Electrocatalytic CO2 reduction research for high efficiency renewable energy systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Reduction Technology Background and Objectives

Electrocatalytic CO2 reduction has emerged as a critical technology in the global effort to address climate change while developing sustainable energy systems. This technology represents a convergence of electrochemistry, materials science, and renewable energy research that has evolved significantly over the past three decades. The fundamental concept involves converting carbon dioxide—a primary greenhouse gas—into valuable chemical feedstocks and fuels using electrical energy, ideally sourced from renewable power generation.

The historical trajectory of CO2 reduction research began in the 1980s with pioneering electrochemical studies, but gained substantial momentum in the early 2000s as climate concerns intensified and renewable energy technologies matured. Early research focused primarily on metal electrodes and basic reaction mechanisms, while contemporary work has expanded to include advanced nanomaterials, molecular catalysts, and hybrid systems designed to overcome efficiency limitations.

Current technological evolution trends point toward multi-component catalytic systems, in-situ characterization techniques, and integration with renewable energy sources. The field is witnessing rapid advancement in catalyst design principles, with increasing emphasis on atomic-level precision and structure-function relationships that govern selectivity and efficiency.

The primary technical objectives in this domain include achieving higher Faradaic efficiencies for target products, enhancing energy efficiency of the overall process, improving catalyst stability for long-term operation, and developing scalable systems suitable for industrial implementation. Specifically, researchers aim to exceed 90% Faradaic efficiency for high-value products while maintaining current densities above 200 mA/cm² at overpotentials below 0.5V.

Another critical objective involves selective production of C2+ products (ethylene, ethanol, etc.) which represent higher energy density fuels and more valuable chemical feedstocks compared to C1 products like carbon monoxide or formate. This selectivity challenge remains one of the field's most significant hurdles.

The technology aims to create a circular carbon economy where CO2 emissions can be recycled into useful products, effectively closing the carbon loop. This approach offers dual benefits: mitigating greenhouse gas emissions while simultaneously producing valuable chemicals and fuels from what is currently considered a waste product.

From a broader perspective, electrocatalytic CO2 reduction represents a key component in the transition toward renewable energy systems by addressing intermittency challenges through energy storage in chemical bonds. The technology potentially enables seasonal storage capabilities that complement shorter-duration battery technologies, thus supporting higher penetration of variable renewable energy sources in the global energy mix.

The historical trajectory of CO2 reduction research began in the 1980s with pioneering electrochemical studies, but gained substantial momentum in the early 2000s as climate concerns intensified and renewable energy technologies matured. Early research focused primarily on metal electrodes and basic reaction mechanisms, while contemporary work has expanded to include advanced nanomaterials, molecular catalysts, and hybrid systems designed to overcome efficiency limitations.

Current technological evolution trends point toward multi-component catalytic systems, in-situ characterization techniques, and integration with renewable energy sources. The field is witnessing rapid advancement in catalyst design principles, with increasing emphasis on atomic-level precision and structure-function relationships that govern selectivity and efficiency.

The primary technical objectives in this domain include achieving higher Faradaic efficiencies for target products, enhancing energy efficiency of the overall process, improving catalyst stability for long-term operation, and developing scalable systems suitable for industrial implementation. Specifically, researchers aim to exceed 90% Faradaic efficiency for high-value products while maintaining current densities above 200 mA/cm² at overpotentials below 0.5V.

Another critical objective involves selective production of C2+ products (ethylene, ethanol, etc.) which represent higher energy density fuels and more valuable chemical feedstocks compared to C1 products like carbon monoxide or formate. This selectivity challenge remains one of the field's most significant hurdles.

The technology aims to create a circular carbon economy where CO2 emissions can be recycled into useful products, effectively closing the carbon loop. This approach offers dual benefits: mitigating greenhouse gas emissions while simultaneously producing valuable chemicals and fuels from what is currently considered a waste product.

From a broader perspective, electrocatalytic CO2 reduction represents a key component in the transition toward renewable energy systems by addressing intermittency challenges through energy storage in chemical bonds. The technology potentially enables seasonal storage capabilities that complement shorter-duration battery technologies, thus supporting higher penetration of variable renewable energy sources in the global energy mix.

Market Analysis for CO2 Conversion Technologies

The global market for CO2 conversion technologies is experiencing significant growth, driven by increasing environmental concerns and the urgent need to reduce greenhouse gas emissions. The market size for carbon capture, utilization, and storage (CCUS) technologies was valued at approximately $1.9 billion in 2020 and is projected to reach $3.5 billion by 2025, growing at a CAGR of 13.2%. Electrocatalytic CO2 reduction represents a particularly promising segment within this broader market.

Industrial sectors including power generation, cement production, and chemical manufacturing constitute the primary demand sources for CO2 conversion technologies. These industries face mounting regulatory pressure to reduce their carbon footprint, creating a robust market pull for innovative solutions. The power generation sector alone accounts for roughly 40% of global CO2 emissions, presenting a substantial addressable market.

Regional analysis reveals varying adoption rates and market maturity. Europe leads in terms of policy support and commercial implementation, with the EU's Green Deal providing significant funding for carbon-neutral technologies. North America follows with strong research infrastructure and increasing corporate commitments to carbon neutrality. The Asia-Pacific region, particularly China, is rapidly scaling up investments in this space, driven by national decarbonization targets.

Market segmentation shows distinct technology categories gaining traction. Conversion to fuels (methanol, syngas) currently dominates with approximately 45% market share, followed by conversion to chemicals (30%) and materials like polymers and building products (25%). Electrocatalytic approaches specifically are growing at above-average rates due to their compatibility with renewable energy systems.

Key market drivers include strengthening regulatory frameworks around carbon pricing, corporate sustainability commitments, and increasing consumer preference for low-carbon products. The integration potential with renewable energy systems adds significant value, as intermittent renewable sources can power electrocatalytic processes during peak production periods.

Barriers to wider market adoption include high capital costs, efficiency limitations of current catalysts, and infrastructure challenges. The levelized cost of converted CO2 products remains 2-3 times higher than conventional alternatives in most applications, though this gap is narrowing as technologies mature and scale.

Market forecasts indicate accelerating growth through 2030, with electrocatalytic CO2 reduction technologies potentially capturing 15-20% of the total CCUS market by that time. Early commercial applications are emerging in niche high-value chemical production, with broader applications expected as efficiency improvements and cost reductions continue.

Industrial sectors including power generation, cement production, and chemical manufacturing constitute the primary demand sources for CO2 conversion technologies. These industries face mounting regulatory pressure to reduce their carbon footprint, creating a robust market pull for innovative solutions. The power generation sector alone accounts for roughly 40% of global CO2 emissions, presenting a substantial addressable market.

Regional analysis reveals varying adoption rates and market maturity. Europe leads in terms of policy support and commercial implementation, with the EU's Green Deal providing significant funding for carbon-neutral technologies. North America follows with strong research infrastructure and increasing corporate commitments to carbon neutrality. The Asia-Pacific region, particularly China, is rapidly scaling up investments in this space, driven by national decarbonization targets.

Market segmentation shows distinct technology categories gaining traction. Conversion to fuels (methanol, syngas) currently dominates with approximately 45% market share, followed by conversion to chemicals (30%) and materials like polymers and building products (25%). Electrocatalytic approaches specifically are growing at above-average rates due to their compatibility with renewable energy systems.

Key market drivers include strengthening regulatory frameworks around carbon pricing, corporate sustainability commitments, and increasing consumer preference for low-carbon products. The integration potential with renewable energy systems adds significant value, as intermittent renewable sources can power electrocatalytic processes during peak production periods.

Barriers to wider market adoption include high capital costs, efficiency limitations of current catalysts, and infrastructure challenges. The levelized cost of converted CO2 products remains 2-3 times higher than conventional alternatives in most applications, though this gap is narrowing as technologies mature and scale.

Market forecasts indicate accelerating growth through 2030, with electrocatalytic CO2 reduction technologies potentially capturing 15-20% of the total CCUS market by that time. Early commercial applications are emerging in niche high-value chemical production, with broader applications expected as efficiency improvements and cost reductions continue.

Current Electrocatalytic CO2 Reduction Challenges

Despite significant advancements in electrocatalytic CO2 reduction (ECR) technology, several critical challenges continue to impede its widespread implementation in renewable energy systems. The primary obstacle remains the low energy efficiency of the conversion process, with most current systems achieving only 30-50% Faradaic efficiency for valuable products like ethylene and ethanol. This inefficiency stems from competing hydrogen evolution reactions that consume electrons without contributing to carbon conversion.

Catalyst selectivity presents another major hurdle, as most existing catalysts produce a mixture of products rather than targeting specific high-value chemicals. This product distribution challenge significantly increases downstream separation costs and reduces overall process economics. Even state-of-the-art copper-based catalysts struggle to maintain consistent selectivity across different operating conditions.

Catalyst stability under industrial conditions represents a persistent challenge, with performance degradation occurring over relatively short timeframes. Most laboratory demonstrations show significant activity loss after just 100-200 hours of operation, far below the thousands of hours required for commercial viability. This degradation results from catalyst poisoning, structural changes, and leaching of active components during extended operation.

The scaling gap between laboratory demonstrations and industrial implementation remains substantial. While impressive results have been achieved in small-scale setups with carefully controlled conditions, translating these successes to industrially relevant current densities (>200 mA/cm²) and electrode areas (>100 cm²) introduces new challenges related to mass transport limitations, heat management, and uniform reactant distribution.

Economic viability continues to constrain commercial adoption, with current ECR systems requiring significant capital investment while producing relatively low-value products. The levelized cost of products from most existing systems exceeds market prices by factors of 2-5, necessitating either substantial technology improvements or supportive policy frameworks.

System integration challenges persist when incorporating ECR technology into broader renewable energy ecosystems. The intermittent nature of renewable electricity sources creates operational complexities for ECR systems that typically perform optimally under steady-state conditions. Additionally, the CO2 supply chain presents logistical and economic barriers, particularly for distributed implementation scenarios.

Fundamental knowledge gaps in reaction mechanisms and catalyst-electrolyte interactions continue to limit rational catalyst design approaches. Despite advanced characterization techniques, the precise atomic-scale understanding of active sites and reaction intermediates remains incomplete, hampering efforts to develop next-generation catalysts through predictive design rather than empirical optimization.

Catalyst selectivity presents another major hurdle, as most existing catalysts produce a mixture of products rather than targeting specific high-value chemicals. This product distribution challenge significantly increases downstream separation costs and reduces overall process economics. Even state-of-the-art copper-based catalysts struggle to maintain consistent selectivity across different operating conditions.

Catalyst stability under industrial conditions represents a persistent challenge, with performance degradation occurring over relatively short timeframes. Most laboratory demonstrations show significant activity loss after just 100-200 hours of operation, far below the thousands of hours required for commercial viability. This degradation results from catalyst poisoning, structural changes, and leaching of active components during extended operation.

The scaling gap between laboratory demonstrations and industrial implementation remains substantial. While impressive results have been achieved in small-scale setups with carefully controlled conditions, translating these successes to industrially relevant current densities (>200 mA/cm²) and electrode areas (>100 cm²) introduces new challenges related to mass transport limitations, heat management, and uniform reactant distribution.

Economic viability continues to constrain commercial adoption, with current ECR systems requiring significant capital investment while producing relatively low-value products. The levelized cost of products from most existing systems exceeds market prices by factors of 2-5, necessitating either substantial technology improvements or supportive policy frameworks.

System integration challenges persist when incorporating ECR technology into broader renewable energy ecosystems. The intermittent nature of renewable electricity sources creates operational complexities for ECR systems that typically perform optimally under steady-state conditions. Additionally, the CO2 supply chain presents logistical and economic barriers, particularly for distributed implementation scenarios.

Fundamental knowledge gaps in reaction mechanisms and catalyst-electrolyte interactions continue to limit rational catalyst design approaches. Despite advanced characterization techniques, the precise atomic-scale understanding of active sites and reaction intermediates remains incomplete, hampering efforts to develop next-generation catalysts through predictive design rather than empirical optimization.

Current Electrocatalytic Materials and Methods

01 Catalyst materials for enhanced CO2 reduction efficiency

Various catalyst materials can significantly improve the efficiency of electrocatalytic CO2 reduction. These include metal-based catalysts (such as copper, silver, gold), metal oxides, and novel composite materials. The selection of appropriate catalyst materials is crucial for achieving high Faradaic efficiency, selectivity towards desired products, and long-term stability during the CO2 reduction process.- Catalyst materials for enhanced CO2 reduction efficiency: Various catalyst materials can significantly improve the efficiency of electrocatalytic CO2 reduction. These include metal-based catalysts, metal oxides, and composite materials that offer high selectivity and conversion rates. The catalysts are designed with specific surface structures and compositions to optimize the electron transfer process and reduce overpotential requirements, thereby enhancing the overall efficiency of CO2 conversion to valuable products.

- Nanostructured electrocatalysts for improved performance: Nanostructured electrocatalysts offer enhanced performance in CO2 reduction due to their high surface area and abundant active sites. These catalysts include nanoparticles, nanosheets, and hierarchical structures that facilitate efficient mass transfer and electron transport. The controlled morphology at the nanoscale allows for better exposure of catalytic sites and improved interaction with CO2 molecules, leading to higher conversion efficiency and product selectivity.

- Electrolyte optimization for CO2 reduction: The composition and properties of the electrolyte significantly impact the efficiency of electrocatalytic CO2 reduction. Factors such as pH, ionic strength, and the presence of specific ions can influence reaction pathways and product distribution. Optimized electrolytes can suppress competing hydrogen evolution reactions, enhance CO2 solubility, and stabilize reaction intermediates, thereby improving the overall efficiency and selectivity of the CO2 reduction process.

- Reactor design and system engineering for efficient CO2 conversion: Advanced reactor designs and system engineering approaches play a crucial role in enhancing the efficiency of electrocatalytic CO2 reduction. These include flow cell configurations, gas diffusion electrodes, and membrane electrode assemblies that improve mass transport and reduce concentration polarization. Optimized reactor designs can enhance CO2 utilization, minimize energy losses, and facilitate the separation of products, leading to higher overall system efficiency.

- Process parameters and operating conditions optimization: Optimization of process parameters and operating conditions is essential for maximizing the efficiency of electrocatalytic CO2 reduction. Key parameters include applied potential, current density, temperature, pressure, and CO2 flow rate. Careful control and tuning of these parameters can significantly enhance reaction kinetics, reduce energy consumption, and improve product selectivity, thereby increasing the overall efficiency of the CO2 reduction process.

02 Nanostructured electrocatalysts for improved performance

Nanostructured electrocatalysts offer enhanced performance for CO2 reduction due to their high surface area, abundant active sites, and unique electronic properties. These include nanoparticles, nanowires, nanosheets, and hierarchical nanostructures. The controlled synthesis of nanostructured catalysts with specific morphologies, sizes, and compositions can significantly improve reaction kinetics and product selectivity in electrocatalytic CO2 reduction.Expand Specific Solutions03 Electrode design and modification strategies

Innovative electrode design and modification approaches can enhance CO2 reduction efficiency. These include surface functionalization, defect engineering, interface optimization, and the development of gas diffusion electrodes. Proper electrode design ensures efficient mass transport, reduces overpotential, and improves the stability of the electrocatalytic system, leading to higher conversion rates and better product selectivity.Expand Specific Solutions04 Electrolyte composition and reaction conditions optimization

The composition of the electrolyte and optimization of reaction conditions play crucial roles in determining the efficiency of CO2 reduction. Factors such as pH, temperature, pressure, electrolyte concentration, and the presence of specific ions or additives can significantly influence reaction pathways and product distribution. Systematic optimization of these parameters can lead to enhanced conversion efficiency and selectivity towards valuable products.Expand Specific Solutions05 Advanced reactor designs and system integration

Advanced reactor designs and integrated systems can overcome mass transfer limitations and improve overall process efficiency. These include flow cells, microfluidic reactors, membrane electrode assemblies, and integrated capture-conversion systems. Innovative reactor configurations enable better CO2 utilization, reduced energy consumption, and enhanced product separation, making the electrocatalytic CO2 reduction process more economically viable and environmentally sustainable.Expand Specific Solutions

Key Industry Players in CO2 Reduction Research

Electrocatalytic CO2 reduction research is currently in a growth phase, with the market expanding rapidly due to increasing focus on renewable energy solutions. The global market size is estimated to reach significant scale as governments and industries invest in carbon neutrality. Technologically, the field shows varying maturity levels across different approaches. Leading players include academic institutions like California Institute of Technology, University of Toronto, and Sorbonne Université, alongside industrial entities such as TotalEnergies, Siemens Energy, and Saudi Aramco. Research centers like CNRS and IFP Energies Nouvelles provide crucial fundamental research, while companies like Hitachi and Toshiba contribute engineering expertise. This competitive landscape reflects a collaborative ecosystem where academic-industrial partnerships are driving innovation toward commercial viability.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed an integrated electrocatalytic CO2 reduction system that combines proprietary catalyst technology with advanced electrolyzer design for industrial-scale implementation. Their approach utilizes silver-based gas diffusion electrodes optimized for CO production, achieving Faradaic efficiencies above 95% at industrially relevant current densities (>200 mA/cm²). The company has engineered complete electrolyzer stacks with innovative flow field designs that address mass transport limitations while maintaining uniform current distribution. Their system architecture incorporates sophisticated control systems that dynamically adjust operating parameters based on input power fluctuations, making it particularly suitable for integration with intermittent renewable energy sources. Siemens has demonstrated pilot plants operating at the 100+ kW scale, with reported energy efficiencies exceeding 60% for conversion of CO2 to CO, which can be further utilized in their Power-to-X technology portfolio for synthetic fuel production.

Strengths: Industrial-scale implementation expertise; system-level integration with renewable energy sources; robust engineering addressing real-world operational challenges. Weaknesses: More focused on CO as primary product rather than higher-value multi-carbon compounds; higher capital costs compared to some competing technologies; dependent on additional process steps for final product synthesis.

The Regents of the University of California

Technical Solution: The University of California has developed advanced copper-based catalysts for electrochemical CO2 reduction with remarkable selectivity toward multi-carbon products. Their approach involves precise nanostructuring of copper surfaces to create optimal binding sites for CO2 activation. They've pioneered the use of oxide-derived copper catalysts that demonstrate Faradaic efficiencies exceeding 60% for C2+ products at industrially relevant current densities. Their research includes innovative electrode designs incorporating gas diffusion layers to overcome mass transport limitations, achieving current densities above 300 mA/cm² while maintaining high selectivity. Recent work has focused on tandem catalytic systems that combine copper with other metals like silver and zinc to optimize the cascade reaction pathway from CO2 to valuable products like ethylene and ethanol.

Strengths: Exceptional selectivity toward multi-carbon products; innovative catalyst design approaches; comprehensive understanding of reaction mechanisms. Weaknesses: Higher overpotentials compared to some competing technologies; challenges in long-term stability under industrial conditions; complex catalyst preparation methods that may limit scalability.

Critical Patents in CO2 Reduction Catalysis

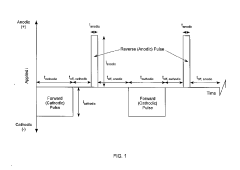

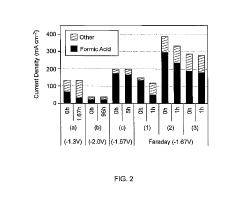

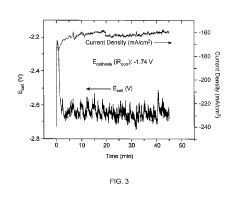

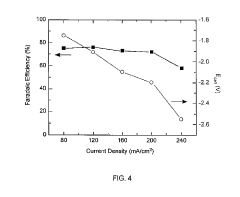

Pulsed current catalyzed gas diffusion electrodes for high rate, efficient co2 conversion reactors

PatentInactiveUS20190112720A1

Innovation

- The development of a gas diffusion electrode (GDE) with a high surface area microporous layer and electrochemically deposited Sn catalyst using pulse/pulse reverse electrodeposition, creating a uniform, adherent nanostructured catalyst layer for enhanced CO2 reduction efficiency and selectivity.

Techno-economic Assessment of CO2 Reduction Systems

The techno-economic assessment of CO2 reduction systems reveals significant challenges and opportunities in scaling this technology for commercial applications. Current economic analyses indicate that capital expenditure for electrocatalytic CO2 reduction facilities ranges between $500-2,000 per kilowatt of installed capacity, with operating costs heavily dependent on electricity prices, which typically constitute 60-70% of total operational expenses.

Energy efficiency remains a critical economic factor, with state-of-the-art systems achieving 40-60% Faradaic efficiency for valuable products like carbon monoxide, formate, and ethylene. However, when considering full system efficiency including separation processes, this often drops to 30-45%, significantly impacting economic viability. The levelized cost of products from these systems currently ranges from $0.80-2.50 per kilogram, substantially higher than conventional fossil-based production methods.

Market sensitivity analysis demonstrates that electricity prices below $0.04/kWh are generally required for cost-competitive operation without subsidies. Carbon pricing mechanisms could substantially improve economic feasibility, with models suggesting that carbon prices of $50-100 per ton of CO2 would make many electrocatalytic reduction pathways economically viable against conventional alternatives.

Scale-up economics show promising cost reduction trajectories, with learning rates of approximately 15-20% for each doubling of installed capacity. This suggests that with sufficient deployment, costs could decrease by 50-60% over the next decade. Integration with renewable energy systems offers additional economic benefits through demand response capabilities and grid balancing services, potentially generating $0.01-0.03/kWh in additional value.

Life cycle assessment indicates that CO2 reduction systems must operate for 3-5 years to offset the embodied carbon from manufacturing and installation. Systems powered by renewable electricity with lifespans exceeding 5 years typically show net positive climate impact, with carbon abatement costs ranging from $100-300 per ton of CO2 avoided.

Regional economic analysis reveals significant variation in feasibility, with locations combining low electricity costs, high carbon prices, and existing CO2 capture infrastructure showing the most promising economics. Industrial clusters with waste CO2 streams and renewable energy access could achieve payback periods as short as 5-7 years under current market conditions, compared to 10-15 years for standalone facilities.

Energy efficiency remains a critical economic factor, with state-of-the-art systems achieving 40-60% Faradaic efficiency for valuable products like carbon monoxide, formate, and ethylene. However, when considering full system efficiency including separation processes, this often drops to 30-45%, significantly impacting economic viability. The levelized cost of products from these systems currently ranges from $0.80-2.50 per kilogram, substantially higher than conventional fossil-based production methods.

Market sensitivity analysis demonstrates that electricity prices below $0.04/kWh are generally required for cost-competitive operation without subsidies. Carbon pricing mechanisms could substantially improve economic feasibility, with models suggesting that carbon prices of $50-100 per ton of CO2 would make many electrocatalytic reduction pathways economically viable against conventional alternatives.

Scale-up economics show promising cost reduction trajectories, with learning rates of approximately 15-20% for each doubling of installed capacity. This suggests that with sufficient deployment, costs could decrease by 50-60% over the next decade. Integration with renewable energy systems offers additional economic benefits through demand response capabilities and grid balancing services, potentially generating $0.01-0.03/kWh in additional value.

Life cycle assessment indicates that CO2 reduction systems must operate for 3-5 years to offset the embodied carbon from manufacturing and installation. Systems powered by renewable electricity with lifespans exceeding 5 years typically show net positive climate impact, with carbon abatement costs ranging from $100-300 per ton of CO2 avoided.

Regional economic analysis reveals significant variation in feasibility, with locations combining low electricity costs, high carbon prices, and existing CO2 capture infrastructure showing the most promising economics. Industrial clusters with waste CO2 streams and renewable energy access could achieve payback periods as short as 5-7 years under current market conditions, compared to 10-15 years for standalone facilities.

Policy Frameworks for Carbon Capture Technologies

Policy frameworks for carbon capture technologies have evolved significantly in response to the growing urgency of climate change mitigation. Governments worldwide are implementing diverse regulatory mechanisms to accelerate the adoption of electrocatalytic CO2 reduction technologies. These frameworks typically include carbon pricing schemes, tax incentives, subsidies, and research grants designed to make carbon capture economically viable while supporting technological innovation.

The European Union leads with its comprehensive Emissions Trading System (ETS), which establishes a carbon price that incentivizes industries to invest in CO2 reduction technologies. This market-based approach is complemented by the Innovation Fund, which allocates substantial resources specifically for breakthrough technologies in carbon capture and utilization. Similarly, the United States has implemented the 45Q tax credit, providing up to $50 per metric ton of CO2 sequestered, creating a significant financial incentive for industrial adoption of electrocatalytic systems.

In Asia, countries like Japan and South Korea have established technology-specific support mechanisms through their respective Green Growth strategies. China's inclusion of carbon capture in its Five-Year Plans signals strong governmental commitment to developing domestic capabilities in this field. These policy frameworks are increasingly being designed with technology-neutrality principles, focusing on performance outcomes rather than prescribing specific technological approaches.

Regulatory standards for renewable energy integration are also evolving to accommodate electrocatalytic CO2 reduction systems. Grid connection policies are being updated to facilitate the coupling of intermittent renewable energy sources with electrocatalytic processes, recognizing their potential role in energy storage and system flexibility. Several jurisdictions have implemented renewable portfolio standards that specifically recognize converted CO2 products as eligible renewable energy contributions.

International cooperation frameworks further enhance policy effectiveness. The Mission Innovation initiative and the Carbon Sequestration Leadership Forum provide platforms for knowledge sharing and collaborative research funding. These multinational efforts help harmonize technical standards and create larger markets for emerging technologies, reducing investment risks and accelerating commercialization pathways.

Recent policy trends indicate a shift toward more holistic approaches that consider entire value chains. Policies increasingly address not only the capture technology but also the utilization pathways for converted CO2, creating markets for derived products through procurement requirements and product standards. This comprehensive approach recognizes that successful deployment requires coordinated support across the innovation spectrum, from basic research to market creation.

The European Union leads with its comprehensive Emissions Trading System (ETS), which establishes a carbon price that incentivizes industries to invest in CO2 reduction technologies. This market-based approach is complemented by the Innovation Fund, which allocates substantial resources specifically for breakthrough technologies in carbon capture and utilization. Similarly, the United States has implemented the 45Q tax credit, providing up to $50 per metric ton of CO2 sequestered, creating a significant financial incentive for industrial adoption of electrocatalytic systems.

In Asia, countries like Japan and South Korea have established technology-specific support mechanisms through their respective Green Growth strategies. China's inclusion of carbon capture in its Five-Year Plans signals strong governmental commitment to developing domestic capabilities in this field. These policy frameworks are increasingly being designed with technology-neutrality principles, focusing on performance outcomes rather than prescribing specific technological approaches.

Regulatory standards for renewable energy integration are also evolving to accommodate electrocatalytic CO2 reduction systems. Grid connection policies are being updated to facilitate the coupling of intermittent renewable energy sources with electrocatalytic processes, recognizing their potential role in energy storage and system flexibility. Several jurisdictions have implemented renewable portfolio standards that specifically recognize converted CO2 products as eligible renewable energy contributions.

International cooperation frameworks further enhance policy effectiveness. The Mission Innovation initiative and the Carbon Sequestration Leadership Forum provide platforms for knowledge sharing and collaborative research funding. These multinational efforts help harmonize technical standards and create larger markets for emerging technologies, reducing investment risks and accelerating commercialization pathways.

Recent policy trends indicate a shift toward more holistic approaches that consider entire value chains. Policies increasingly address not only the capture technology but also the utilization pathways for converted CO2, creating markets for derived products through procurement requirements and product standards. This comprehensive approach recognizes that successful deployment requires coordinated support across the innovation spectrum, from basic research to market creation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!