What technical strategies enhance Electrocatalytic CO2 reduction reaction rates and selectivity

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Reduction Technology Background and Objectives

Electrocatalytic CO2 reduction reaction (CO2RR) has emerged as a promising approach to address the dual challenges of climate change and sustainable energy production. The technology has evolved significantly since its initial conceptualization in the 1980s, with major breakthroughs occurring in the past decade. The fundamental principle involves converting carbon dioxide into value-added chemicals and fuels using electrical energy, ideally derived from renewable sources, thereby creating a carbon-neutral or even carbon-negative cycle.

The historical trajectory of CO2RR technology shows three distinct phases: early fundamental studies (1980s-2000s), catalyst optimization period (2000s-2015), and the current system integration and commercialization efforts (2015-present). Each phase has contributed to our understanding of reaction mechanisms, catalyst design principles, and system engineering requirements.

Current technological trends indicate a shift toward multi-metallic catalysts, nanostructured materials, and molecular engineering approaches to enhance both reaction rates and product selectivity. The field is increasingly moving toward integrated systems that combine CO2 capture and conversion in a single process, maximizing energy efficiency and economic viability.

The primary technical objectives in this field include achieving Faradaic efficiencies exceeding 90% for target products, maintaining current densities above 200 mA/cm² for industrial relevance, demonstrating long-term stability (>1000 hours) without significant performance degradation, and developing catalysts from earth-abundant materials to ensure economic feasibility and scalability.

Additionally, researchers aim to understand and control the complex interplay between catalyst surface structure, electrolyte composition, and operating conditions that collectively determine reaction pathways and product distributions. This fundamental understanding is crucial for rational catalyst design and system optimization.

From an environmental perspective, the technology aims to achieve a net reduction in carbon emissions when considering the entire life cycle, including catalyst production and energy inputs. The ideal scenario involves powering CO2RR systems with renewable electricity, creating a sustainable carbon cycle that helps mitigate climate change while producing valuable chemical feedstocks.

The ultimate goal extends beyond laboratory demonstrations to commercial deployment, requiring advances in catalyst performance, system engineering, and process integration. Success will be measured not only by technical metrics but also by economic viability compared to conventional production methods for chemicals and fuels.

The historical trajectory of CO2RR technology shows three distinct phases: early fundamental studies (1980s-2000s), catalyst optimization period (2000s-2015), and the current system integration and commercialization efforts (2015-present). Each phase has contributed to our understanding of reaction mechanisms, catalyst design principles, and system engineering requirements.

Current technological trends indicate a shift toward multi-metallic catalysts, nanostructured materials, and molecular engineering approaches to enhance both reaction rates and product selectivity. The field is increasingly moving toward integrated systems that combine CO2 capture and conversion in a single process, maximizing energy efficiency and economic viability.

The primary technical objectives in this field include achieving Faradaic efficiencies exceeding 90% for target products, maintaining current densities above 200 mA/cm² for industrial relevance, demonstrating long-term stability (>1000 hours) without significant performance degradation, and developing catalysts from earth-abundant materials to ensure economic feasibility and scalability.

Additionally, researchers aim to understand and control the complex interplay between catalyst surface structure, electrolyte composition, and operating conditions that collectively determine reaction pathways and product distributions. This fundamental understanding is crucial for rational catalyst design and system optimization.

From an environmental perspective, the technology aims to achieve a net reduction in carbon emissions when considering the entire life cycle, including catalyst production and energy inputs. The ideal scenario involves powering CO2RR systems with renewable electricity, creating a sustainable carbon cycle that helps mitigate climate change while producing valuable chemical feedstocks.

The ultimate goal extends beyond laboratory demonstrations to commercial deployment, requiring advances in catalyst performance, system engineering, and process integration. Success will be measured not only by technical metrics but also by economic viability compared to conventional production methods for chemicals and fuels.

Market Analysis for CO2 Conversion Technologies

The global market for CO2 conversion technologies is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions. The market size for carbon capture, utilization, and storage (CCUS) technologies was valued at approximately $1.9 billion in 2020 and is projected to reach $3.5 billion by 2025, growing at a CAGR of 13.2%. Electrocatalytic CO2 reduction represents a promising segment within this broader market.

Industrial sectors including power generation, cement production, and chemical manufacturing are primary targets for CO2 conversion technologies, collectively accounting for over 60% of global CO2 emissions. These industries face mounting pressure from carbon pricing mechanisms and emissions regulations, creating strong market pull for effective CO2 reduction solutions.

Regionally, North America and Europe lead in technology adoption, with substantial government funding supporting research and commercialization efforts. The European Union's Green Deal and carbon neutrality targets have established a favorable market environment, while China's recent climate commitments have accelerated market development in Asia-Pacific regions.

Venture capital investment in CO2 conversion startups has surged, with funding exceeding $1.4 billion in 2021 alone. This represents a threefold increase compared to 2018 figures, indicating strong investor confidence in the sector's growth potential. Companies developing selective catalysts for high-value chemical production from CO2 have attracted particular interest.

Market segmentation reveals distinct application areas: conversion to fuels (methanol, syngas), chemicals (formic acid, ethylene), and materials (polymers, carbonates). The chemicals segment shows the highest growth potential due to higher margins and established market channels. Products with demonstrated carbon reduction benefits command premium pricing in environmentally conscious markets.

Customer willingness to pay for green products varies significantly by sector. Consumer-facing industries demonstrate up to 15% premium acceptance for carbon-neutral products, while industrial customers remain more price-sensitive, typically accepting premiums under 5% unless regulatory compliance is involved.

Key market barriers include high capital costs for electrocatalytic systems, energy efficiency challenges, and competition from established fossil-based production routes. However, declining renewable electricity costs are improving the economic viability of electrocatalytic approaches, with production cost parity projected within 5-7 years for certain high-value chemicals.

Industrial sectors including power generation, cement production, and chemical manufacturing are primary targets for CO2 conversion technologies, collectively accounting for over 60% of global CO2 emissions. These industries face mounting pressure from carbon pricing mechanisms and emissions regulations, creating strong market pull for effective CO2 reduction solutions.

Regionally, North America and Europe lead in technology adoption, with substantial government funding supporting research and commercialization efforts. The European Union's Green Deal and carbon neutrality targets have established a favorable market environment, while China's recent climate commitments have accelerated market development in Asia-Pacific regions.

Venture capital investment in CO2 conversion startups has surged, with funding exceeding $1.4 billion in 2021 alone. This represents a threefold increase compared to 2018 figures, indicating strong investor confidence in the sector's growth potential. Companies developing selective catalysts for high-value chemical production from CO2 have attracted particular interest.

Market segmentation reveals distinct application areas: conversion to fuels (methanol, syngas), chemicals (formic acid, ethylene), and materials (polymers, carbonates). The chemicals segment shows the highest growth potential due to higher margins and established market channels. Products with demonstrated carbon reduction benefits command premium pricing in environmentally conscious markets.

Customer willingness to pay for green products varies significantly by sector. Consumer-facing industries demonstrate up to 15% premium acceptance for carbon-neutral products, while industrial customers remain more price-sensitive, typically accepting premiums under 5% unless regulatory compliance is involved.

Key market barriers include high capital costs for electrocatalytic systems, energy efficiency challenges, and competition from established fossil-based production routes. However, declining renewable electricity costs are improving the economic viability of electrocatalytic approaches, with production cost parity projected within 5-7 years for certain high-value chemicals.

Current Electrocatalytic CO2 Reduction Challenges

Despite significant advancements in electrocatalytic CO2 reduction reaction (CO2RR) technologies, several critical challenges continue to impede widespread commercial implementation. The primary obstacle remains the low energy efficiency of the process, with current systems typically achieving only 30-50% Faradaic efficiency for valuable products like ethylene and ethanol. This inefficiency stems from competing hydrogen evolution reactions that consume electrons without contributing to carbon conversion.

Selectivity presents another major hurdle, as CO2RR pathways can lead to numerous products including carbon monoxide, formate, methane, ethylene, ethanol, and other C2+ compounds. Most catalysts fail to achieve product selectivity above 80% for any single product, complicating downstream separation processes and reducing economic viability. The inability to precisely control reaction pathways results in product mixtures that require energy-intensive separation.

Catalyst stability under reaction conditions represents a significant technical barrier. Many promising materials, particularly copper-based catalysts that show high activity for C2+ products, suffer from degradation mechanisms including surface reconstruction, poisoning, and leaching during extended operation. Current benchmark systems typically demonstrate stability for only 100-200 hours, far below the thousands of hours required for industrial applications.

Mass transport limitations significantly constrain reaction rates in existing systems. The low solubility of CO2 in aqueous electrolytes (approximately 33 mM at ambient conditions) creates concentration gradients near catalyst surfaces, while the formation of bicarbonate and carbonate species further complicates reactant delivery. These factors limit achievable current densities to typically below 200 mA/cm², whereas commercial viability likely requires 500+ mA/cm².

Scale-up challenges persist in translating laboratory results to industrial applications. Most high-performance catalysts have been demonstrated only at the milligram scale in small electrochemical cells, while industrial implementation would require kilogram quantities in stack configurations. The gap between laboratory performance and industrial requirements remains substantial.

Economic barriers compound these technical challenges. Current CO2RR systems produce carbon-based products at costs significantly higher than conventional petrochemical routes. The capital expenditure for electrolyzer systems, coupled with high electricity costs and low product values, creates unfavorable economics that require either carbon pricing mechanisms or premium markets to overcome.

Selectivity presents another major hurdle, as CO2RR pathways can lead to numerous products including carbon monoxide, formate, methane, ethylene, ethanol, and other C2+ compounds. Most catalysts fail to achieve product selectivity above 80% for any single product, complicating downstream separation processes and reducing economic viability. The inability to precisely control reaction pathways results in product mixtures that require energy-intensive separation.

Catalyst stability under reaction conditions represents a significant technical barrier. Many promising materials, particularly copper-based catalysts that show high activity for C2+ products, suffer from degradation mechanisms including surface reconstruction, poisoning, and leaching during extended operation. Current benchmark systems typically demonstrate stability for only 100-200 hours, far below the thousands of hours required for industrial applications.

Mass transport limitations significantly constrain reaction rates in existing systems. The low solubility of CO2 in aqueous electrolytes (approximately 33 mM at ambient conditions) creates concentration gradients near catalyst surfaces, while the formation of bicarbonate and carbonate species further complicates reactant delivery. These factors limit achievable current densities to typically below 200 mA/cm², whereas commercial viability likely requires 500+ mA/cm².

Scale-up challenges persist in translating laboratory results to industrial applications. Most high-performance catalysts have been demonstrated only at the milligram scale in small electrochemical cells, while industrial implementation would require kilogram quantities in stack configurations. The gap between laboratory performance and industrial requirements remains substantial.

Economic barriers compound these technical challenges. Current CO2RR systems produce carbon-based products at costs significantly higher than conventional petrochemical routes. The capital expenditure for electrolyzer systems, coupled with high electricity costs and low product values, creates unfavorable economics that require either carbon pricing mechanisms or premium markets to overcome.

State-of-the-Art Catalyst Design Approaches

01 Catalyst composition for enhanced CO2 reduction selectivity

Various catalyst compositions can significantly improve the selectivity of electrocatalytic CO2 reduction reactions. These catalysts include metal-based materials, alloys, and nanostructured materials that can selectively produce specific carbon products while minimizing competing hydrogen evolution reactions. The composition of these catalysts plays a crucial role in determining which carbon products (CO, formate, hydrocarbons, alcohols) are preferentially formed during the reduction process.- Catalyst composition for enhanced CO2 reduction selectivity: Various catalyst compositions can significantly improve the selectivity of electrocatalytic CO2 reduction reactions. These catalysts include metal-based materials, alloys, and nanostructured materials that can selectively produce specific carbon products like CO, formate, or hydrocarbons. The composition of these catalysts directly influences which carbon products are formed during the reduction process, allowing for targeted production of valuable chemicals.

- Reaction rate enhancement through electrode design: The design and structure of electrodes play a crucial role in determining the reaction rates of electrocatalytic CO2 reduction. Factors such as surface area, porosity, and morphology can significantly enhance the catalytic activity and increase reaction rates. Advanced electrode designs that optimize mass transport and electron transfer can overcome kinetic limitations, resulting in higher current densities and improved overall performance of CO2 reduction systems.

- Electrolyte composition effects on reaction pathways: The composition of the electrolyte solution significantly impacts both the reaction rates and product selectivity in CO2 electroreduction. Parameters such as pH, ionic strength, and specific ions present can alter reaction pathways and influence the formation of different products. Tailored electrolyte formulations can suppress competing hydrogen evolution reactions and promote desired CO2 reduction pathways, thereby enhancing overall efficiency and selectivity.

- Operating conditions optimization for selectivity control: Operating conditions such as applied potential, temperature, pressure, and CO2 concentration significantly affect the selectivity and rates of electrocatalytic CO2 reduction. Precise control of these parameters allows for directing the reaction toward specific products and optimizing reaction kinetics. Systematic optimization of these conditions can lead to enhanced Faradaic efficiency, higher current densities, and improved selectivity toward valuable carbon products.

- Novel reactor designs for improved mass transfer: Innovative reactor designs can overcome mass transfer limitations that typically constrain CO2 reduction reaction rates. These designs include flow cells, gas diffusion electrodes, and microfluidic systems that enhance CO2 delivery to catalytic sites. By improving the mass transfer of reactants and products, these reactor configurations can significantly increase reaction rates, maintain high selectivity, and enable more efficient large-scale implementation of electrocatalytic CO2 reduction processes.

02 Electrode structure and morphology effects on reaction rates

The physical structure and morphology of electrodes significantly impact the reaction rates in electrocatalytic CO2 reduction. Factors such as porosity, surface area, defect sites, and crystallographic orientation can enhance mass transport, increase active site density, and improve electron transfer kinetics. Nanostructured electrodes with optimized morphologies can achieve higher current densities and faster conversion rates compared to conventional flat electrodes.Expand Specific Solutions03 Electrolyte composition and reaction environment optimization

The composition of the electrolyte and the reaction environment significantly influence both reaction rates and product selectivity in CO2 electroreduction. Parameters such as pH, ionic strength, buffer capacity, and the presence of specific ions can alter the local reaction environment at the electrode-electrolyte interface. Optimizing these conditions can suppress competing reactions, stabilize reaction intermediates, and enhance the formation of desired products.Expand Specific Solutions04 Process parameters and operating conditions

Operating conditions such as applied potential, current density, temperature, pressure, and CO2 concentration significantly affect the performance of electrocatalytic CO2 reduction. These parameters can be tuned to optimize reaction rates and product selectivity. Higher pressures can increase CO2 solubility and availability at the electrode surface, while temperature affects both reaction kinetics and thermodynamics. The applied potential determines which reaction pathways are energetically favorable.Expand Specific Solutions05 Reactor design and system integration for improved performance

Advanced reactor designs and integrated systems can significantly enhance the efficiency of electrocatalytic CO2 reduction. Innovations include flow-cell configurations, gas diffusion electrodes, membrane electrode assemblies, and microfluidic reactors that improve mass transport limitations and reaction kinetics. These designs can address challenges such as CO2 solubility limitations, product crossover, and ohmic losses, leading to higher reaction rates and better control over product selectivity.Expand Specific Solutions

Leading Research Groups and Industrial Players

The electrocatalytic CO2 reduction reaction (CO2RR) market is currently in a growth phase, with increasing research momentum and early commercial applications emerging. The global market size for CO2 conversion technologies is projected to reach $1.5-2 billion by 2025, driven by decarbonization initiatives. Technologically, the field remains in early-to-mid maturity, with significant advances in catalyst design and selectivity. Leading academic institutions (MIT, Caltech, University of Toronto, Kyushu University) are pioneering fundamental research, while energy corporations (TotalEnergies, Saudi Aramco) are scaling applications. Industrial players like Siemens Energy and Ballard Power Systems are developing integrated systems for commercial deployment. Research collaborations between CNRS, KIST, and Chinese institutions (Tianjin University, Dalian Institute) are accelerating catalyst development, while startups like Liquid Sun Oy represent emerging commercial innovation in e-fuels production from CO2.

TotalEnergies SE

Technical Solution: TotalEnergies has developed a comprehensive approach to electrocatalytic CO2 reduction focusing on industrial scalability and integration with existing energy infrastructure. Their technology platform centers on copper-based catalysts modified with secondary metals and promoters to enhance selectivity toward C2+ products like ethylene and ethanol. The company has engineered specialized gas diffusion electrodes with optimized hydrophobicity profiles that maintain stable three-phase boundaries during extended operation. A distinguishing feature of TotalEnergies' approach is their membrane electrode assembly (MEA) design that enables high current density operation (>200 mA/cm²) while minimizing ohmic losses. Their system architecture incorporates innovative CO2 capture and concentration technologies directly integrated with the electrolyzer stack, creating a more energy-efficient overall process. TotalEnergies has also developed proprietary electrolyte formulations that suppress the competing hydrogen evolution reaction while enhancing CO2 activation, achieving Faradaic efficiencies exceeding 70% for target products under industrially relevant conditions.

Strengths: Strong focus on industrial scalability and system integration; robust engineering approach to electrode and cell design; extensive experience with large-scale electrochemical processes. Weaknesses: May prioritize practical solutions over fundamental breakthroughs; corporate R&D sometimes faces longer development timelines due to commercial validation requirements.

Dalian Institute of Chemical Physics of CAS

Technical Solution: The Dalian Institute has pioneered advanced catalyst design strategies for electrocatalytic CO2 reduction with exceptional selectivity control. Their approach centers on atomic-level engineering of catalyst surfaces, particularly using single-atom catalysts (SACs) where isolated metal atoms are anchored on conductive supports like nitrogen-doped carbon. These SACs provide uniform active sites with precisely tuned electronic structures, achieving CO selectivities exceeding 95% with low overpotentials. The institute has developed innovative synthesis methods for creating hierarchically porous catalysts that optimize mass transport while maximizing active site density. Their research includes novel in-situ characterization techniques that reveal reaction intermediates and pathways under operating conditions. A significant contribution is their development of tandem catalytic systems where CO2 is reduced sequentially on different catalyst sites, enabling formation of more complex products like ethanol and propanol with enhanced selectivity. The institute has also made breakthroughs in understanding the critical role of the catalyst-electrolyte interface, developing strategies to manipulate the local pH and ion concentrations to favor specific reaction pathways.

Strengths: Exceptional capabilities in advanced catalyst synthesis and characterization; strong fundamental understanding of reaction mechanisms; excellent control over catalyst structure at atomic level. Weaknesses: Some highly specialized catalyst preparation methods may face challenges in large-scale manufacturing; focus sometimes prioritizes academic novelty over practical implementation.

Key Patents and Breakthroughs in Electrocatalysis

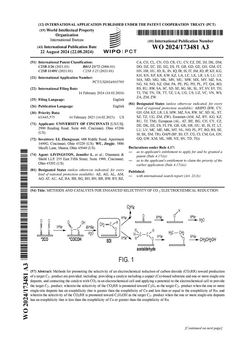

Methods and catalysts for enhanced selectivity of co 2 electrochemical reduction

PatentWO2024173481A3

Innovation

- Selective control of CO2 electrochemical reduction products (C2H4 or C2H5OH) through precise tuning of catalyst dopant oxophilicity relative to copper.

- Development of single-site dopant strategy on copper-based substrates to direct product formation pathways in CO2RR.

- Establishment of a structure-property relationship between dopant oxophilicity and C2+ product selectivity in CO2 electroreduction.

Techno-economic Assessment of CO2 Reduction Systems

The techno-economic assessment of CO2 reduction systems requires a comprehensive analysis of both technical performance and economic viability. Current electrocatalytic CO2 reduction technologies demonstrate promising laboratory results but face significant challenges in commercial implementation. Capital costs for these systems range from $500-2,000/kW depending on system complexity and materials used, with noble metal catalysts substantially increasing expenses compared to earth-abundant alternatives.

Operating costs are dominated by electricity consumption, typically requiring 6-15 kWh per kg of CO2 converted, representing 60-75% of total operational expenses. The economic viability threshold currently stands at approximately $50-70 per ton of CO2 processed, significantly higher than conventional carbon capture methods. However, this calculation changes dramatically when considering the value of reduction products such as carbon monoxide, formic acid, ethylene, or methanol.

Energy efficiency remains a critical economic factor, with current systems achieving 30-65% faradaic efficiency for target products. Each percentage point improvement in efficiency translates to approximately 3-5% reduction in operational costs. System durability presents another economic challenge, with catalyst degradation occurring after 1,000-5,000 hours of operation, necessitating replacement costs that significantly impact long-term economics.

Scale-up considerations reveal that while laboratory systems operate at 10-100 cm² active areas, commercial viability requires scaling to several square meters while maintaining performance metrics. This scale-up typically introduces a 20-40% efficiency penalty that must be factored into economic models.

Market analysis indicates that CO2 reduction products must compete with conventional production routes, with current cost premiums of 1.5-3x over traditional methods. However, carbon pricing mechanisms, renewable energy integration, and regulatory frameworks are rapidly evolving factors that could substantially improve the economic equation.

Sensitivity analysis reveals that electricity costs, system durability, and product selectivity are the most influential parameters affecting economic viability. A 10% decrease in electricity costs or 10% increase in system lifetime can improve economic returns by approximately 7-12%, highlighting key areas for technological development to enhance commercial feasibility.

Operating costs are dominated by electricity consumption, typically requiring 6-15 kWh per kg of CO2 converted, representing 60-75% of total operational expenses. The economic viability threshold currently stands at approximately $50-70 per ton of CO2 processed, significantly higher than conventional carbon capture methods. However, this calculation changes dramatically when considering the value of reduction products such as carbon monoxide, formic acid, ethylene, or methanol.

Energy efficiency remains a critical economic factor, with current systems achieving 30-65% faradaic efficiency for target products. Each percentage point improvement in efficiency translates to approximately 3-5% reduction in operational costs. System durability presents another economic challenge, with catalyst degradation occurring after 1,000-5,000 hours of operation, necessitating replacement costs that significantly impact long-term economics.

Scale-up considerations reveal that while laboratory systems operate at 10-100 cm² active areas, commercial viability requires scaling to several square meters while maintaining performance metrics. This scale-up typically introduces a 20-40% efficiency penalty that must be factored into economic models.

Market analysis indicates that CO2 reduction products must compete with conventional production routes, with current cost premiums of 1.5-3x over traditional methods. However, carbon pricing mechanisms, renewable energy integration, and regulatory frameworks are rapidly evolving factors that could substantially improve the economic equation.

Sensitivity analysis reveals that electricity costs, system durability, and product selectivity are the most influential parameters affecting economic viability. A 10% decrease in electricity costs or 10% increase in system lifetime can improve economic returns by approximately 7-12%, highlighting key areas for technological development to enhance commercial feasibility.

Environmental Impact and Carbon Neutrality Implications

Electrocatalytic CO2 reduction reaction (CO2RR) represents a pivotal technology in addressing global climate change challenges. The environmental implications of advancing this technology extend far beyond laboratory efficiency metrics, potentially transforming our approach to carbon management on an industrial scale.

The successful implementation of enhanced CO2RR systems offers a dual environmental benefit: reducing atmospheric CO2 concentrations while simultaneously producing valuable carbon-based products. This carbon-negative or carbon-neutral pathway aligns perfectly with international climate agreements and corporate sustainability goals. Current estimates suggest that optimized CO2RR technologies could contribute to reducing global carbon emissions by 5-8% by 2050 if deployed at industrial scale.

When evaluating the environmental footprint of CO2RR technologies, life cycle assessment (LCA) studies reveal complex trade-offs. While the process consumes electricity, the net environmental impact remains positive when powered by renewable energy sources. Recent analyses demonstrate that CO2RR systems utilizing solar or wind power can achieve carbon neutrality within 1.5-3 years of operation, depending on catalyst efficiency and system design.

Water consumption represents another critical environmental consideration. Advanced CO2RR systems typically require 3-7 liters of water per kilogram of CO2 processed, significantly lower than comparable carbon capture technologies. However, water quality impacts from catalyst degradation and electrolyte disposal require careful management to prevent secondary environmental contamination.

The carbon neutrality implications extend to industrial sectors previously considered difficult to decarbonize. Chemical manufacturing, metallurgy, and cement production could potentially integrate CO2RR technologies to create closed-loop carbon systems. This integration could reduce these industries' carbon footprints by 30-45% according to recent modeling studies, while maintaining production capacity.

Land use considerations also factor into environmental impact assessments. Unlike biofuel approaches to carbon neutrality, CO2RR systems have minimal land requirements, typically occupying less than 5% of the area needed for equivalent biofuel production. This advantage becomes particularly significant when considering scaling to industrial levels.

The potential for CO2RR to contribute to circular economy models represents perhaps its most profound environmental implication. By converting waste CO2 into chemical feedstocks that replace petroleum-derived alternatives, these systems could fundamentally reshape industrial carbon flows, transitioning from linear extraction-production-disposal models toward regenerative cycles that minimize environmental degradation while supporting economic growth.

The successful implementation of enhanced CO2RR systems offers a dual environmental benefit: reducing atmospheric CO2 concentrations while simultaneously producing valuable carbon-based products. This carbon-negative or carbon-neutral pathway aligns perfectly with international climate agreements and corporate sustainability goals. Current estimates suggest that optimized CO2RR technologies could contribute to reducing global carbon emissions by 5-8% by 2050 if deployed at industrial scale.

When evaluating the environmental footprint of CO2RR technologies, life cycle assessment (LCA) studies reveal complex trade-offs. While the process consumes electricity, the net environmental impact remains positive when powered by renewable energy sources. Recent analyses demonstrate that CO2RR systems utilizing solar or wind power can achieve carbon neutrality within 1.5-3 years of operation, depending on catalyst efficiency and system design.

Water consumption represents another critical environmental consideration. Advanced CO2RR systems typically require 3-7 liters of water per kilogram of CO2 processed, significantly lower than comparable carbon capture technologies. However, water quality impacts from catalyst degradation and electrolyte disposal require careful management to prevent secondary environmental contamination.

The carbon neutrality implications extend to industrial sectors previously considered difficult to decarbonize. Chemical manufacturing, metallurgy, and cement production could potentially integrate CO2RR technologies to create closed-loop carbon systems. This integration could reduce these industries' carbon footprints by 30-45% according to recent modeling studies, while maintaining production capacity.

Land use considerations also factor into environmental impact assessments. Unlike biofuel approaches to carbon neutrality, CO2RR systems have minimal land requirements, typically occupying less than 5% of the area needed for equivalent biofuel production. This advantage becomes particularly significant when considering scaling to industrial levels.

The potential for CO2RR to contribute to circular economy models represents perhaps its most profound environmental implication. By converting waste CO2 into chemical feedstocks that replace petroleum-derived alternatives, these systems could fundamentally reshape industrial carbon flows, transitioning from linear extraction-production-disposal models toward regenerative cycles that minimize environmental degradation while supporting economic growth.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!