lithium-ion chemistries remains a limitation, particularly for applications where weight and space are critical factors. This constraint is less significant in stationary energy storage applications but can be a consideration in the EV sector, especially for high-end vehicles where range is a key selling point.

LFP Battery Technology Status and Challenges

Lithium Iron Phosphate (LFP) batteries have emerged as a prominent technology in the energy storage sector, particularly for electric vehicles and grid-scale applications. The current status of LFP battery technology is characterized by significant advancements in performance, cost-effectiveness, and safety features. These batteries have gained traction due to their thermal stability, long cycle life, and improved energy density compared to earlier generations.

One of the primary challenges facing LFP battery technology is its relatively lower energy density compared to other lithium-ion chemistries, such as nickel-manganese-cobalt (NMC) batteries. This limitation can result in reduced driving range for electric vehicles, potentially impacting consumer adoption rates. However, ongoing research and development efforts are focused on enhancing the energy density of LFP batteries through various approaches, including nanostructuring and doping of cathode materials.

Another significant challenge is the optimization of manufacturing processes to further reduce production costs. While LFP batteries are generally less expensive than some alternative chemistries, there is still room for improvement in terms of economies of scale and production efficiency. This is particularly crucial for widespread adoption in price-sensitive markets and applications.

The raw material supply chain presents both opportunities and challenges for LFP battery technology. Unlike some other lithium-ion chemistries, LFP batteries do not rely on cobalt, which has been associated with supply chain concerns and ethical issues. However, ensuring a stable and cost-effective supply of high-quality lithium and iron phosphate remains a priority for manufacturers.

Environmental considerations also pose challenges for LFP battery technology. While these batteries are generally considered more environmentally friendly due to their longer lifespan and the absence of cobalt, end-of-life recycling processes still need improvement. Developing efficient and economically viable recycling methods for LFP batteries is crucial for sustainable long-term deployment.

Performance at low temperatures is another area where LFP batteries face challenges. Their capacity and power output can be significantly reduced in cold environments, which may limit their applicability in certain regions or use cases. Research is ongoing to address this issue through electrolyte modifications and battery management system optimizations.

Despite these challenges, the overall trajectory of LFP battery technology is positive. Continuous improvements in energy density, cost reduction, and manufacturing processes are expanding the potential applications and market share of LFP batteries. The technology's inherent safety advantages and long cycle life make it particularly attractive for large-scale energy storage systems and certain electric vehicle segments.

One of the primary challenges facing LFP battery technology is its relatively lower energy density compared to other lithium-ion chemistries, such as nickel-manganese-cobalt (NMC) batteries. This limitation can result in reduced driving range for electric vehicles, potentially impacting consumer adoption rates. However, ongoing research and development efforts are focused on enhancing the energy density of LFP batteries through various approaches, including nanostructuring and doping of cathode materials.

Another significant challenge is the optimization of manufacturing processes to further reduce production costs. While LFP batteries are generally less expensive than some alternative chemistries, there is still room for improvement in terms of economies of scale and production efficiency. This is particularly crucial for widespread adoption in price-sensitive markets and applications.

The raw material supply chain presents both opportunities and challenges for LFP battery technology. Unlike some other lithium-ion chemistries, LFP batteries do not rely on cobalt, which has been associated with supply chain concerns and ethical issues. However, ensuring a stable and cost-effective supply of high-quality lithium and iron phosphate remains a priority for manufacturers.

Environmental considerations also pose challenges for LFP battery technology. While these batteries are generally considered more environmentally friendly due to their longer lifespan and the absence of cobalt, end-of-life recycling processes still need improvement. Developing efficient and economically viable recycling methods for LFP batteries is crucial for sustainable long-term deployment.

Performance at low temperatures is another area where LFP batteries face challenges. Their capacity and power output can be significantly reduced in cold environments, which may limit their applicability in certain regions or use cases. Research is ongoing to address this issue through electrolyte modifications and battery management system optimizations.

Despite these challenges, the overall trajectory of LFP battery technology is positive. Continuous improvements in energy density, cost reduction, and manufacturing processes are expanding the potential applications and market share of LFP batteries. The technology's inherent safety advantages and long cycle life make it particularly attractive for large-scale energy storage systems and certain electric vehicle segments.

Current LFP Battery Solutions

01 Cost-effective production methods

Innovative manufacturing techniques and processes are being developed to reduce the production costs of lithium iron phosphate (LFP) batteries. These methods include optimized synthesis routes, improved material utilization, and streamlined assembly processes. By reducing production costs, the overall cost-benefit ratio of LFP batteries can be significantly improved, making them more competitive in the market.- Cost-effective production methods: Innovative manufacturing techniques and processes are being developed to reduce the production costs of lithium iron phosphate (LFP) batteries. These methods include optimized synthesis routes, improved material utilization, and streamlined production processes. By reducing manufacturing costs, the overall cost-benefit ratio of LFP batteries can be significantly improved.

- Enhanced energy density and performance: Research is focused on improving the energy density and overall performance of LFP batteries. This includes developing new electrode materials, optimizing particle size and morphology, and enhancing the electrolyte composition. These advancements aim to increase the battery's capacity, power output, and cycle life, thereby improving its cost-benefit ratio.

- Integration with renewable energy systems: LFP batteries are being increasingly integrated with renewable energy systems, such as solar and wind power. This integration allows for efficient energy storage and grid stabilization, enhancing the overall cost-benefit of both the battery and renewable energy systems. The long cycle life and safety characteristics of LFP batteries make them particularly suitable for these applications.

- Recycling and sustainability: Advancements in recycling technologies for LFP batteries are improving their overall sustainability and reducing long-term costs. These recycling methods focus on recovering valuable materials, reducing environmental impact, and creating a circular economy for battery components. The improved recyclability enhances the cost-benefit ratio of LFP batteries over their entire lifecycle.

- Application-specific optimizations: LFP batteries are being optimized for specific applications, such as electric vehicles, stationary energy storage, and portable electronics. These optimizations include tailoring the battery design, management systems, and packaging to meet the unique requirements of each application. By focusing on application-specific improvements, the cost-benefit ratio of LFP batteries can be maximized for different use cases.

02 Enhanced energy density and performance

Research is focused on improving the energy density and overall performance of LFP batteries. This includes developing new cathode materials, optimizing particle size and morphology, and enhancing the electrode structure. These advancements aim to increase the battery's capacity, power output, and cycle life, thereby improving its cost-benefit ratio by providing more value per unit cost.Expand Specific Solutions03 Integration with renewable energy systems

LFP batteries are being increasingly integrated with renewable energy systems, such as solar and wind power. This integration allows for more efficient energy storage and utilization, improving the overall cost-benefit of both the battery and the renewable energy system. The long cycle life and safety characteristics of LFP batteries make them particularly suitable for these applications.Expand Specific Solutions04 Recycling and sustainability

Advancements in recycling technologies for LFP batteries are improving their overall sustainability and reducing long-term costs. These recycling methods focus on recovering valuable materials, reducing waste, and minimizing environmental impact. By improving the end-of-life management of LFP batteries, their lifecycle cost-benefit ratio is enhanced.Expand Specific Solutions05 Application-specific optimizations

LFP batteries are being optimized for specific applications, such as electric vehicles, grid storage, and portable electronics. These optimizations involve tailoring the battery design, chemistry, and management systems to meet the unique requirements of each application. By focusing on application-specific improvements, the cost-benefit ratio of LFP batteries can be maximized for different use cases.Expand Specific Solutions

Key Players in LFP Battery Industry

The cost-benefit analysis of Lithium Iron Phosphate (LFP) battery deployment is currently in a growth phase, with the market expanding rapidly due to increasing demand for electric vehicles and energy storage systems. The global LFP battery market size is projected to reach significant volumes in the coming years, driven by its cost-effectiveness and safety advantages. Technologically, LFP batteries are relatively mature, with companies like CATL, BYD, and LG Energy Solution leading in innovation and production. However, there's ongoing research to improve energy density and charging speeds, indicating potential for further advancements. Emerging players such as Svolt Energy and OptimumNano Energy are also contributing to the competitive landscape, fostering innovation and market expansion.

BYD Co., Ltd.

Technical Solution: BYD has developed the Blade Battery, a revolutionary LFP battery technology. This innovation significantly improves energy density, achieving up to 140Wh/kg[1], while maintaining the inherent safety advantages of LFP chemistry. The Blade Battery's unique structural design allows for better space utilization, increasing the battery pack's energy density by up to 50% compared to conventional LFP batteries[2]. BYD's cost-benefit analysis shows that the Blade Battery can reduce production costs by approximately 30% due to its simplified manufacturing process and lower raw material costs[3]. The company has also implemented a vertical integration strategy, controlling the entire supply chain from raw materials to finished batteries, which further optimizes costs and ensures quality control.

Strengths: High energy density, improved safety, cost-effective production, and vertical integration. Weaknesses: Limited global market presence compared to some competitors, and potential challenges in scaling up production to meet growing demand.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced LFP battery technology with a focus on improving energy density and reducing costs. Their LFP cells achieve an energy density of up to 155Wh/kg[4], which is among the highest in the industry for this chemistry. The company utilizes a proprietary manufacturing process that incorporates silicon-based anodes, enhancing both performance and longevity. LG's cost-benefit analysis indicates that their LFP batteries can offer a 20-25% cost reduction compared to NMC batteries while maintaining comparable performance in many applications[5]. They have also invested in AI-driven quality control systems, reducing defect rates by up to 40% and improving overall production efficiency[6].

Strengths: High energy density for LFP, advanced manufacturing processes, and strong quality control. Weaknesses: Relatively new entrant to LFP market, with less experience compared to some competitors in this specific chemistry.

Core LFP Battery Innovations

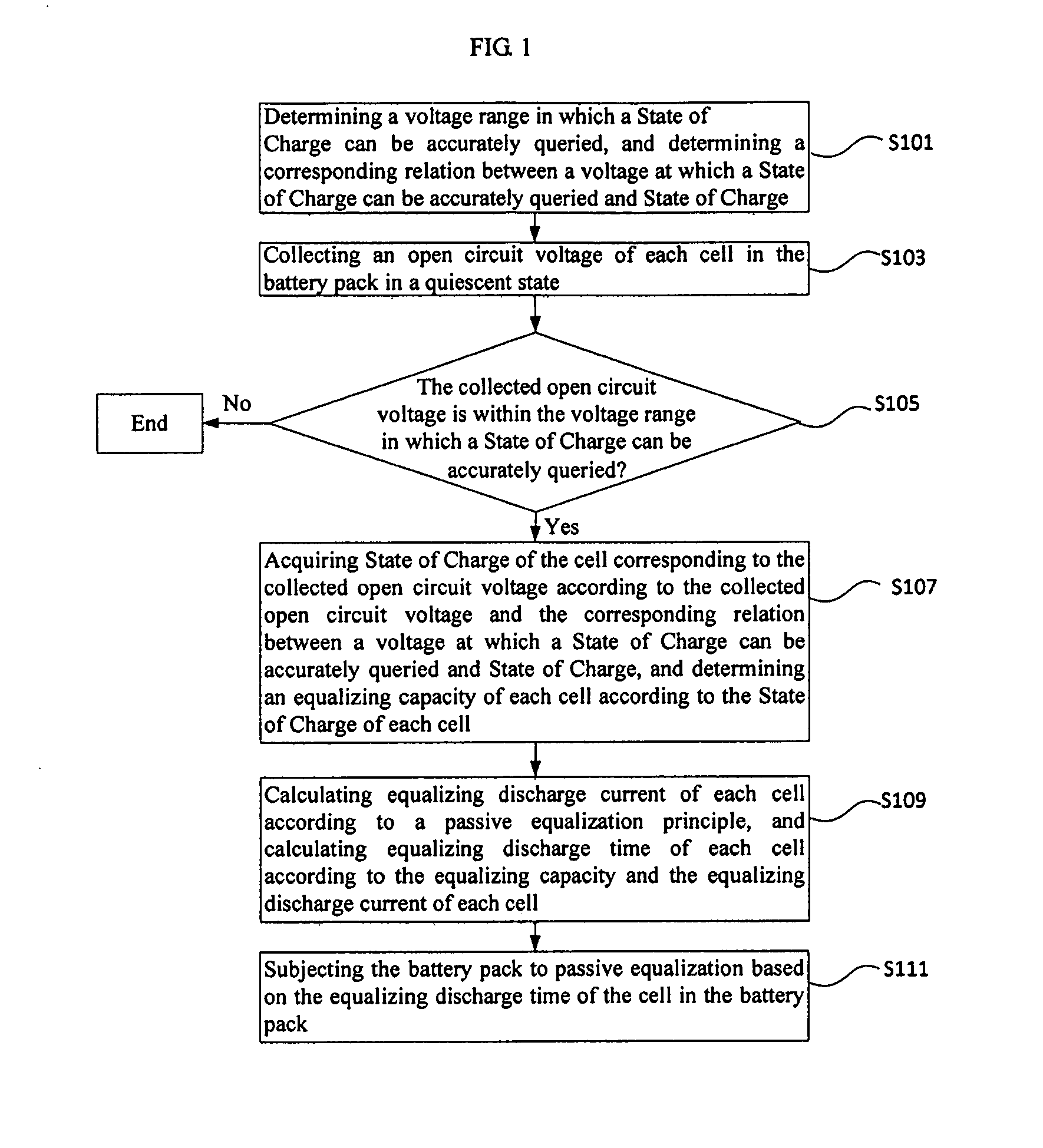

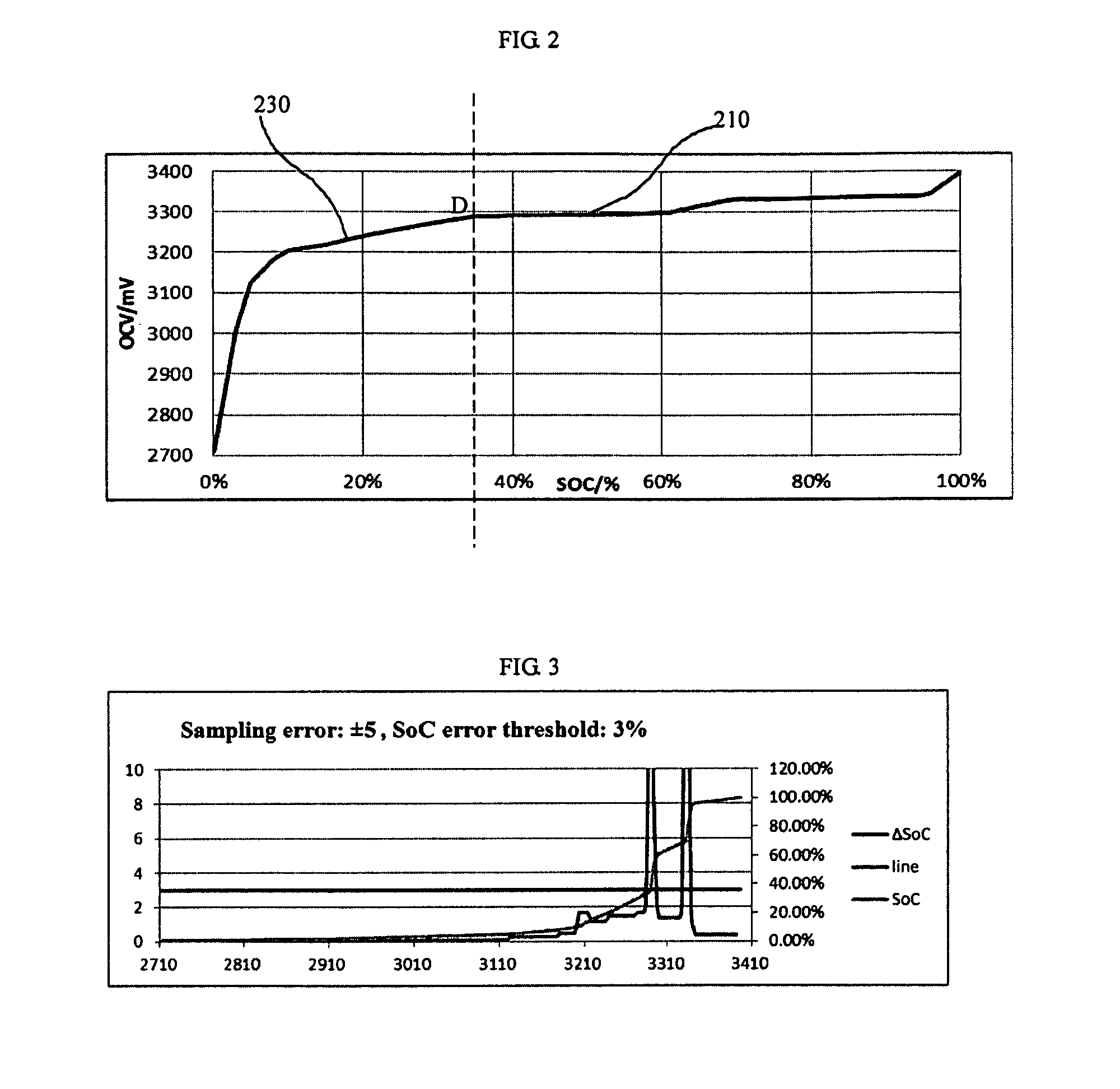

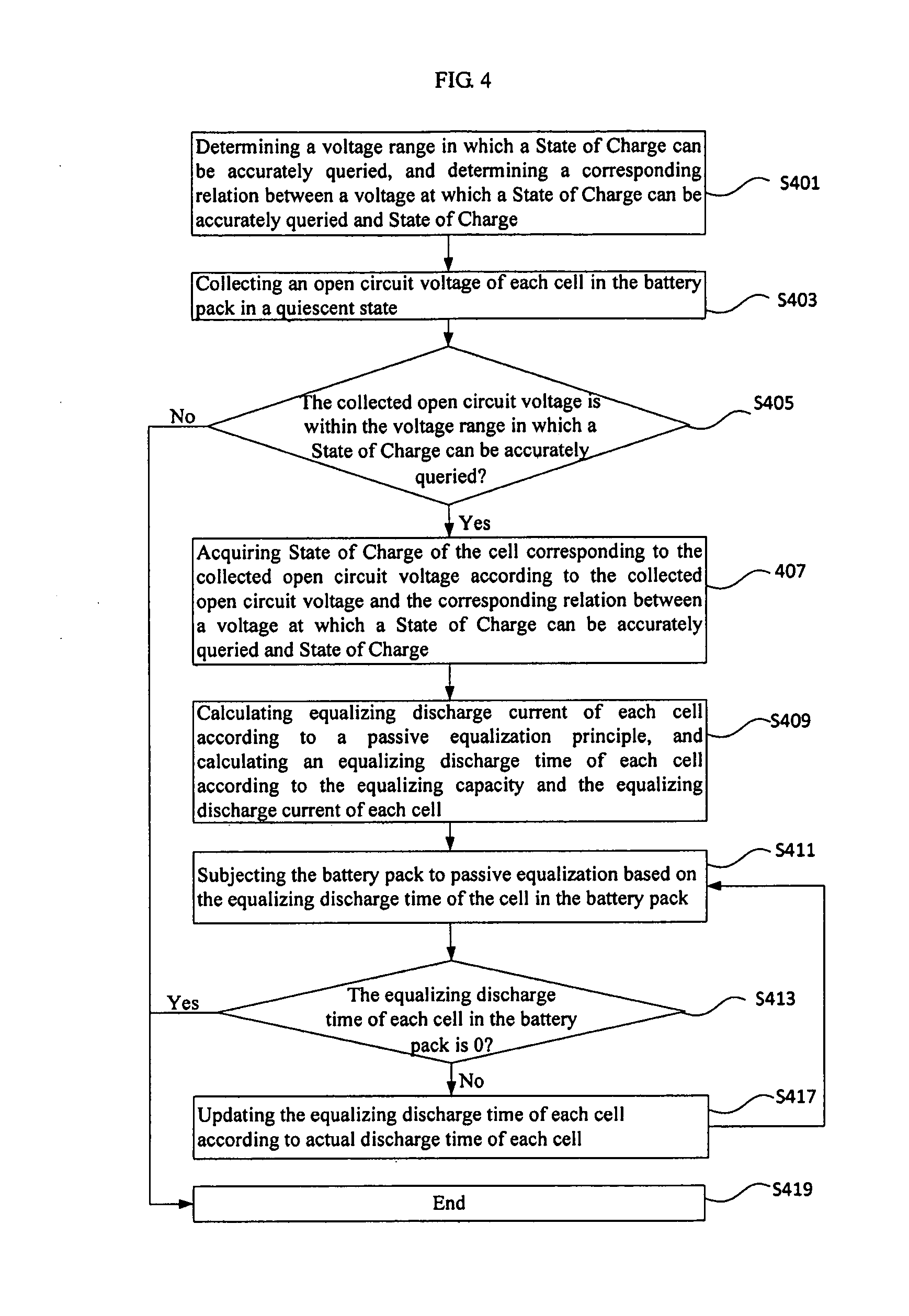

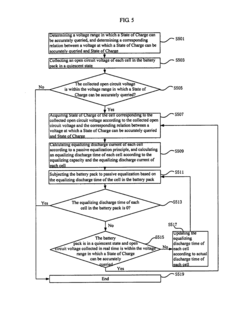

Passive equalization method and system for lithium iron phosphate battery pack

PatentActiveUS20160190829A1

Innovation

- A passive equalization method and system that determines an accurate voltage range for SoC querying, calculates equalizing capacity and discharge time for each cell, and subjects the battery pack to passive equalization based on these calculations, using a system with a storage module, collection module, judgment module, acquisition module, and equalization module, including an energy consumption circuit with a discharge equalizing resistor and field effect transistor.

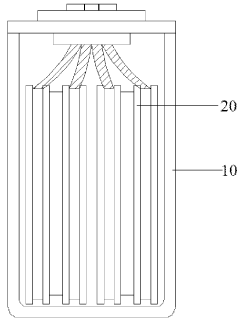

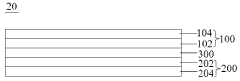

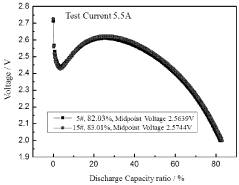

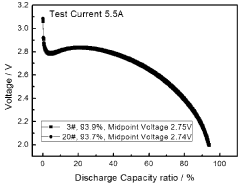

Lithium iron phosphate power battery and method for preparing the same

PatentInactiveUS20180108936A1

Innovation

- A lithium iron phosphate power battery with a positive active material of lithium iron phosphate having a primary particle diameter of no more than 200 nm and a D50 of no more than 3 μm, combined with a negative active material of graphite and conductive agents like carbon nanotubes or graphene, and an optimized electrolyte composition, to enhance conductivity and ion diffusion rates.

Economic Feasibility of LFP Batteries

The economic feasibility of Lithium Iron Phosphate (LFP) batteries is a critical factor in their widespread adoption and deployment. As the demand for sustainable energy storage solutions continues to grow, LFP batteries have emerged as a promising alternative to traditional lithium-ion batteries due to their unique characteristics and potential cost advantages.

One of the primary economic benefits of LFP batteries is their lower production cost compared to other lithium-ion chemistries. The raw materials used in LFP batteries, particularly iron and phosphate, are more abundant and less expensive than the cobalt and nickel used in other lithium-ion batteries. This cost advantage in materials translates to a lower overall battery pack cost, making LFP batteries an attractive option for large-scale energy storage applications and electric vehicles in price-sensitive markets.

LFP batteries also demonstrate superior longevity and cycle life compared to other lithium-ion chemistries. This extended lifespan results in lower total cost of ownership over the battery's lifetime, as fewer replacements are required. The improved durability of LFP batteries makes them particularly suitable for applications that demand frequent charging and discharging cycles, such as grid energy storage and electric buses.

Safety is another crucial factor contributing to the economic feasibility of LFP batteries. Their inherent thermal and chemical stability reduces the risk of thermal runaway and fire, potentially lowering insurance costs and simplifying battery management systems. This enhanced safety profile can lead to reduced expenses in safety equipment and monitoring systems, further improving the overall economic proposition of LFP battery deployment.

The scalability of LFP battery production is also a significant economic advantage. The manufacturing process for LFP batteries is relatively straightforward and can be easily scaled up to meet growing demand. This scalability potential allows for economies of scale, driving down production costs as manufacturing volumes increase. Additionally, the simpler production process may result in lower capital expenditure requirements for setting up new manufacturing facilities.

However, it is important to consider the trade-offs associated with LFP batteries. While they offer cost advantages and improved safety, they typically have lower energy density compared to other lithium-ion chemistries. This lower energy density may result in larger and heavier battery packs for a given energy capacity, potentially increasing costs in applications where weight and space are critical factors, such as in electric vehicles.

The economic feasibility of LFP batteries is also influenced by evolving market dynamics and regulatory environments. Government incentives, environmental regulations, and shifting consumer preferences towards sustainable technologies can significantly impact the adoption rate and economic viability of LFP batteries. As the global focus on reducing carbon emissions intensifies, the demand for LFP batteries in both stationary and mobile applications is expected to grow, potentially leading to further cost reductions through increased production volumes and technological advancements.

In conclusion, the economic feasibility of LFP batteries is driven by their lower production costs, extended lifespan, enhanced safety features, and scalability potential. While challenges such as lower energy density exist, the overall cost-benefit analysis suggests that LFP batteries have a strong economic proposition in various applications, particularly in large-scale energy storage and certain electric vehicle segments. As technology continues to advance and production scales up, the economic advantages of LFP batteries are likely to become even more pronounced, solidifying their position in the global energy storage market.

One of the primary economic benefits of LFP batteries is their lower production cost compared to other lithium-ion chemistries. The raw materials used in LFP batteries, particularly iron and phosphate, are more abundant and less expensive than the cobalt and nickel used in other lithium-ion batteries. This cost advantage in materials translates to a lower overall battery pack cost, making LFP batteries an attractive option for large-scale energy storage applications and electric vehicles in price-sensitive markets.

LFP batteries also demonstrate superior longevity and cycle life compared to other lithium-ion chemistries. This extended lifespan results in lower total cost of ownership over the battery's lifetime, as fewer replacements are required. The improved durability of LFP batteries makes them particularly suitable for applications that demand frequent charging and discharging cycles, such as grid energy storage and electric buses.

Safety is another crucial factor contributing to the economic feasibility of LFP batteries. Their inherent thermal and chemical stability reduces the risk of thermal runaway and fire, potentially lowering insurance costs and simplifying battery management systems. This enhanced safety profile can lead to reduced expenses in safety equipment and monitoring systems, further improving the overall economic proposition of LFP battery deployment.

The scalability of LFP battery production is also a significant economic advantage. The manufacturing process for LFP batteries is relatively straightforward and can be easily scaled up to meet growing demand. This scalability potential allows for economies of scale, driving down production costs as manufacturing volumes increase. Additionally, the simpler production process may result in lower capital expenditure requirements for setting up new manufacturing facilities.

However, it is important to consider the trade-offs associated with LFP batteries. While they offer cost advantages and improved safety, they typically have lower energy density compared to other lithium-ion chemistries. This lower energy density may result in larger and heavier battery packs for a given energy capacity, potentially increasing costs in applications where weight and space are critical factors, such as in electric vehicles.

The economic feasibility of LFP batteries is also influenced by evolving market dynamics and regulatory environments. Government incentives, environmental regulations, and shifting consumer preferences towards sustainable technologies can significantly impact the adoption rate and economic viability of LFP batteries. As the global focus on reducing carbon emissions intensifies, the demand for LFP batteries in both stationary and mobile applications is expected to grow, potentially leading to further cost reductions through increased production volumes and technological advancements.

In conclusion, the economic feasibility of LFP batteries is driven by their lower production costs, extended lifespan, enhanced safety features, and scalability potential. While challenges such as lower energy density exist, the overall cost-benefit analysis suggests that LFP batteries have a strong economic proposition in various applications, particularly in large-scale energy storage and certain electric vehicle segments. As technology continues to advance and production scales up, the economic advantages of LFP batteries are likely to become even more pronounced, solidifying their position in the global energy storage market.

Environmental Impact of LFP Batteries

The environmental impact of Lithium Iron Phosphate (LFP) batteries is a crucial consideration in their deployment and cost-benefit analysis. LFP batteries offer several environmental advantages compared to other lithium-ion battery chemistries, particularly in terms of their production and end-of-life management.

During the manufacturing process, LFP batteries require less energy and produce fewer greenhouse gas emissions compared to other lithium-ion technologies. The production of LFP cathodes involves lower temperatures and simpler processes, resulting in reduced energy consumption and associated carbon footprint. Additionally, LFP batteries do not contain cobalt, a metal often associated with ethical and environmental concerns in its mining practices.

The longevity of LFP batteries contributes positively to their environmental profile. With a higher cycle life than many other battery chemistries, LFP batteries can withstand more charge-discharge cycles before significant degradation occurs. This extended lifespan reduces the frequency of battery replacements, thereby minimizing waste generation and the need for new battery production.

In terms of safety and stability, LFP batteries exhibit superior thermal and chemical stability compared to other lithium-ion variants. This inherent safety reduces the risk of thermal runaway and fire incidents, potentially mitigating environmental hazards associated with battery failures or accidents.

At the end of their life cycle, LFP batteries present favorable characteristics for recycling. The absence of cobalt and the use of abundant materials like iron and phosphate make the recycling process more straightforward and economically viable. Efficient recycling can recover a significant portion of the battery materials, reducing the demand for new raw material extraction and associated environmental impacts.

However, the environmental benefits of LFP batteries must be weighed against certain challenges. The lower energy density of LFP batteries compared to some other lithium-ion chemistries may require larger battery packs for equivalent energy storage, potentially increasing material usage and transportation-related emissions.

Water usage and potential contamination during the mining and processing of lithium and other raw materials remain environmental concerns, although these issues are not unique to LFP batteries and affect the broader lithium-ion battery industry.

In conclusion, while LFP batteries offer significant environmental advantages, a comprehensive life cycle assessment is essential to fully understand their environmental impact. Factors such as raw material sourcing, manufacturing processes, use-phase efficiency, and end-of-life management all play crucial roles in determining the overall environmental footprint of LFP battery deployment.

During the manufacturing process, LFP batteries require less energy and produce fewer greenhouse gas emissions compared to other lithium-ion technologies. The production of LFP cathodes involves lower temperatures and simpler processes, resulting in reduced energy consumption and associated carbon footprint. Additionally, LFP batteries do not contain cobalt, a metal often associated with ethical and environmental concerns in its mining practices.

The longevity of LFP batteries contributes positively to their environmental profile. With a higher cycle life than many other battery chemistries, LFP batteries can withstand more charge-discharge cycles before significant degradation occurs. This extended lifespan reduces the frequency of battery replacements, thereby minimizing waste generation and the need for new battery production.

In terms of safety and stability, LFP batteries exhibit superior thermal and chemical stability compared to other lithium-ion variants. This inherent safety reduces the risk of thermal runaway and fire incidents, potentially mitigating environmental hazards associated with battery failures or accidents.

At the end of their life cycle, LFP batteries present favorable characteristics for recycling. The absence of cobalt and the use of abundant materials like iron and phosphate make the recycling process more straightforward and economically viable. Efficient recycling can recover a significant portion of the battery materials, reducing the demand for new raw material extraction and associated environmental impacts.

However, the environmental benefits of LFP batteries must be weighed against certain challenges. The lower energy density of LFP batteries compared to some other lithium-ion chemistries may require larger battery packs for equivalent energy storage, potentially increasing material usage and transportation-related emissions.

Water usage and potential contamination during the mining and processing of lithium and other raw materials remain environmental concerns, although these issues are not unique to LFP batteries and affect the broader lithium-ion battery industry.

In conclusion, while LFP batteries offer significant environmental advantages, a comprehensive life cycle assessment is essential to fully understand their environmental impact. Factors such as raw material sourcing, manufacturing processes, use-phase efficiency, and end-of-life management all play crucial roles in determining the overall environmental footprint of LFP battery deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!