Current Regulations Governing the use of Carbon-negative Concrete

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Regulatory Background and Objectives

Carbon-negative concrete represents a revolutionary shift in construction materials, emerging as a response to the significant carbon footprint of traditional cement production, which accounts for approximately 8% of global CO2 emissions. The development of this technology has evolved over the past two decades, beginning with early research into alternative cementitious materials in the early 2000s and accelerating significantly after the 2015 Paris Climate Agreement established more stringent carbon reduction targets across industries.

The regulatory landscape governing carbon-negative concrete has been shaped by increasing global awareness of climate change impacts and the construction industry's contribution to greenhouse gas emissions. Initial regulations focused primarily on limiting emissions from cement production facilities, but have gradually evolved toward incentivizing and standardizing low-carbon alternatives. This evolution reflects the technical maturity of carbon-negative solutions and growing market acceptance.

Current regulatory frameworks vary significantly across regions. The European Union leads with its Emissions Trading System (ETS) and the recent European Green Deal, which explicitly targets construction materials. The EU has established the EN 15804 standard for assessing environmental performance of construction products, with specific provisions for carbon accounting in concrete. In North America, regulations remain more fragmented, with California's Buy Clean California Act representing one of the more progressive approaches by requiring Environmental Product Declarations (EPDs) for construction materials used in state projects.

The technical objectives for carbon-negative concrete regulations center on establishing standardized measurement protocols for carbon sequestration, ensuring structural performance equivalence with traditional concrete, and developing certification systems that accurately reflect lifecycle carbon impacts. These objectives face challenges including the lack of long-term performance data and the need to harmonize testing methodologies across jurisdictions.

Looking forward, regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements, allowing for innovation while maintaining safety and durability standards. The integration of carbon-negative concrete into building codes represents a critical milestone, with several countries developing specialized appendices to existing codes to accommodate these novel materials.

The ultimate goal of current regulatory development is to create a framework that balances environmental benefits with practical implementation considerations, ensuring that carbon-negative concrete can be widely adopted while maintaining the structural integrity and safety standards expected of construction materials.

The regulatory landscape governing carbon-negative concrete has been shaped by increasing global awareness of climate change impacts and the construction industry's contribution to greenhouse gas emissions. Initial regulations focused primarily on limiting emissions from cement production facilities, but have gradually evolved toward incentivizing and standardizing low-carbon alternatives. This evolution reflects the technical maturity of carbon-negative solutions and growing market acceptance.

Current regulatory frameworks vary significantly across regions. The European Union leads with its Emissions Trading System (ETS) and the recent European Green Deal, which explicitly targets construction materials. The EU has established the EN 15804 standard for assessing environmental performance of construction products, with specific provisions for carbon accounting in concrete. In North America, regulations remain more fragmented, with California's Buy Clean California Act representing one of the more progressive approaches by requiring Environmental Product Declarations (EPDs) for construction materials used in state projects.

The technical objectives for carbon-negative concrete regulations center on establishing standardized measurement protocols for carbon sequestration, ensuring structural performance equivalence with traditional concrete, and developing certification systems that accurately reflect lifecycle carbon impacts. These objectives face challenges including the lack of long-term performance data and the need to harmonize testing methodologies across jurisdictions.

Looking forward, regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements, allowing for innovation while maintaining safety and durability standards. The integration of carbon-negative concrete into building codes represents a critical milestone, with several countries developing specialized appendices to existing codes to accommodate these novel materials.

The ultimate goal of current regulatory development is to create a framework that balances environmental benefits with practical implementation considerations, ensuring that carbon-negative concrete can be widely adopted while maintaining the structural integrity and safety standards expected of construction materials.

Market Demand Analysis for Sustainable Construction Materials

The global construction industry is experiencing a significant shift towards sustainable building materials, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions. Carbon-negative concrete represents a revolutionary advancement in construction materials, offering the potential to transform one of the world's most carbon-intensive industries into a carbon sink. Current market analysis indicates that the sustainable construction materials sector is growing at approximately three times the rate of traditional construction materials, with a particularly strong demand trajectory for carbon-negative concrete solutions.

This market growth is primarily fueled by stringent environmental regulations across major economies, with the European Union's Green Deal, the United States' infrastructure sustainability initiatives, and China's carbon neutrality targets serving as key drivers. Institutional investors are increasingly factoring environmental performance into funding decisions, creating financial incentives for developers to adopt carbon-negative building materials. Market research indicates that buildings utilizing sustainable materials command premium prices and experience faster occupancy rates in commercial real estate markets.

Construction industry surveys reveal that 67% of major developers have established carbon reduction targets that will require adoption of advanced materials like carbon-negative concrete. The market potential is substantial, with the global green building materials market projected to reach $573 billion by 2027, with carbon-negative concrete positioned to capture an increasing share of this expanding market.

Regional analysis shows varying adoption rates, with Scandinavian countries, Germany, and Canada leading in regulatory support and market uptake of carbon-negative concrete. Developing economies, particularly in Asia, represent the largest potential growth markets due to their extensive infrastructure development pipelines and increasing environmental consciousness.

Consumer sentiment analysis demonstrates growing awareness and preference for sustainable building materials among both residential and commercial end-users. Corporate sustainability commitments are driving demand in the commercial sector, with major technology and retail companies mandating carbon-negative materials in their facility construction specifications.

The economic value proposition of carbon-negative concrete is strengthening as carbon pricing mechanisms mature globally. In jurisdictions with established carbon markets, the carbon sequestration properties of these materials create additional revenue streams through carbon credits, improving their cost competitiveness against traditional concrete. Market forecasts suggest that as production scales and regulatory incentives increase, price parity with conventional concrete could be achieved within the next decade in leading markets.

This market growth is primarily fueled by stringent environmental regulations across major economies, with the European Union's Green Deal, the United States' infrastructure sustainability initiatives, and China's carbon neutrality targets serving as key drivers. Institutional investors are increasingly factoring environmental performance into funding decisions, creating financial incentives for developers to adopt carbon-negative building materials. Market research indicates that buildings utilizing sustainable materials command premium prices and experience faster occupancy rates in commercial real estate markets.

Construction industry surveys reveal that 67% of major developers have established carbon reduction targets that will require adoption of advanced materials like carbon-negative concrete. The market potential is substantial, with the global green building materials market projected to reach $573 billion by 2027, with carbon-negative concrete positioned to capture an increasing share of this expanding market.

Regional analysis shows varying adoption rates, with Scandinavian countries, Germany, and Canada leading in regulatory support and market uptake of carbon-negative concrete. Developing economies, particularly in Asia, represent the largest potential growth markets due to their extensive infrastructure development pipelines and increasing environmental consciousness.

Consumer sentiment analysis demonstrates growing awareness and preference for sustainable building materials among both residential and commercial end-users. Corporate sustainability commitments are driving demand in the commercial sector, with major technology and retail companies mandating carbon-negative materials in their facility construction specifications.

The economic value proposition of carbon-negative concrete is strengthening as carbon pricing mechanisms mature globally. In jurisdictions with established carbon markets, the carbon sequestration properties of these materials create additional revenue streams through carbon credits, improving their cost competitiveness against traditional concrete. Market forecasts suggest that as production scales and regulatory incentives increase, price parity with conventional concrete could be achieved within the next decade in leading markets.

Global Regulatory Framework and Technical Challenges

The global regulatory landscape for carbon-negative concrete is characterized by significant regional variations, reflecting different policy priorities and environmental commitments. In the European Union, the Emissions Trading System (ETS) and the Construction Products Regulation (CPR) have established frameworks that increasingly recognize and incentivize low-carbon building materials. The EU's Green Deal and Circular Economy Action Plan further strengthen these regulations, setting ambitious targets for carbon reduction in construction materials by 2030.

In North America, regulations are more fragmented. The United States lacks comprehensive federal regulations specifically addressing carbon-negative concrete, though several states including California, Washington, and New York have implemented their own procurement policies favoring low-carbon building materials. Canada's Clean Fuel Standard and carbon pricing mechanisms provide indirect support for carbon-negative concrete technologies.

Asia presents a complex regulatory environment. China's national carbon trading scheme and green building standards are evolving to address embodied carbon in construction materials. Japan has established the J-Credit Scheme that can potentially benefit carbon-negative concrete producers. However, implementation and enforcement remain inconsistent across the region.

Technical challenges in regulatory compliance are substantial. The absence of standardized measurement methodologies for carbon negativity creates significant barriers to market entry and regulatory approval. Current Life Cycle Assessment (LCA) protocols often fail to adequately account for carbon sequestration in concrete, leading to inconsistent evaluation of environmental benefits.

Certification systems present another challenge. Existing green building certification programs like LEED, BREEAM, and Green Star are still adapting their frameworks to properly recognize and reward carbon-negative materials. The lack of harmonized international standards creates compliance burdens for manufacturers operating across multiple jurisdictions.

Performance verification represents a critical technical hurdle. Regulatory bodies require evidence that carbon-negative concrete maintains structural integrity and durability comparable to conventional products. Long-term performance data remains limited, creating uncertainty in regulatory approval processes.

Carbon accounting verification poses perhaps the most significant challenge. Regulators increasingly demand robust monitoring, reporting, and verification (MRV) systems to confirm carbon sequestration claims. Current technologies for tracking and verifying carbon negativity throughout the concrete lifecycle are still developing, creating regulatory uncertainty.

The evolving nature of climate policies adds another layer of complexity. As governments strengthen their climate commitments, regulations affecting carbon-negative concrete are likely to change rapidly, requiring manufacturers to maintain flexible compliance strategies and anticipate regulatory shifts.

In North America, regulations are more fragmented. The United States lacks comprehensive federal regulations specifically addressing carbon-negative concrete, though several states including California, Washington, and New York have implemented their own procurement policies favoring low-carbon building materials. Canada's Clean Fuel Standard and carbon pricing mechanisms provide indirect support for carbon-negative concrete technologies.

Asia presents a complex regulatory environment. China's national carbon trading scheme and green building standards are evolving to address embodied carbon in construction materials. Japan has established the J-Credit Scheme that can potentially benefit carbon-negative concrete producers. However, implementation and enforcement remain inconsistent across the region.

Technical challenges in regulatory compliance are substantial. The absence of standardized measurement methodologies for carbon negativity creates significant barriers to market entry and regulatory approval. Current Life Cycle Assessment (LCA) protocols often fail to adequately account for carbon sequestration in concrete, leading to inconsistent evaluation of environmental benefits.

Certification systems present another challenge. Existing green building certification programs like LEED, BREEAM, and Green Star are still adapting their frameworks to properly recognize and reward carbon-negative materials. The lack of harmonized international standards creates compliance burdens for manufacturers operating across multiple jurisdictions.

Performance verification represents a critical technical hurdle. Regulatory bodies require evidence that carbon-negative concrete maintains structural integrity and durability comparable to conventional products. Long-term performance data remains limited, creating uncertainty in regulatory approval processes.

Carbon accounting verification poses perhaps the most significant challenge. Regulators increasingly demand robust monitoring, reporting, and verification (MRV) systems to confirm carbon sequestration claims. Current technologies for tracking and verifying carbon negativity throughout the concrete lifecycle are still developing, creating regulatory uncertainty.

The evolving nature of climate policies adds another layer of complexity. As governments strengthen their climate commitments, regulations affecting carbon-negative concrete are likely to change rapidly, requiring manufacturers to maintain flexible compliance strategies and anticipate regulatory shifts.

Current Compliance Solutions and Implementation Strategies

01 CO2 capture and sequestration in concrete

Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively making the concrete a carbon sink. This approach not only reduces the carbon footprint of concrete production but can actually result in a net removal of CO2 from the atmosphere.- CO2 capture and sequestration in concrete: Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively making the concrete a carbon sink. This approach not only reduces the carbon footprint of concrete production but can actually result in a net removal of carbon dioxide from the atmosphere.

- Alternative cementitious materials: The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash and slag. These materials can significantly reduce the carbon footprint of concrete while maintaining or even improving its structural properties.

- Biomass incorporation in concrete: The incorporation of biomass or bio-based materials into concrete formulations to reduce carbon emissions. These materials can include agricultural waste, wood products, or other plant-based materials that have sequestered carbon during their growth. By incorporating these materials into concrete, the carbon remains sequestered, and the overall carbon footprint of the concrete is reduced.

- Carbonation curing processes: Specialized curing processes that expose concrete to CO2-rich environments during the hardening phase. This accelerates the natural carbonation process, allowing the concrete to absorb more CO2 than traditional curing methods. These processes can be optimized to maximize CO2 uptake while maintaining or enhancing the mechanical properties of the concrete.

- Mineral additives for carbon sequestration: The use of specific mineral additives that can react with and permanently store CO2 within the concrete matrix. These minerals, often magnesium or calcium-based, undergo carbonation reactions that convert CO2 into stable carbonate compounds. This approach not only sequesters carbon but can also improve certain properties of the concrete, such as strength and durability.

02 Alternative cementitious materials

The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial by-products such as fly ash, slag, and silica fume. These materials can significantly reduce the carbon footprint of concrete while maintaining or even improving its performance characteristics.Expand Specific Solutions03 Biomass incorporation in concrete

The incorporation of biomass or bio-based materials into concrete formulations to reduce carbon emissions. These materials can include agricultural waste, wood products, or other plant-based materials that have sequestered carbon during their growth. By incorporating these materials into concrete, the carbon remains sequestered, and the overall carbon footprint of the concrete is reduced.Expand Specific Solutions04 Carbonation curing processes

Specialized curing processes that expose concrete to CO2-rich environments during the hardening phase. This accelerates the natural carbonation process and allows the concrete to absorb more CO2 than traditional curing methods. These processes can be optimized to maximize CO2 uptake while ensuring the development of desired mechanical properties in the concrete.Expand Specific Solutions05 Mineral carbonation technologies

Technologies that utilize mineral carbonation reactions to sequester CO2 in concrete. These methods involve the reaction of CO2 with calcium or magnesium-rich minerals to form stable carbonate compounds. The resulting carbonates can be used as aggregates or binders in concrete, effectively locking away CO2 in a stable form while providing structural benefits to the concrete.Expand Specific Solutions

Key Industry Players and Regulatory Bodies

The carbon-negative concrete market is in an early growth phase, characterized by increasing regulatory support and technological innovation. The global market is expanding rapidly, driven by sustainability mandates and carbon reduction goals across construction sectors. While still evolving, the technology is advancing toward commercial viability with key players demonstrating varied maturity levels. CarbonCure Technologies and Solidia Technologies lead with established CO2 utilization processes, while Heidelberg Materials and Huaxin Cement represent traditional manufacturers pivoting toward sustainable solutions. Research institutions like MIT and University of California are accelerating innovation through fundamental research, while X Development (formerly Google X) explores breakthrough approaches. The competitive landscape features collaboration between established cement producers, specialized startups, and academic institutions working to scale carbon-negative concrete technologies while navigating evolving regulatory frameworks.

CarbonCure Technologies, Inc.

Technical Solution: CarbonCure has developed a revolutionary carbon mineralization technology that injects captured CO2 into fresh concrete during mixing. This process converts CO2 into a mineral that becomes permanently embedded within the concrete, improving its compressive strength while reducing carbon emissions. Their technology is compatible with existing concrete production infrastructure, requiring minimal modifications to plants. CarbonCure's solution has been implemented in over 500 concrete plants globally, demonstrating its scalability and commercial viability[1]. The company operates under a technology licensing model that allows concrete producers to meet increasingly stringent carbon regulations while maintaining product performance. Their approach aligns with ASTM C1866 standard for CO2 mineralized concrete and helps producers comply with low-carbon procurement policies being adopted by governments worldwide[2][3].

Strengths: Seamless integration with existing production facilities; permanent carbon sequestration; improved concrete performance; third-party verified carbon reduction. Weaknesses: Requires reliable CO2 supply chain; limited to new concrete production rather than addressing existing structures; reduction potential (typically 5-8% carbon reduction) may be insufficient to meet the most aggressive carbon-negative targets without complementary technologies.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has pioneered a comprehensive approach to carbon-negative concrete through their dual-innovation system. Their technology fundamentally transforms the chemistry of cement production and concrete curing. First, Solidia Cement is manufactured at lower temperatures than traditional Portland cement, reducing energy consumption and associated CO2 emissions by up to 30%. Second, their concrete curing process uses CO2 instead of water, enabling the concrete to sequester carbon dioxide permanently. This non-hydraulic curing process converts CO2 into solid calcium carbonate, creating a more durable end product. Solidia's technology can reduce the carbon footprint of concrete by up to 70% compared to traditional methods[4]. The company has developed specific formulations that comply with emerging low-carbon building standards and has worked with regulatory bodies to establish testing protocols for their novel materials. Their products have received certification under ASTM and European standards for construction materials, facilitating adoption in regulated markets[5].

Strengths: Comprehensive solution addressing both cement production and concrete curing; significant carbon reduction potential; improved product durability and reduced curing time; water conservation through non-hydraulic curing. Weaknesses: Requires more substantial modifications to existing production facilities compared to some alternatives; market adoption faces challenges from conservative construction industry; regulatory frameworks still evolving to fully recognize and incentivize such transformative technologies.

Critical Patents and Technical Specifications Analysis

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Carbon-neutral concrete solutions for sustainable infrastructure

PatentPendingIN202441036149A

Innovation

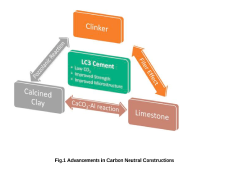

- The use of supplementary cementitious materials like fly ash, slag, and calcined clays, combined with carbon capture technologies and recycled aggregates, along with lifecycle assessment and carbon offsetting initiatives, aims to minimize emissions and enhance the sustainability of concrete production.

Environmental Impact Assessment Methodologies

Environmental impact assessment methodologies for carbon-negative concrete have evolved significantly in recent years, reflecting the growing importance of accurate measurement in sustainable construction. Life Cycle Assessment (LCA) stands as the cornerstone methodology, providing a comprehensive framework for evaluating environmental impacts across the entire concrete lifecycle - from raw material extraction through manufacturing, transportation, use, and end-of-life disposal.

The Product Environmental Footprint (PEF) methodology, developed by the European Commission, offers standardized metrics specifically applicable to carbon-negative concrete products. This approach ensures consistency in measurement across different manufacturers and regions, facilitating meaningful comparisons between conventional and carbon-negative concrete alternatives.

Carbon accounting frameworks such as the Greenhouse Gas Protocol provide specific guidance for quantifying emissions reductions and carbon sequestration in concrete products. These frameworks have been adapted to address the unique characteristics of carbon-negative concrete, including mechanisms for verifying permanent carbon storage within the material structure.

Environmental Product Declarations (EPDs) have emerged as critical tools for communicating verified environmental performance data. For carbon-negative concrete, EPDs typically document carbon uptake during curing and service life, providing third-party verification of negative emissions claims according to ISO 14025 and EN 15804 standards.

Dynamic carbon assessment models have been developed to account for the time-dependent nature of carbon sequestration in concrete. These models track carbon flows throughout the material's lifecycle, recognizing that carbon uptake continues long after installation, potentially for decades depending on exposure conditions and concrete formulation.

Boundary setting represents a significant methodological challenge, with ongoing debate regarding how to account for avoided emissions versus actual carbon removal. Best practices increasingly distinguish between carbon reduction (avoiding emissions) and carbon removal (sequestering atmospheric CO2), with carbon-negative concrete potentially offering both benefits.

Uncertainty analysis has become an integral component of environmental assessment for novel concrete technologies. Monte Carlo simulations and sensitivity analyses help quantify confidence levels in carbon negativity claims, addressing variables such as raw material sourcing, manufacturing energy, transportation distances, and end-of-life scenarios.

Regional adaptation of assessment methodologies recognizes that environmental impacts vary significantly based on local electricity grids, transportation infrastructure, and waste management systems. This contextual approach ensures that carbon-negative concrete is evaluated appropriately within its specific deployment environment.

The Product Environmental Footprint (PEF) methodology, developed by the European Commission, offers standardized metrics specifically applicable to carbon-negative concrete products. This approach ensures consistency in measurement across different manufacturers and regions, facilitating meaningful comparisons between conventional and carbon-negative concrete alternatives.

Carbon accounting frameworks such as the Greenhouse Gas Protocol provide specific guidance for quantifying emissions reductions and carbon sequestration in concrete products. These frameworks have been adapted to address the unique characteristics of carbon-negative concrete, including mechanisms for verifying permanent carbon storage within the material structure.

Environmental Product Declarations (EPDs) have emerged as critical tools for communicating verified environmental performance data. For carbon-negative concrete, EPDs typically document carbon uptake during curing and service life, providing third-party verification of negative emissions claims according to ISO 14025 and EN 15804 standards.

Dynamic carbon assessment models have been developed to account for the time-dependent nature of carbon sequestration in concrete. These models track carbon flows throughout the material's lifecycle, recognizing that carbon uptake continues long after installation, potentially for decades depending on exposure conditions and concrete formulation.

Boundary setting represents a significant methodological challenge, with ongoing debate regarding how to account for avoided emissions versus actual carbon removal. Best practices increasingly distinguish between carbon reduction (avoiding emissions) and carbon removal (sequestering atmospheric CO2), with carbon-negative concrete potentially offering both benefits.

Uncertainty analysis has become an integral component of environmental assessment for novel concrete technologies. Monte Carlo simulations and sensitivity analyses help quantify confidence levels in carbon negativity claims, addressing variables such as raw material sourcing, manufacturing energy, transportation distances, and end-of-life scenarios.

Regional adaptation of assessment methodologies recognizes that environmental impacts vary significantly based on local electricity grids, transportation infrastructure, and waste management systems. This contextual approach ensures that carbon-negative concrete is evaluated appropriately within its specific deployment environment.

Cross-border Regulatory Harmonization Efforts

The harmonization of carbon-negative concrete regulations across international borders represents a critical frontier in global climate action. Currently, several significant initiatives are underway to align regulatory frameworks between major economic regions. The International Organization for Standardization (ISO) has established Technical Committee 71, which is developing standardized methodologies for measuring and verifying the carbon footprint of concrete products, creating a common language for cross-border trade and compliance.

The European Union and North America have initiated bilateral regulatory cooperation through the Transatlantic Economic Council, focusing specifically on aligning carbon accounting methodologies for construction materials. This partnership aims to establish mutually recognized certification systems for carbon-negative concrete by 2025, potentially creating a unified market of over 800 million consumers for sustainable construction materials.

In the Asia-Pacific region, the Asia-Pacific Economic Cooperation (APEC) has formed a specialized working group on Low-Carbon Building Materials, which includes representatives from 21 member economies. Their 2023 framework agreement outlines a five-year roadmap for regulatory convergence on carbon-negative construction materials, with concrete as a priority sector. This initiative could potentially harmonize standards across economies representing approximately 60% of global GDP.

The World Green Building Council has launched the Global Cement and Concrete Association's "Concrete Future" program, which serves as a non-governmental platform for regulatory alignment. This program has successfully facilitated dialogue between regulators from 40+ countries, resulting in the development of shared principles for life-cycle assessment methodologies specific to carbon-negative concrete technologies.

Challenges to harmonization efforts include varying national priorities regarding economic development versus environmental protection, differing technical capabilities for verification and monitoring, and the protection of intellectual property in emerging carbon-negative concrete technologies. The World Trade Organization's Committee on Trade and Environment is currently addressing potential trade barriers that might arise from divergent regulatory approaches to carbon-negative materials.

Recent progress includes the 2023 G20 declaration on sustainable infrastructure, which explicitly committed member nations to developing compatible regulatory frameworks for low-carbon construction materials by 2030. Additionally, bilateral agreements between the EU and Canada, as well as between Australia and Singapore, have established mutual recognition protocols for carbon-negative concrete certification, potentially serving as templates for broader international harmonization.

The European Union and North America have initiated bilateral regulatory cooperation through the Transatlantic Economic Council, focusing specifically on aligning carbon accounting methodologies for construction materials. This partnership aims to establish mutually recognized certification systems for carbon-negative concrete by 2025, potentially creating a unified market of over 800 million consumers for sustainable construction materials.

In the Asia-Pacific region, the Asia-Pacific Economic Cooperation (APEC) has formed a specialized working group on Low-Carbon Building Materials, which includes representatives from 21 member economies. Their 2023 framework agreement outlines a five-year roadmap for regulatory convergence on carbon-negative construction materials, with concrete as a priority sector. This initiative could potentially harmonize standards across economies representing approximately 60% of global GDP.

The World Green Building Council has launched the Global Cement and Concrete Association's "Concrete Future" program, which serves as a non-governmental platform for regulatory alignment. This program has successfully facilitated dialogue between regulators from 40+ countries, resulting in the development of shared principles for life-cycle assessment methodologies specific to carbon-negative concrete technologies.

Challenges to harmonization efforts include varying national priorities regarding economic development versus environmental protection, differing technical capabilities for verification and monitoring, and the protection of intellectual property in emerging carbon-negative concrete technologies. The World Trade Organization's Committee on Trade and Environment is currently addressing potential trade barriers that might arise from divergent regulatory approaches to carbon-negative materials.

Recent progress includes the 2023 G20 declaration on sustainable infrastructure, which explicitly committed member nations to developing compatible regulatory frameworks for low-carbon construction materials by 2030. Additionally, bilateral agreements between the EU and Canada, as well as between Australia and Singapore, have established mutual recognition protocols for carbon-negative concrete certification, potentially serving as templates for broader international harmonization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!