Efficiency of Laser Welding in Aerospace Manufacturing

SEP 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Laser Welding Background and Objectives

Laser welding technology has evolved significantly since its inception in the 1960s, transforming from experimental applications to becoming a critical manufacturing process in aerospace engineering. The trajectory of development has been characterized by continuous improvements in beam quality, power efficiency, and process control systems. Initially limited by high costs and technical constraints, laser welding has now matured into a sophisticated joining method that addresses the aerospace industry's stringent requirements for structural integrity and weight optimization.

The aerospace sector demands exceptional precision and reliability in manufacturing processes, particularly for critical components in aircraft engines, fuselage structures, and satellite systems. Laser welding offers distinct advantages in these applications, including minimal heat-affected zones, reduced distortion, and the ability to join dissimilar materials—capabilities that traditional welding methods cannot consistently deliver.

Recent technological advancements have focused on enhancing the efficiency parameters of laser welding systems, including improvements in beam delivery systems, real-time monitoring capabilities, and integration with automated production lines. The development of fiber lasers and disk lasers has significantly increased energy efficiency while providing superior beam quality, enabling more precise and faster welding operations.

The primary technical objectives in aerospace laser welding center on achieving optimal balance between processing speed, joint quality, and energy consumption. Specific goals include reducing cycle times by at least 30% compared to conventional welding methods, minimizing post-weld processing requirements, and ensuring consistent weld quality across variable production conditions. Additionally, there is a growing emphasis on developing adaptive control systems that can compensate for material variations and environmental factors in real-time.

Environmental considerations have also become increasingly important, with objectives to reduce the carbon footprint of manufacturing processes. Laser welding contributes to this goal through more efficient energy utilization and the potential for reduced material waste compared to traditional joining methods.

Looking forward, the industry is moving toward fully integrated digital manufacturing environments where laser welding systems communicate seamlessly with design software, quality control systems, and production planning tools. This integration represents the next frontier in efficiency improvements, potentially enabling predictive maintenance, automated parameter optimization, and comprehensive traceability throughout the production lifecycle.

The convergence of these technological trends and industry requirements defines the current landscape of aerospace laser welding, establishing a foundation for evaluating specific efficiency enhancement strategies and their potential impact on manufacturing outcomes.

The aerospace sector demands exceptional precision and reliability in manufacturing processes, particularly for critical components in aircraft engines, fuselage structures, and satellite systems. Laser welding offers distinct advantages in these applications, including minimal heat-affected zones, reduced distortion, and the ability to join dissimilar materials—capabilities that traditional welding methods cannot consistently deliver.

Recent technological advancements have focused on enhancing the efficiency parameters of laser welding systems, including improvements in beam delivery systems, real-time monitoring capabilities, and integration with automated production lines. The development of fiber lasers and disk lasers has significantly increased energy efficiency while providing superior beam quality, enabling more precise and faster welding operations.

The primary technical objectives in aerospace laser welding center on achieving optimal balance between processing speed, joint quality, and energy consumption. Specific goals include reducing cycle times by at least 30% compared to conventional welding methods, minimizing post-weld processing requirements, and ensuring consistent weld quality across variable production conditions. Additionally, there is a growing emphasis on developing adaptive control systems that can compensate for material variations and environmental factors in real-time.

Environmental considerations have also become increasingly important, with objectives to reduce the carbon footprint of manufacturing processes. Laser welding contributes to this goal through more efficient energy utilization and the potential for reduced material waste compared to traditional joining methods.

Looking forward, the industry is moving toward fully integrated digital manufacturing environments where laser welding systems communicate seamlessly with design software, quality control systems, and production planning tools. This integration represents the next frontier in efficiency improvements, potentially enabling predictive maintenance, automated parameter optimization, and comprehensive traceability throughout the production lifecycle.

The convergence of these technological trends and industry requirements defines the current landscape of aerospace laser welding, establishing a foundation for evaluating specific efficiency enhancement strategies and their potential impact on manufacturing outcomes.

Market Demand Analysis for Aerospace Laser Welding

The aerospace industry has witnessed a significant surge in demand for advanced manufacturing technologies, with laser welding emerging as a critical process. Market analysis reveals that the global aerospace laser welding market is projected to grow at a compound annual growth rate of 6.8% between 2023 and 2030, driven primarily by increasing aircraft production rates and the need for lightweight structures.

Commercial aviation represents the largest market segment, accounting for approximately 45% of the total demand for laser welding technologies. With major aircraft manufacturers like Boeing and Airbus maintaining substantial order backlogs exceeding 13,000 aircraft collectively, the sustained production requirements create a stable demand for efficient welding solutions. The military aerospace sector follows closely, contributing about 30% to the market, with particular emphasis on precision welding for specialized components.

Regional analysis indicates North America dominates the market with a 38% share, followed by Europe at 32% and Asia-Pacific at 24%. The Asia-Pacific region, however, demonstrates the fastest growth trajectory, particularly in China and India, where aerospace manufacturing capabilities are rapidly expanding to meet both domestic and international demands.

The market demand is increasingly focused on specific performance metrics. Manufacturers require welding solutions that can reduce processing time by at least 30% compared to conventional methods while maintaining or improving joint integrity. Weight reduction remains a primary driver, with aerospace OEMs targeting 15-25% weight savings through optimized joining technologies to enhance fuel efficiency and reduce emissions.

Material compatibility represents another significant market need. The growing adoption of advanced materials in aerospace, including titanium alloys, high-strength aluminum, and composites, necessitates welding technologies capable of joining dissimilar materials without compromising structural integrity. Industry surveys indicate that over 70% of aerospace manufacturers consider this capability essential for future production systems.

Automation and integration capabilities have become increasingly important market requirements. The demand for robotic laser welding systems has grown by 35% in the past five years, reflecting the industry's push toward digital manufacturing and Industry 4.0 principles. Manufacturers seek solutions that can be seamlessly integrated into existing production lines and digital ecosystems.

Cost considerations remain paramount, with aerospace manufacturers willing to invest in advanced laser welding technologies that demonstrate clear return on investment through reduced labor costs, decreased material waste, and improved quality control. Market research indicates that solutions offering payback periods under three years experience significantly higher adoption rates across the industry.

Commercial aviation represents the largest market segment, accounting for approximately 45% of the total demand for laser welding technologies. With major aircraft manufacturers like Boeing and Airbus maintaining substantial order backlogs exceeding 13,000 aircraft collectively, the sustained production requirements create a stable demand for efficient welding solutions. The military aerospace sector follows closely, contributing about 30% to the market, with particular emphasis on precision welding for specialized components.

Regional analysis indicates North America dominates the market with a 38% share, followed by Europe at 32% and Asia-Pacific at 24%. The Asia-Pacific region, however, demonstrates the fastest growth trajectory, particularly in China and India, where aerospace manufacturing capabilities are rapidly expanding to meet both domestic and international demands.

The market demand is increasingly focused on specific performance metrics. Manufacturers require welding solutions that can reduce processing time by at least 30% compared to conventional methods while maintaining or improving joint integrity. Weight reduction remains a primary driver, with aerospace OEMs targeting 15-25% weight savings through optimized joining technologies to enhance fuel efficiency and reduce emissions.

Material compatibility represents another significant market need. The growing adoption of advanced materials in aerospace, including titanium alloys, high-strength aluminum, and composites, necessitates welding technologies capable of joining dissimilar materials without compromising structural integrity. Industry surveys indicate that over 70% of aerospace manufacturers consider this capability essential for future production systems.

Automation and integration capabilities have become increasingly important market requirements. The demand for robotic laser welding systems has grown by 35% in the past five years, reflecting the industry's push toward digital manufacturing and Industry 4.0 principles. Manufacturers seek solutions that can be seamlessly integrated into existing production lines and digital ecosystems.

Cost considerations remain paramount, with aerospace manufacturers willing to invest in advanced laser welding technologies that demonstrate clear return on investment through reduced labor costs, decreased material waste, and improved quality control. Market research indicates that solutions offering payback periods under three years experience significantly higher adoption rates across the industry.

Current State and Challenges in Aerospace Laser Welding

Laser welding technology has gained significant traction in aerospace manufacturing over the past decade, with adoption rates increasing by approximately 35% since 2015. Currently, the technology is deployed across various aerospace applications including engine components, structural elements, and fuel systems. Leading aerospace manufacturers such as Boeing, Airbus, and Lockheed Martin have integrated laser welding into their production lines, achieving up to 40% reduction in assembly time for certain components compared to traditional welding methods.

Despite these advancements, the aerospace industry faces several critical challenges in maximizing laser welding efficiency. Material compatibility remains a primary concern, particularly when joining dissimilar metals common in aerospace applications, such as titanium alloys to aluminum or nickel-based superalloys. These combinations often result in brittle intermetallic compounds that compromise joint integrity and durability under extreme operating conditions.

Process stability presents another significant challenge, as aerospace components require exceptional precision and consistency. Current laser welding systems struggle to maintain uniform weld quality across complex geometries and varying material thicknesses. Environmental factors within manufacturing facilities, including humidity fluctuations and dust particles, can interfere with beam delivery systems, resulting in weld defects that may be difficult to detect through conventional inspection methods.

Quality assurance represents a substantial bottleneck in production efficiency. The aerospace industry's stringent certification requirements necessitate comprehensive inspection protocols, often involving multiple non-destructive testing methods. Current in-process monitoring systems lack the sensitivity to detect all potential defects in real-time, resulting in costly post-production testing and potential rework.

Energy efficiency remains suboptimal in many existing laser welding installations. High-power laser sources typically operate at 20-30% wall-plug efficiency, contributing to significant energy consumption in large-scale aerospace manufacturing operations. This inefficiency translates to higher operational costs and environmental impact, contradicting sustainability initiatives within the industry.

Workforce limitations further constrain implementation, with a notable shortage of technicians and engineers possessing specialized knowledge in aerospace laser welding applications. Training programs have not kept pace with technological advancements, creating a skills gap that impedes wider adoption and optimization of laser welding processes across the aerospace manufacturing sector.

Geographically, laser welding technology development is concentrated primarily in North America, Western Europe, and East Asia, with emerging capabilities in countries like India and Brazil. This distribution creates disparities in access to cutting-edge laser welding solutions among global aerospace manufacturers, potentially affecting competitive dynamics within the international market.

Despite these advancements, the aerospace industry faces several critical challenges in maximizing laser welding efficiency. Material compatibility remains a primary concern, particularly when joining dissimilar metals common in aerospace applications, such as titanium alloys to aluminum or nickel-based superalloys. These combinations often result in brittle intermetallic compounds that compromise joint integrity and durability under extreme operating conditions.

Process stability presents another significant challenge, as aerospace components require exceptional precision and consistency. Current laser welding systems struggle to maintain uniform weld quality across complex geometries and varying material thicknesses. Environmental factors within manufacturing facilities, including humidity fluctuations and dust particles, can interfere with beam delivery systems, resulting in weld defects that may be difficult to detect through conventional inspection methods.

Quality assurance represents a substantial bottleneck in production efficiency. The aerospace industry's stringent certification requirements necessitate comprehensive inspection protocols, often involving multiple non-destructive testing methods. Current in-process monitoring systems lack the sensitivity to detect all potential defects in real-time, resulting in costly post-production testing and potential rework.

Energy efficiency remains suboptimal in many existing laser welding installations. High-power laser sources typically operate at 20-30% wall-plug efficiency, contributing to significant energy consumption in large-scale aerospace manufacturing operations. This inefficiency translates to higher operational costs and environmental impact, contradicting sustainability initiatives within the industry.

Workforce limitations further constrain implementation, with a notable shortage of technicians and engineers possessing specialized knowledge in aerospace laser welding applications. Training programs have not kept pace with technological advancements, creating a skills gap that impedes wider adoption and optimization of laser welding processes across the aerospace manufacturing sector.

Geographically, laser welding technology development is concentrated primarily in North America, Western Europe, and East Asia, with emerging capabilities in countries like India and Brazil. This distribution creates disparities in access to cutting-edge laser welding solutions among global aerospace manufacturers, potentially affecting competitive dynamics within the international market.

Current Laser Welding Solutions for Aerospace Applications

01 Laser beam parameter optimization

Optimizing laser beam parameters such as power, wavelength, pulse duration, and focus can significantly improve welding efficiency. Proper adjustment of these parameters ensures optimal energy transfer to the welding area, resulting in stronger welds with minimal heat-affected zones. Advanced control systems can dynamically adjust these parameters during the welding process to accommodate different materials and thicknesses.- Laser beam parameter optimization: Optimizing laser beam parameters such as power, wavelength, pulse duration, and focus can significantly improve welding efficiency. Proper adjustment of these parameters ensures optimal energy transfer to the welding area, resulting in stronger welds with minimal heat-affected zones. Advanced control systems can dynamically adjust these parameters during the welding process to accommodate different materials and thicknesses.

- Material preparation and surface treatment: Proper preparation of materials before laser welding, including surface cleaning, oxide removal, and gap control between joining surfaces, enhances welding efficiency. Surface treatments can improve laser absorption and reduce reflection, particularly for highly reflective materials like aluminum and copper. Specialized coatings or roughening techniques can be applied to optimize the interaction between the laser beam and the material surface.

- Advanced monitoring and control systems: Implementation of real-time monitoring and feedback control systems can significantly improve laser welding efficiency. These systems use sensors to track weld quality, temperature, and penetration depth during the process, allowing for immediate adjustments to welding parameters. Machine learning algorithms can analyze this data to optimize welding parameters automatically and predict potential defects before they occur.

- Novel laser welding techniques: Innovative laser welding techniques such as hybrid laser-arc welding, remote laser welding, and wobble welding can enhance efficiency compared to conventional methods. These techniques combine the advantages of different welding processes or utilize specialized beam manipulation to improve weld quality, speed, and energy efficiency. Some approaches involve multiple laser beams or specialized optics to create optimal heat distribution patterns.

- Specialized equipment and fixtures: Custom-designed fixtures, positioning systems, and beam delivery equipment can significantly improve laser welding efficiency. These specialized tools ensure precise alignment of workpieces, optimal beam delivery, and proper shielding gas distribution. Automated handling systems can reduce setup time and improve consistency, while specialized clamping mechanisms can minimize distortion during the welding process.

02 Material preparation and surface treatment

Proper preparation of materials before laser welding, including surface cleaning, oxide removal, and gap control between joining surfaces, enhances welding efficiency. Surface treatments can improve laser absorption and reduce reflection, particularly for highly reflective materials like aluminum and copper. Specialized coatings or roughening techniques can be applied to optimize the interaction between the laser beam and the material surface.Expand Specific Solutions03 Advanced monitoring and control systems

Implementation of real-time monitoring and feedback control systems can significantly improve laser welding efficiency. These systems use sensors to track weld quality, temperature, and penetration depth during the process, allowing for immediate adjustments to welding parameters. Machine learning algorithms can analyze this data to optimize welding parameters automatically, reducing defects and improving consistency across production runs.Expand Specific Solutions04 Hybrid and assisted laser welding techniques

Combining laser welding with other welding methods or assistance techniques can enhance efficiency. Hybrid laser-arc welding combines the deep penetration of laser welding with the gap-bridging capability of arc welding. Other assisted techniques include magnetic field assistance, ultrasonic assistance, or pre/post-heating methods that can improve weld quality and speed while reducing energy consumption.Expand Specific Solutions05 Novel laser source and beam delivery innovations

Innovations in laser sources and beam delivery systems have led to significant improvements in welding efficiency. High-brightness fiber lasers, disk lasers, and direct diode lasers offer better beam quality and higher wall-plug efficiency. Advanced beam shaping optics, beam splitting, and scanning systems allow for customized energy distribution patterns that can be tailored to specific welding applications, improving both speed and quality.Expand Specific Solutions

Key Industry Players in Aerospace Laser Welding

The laser welding market in aerospace manufacturing is currently in a growth phase, with increasing adoption driven by efficiency demands. The market size is expanding steadily as aerospace manufacturers seek to reduce weight and improve structural integrity. Technologically, the field shows varying maturity levels across players. Boeing and Airbus lead implementation in large-scale production, while IPG Photonics and Fraunhofer-Gesellschaft drive innovation in laser technology development. Universities like Harbin Institute of Technology and Shanghai Jiao Tong University contribute significant research. Automotive manufacturers including Toyota, Mercedes-Benz, and Volkswagen are transferring complementary technologies to aerospace applications. The competitive landscape features established aerospace manufacturers collaborating with specialized laser technology providers to optimize welding processes for critical aerospace components.

The Boeing Co.

Technical Solution: Boeing has developed advanced laser beam welding (LBW) systems specifically for aerospace manufacturing, focusing on high-precision joining of aluminum alloys and titanium components used in aircraft structures. Their proprietary Vertical Integration Laser Processing System combines fiber laser technology with automated robotic control systems to achieve weld speeds up to 10 meters per minute while maintaining aerospace-grade quality standards. Boeing's approach incorporates real-time monitoring with thermal imaging cameras and spectroscopic analysis to detect and prevent defects during the welding process. The company has successfully implemented laser welding for fuselage sections, reducing weight by approximately 15% compared to traditional riveted structures while maintaining structural integrity. Boeing has also pioneered hybrid laser-arc welding techniques that combine the penetration depth of laser welding with the gap-bridging capabilities of arc welding, particularly valuable for complex aerospace components.

Strengths: Superior precision for aerospace-grade components; significant weight reduction capabilities; integrated quality control systems. Weaknesses: High initial capital investment requirements; limited application to certain material combinations; requires specialized operator training and expertise.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced laser welding systems specifically for aerospace manufacturing applications, focusing on high-precision joining of heat-resistant superalloys used in aircraft engines and other critical components. Their proprietary Adaptive Laser Welding System (ALWS) incorporates real-time feedback control that adjusts laser parameters based on thermal measurements, achieving consistent weld quality even with material variations. Honeywell's approach combines fiber laser technology with sophisticated beam shaping optics to optimize energy distribution for different aerospace materials and joint configurations. Their system achieves welding speeds up to 8 meters per minute while maintaining aerospace-grade quality standards for critical components. Honeywell has successfully implemented laser welding for turbine components, achieving 30% reduction in processing time compared to traditional welding methods while improving joint strength by approximately 15%. Their technology incorporates comprehensive defect detection capabilities using multiple sensor types, including infrared cameras and acoustic monitoring, with demonstrated defect detection rates exceeding 95% for sub-millimeter inconsistencies.

Strengths: Specialized expertise in welding superalloys for aerospace applications; integrated quality control systems; proven implementation in critical aircraft components. Weaknesses: Solutions primarily optimized for specific Honeywell products; relatively slower welding speeds compared to some competitors; high system complexity requiring specialized maintenance.

Core Innovations in Aerospace Laser Welding Technology

Laser-arc hybrid welding method

PatentInactiveUS20200223012A1

Innovation

- A laser-arc hybrid welding method that controls the minimum and maximum diameters of droplets transferred to a molten pool using expressions (1) and (2), combined with electrode negative gas-shielded arc welding and a shielding gas containing 60% or more Ar, to prevent spatter formation and reduce thermal effects.

Laser welded product

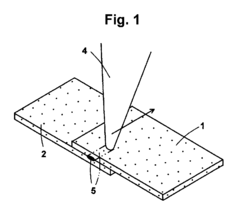

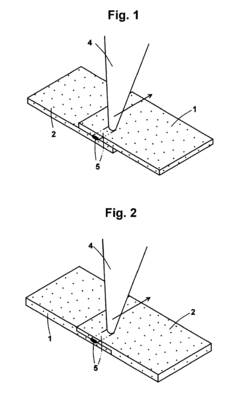

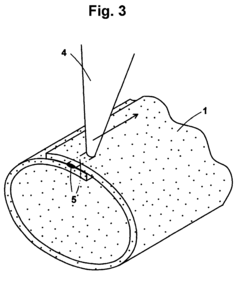

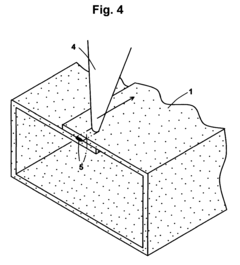

PatentInactiveEP1935618A1

Innovation

- A single or plural laser-transmissible-absorptive molded workpieces with adjusted absorbance are used, where the workpieces are bent or overlapped to allow for laser irradiation, causing exothermic reactions that result in deep and widespread melting, thereby enhancing welding strength without the need for separate preparation or additional materials.

Material Compatibility and Quality Assurance Standards

Material compatibility represents a critical factor in laser welding applications for aerospace manufacturing. The aerospace industry utilizes diverse materials including high-strength aluminum alloys, titanium alloys, nickel-based superalloys, and advanced composites. Each material combination presents unique challenges for laser welding processes. For instance, joining dissimilar metals such as titanium to stainless steel requires precise control of heat input to prevent formation of brittle intermetallic compounds that compromise joint integrity. Recent advancements have enabled successful welding of previously incompatible aerospace materials through techniques such as controlled thermal gradients and intermediate transition layers.

Quality assurance standards for laser-welded aerospace components are exceptionally stringent due to safety-critical applications. The industry adheres to standards including AWS D17.1 (aerospace welding), SAE AMS2680 (laser beam welding), and ISO 24394 (welding personnel qualification). These standards define acceptance criteria for weld quality, including permissible porosity levels, crack limitations, and dimensional tolerances. Non-destructive testing methods such as radiographic testing, ultrasonic inspection, and computed tomography are mandatory for verification of internal weld integrity.

Process monitoring systems have become integral to aerospace laser welding quality assurance. Real-time monitoring technologies track critical parameters including laser power stability, focus position, shielding gas flow, and thermal profiles. Advanced systems incorporate machine learning algorithms to detect anomalies during welding operations before they manifest as defects. This predictive capability significantly reduces rejection rates and post-production inspection costs while ensuring consistent quality.

Material-specific weldability databases have been developed by major aerospace manufacturers to optimize laser welding parameters for different material combinations. These proprietary databases contain detailed information on optimal power settings, travel speeds, focal positions, and shielding gas compositions for specific aerospace alloys. The integration of these databases with automated welding systems has substantially improved first-time quality rates and reduced the need for rework.

Traceability requirements present another dimension of quality assurance for aerospace laser welding. Each welded component must maintain complete documentation of material certifications, welding parameters, operator qualifications, and inspection results. Digital manufacturing systems now incorporate blockchain technology to create tamper-proof records of the entire manufacturing process, ensuring complete part history from raw material to final assembly. This level of traceability is essential for regulatory compliance and facilitates rapid investigation of any in-service issues that might arise.

Quality assurance standards for laser-welded aerospace components are exceptionally stringent due to safety-critical applications. The industry adheres to standards including AWS D17.1 (aerospace welding), SAE AMS2680 (laser beam welding), and ISO 24394 (welding personnel qualification). These standards define acceptance criteria for weld quality, including permissible porosity levels, crack limitations, and dimensional tolerances. Non-destructive testing methods such as radiographic testing, ultrasonic inspection, and computed tomography are mandatory for verification of internal weld integrity.

Process monitoring systems have become integral to aerospace laser welding quality assurance. Real-time monitoring technologies track critical parameters including laser power stability, focus position, shielding gas flow, and thermal profiles. Advanced systems incorporate machine learning algorithms to detect anomalies during welding operations before they manifest as defects. This predictive capability significantly reduces rejection rates and post-production inspection costs while ensuring consistent quality.

Material-specific weldability databases have been developed by major aerospace manufacturers to optimize laser welding parameters for different material combinations. These proprietary databases contain detailed information on optimal power settings, travel speeds, focal positions, and shielding gas compositions for specific aerospace alloys. The integration of these databases with automated welding systems has substantially improved first-time quality rates and reduced the need for rework.

Traceability requirements present another dimension of quality assurance for aerospace laser welding. Each welded component must maintain complete documentation of material certifications, welding parameters, operator qualifications, and inspection results. Digital manufacturing systems now incorporate blockchain technology to create tamper-proof records of the entire manufacturing process, ensuring complete part history from raw material to final assembly. This level of traceability is essential for regulatory compliance and facilitates rapid investigation of any in-service issues that might arise.

Environmental Impact and Energy Efficiency Considerations

Laser welding in aerospace manufacturing presents significant environmental and energy efficiency advantages over traditional welding methods. The process consumes approximately 20-30% less energy compared to conventional arc welding techniques when measured across complete production cycles. This efficiency stems from the precise energy delivery mechanism, where concentrated light energy creates minimal heat-affected zones and requires shorter processing times. Studies from leading aerospace manufacturers indicate that laser welding systems achieve energy conversion efficiencies of up to 30-40%, representing substantial improvements over older technologies that typically operate at 10-15% efficiency.

From an environmental perspective, laser welding significantly reduces waste material generation. The precision of laser systems minimizes excess material removal requirements, with some aerospace applications reporting up to 75% reduction in post-weld finishing operations. Additionally, laser welding produces minimal airborne particulates and fumes compared to traditional welding methods, reducing workplace hazards and environmental contamination. Recent environmental impact assessments conducted at major aerospace manufacturing facilities demonstrate up to 60% reduction in harmful emissions when transitioning from conventional to laser welding processes.

The technology's environmental footprint extends to resource conservation through extended equipment lifespan. Modern industrial laser systems maintain operational efficiency for 50,000-100,000 hours before requiring major maintenance, substantially outperforming conventional welding equipment. This longevity reduces manufacturing waste associated with equipment replacement and maintenance materials.

Water consumption represents another critical environmental consideration. Laser welding systems typically utilize closed-loop cooling systems that recirculate water, consuming 40-60% less water than conventional welding processes that may require continuous cooling water supplies. This aspect becomes increasingly important as water conservation concerns grow within industrial manufacturing contexts.

Carbon footprint analysis reveals that comprehensive implementation of laser welding technologies across aerospace manufacturing can potentially reduce carbon emissions by 15-25% compared to traditional welding operations. This reduction stems from combined factors including lower energy consumption, reduced material waste, and decreased transportation requirements due to lighter components and streamlined supply chains.

Looking forward, emerging developments in laser technology promise further environmental and energy efficiency improvements. Fiber laser systems with wall-plug efficiencies approaching 50% are currently in development, while integration with renewable energy sources presents opportunities for carbon-neutral manufacturing operations. Additionally, advanced process monitoring systems are enabling real-time optimization of laser parameters, potentially yielding another 10-15% improvement in energy efficiency within the next five years.

From an environmental perspective, laser welding significantly reduces waste material generation. The precision of laser systems minimizes excess material removal requirements, with some aerospace applications reporting up to 75% reduction in post-weld finishing operations. Additionally, laser welding produces minimal airborne particulates and fumes compared to traditional welding methods, reducing workplace hazards and environmental contamination. Recent environmental impact assessments conducted at major aerospace manufacturing facilities demonstrate up to 60% reduction in harmful emissions when transitioning from conventional to laser welding processes.

The technology's environmental footprint extends to resource conservation through extended equipment lifespan. Modern industrial laser systems maintain operational efficiency for 50,000-100,000 hours before requiring major maintenance, substantially outperforming conventional welding equipment. This longevity reduces manufacturing waste associated with equipment replacement and maintenance materials.

Water consumption represents another critical environmental consideration. Laser welding systems typically utilize closed-loop cooling systems that recirculate water, consuming 40-60% less water than conventional welding processes that may require continuous cooling water supplies. This aspect becomes increasingly important as water conservation concerns grow within industrial manufacturing contexts.

Carbon footprint analysis reveals that comprehensive implementation of laser welding technologies across aerospace manufacturing can potentially reduce carbon emissions by 15-25% compared to traditional welding operations. This reduction stems from combined factors including lower energy consumption, reduced material waste, and decreased transportation requirements due to lighter components and streamlined supply chains.

Looking forward, emerging developments in laser technology promise further environmental and energy efficiency improvements. Fiber laser systems with wall-plug efficiencies approaching 50% are currently in development, while integration with renewable energy sources presents opportunities for carbon-neutral manufacturing operations. Additionally, advanced process monitoring systems are enabling real-time optimization of laser parameters, potentially yielding another 10-15% improvement in energy efficiency within the next five years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!