Discovering New Avenues for Ethylene Vinyl Acetate

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Technology Evolution

Ethylene Vinyl Acetate (EVA) has undergone significant technological evolution since its introduction in the 1950s. Initially developed as a copolymer of ethylene and vinyl acetate, EVA's journey has been marked by continuous improvements in production processes and expanding applications across various industries.

In the early stages, EVA was primarily used in the packaging industry due to its flexibility and low-temperature toughness. The 1960s and 1970s saw advancements in polymerization techniques, leading to better control over the vinyl acetate content and molecular weight distribution. This enabled manufacturers to tailor EVA properties for specific applications, broadening its use in footwear, adhesives, and wire insulation.

The 1980s marked a significant milestone in EVA technology with the introduction of metallocene catalysts. These single-site catalysts allowed for more precise control over copolymer composition and molecular architecture, resulting in EVA grades with enhanced performance characteristics. This breakthrough opened up new possibilities in areas such as solar panel encapsulation and high-performance packaging materials.

The 1990s and early 2000s witnessed further refinements in EVA production technology. Improved reactor designs and process control systems led to more efficient and cost-effective manufacturing processes. Simultaneously, the development of new additives and compatibilizers expanded EVA's compatibility with other polymers, facilitating its use in multi-layer films and blends.

In recent years, the focus of EVA technology evolution has shifted towards sustainability and circular economy principles. Researchers are exploring bio-based feedstocks for EVA production, aiming to reduce reliance on fossil fuels. Additionally, efforts are being made to improve the recyclability and biodegradability of EVA products, addressing growing environmental concerns.

The advent of nanotechnology has also influenced EVA development. Incorporation of nanofillers such as carbon nanotubes and graphene has led to EVA nanocomposites with enhanced mechanical, thermal, and barrier properties. These advanced materials are finding applications in high-performance sports equipment, automotive components, and advanced packaging solutions.

Looking ahead, the evolution of EVA technology is likely to continue along several trajectories. One promising avenue is the development of smart EVA materials with self-healing or stimuli-responsive properties. Another area of focus is the integration of EVA with emerging technologies such as 3D printing and wearable electronics, potentially revolutionizing product design and manufacturing processes in various industries.

In the early stages, EVA was primarily used in the packaging industry due to its flexibility and low-temperature toughness. The 1960s and 1970s saw advancements in polymerization techniques, leading to better control over the vinyl acetate content and molecular weight distribution. This enabled manufacturers to tailor EVA properties for specific applications, broadening its use in footwear, adhesives, and wire insulation.

The 1980s marked a significant milestone in EVA technology with the introduction of metallocene catalysts. These single-site catalysts allowed for more precise control over copolymer composition and molecular architecture, resulting in EVA grades with enhanced performance characteristics. This breakthrough opened up new possibilities in areas such as solar panel encapsulation and high-performance packaging materials.

The 1990s and early 2000s witnessed further refinements in EVA production technology. Improved reactor designs and process control systems led to more efficient and cost-effective manufacturing processes. Simultaneously, the development of new additives and compatibilizers expanded EVA's compatibility with other polymers, facilitating its use in multi-layer films and blends.

In recent years, the focus of EVA technology evolution has shifted towards sustainability and circular economy principles. Researchers are exploring bio-based feedstocks for EVA production, aiming to reduce reliance on fossil fuels. Additionally, efforts are being made to improve the recyclability and biodegradability of EVA products, addressing growing environmental concerns.

The advent of nanotechnology has also influenced EVA development. Incorporation of nanofillers such as carbon nanotubes and graphene has led to EVA nanocomposites with enhanced mechanical, thermal, and barrier properties. These advanced materials are finding applications in high-performance sports equipment, automotive components, and advanced packaging solutions.

Looking ahead, the evolution of EVA technology is likely to continue along several trajectories. One promising avenue is the development of smart EVA materials with self-healing or stimuli-responsive properties. Another area of focus is the integration of EVA with emerging technologies such as 3D printing and wearable electronics, potentially revolutionizing product design and manufacturing processes in various industries.

Market Demand Analysis

The market demand for Ethylene Vinyl Acetate (EVA) has been steadily growing across various industries, driven by its versatile properties and wide range of applications. The global EVA market size was valued at over $7 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of around 5% from 2021 to 2028.

One of the primary drivers of EVA market growth is the increasing demand in the packaging industry. EVA's excellent flexibility, toughness, and barrier properties make it an ideal material for food packaging, shrink wrap, and protective films. The rise in e-commerce and the need for sustainable packaging solutions have further boosted the demand for EVA-based materials.

The footwear industry represents another significant market for EVA. The material's lightweight nature, shock absorption properties, and durability have made it a popular choice for shoe soles, especially in sports and casual footwear. As consumer preferences shift towards comfortable and performance-oriented footwear, the demand for EVA in this sector is expected to continue its upward trajectory.

In the renewable energy sector, EVA has found a crucial application in the manufacturing of solar panels. The material is used as an encapsulant in photovoltaic modules, providing protection and enhancing the efficiency of solar cells. With the global push towards clean energy and the rapid growth of the solar power industry, the demand for EVA in this sector is anticipated to witness substantial growth in the coming years.

The automotive industry is another key market for EVA, where it is used in various applications such as wire and cable insulation, gaskets, and interior components. The trend towards lightweight vehicles and improved fuel efficiency is expected to drive the demand for EVA-based materials in automotive manufacturing.

Emerging applications in the medical and healthcare sectors are also contributing to the market growth of EVA. The material's biocompatibility and flexibility make it suitable for medical tubing, drug delivery systems, and prosthetics. As healthcare technologies advance and the demand for innovative medical devices increases, the market for EVA in this sector is poised for significant expansion.

Despite the positive market outlook, challenges such as fluctuating raw material prices and environmental concerns regarding the disposal of EVA-based products may impact market growth. However, ongoing research and development efforts are focused on addressing these issues, exploring bio-based alternatives, and improving recycling technologies for EVA materials.

One of the primary drivers of EVA market growth is the increasing demand in the packaging industry. EVA's excellent flexibility, toughness, and barrier properties make it an ideal material for food packaging, shrink wrap, and protective films. The rise in e-commerce and the need for sustainable packaging solutions have further boosted the demand for EVA-based materials.

The footwear industry represents another significant market for EVA. The material's lightweight nature, shock absorption properties, and durability have made it a popular choice for shoe soles, especially in sports and casual footwear. As consumer preferences shift towards comfortable and performance-oriented footwear, the demand for EVA in this sector is expected to continue its upward trajectory.

In the renewable energy sector, EVA has found a crucial application in the manufacturing of solar panels. The material is used as an encapsulant in photovoltaic modules, providing protection and enhancing the efficiency of solar cells. With the global push towards clean energy and the rapid growth of the solar power industry, the demand for EVA in this sector is anticipated to witness substantial growth in the coming years.

The automotive industry is another key market for EVA, where it is used in various applications such as wire and cable insulation, gaskets, and interior components. The trend towards lightweight vehicles and improved fuel efficiency is expected to drive the demand for EVA-based materials in automotive manufacturing.

Emerging applications in the medical and healthcare sectors are also contributing to the market growth of EVA. The material's biocompatibility and flexibility make it suitable for medical tubing, drug delivery systems, and prosthetics. As healthcare technologies advance and the demand for innovative medical devices increases, the market for EVA in this sector is poised for significant expansion.

Despite the positive market outlook, challenges such as fluctuating raw material prices and environmental concerns regarding the disposal of EVA-based products may impact market growth. However, ongoing research and development efforts are focused on addressing these issues, exploring bio-based alternatives, and improving recycling technologies for EVA materials.

Technical Challenges

Ethylene Vinyl Acetate (EVA) has been a versatile material in various industries for decades. However, as technology advances and market demands evolve, the polymer faces several technical challenges that need to be addressed to unlock its full potential and discover new avenues for application.

One of the primary technical challenges in EVA development is improving its thermal stability. While EVA exhibits excellent flexibility and toughness, its performance at elevated temperatures is limited. This constraint restricts its use in high-temperature applications, such as automotive components or advanced electronics. Researchers are exploring various approaches to enhance EVA's thermal properties, including the incorporation of nanofillers and the development of novel copolymer structures.

Another significant challenge lies in enhancing EVA's barrier properties. Although EVA is widely used in packaging applications, its permeability to gases and moisture remains a concern. Improving the barrier properties without compromising the material's flexibility and transparency is crucial for expanding its use in food packaging and medical applications. Current research focuses on developing multi-layer structures and incorporating functional additives to achieve better barrier performance.

The recyclability of EVA presents a technical hurdle in the context of increasing environmental concerns. While EVA is theoretically recyclable, the presence of various additives and cross-linking agents often complicates the recycling process. Developing eco-friendly formulations and efficient recycling technologies for EVA is essential for its sustainable use in the future.

Enhancing the adhesion properties of EVA is another area of technical challenge. While EVA is known for its good adhesion to various substrates, there is a growing demand for stronger and more durable bonding in applications such as solar panels and advanced composites. Researchers are investigating surface modification techniques and novel adhesive formulations to improve EVA's bonding strength and durability.

The development of EVA with improved electrical properties represents another technical frontier. As the demand for flexible electronics and smart textiles grows, there is a need for EVA formulations with enhanced conductivity and dielectric properties. This challenge involves finding the right balance between electrical performance and the material's inherent flexibility and processability.

Lastly, the customization of EVA for specific high-performance applications poses a significant technical challenge. This includes developing grades with tailored mechanical properties, UV resistance, and chemical compatibility for use in specialized fields such as aerospace, biomedical devices, and advanced sports equipment. Achieving these targeted properties often requires a deep understanding of polymer chemistry and innovative processing techniques.

One of the primary technical challenges in EVA development is improving its thermal stability. While EVA exhibits excellent flexibility and toughness, its performance at elevated temperatures is limited. This constraint restricts its use in high-temperature applications, such as automotive components or advanced electronics. Researchers are exploring various approaches to enhance EVA's thermal properties, including the incorporation of nanofillers and the development of novel copolymer structures.

Another significant challenge lies in enhancing EVA's barrier properties. Although EVA is widely used in packaging applications, its permeability to gases and moisture remains a concern. Improving the barrier properties without compromising the material's flexibility and transparency is crucial for expanding its use in food packaging and medical applications. Current research focuses on developing multi-layer structures and incorporating functional additives to achieve better barrier performance.

The recyclability of EVA presents a technical hurdle in the context of increasing environmental concerns. While EVA is theoretically recyclable, the presence of various additives and cross-linking agents often complicates the recycling process. Developing eco-friendly formulations and efficient recycling technologies for EVA is essential for its sustainable use in the future.

Enhancing the adhesion properties of EVA is another area of technical challenge. While EVA is known for its good adhesion to various substrates, there is a growing demand for stronger and more durable bonding in applications such as solar panels and advanced composites. Researchers are investigating surface modification techniques and novel adhesive formulations to improve EVA's bonding strength and durability.

The development of EVA with improved electrical properties represents another technical frontier. As the demand for flexible electronics and smart textiles grows, there is a need for EVA formulations with enhanced conductivity and dielectric properties. This challenge involves finding the right balance between electrical performance and the material's inherent flexibility and processability.

Lastly, the customization of EVA for specific high-performance applications poses a significant technical challenge. This includes developing grades with tailored mechanical properties, UV resistance, and chemical compatibility for use in specialized fields such as aerospace, biomedical devices, and advanced sports equipment. Achieving these targeted properties often requires a deep understanding of polymer chemistry and innovative processing techniques.

Current EVA Solutions

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be varied to achieve different characteristics, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, providing good bond strength and flexibility. EVA-based adhesives find applications in packaging, bookbinding, and construction industries.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it suitable for applications such as footwear, sports equipment, and building insulation. EVA foams offer good shock absorption and cushioning properties.

- EVA in solar panel encapsulation: EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weather resistance, and electrical insulation properties. EVA encapsulants help protect solar cells from environmental factors and enhance the overall performance and durability of solar panels.

- EVA in film and packaging applications: EVA is extensively used in the production of flexible films and packaging materials. Its properties such as clarity, flexibility, and heat-sealing capabilities make it suitable for food packaging, agricultural films, and stretch wraps. EVA films offer good barrier properties and can be easily processed using various film extrusion techniques.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is commonly employed in hot melt adhesives, pressure-sensitive adhesives, and sealants. The addition of EVA can improve the flexibility and tack of adhesive compositions.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it suitable for applications such as footwear, sports equipment, and building insulation. EVA foams can be crosslinked to enhance their properties further.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is a popular material for encapsulating solar cells in photovoltaic modules. It provides excellent transparency, weatherability, and electrical insulation properties. The material helps protect the solar cells from environmental factors and ensures long-term performance of the modules.Expand Specific Solutions05 Modifications and blends of EVA

EVA can be modified or blended with other materials to enhance its properties or create new functionalities. This includes the addition of fillers, crosslinking agents, or blending with other polymers. Such modifications can improve mechanical properties, flame retardancy, or compatibility with specific applications.Expand Specific Solutions

Key Industry Players

The market for Ethylene Vinyl Acetate (EVA) is in a mature growth stage, with a global market size expected to reach $9.71 billion by 2027. The technology is well-established, with major players like Celanese International Corp., China Petroleum & Chemical Corp., and Wanhua Chemical Group Co., Ltd. leading the industry. These companies have robust R&D capabilities and extensive production facilities, indicating high technological maturity. However, there's ongoing innovation in EVA applications, particularly in renewable energy and advanced materials, driven by research institutions like Tianjin University and Dalian Institute of Chemical Physics. The competitive landscape is characterized by a mix of established petrochemical giants and specialized chemical companies, with increasing focus on sustainable and high-performance EVA formulations.

Celanese International Corp.

Technical Solution: Celanese has developed a novel approach to ethylene vinyl acetate (EVA) production, focusing on sustainability and performance enhancement. Their process utilizes bio-based feedstocks, reducing reliance on fossil fuels[1]. The company has implemented advanced catalyst systems that improve reaction efficiency and product consistency[2]. Celanese's EVA grades offer enhanced thermal stability and improved adhesion properties, making them suitable for a wide range of applications including solar panel encapsulation, packaging, and footwear[3]. The company has also invested in research to develop EVA with higher vinyl acetate content, up to 40%, which expands its potential uses in specialized markets[4].

Strengths: Sustainable production methods, improved product performance, and versatility in applications. Weaknesses: Potentially higher production costs due to bio-based feedstocks and advanced catalysts.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in EVA production and innovation. The company has developed a proprietary high-pressure tubular reactor technology that allows for precise control of the polymerization process, resulting in EVA with tailored properties[5]. Sinopec's research has led to the creation of EVA grades with improved transparency and flexibility, particularly beneficial for film applications[6]. They have also focused on enhancing the melt flow rate of their EVA products, which has opened up new possibilities in injection molding and 3D printing applications[7]. Additionally, Sinopec has invested in the development of EVA foam technology, creating lightweight materials with excellent shock absorption properties for the automotive and sports equipment industries[8].

Strengths: Advanced reactor technology, diverse product portfolio, and strong presence in the Asian market. Weaknesses: Potential environmental concerns due to reliance on traditional petrochemical processes.

Core EVA Patents

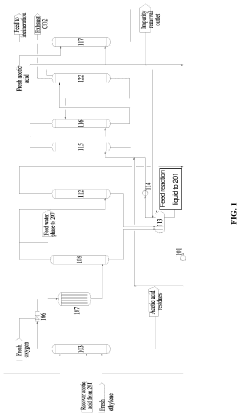

Integrated process for the production of vinyl acetate from acetic acid via ethyl acetate

PatentInactiveEP2382179A1

Innovation

- An integrated process involving the hydrogenation of acetic acid to form ethyl acetate with high selectivity, followed by pyrolysis to produce ethylene, and subsequent reaction with molecular oxygen over a suitable catalyst to form vinyl acetate, using a bimetallic catalyst system such as platinum and copper or palladium and cobalt supported on a catalyst support.

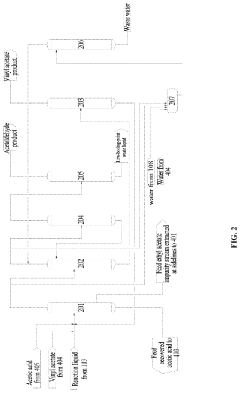

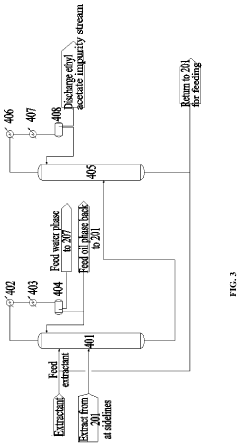

Method for producing vinyl acetate

PatentActiveUS20230312452A1

Innovation

- A method involving a gas phase oxidation process with a system integration that includes specific towers and reactors for ethylene recovery, acetic acid evaporation, oxygen mixing, and separation processes, utilizing acetic acid as an extractant in the rectifying and separating towers to enhance the separation of vinyl acetate from ethyl acetate.

Sustainability Aspects

Ethylene Vinyl Acetate (EVA) has gained significant attention in recent years due to its versatile properties and wide range of applications. As the focus on sustainability intensifies across industries, exploring sustainable aspects of EVA has become crucial for its continued growth and adoption.

One of the primary sustainability concerns surrounding EVA is its production process. Traditional methods often rely on fossil fuel-based feedstocks, contributing to carbon emissions and environmental degradation. However, recent advancements in bio-based feedstocks offer promising alternatives. Researchers are exploring the use of renewable resources, such as sugarcane and corn, to produce ethylene and vinyl acetate monomers, potentially reducing the carbon footprint of EVA production.

Recycling and end-of-life management present another critical sustainability challenge for EVA. As a thermoplastic material, EVA can theoretically be recycled multiple times. However, the presence of additives and cross-linking agents in many EVA products complicates the recycling process. Innovative recycling technologies, such as chemical recycling and advanced sorting methods, are being developed to address these challenges and improve the circularity of EVA products.

The durability and longevity of EVA products contribute to their sustainability profile. In applications such as solar panel encapsulation, EVA's ability to withstand harsh environmental conditions extends the lifespan of solar modules, reducing the need for frequent replacements and associated resource consumption. Similarly, in footwear and packaging applications, EVA's resilience can lead to longer-lasting products, potentially decreasing overall material consumption.

Energy efficiency in EVA processing is another area of focus for sustainability improvements. Advanced extrusion and molding technologies are being developed to reduce energy consumption during manufacturing. Additionally, the lightweight nature of EVA contributes to fuel efficiency in transportation applications, indirectly supporting sustainability goals in various industries.

Biodegradability and compostability are emerging areas of research for EVA sustainability. While traditional EVA is not biodegradable, efforts are underway to develop biodegradable variants or incorporate EVA into biodegradable composites. These innovations could significantly reduce the environmental impact of EVA in single-use or short-lifecycle applications.

As regulations and consumer preferences increasingly prioritize sustainable materials, the EVA industry is adapting by implementing life cycle assessments and exploring eco-design principles. These approaches help identify opportunities for improvement throughout the EVA value chain, from raw material sourcing to product disposal or recycling.

In conclusion, the sustainability aspects of EVA present both challenges and opportunities. By addressing production methods, recycling capabilities, product longevity, energy efficiency, and end-of-life management, the EVA industry can enhance its environmental profile and maintain its relevance in a sustainability-focused future.

One of the primary sustainability concerns surrounding EVA is its production process. Traditional methods often rely on fossil fuel-based feedstocks, contributing to carbon emissions and environmental degradation. However, recent advancements in bio-based feedstocks offer promising alternatives. Researchers are exploring the use of renewable resources, such as sugarcane and corn, to produce ethylene and vinyl acetate monomers, potentially reducing the carbon footprint of EVA production.

Recycling and end-of-life management present another critical sustainability challenge for EVA. As a thermoplastic material, EVA can theoretically be recycled multiple times. However, the presence of additives and cross-linking agents in many EVA products complicates the recycling process. Innovative recycling technologies, such as chemical recycling and advanced sorting methods, are being developed to address these challenges and improve the circularity of EVA products.

The durability and longevity of EVA products contribute to their sustainability profile. In applications such as solar panel encapsulation, EVA's ability to withstand harsh environmental conditions extends the lifespan of solar modules, reducing the need for frequent replacements and associated resource consumption. Similarly, in footwear and packaging applications, EVA's resilience can lead to longer-lasting products, potentially decreasing overall material consumption.

Energy efficiency in EVA processing is another area of focus for sustainability improvements. Advanced extrusion and molding technologies are being developed to reduce energy consumption during manufacturing. Additionally, the lightweight nature of EVA contributes to fuel efficiency in transportation applications, indirectly supporting sustainability goals in various industries.

Biodegradability and compostability are emerging areas of research for EVA sustainability. While traditional EVA is not biodegradable, efforts are underway to develop biodegradable variants or incorporate EVA into biodegradable composites. These innovations could significantly reduce the environmental impact of EVA in single-use or short-lifecycle applications.

As regulations and consumer preferences increasingly prioritize sustainable materials, the EVA industry is adapting by implementing life cycle assessments and exploring eco-design principles. These approaches help identify opportunities for improvement throughout the EVA value chain, from raw material sourcing to product disposal or recycling.

In conclusion, the sustainability aspects of EVA present both challenges and opportunities. By addressing production methods, recycling capabilities, product longevity, energy efficiency, and end-of-life management, the EVA industry can enhance its environmental profile and maintain its relevance in a sustainability-focused future.

Regulatory Landscape

The regulatory landscape for Ethylene Vinyl Acetate (EVA) is complex and multifaceted, reflecting the diverse applications of this versatile copolymer across various industries. As EVA finds its way into consumer products, packaging materials, and industrial applications, regulatory bodies worldwide have implemented stringent guidelines to ensure safety, quality, and environmental compliance.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA used in food contact materials. The agency has established specific requirements for EVA compositions and manufacturing processes to ensure the safety of food packaging and other food-related applications. Similarly, the European Food Safety Authority (EFSA) has set forth regulations governing the use of EVA in food contact materials within the European Union.

Environmental regulations have also significantly impacted the EVA industry. The increasing focus on sustainability and circular economy principles has led to the development of regulations aimed at reducing plastic waste and promoting recycling. For instance, the European Union's Circular Economy Action Plan has implications for EVA manufacturers, encouraging the development of more recyclable and biodegradable EVA formulations.

In the medical and pharmaceutical sectors, regulatory bodies such as the FDA and the European Medicines Agency (EMA) have established guidelines for the use of EVA in medical devices and drug delivery systems. These regulations ensure the biocompatibility and safety of EVA-based products in healthcare applications.

The automotive industry, another significant consumer of EVA, faces regulations related to vehicle emissions and fuel efficiency. As a result, there is a growing demand for lightweight materials, including EVA-based components, to meet these regulatory requirements. This has spurred innovation in EVA formulations tailored for automotive applications.

Occupational safety regulations also play a role in the EVA industry. Organizations such as the Occupational Safety and Health Administration (OSHA) in the United States have established guidelines for the safe handling and processing of EVA materials in manufacturing environments.

As the global regulatory landscape continues to evolve, EVA manufacturers and users must stay abreast of changing requirements and adapt their products and processes accordingly. This dynamic regulatory environment presents both challenges and opportunities for innovation in EVA technology, driving the development of new formulations and applications that meet increasingly stringent regulatory standards while addressing market demands for performance and sustainability.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA used in food contact materials. The agency has established specific requirements for EVA compositions and manufacturing processes to ensure the safety of food packaging and other food-related applications. Similarly, the European Food Safety Authority (EFSA) has set forth regulations governing the use of EVA in food contact materials within the European Union.

Environmental regulations have also significantly impacted the EVA industry. The increasing focus on sustainability and circular economy principles has led to the development of regulations aimed at reducing plastic waste and promoting recycling. For instance, the European Union's Circular Economy Action Plan has implications for EVA manufacturers, encouraging the development of more recyclable and biodegradable EVA formulations.

In the medical and pharmaceutical sectors, regulatory bodies such as the FDA and the European Medicines Agency (EMA) have established guidelines for the use of EVA in medical devices and drug delivery systems. These regulations ensure the biocompatibility and safety of EVA-based products in healthcare applications.

The automotive industry, another significant consumer of EVA, faces regulations related to vehicle emissions and fuel efficiency. As a result, there is a growing demand for lightweight materials, including EVA-based components, to meet these regulatory requirements. This has spurred innovation in EVA formulations tailored for automotive applications.

Occupational safety regulations also play a role in the EVA industry. Organizations such as the Occupational Safety and Health Administration (OSHA) in the United States have established guidelines for the safe handling and processing of EVA materials in manufacturing environments.

As the global regulatory landscape continues to evolve, EVA manufacturers and users must stay abreast of changing requirements and adapt their products and processes accordingly. This dynamic regulatory environment presents both challenges and opportunities for innovation in EVA technology, driving the development of new formulations and applications that meet increasingly stringent regulatory standards while addressing market demands for performance and sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!