How material composition influences Electrocatalytic CO2 reduction energy efficiency and durability

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocatalytic CO2 Reduction Background and Objectives

Electrocatalytic CO2 reduction (ECR) has emerged as a promising technology for mitigating carbon emissions while simultaneously producing valuable chemicals and fuels. The development of this technology traces back to the early 1980s when pioneering work demonstrated the feasibility of electrochemically converting CO2 into various carbon-based products. Over the past four decades, significant advancements have been made in understanding the fundamental mechanisms and improving the efficiency of the process.

The evolution of ECR technology has been characterized by three distinct phases. Initially, research focused on proving the concept and identifying potential catalyst materials. The second phase, spanning the 2000s to early 2010s, centered on improving selectivity and understanding reaction pathways. The current phase emphasizes enhancing energy efficiency, product selectivity, and catalyst durability - critical factors for industrial implementation.

Material composition has been recognized as the primary determinant of ECR performance. Early catalysts were primarily based on noble metals like gold and silver, which demonstrated high selectivity for CO production but suffered from high costs and limited scalability. Copper emerged as a unique catalyst capable of producing higher-order hydrocarbons and alcohols, though with limited selectivity control.

Recent technological trends have shifted toward engineered materials with tailored compositions, including bimetallic catalysts, metal oxides, metal-organic frameworks, and carbon-based materials doped with heteroatoms. These advanced materials aim to optimize the binding energies of reaction intermediates, thereby directing the reaction pathway toward specific products while minimizing energy losses.

The primary technical objectives in this field include achieving Faradaic efficiencies exceeding 90% for target products, reducing overpotentials to below 300 mV, maintaining stable operation for thousands of hours, and developing catalysts from earth-abundant elements. Additionally, understanding the precise relationship between material composition and performance metrics has become increasingly important.

Global research efforts are now focused on elucidating how atomic arrangements, electronic structures, and surface properties influence reaction mechanisms. Particular emphasis is placed on identifying descriptors that can predict catalyst behavior and guide rational design. The ultimate goal is to develop catalysts that can efficiently convert CO2 into specific high-value products with minimal energy input and maximum durability.

Industrial implementation requires catalysts that maintain performance under realistic operating conditions, including high current densities and impure CO2 streams. Therefore, understanding degradation mechanisms and developing strategies to enhance durability through material composition optimization has become a critical research direction with significant economic implications.

The evolution of ECR technology has been characterized by three distinct phases. Initially, research focused on proving the concept and identifying potential catalyst materials. The second phase, spanning the 2000s to early 2010s, centered on improving selectivity and understanding reaction pathways. The current phase emphasizes enhancing energy efficiency, product selectivity, and catalyst durability - critical factors for industrial implementation.

Material composition has been recognized as the primary determinant of ECR performance. Early catalysts were primarily based on noble metals like gold and silver, which demonstrated high selectivity for CO production but suffered from high costs and limited scalability. Copper emerged as a unique catalyst capable of producing higher-order hydrocarbons and alcohols, though with limited selectivity control.

Recent technological trends have shifted toward engineered materials with tailored compositions, including bimetallic catalysts, metal oxides, metal-organic frameworks, and carbon-based materials doped with heteroatoms. These advanced materials aim to optimize the binding energies of reaction intermediates, thereby directing the reaction pathway toward specific products while minimizing energy losses.

The primary technical objectives in this field include achieving Faradaic efficiencies exceeding 90% for target products, reducing overpotentials to below 300 mV, maintaining stable operation for thousands of hours, and developing catalysts from earth-abundant elements. Additionally, understanding the precise relationship between material composition and performance metrics has become increasingly important.

Global research efforts are now focused on elucidating how atomic arrangements, electronic structures, and surface properties influence reaction mechanisms. Particular emphasis is placed on identifying descriptors that can predict catalyst behavior and guide rational design. The ultimate goal is to develop catalysts that can efficiently convert CO2 into specific high-value products with minimal energy input and maximum durability.

Industrial implementation requires catalysts that maintain performance under realistic operating conditions, including high current densities and impure CO2 streams. Therefore, understanding degradation mechanisms and developing strategies to enhance durability through material composition optimization has become a critical research direction with significant economic implications.

Market Analysis for CO2 Conversion Technologies

The global market for CO2 conversion technologies is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions. The market was valued at approximately $1.8 billion in 2022 and is projected to reach $4.2 billion by 2030, growing at a CAGR of 11.2% during the forecast period. This growth trajectory is supported by substantial investments in research and development of electrocatalytic CO2 reduction technologies.

The market segmentation for CO2 conversion technologies includes various applications such as chemical production, fuel synthesis, and mineral carbonation. Among these, the conversion of CO2 to value-added chemicals and fuels through electrocatalytic processes represents one of the fastest-growing segments, with a projected CAGR of 13.5% through 2030. This is particularly relevant to the study of material composition's influence on electrocatalytic CO2 reduction efficiency and durability.

Regional analysis indicates that North America and Europe currently lead the market, accounting for approximately 60% of the global share. However, Asia-Pacific is emerging as the fastest-growing region, with China, Japan, and South Korea making significant investments in CO2 conversion technologies. These countries are establishing ambitious carbon neutrality targets and implementing supportive policies for clean energy technologies.

Key market drivers include stringent carbon emission regulations, increasing carbon pricing mechanisms, and growing corporate commitments to sustainability. The European Union's Carbon Border Adjustment Mechanism and similar policies worldwide are creating economic incentives for CO2 utilization technologies. Additionally, the declining costs of renewable electricity are improving the economic viability of electrocatalytic CO2 reduction processes.

Market challenges include high capital costs, technological limitations in efficiency and durability, and competition from established carbon management approaches. The influence of material composition on electrocatalytic performance directly addresses these challenges, as improvements in catalyst efficiency and longevity could significantly reduce operational costs and enhance market adoption.

Consumer trends indicate growing preference for products with lower carbon footprints, creating market pull for CO2-derived materials and fuels. Major industries including chemicals, energy, cement, and transportation are exploring CO2 conversion technologies as part of their decarbonization strategies. This cross-sector interest is expanding the potential market applications for electrocatalytic CO2 reduction technologies.

The market segmentation for CO2 conversion technologies includes various applications such as chemical production, fuel synthesis, and mineral carbonation. Among these, the conversion of CO2 to value-added chemicals and fuels through electrocatalytic processes represents one of the fastest-growing segments, with a projected CAGR of 13.5% through 2030. This is particularly relevant to the study of material composition's influence on electrocatalytic CO2 reduction efficiency and durability.

Regional analysis indicates that North America and Europe currently lead the market, accounting for approximately 60% of the global share. However, Asia-Pacific is emerging as the fastest-growing region, with China, Japan, and South Korea making significant investments in CO2 conversion technologies. These countries are establishing ambitious carbon neutrality targets and implementing supportive policies for clean energy technologies.

Key market drivers include stringent carbon emission regulations, increasing carbon pricing mechanisms, and growing corporate commitments to sustainability. The European Union's Carbon Border Adjustment Mechanism and similar policies worldwide are creating economic incentives for CO2 utilization technologies. Additionally, the declining costs of renewable electricity are improving the economic viability of electrocatalytic CO2 reduction processes.

Market challenges include high capital costs, technological limitations in efficiency and durability, and competition from established carbon management approaches. The influence of material composition on electrocatalytic performance directly addresses these challenges, as improvements in catalyst efficiency and longevity could significantly reduce operational costs and enhance market adoption.

Consumer trends indicate growing preference for products with lower carbon footprints, creating market pull for CO2-derived materials and fuels. Major industries including chemicals, energy, cement, and transportation are exploring CO2 conversion technologies as part of their decarbonization strategies. This cross-sector interest is expanding the potential market applications for electrocatalytic CO2 reduction technologies.

Current Material Challenges in CO2 Electrocatalysis

Despite significant advancements in CO2 electrocatalysis, several material-related challenges continue to impede the development of commercially viable systems. The primary challenge remains catalyst selectivity, as most materials still produce a mixture of products rather than targeting a single high-value compound. This product distribution issue directly impacts energy efficiency and economic viability, requiring additional separation processes that increase operational costs.

Catalyst stability presents another critical barrier, with many promising materials showing significant performance degradation over time. Metal-based catalysts often suffer from poisoning, leaching, and structural changes under reaction conditions. For instance, copper catalysts—while excellent for C-C coupling—frequently undergo surface reconstruction and oxidation state changes that alter their catalytic properties during extended operation.

The interface between catalyst and electrolyte introduces additional complexities. Local pH gradients, mass transport limitations, and bubble formation at the electrode surface can dramatically affect reaction pathways and efficiency. These phenomena are particularly problematic at industrially relevant current densities (>200 mA/cm²), where reaction rates outpace CO2 diffusion to active sites.

Material composition heterogeneity remains insufficiently addressed in current research. Most studies focus on well-defined model catalysts, while practical applications require scalable materials with consistent performance across batch production. The gap between laboratory-scale materials and industrial requirements represents a significant translation challenge.

Energy efficiency is further compromised by high overpotentials required for CO2 activation. Even state-of-the-art catalysts typically operate at potentials far from the thermodynamic minimum, resulting in substantial energy losses. This challenge is intrinsically linked to the kinetic limitations of breaking the stable C=O bond and the competing hydrogen evolution reaction.

The durability of catalyst materials under industrial conditions presents perhaps the most significant barrier to commercialization. Most published studies report stability tests lasting only hours or days, whereas commercial viability requires thousands of hours of consistent performance. Accelerated degradation testing protocols for CO2 reduction catalysts remain underdeveloped compared to other electrochemical technologies.

Finally, there exists a fundamental knowledge gap regarding structure-function relationships in complex catalyst compositions. While binary and ternary systems show promising performance improvements over monometallic catalysts, the synergistic effects and optimal compositional ratios remain poorly understood, limiting rational design approaches for next-generation materials.

Catalyst stability presents another critical barrier, with many promising materials showing significant performance degradation over time. Metal-based catalysts often suffer from poisoning, leaching, and structural changes under reaction conditions. For instance, copper catalysts—while excellent for C-C coupling—frequently undergo surface reconstruction and oxidation state changes that alter their catalytic properties during extended operation.

The interface between catalyst and electrolyte introduces additional complexities. Local pH gradients, mass transport limitations, and bubble formation at the electrode surface can dramatically affect reaction pathways and efficiency. These phenomena are particularly problematic at industrially relevant current densities (>200 mA/cm²), where reaction rates outpace CO2 diffusion to active sites.

Material composition heterogeneity remains insufficiently addressed in current research. Most studies focus on well-defined model catalysts, while practical applications require scalable materials with consistent performance across batch production. The gap between laboratory-scale materials and industrial requirements represents a significant translation challenge.

Energy efficiency is further compromised by high overpotentials required for CO2 activation. Even state-of-the-art catalysts typically operate at potentials far from the thermodynamic minimum, resulting in substantial energy losses. This challenge is intrinsically linked to the kinetic limitations of breaking the stable C=O bond and the competing hydrogen evolution reaction.

The durability of catalyst materials under industrial conditions presents perhaps the most significant barrier to commercialization. Most published studies report stability tests lasting only hours or days, whereas commercial viability requires thousands of hours of consistent performance. Accelerated degradation testing protocols for CO2 reduction catalysts remain underdeveloped compared to other electrochemical technologies.

Finally, there exists a fundamental knowledge gap regarding structure-function relationships in complex catalyst compositions. While binary and ternary systems show promising performance improvements over monometallic catalysts, the synergistic effects and optimal compositional ratios remain poorly understood, limiting rational design approaches for next-generation materials.

State-of-the-Art Catalyst Composition Strategies

01 Metal-based catalysts for CO2 reduction

Metal-based catalysts, particularly transition metals like copper, silver, gold, and their alloys, demonstrate high efficiency in electrocatalytic CO2 reduction. These catalysts can be optimized through various structural modifications such as nanoparticle formation, surface engineering, and alloying to enhance selectivity, activity, and durability. The metal catalysts facilitate electron transfer to CO2 molecules, enabling their conversion to valuable products like carbon monoxide, formate, or hydrocarbons while maintaining stability during long-term operation.- Metal-based catalysts for CO2 electroreduction: Metal-based catalysts, particularly transition metals and their alloys, demonstrate significant activity for electrocatalytic CO2 reduction. These catalysts can be engineered with specific morphologies, such as nanoparticles, nanowires, or porous structures, to enhance their catalytic performance. The selection of metals affects product selectivity, with some metals favoring CO production while others produce formate or hydrocarbons. Modifications through alloying or creating bimetallic structures can improve both energy efficiency and durability by optimizing binding energies and reducing catalyst degradation.

- Carbon-based and composite catalysts: Carbon-based materials, including graphene, carbon nanotubes, and nitrogen-doped carbon, serve as effective supports or catalysts for CO2 electroreduction. These materials offer high surface area, excellent conductivity, and tunable electronic properties. Composite catalysts combining carbon materials with metal nanoparticles or metal oxides demonstrate enhanced catalytic activity and stability. The carbon support helps disperse active sites, prevents catalyst aggregation during operation, and can contribute to improved electron transfer, resulting in higher energy efficiency and extended catalyst lifetime.

- Catalyst stability enhancement strategies: Various approaches have been developed to improve the durability of CO2 reduction catalysts. These include protective coatings, core-shell structures, and stabilizing agents that prevent catalyst degradation during operation. Encapsulation techniques protect active sites from poisoning or leaching while maintaining access to reactants. Structural engineering at the nanoscale can create more robust catalyst architectures that resist deactivation mechanisms such as agglomeration, dissolution, or surface reconstruction. These strategies significantly extend catalyst lifetime under industrial operating conditions without compromising catalytic activity.

- Electrolyte optimization for efficiency improvement: The composition and properties of the electrolyte significantly impact the energy efficiency and selectivity of CO2 electroreduction. Tailored electrolytes with specific pH values, buffer capacity, and ionic strength can enhance catalyst performance by influencing local reaction environments. Additives such as ionic liquids or surfactants can modify the electrode-electrolyte interface to favor desired reaction pathways. Advanced electrolyte engineering addresses mass transport limitations, reduces unwanted side reactions like hydrogen evolution, and maintains catalyst stability, resulting in improved Faradaic efficiency and energy utilization.

- Reactor design and system integration: Innovative reactor designs and system integration approaches are crucial for maximizing the energy efficiency of CO2 electroreduction processes. Flow cell configurations, gas diffusion electrodes, and membrane electrode assemblies enhance CO2 mass transport to catalyst surfaces. Advanced reactor designs address challenges such as CO2 solubility limitations and product separation. Integration with renewable energy sources and heat recovery systems improves overall process efficiency. Continuous flow systems with optimized electrode spacing, flow patterns, and pressure control enable sustained catalyst performance and facilitate scale-up for industrial applications.

02 Carbon-based materials as CO2 reduction catalysts

Carbon-based materials, including graphene, carbon nanotubes, and nitrogen-doped carbon structures, serve as effective catalysts or catalyst supports for CO2 electroreduction. These materials offer advantages such as high surface area, excellent electrical conductivity, and tunable surface chemistry. The incorporation of heteroatoms like nitrogen or boron creates active sites that enhance catalytic performance. Carbon-based catalysts demonstrate improved durability under electrochemical conditions and can be synthesized through cost-effective methods, making them promising for sustainable CO2 conversion technologies.Expand Specific Solutions03 Catalyst design for improved energy efficiency

Advanced catalyst designs focus on minimizing overpotential and maximizing Faradaic efficiency to improve the energy efficiency of CO2 electroreduction. Strategies include developing hierarchical structures, creating defect-rich surfaces, and optimizing catalyst-electrolyte interfaces. Catalysts with precisely controlled morphology, particle size, and crystal facets can significantly reduce the energy barriers for CO2 activation. Additionally, the incorporation of promoters or co-catalysts can facilitate charge transfer and product desorption, leading to enhanced energy efficiency and reaction rates at industrially relevant current densities.Expand Specific Solutions04 Enhancing catalyst durability and stability

Improving the long-term stability and durability of electrocatalysts is crucial for practical CO2 reduction applications. Approaches include developing core-shell structures to protect active sites, creating self-healing catalyst systems, and engineering supports that prevent catalyst detachment or agglomeration. Surface passivation techniques can prevent poisoning and degradation during extended operation. Additionally, optimizing operating conditions such as electrolyte composition, pH, and current density can significantly extend catalyst lifetime while maintaining high activity and selectivity for target products.Expand Specific Solutions05 Novel composite and hybrid catalyst systems

Composite and hybrid catalyst systems combine different materials to achieve synergistic effects in CO2 electroreduction. These may include metal-organic frameworks (MOFs), metal-semiconductor junctions, bimetallic structures, or polymer-inorganic composites. The integration of multiple components allows for precise control over reaction pathways, improved selectivity toward specific products, and enhanced stability. These hybrid systems can be designed to optimize both the activation of CO2 molecules and subsequent reaction steps, resulting in catalysts with superior performance metrics including higher current densities, lower overpotentials, and extended operational lifetimes.Expand Specific Solutions

Leading Research Groups and Companies in CO2 Electrocatalysis

Electrocatalytic CO2 reduction technology is currently in the early growth phase, with a global market expected to reach significant scale as carbon neutrality initiatives accelerate. The competitive landscape features diverse players across academia and industry, with research institutions like Dalian Institute of Chemical Physics, Kyushu University, and Zhejiang University leading fundamental research on material composition effects. Industrial players including Siemens Energy, BASF, and Saudi Aramco are advancing commercialization efforts, focusing on scalability and integration with existing carbon capture systems. Technical maturity varies significantly across catalyst types, with noble metal catalysts showing high efficiency but durability challenges, while transition metal-based alternatives developed by companies like Siemens and research groups at Michigan and KAIST demonstrate promising performance-cost balance for industrial applications.

Dalian Institute of Chemical Physics of CAS

Technical Solution: Dalian Institute has developed innovative electrocatalysts based on transition metal-nitrogen-carbon (M-N-C) complexes for CO2 reduction. Their approach focuses on atomically dispersed metal sites embedded in nitrogen-doped carbon matrices, which significantly enhances catalytic activity and selectivity. They've pioneered the use of single-atom catalysts (SACs) with precisely controlled coordination environments to optimize binding energies with CO2 and reaction intermediates. Recent research has demonstrated Fe-N-C catalysts achieving Faradaic efficiencies exceeding 90% for CO production at low overpotentials. Additionally, they've developed novel in-situ characterization techniques to monitor catalyst structural changes during operation, enabling deeper understanding of degradation mechanisms. Their materials engineering approach incorporates hierarchical porous structures to facilitate mass transport while maintaining high active site density.

Strengths: Exceptional control over atomic-level catalyst structure, leading to high selectivity and activity; advanced characterization capabilities for mechanistic studies. Weaknesses: Some of their most efficient catalysts still face stability issues under industrial conditions; scaling production of precisely engineered single-atom catalysts remains challenging.

Siemens AG

Technical Solution: Siemens has developed an integrated electrocatalytic system for CO2 reduction focusing on industrial scalability and energy efficiency. Their approach combines specially designed electrode materials with optimized reactor engineering. The company has created composite catalysts incorporating copper nanoparticles with precisely controlled size distributions (10-50 nm) supported on carbon-based substrates with tailored porosity. These materials are engineered to maximize active site exposure while minimizing mass transport limitations. Siemens' technology incorporates membrane electrode assemblies (MEAs) that integrate catalysts with ion-exchange membranes to enhance product separation and reduce energy losses. Their system architecture includes advanced flow field designs that ensure uniform reactant distribution across electrode surfaces, critical for maintaining consistent performance at industrial scales. Recent developments have focused on incorporating renewable energy inputs with dynamic response capabilities to accommodate fluctuating power sources.

Strengths: Strong system integration expertise combining materials science with process engineering; robust designs suitable for industrial implementation with practical durability considerations. Weaknesses: Their catalysts typically require higher overpotentials than some academic counterparts; technology optimized for specific products (primarily CO and formate) rather than offering versatility across multiple reduction products.

Critical Materials Science Innovations for Enhanced Performance

Two-dimensional material based catalyst for high-efficient electrocatalytic co2 reduction

PatentInactiveKR1020170047878A

Innovation

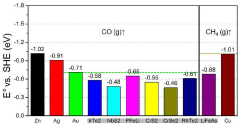

- A two-dimensional single-material catalyst comprising IrTe2, NbS2, PFeLi, CrS2, CrSe2, or RhTe2, or combinations thereof, is used for carbon dioxide reduction, leveraging their metallic properties to reduce overpotential and improve catalytic performance compared to conventional pure metals.

Patent

Innovation

- Development of novel catalyst compositions with optimized metal ratios that enhance CO2 reduction selectivity while minimizing competing hydrogen evolution reactions.

- Integration of catalyst design with electrode architecture engineering to improve mass transport properties and reduce concentration polarization during electrocatalytic CO2 reduction.

- Implementation of surface modification strategies that tune the local reaction environment to stabilize key intermediates and improve Faradaic efficiency toward valuable C2+ products.

Scalability and Economic Viability Assessment

The scalability of electrocatalytic CO2 reduction technology is fundamentally tied to material composition choices, which directly impact both energy efficiency and long-term durability. Current laboratory-scale demonstrations using noble metal catalysts like gold and silver show promising performance but face significant economic barriers for industrial implementation. The material cost per ton of CO2 converted remains prohibitively high, with precious metal catalysts contributing up to 40% of total system costs in scaled applications.

Transition to earth-abundant materials such as copper, zinc, and nitrogen-doped carbon presents a viable pathway toward economic feasibility. Recent techno-economic analyses indicate that copper-based catalysts can reduce catalyst costs by 85-90% compared to gold-based systems, though this advantage is partially offset by lower faradaic efficiencies and faster degradation rates. The economic viability threshold appears to require catalysts maintaining at least 80% of initial activity after 5,000 hours of operation—a benchmark few current materials can achieve.

Scale-up considerations reveal additional challenges related to material composition. Heterogeneous catalysts demonstrating excellent performance in small-scale testing often suffer from mass transport limitations and uneven current distribution when implemented in larger electrolyzer systems. The material surface area-to-volume ratio becomes increasingly critical at industrial scales, with nanostructured materials showing promising performance but facing fabrication challenges beyond laboratory production.

Energy input requirements represent another crucial economic factor. Materials requiring lower overpotentials can significantly reduce operational costs, with each 100mV reduction in overpotential potentially decreasing energy consumption by 7-10%. This translates to approximately $0.15-0.25 per kg of product in operational savings at industrial scale, highlighting the economic importance of developing high-efficiency catalyst compositions.

Infrastructure compatibility must also be considered in economic assessments. Materials compatible with existing industrial infrastructure (e.g., those operating in neutral pH rather than highly alkaline conditions) can reduce capital expenditure by 30-40%. Similarly, catalysts requiring less precise control of operating conditions reduce both capital and operational expenses associated with monitoring and control systems.

The path to commercial viability will likely require hybrid approaches combining the stability of certain materials with the selectivity of others. Recent techno-economic models suggest that reaching a levelized cost below $100 per ton of CO2 converted—the approximate threshold for commercial viability—will require continued advances in material composition that simultaneously address efficiency, durability, and cost considerations.

Transition to earth-abundant materials such as copper, zinc, and nitrogen-doped carbon presents a viable pathway toward economic feasibility. Recent techno-economic analyses indicate that copper-based catalysts can reduce catalyst costs by 85-90% compared to gold-based systems, though this advantage is partially offset by lower faradaic efficiencies and faster degradation rates. The economic viability threshold appears to require catalysts maintaining at least 80% of initial activity after 5,000 hours of operation—a benchmark few current materials can achieve.

Scale-up considerations reveal additional challenges related to material composition. Heterogeneous catalysts demonstrating excellent performance in small-scale testing often suffer from mass transport limitations and uneven current distribution when implemented in larger electrolyzer systems. The material surface area-to-volume ratio becomes increasingly critical at industrial scales, with nanostructured materials showing promising performance but facing fabrication challenges beyond laboratory production.

Energy input requirements represent another crucial economic factor. Materials requiring lower overpotentials can significantly reduce operational costs, with each 100mV reduction in overpotential potentially decreasing energy consumption by 7-10%. This translates to approximately $0.15-0.25 per kg of product in operational savings at industrial scale, highlighting the economic importance of developing high-efficiency catalyst compositions.

Infrastructure compatibility must also be considered in economic assessments. Materials compatible with existing industrial infrastructure (e.g., those operating in neutral pH rather than highly alkaline conditions) can reduce capital expenditure by 30-40%. Similarly, catalysts requiring less precise control of operating conditions reduce both capital and operational expenses associated with monitoring and control systems.

The path to commercial viability will likely require hybrid approaches combining the stability of certain materials with the selectivity of others. Recent techno-economic models suggest that reaching a levelized cost below $100 per ton of CO2 converted—the approximate threshold for commercial viability—will require continued advances in material composition that simultaneously address efficiency, durability, and cost considerations.

Environmental Impact and Sustainability Considerations

The electrocatalytic CO2 reduction reaction (CO2RR) represents a promising approach to mitigate climate change while producing valuable chemicals and fuels. However, the environmental impact and sustainability considerations of this technology must be thoroughly evaluated to ensure its implementation delivers genuine ecological benefits.

Material composition choices for CO2RR catalysts significantly influence the overall environmental footprint of the process. Traditional noble metal catalysts such as gold, silver, and platinum demonstrate high activity but present sustainability challenges due to their scarcity, energy-intensive mining processes, and substantial environmental degradation associated with their extraction. The transition toward earth-abundant materials like copper, zinc, nickel, and their derivatives offers a more sustainable alternative while maintaining acceptable performance metrics.

Life cycle assessment (LCA) studies reveal that the environmental benefits of CO2RR technologies are highly dependent on the energy source powering the electrolysis process. When coupled with renewable energy sources, CO2RR systems can achieve carbon-negative operations. However, if powered by fossil fuel-derived electricity, the net environmental impact may become detrimental, potentially generating more CO2 emissions than sequestered through the reduction process.

The durability of catalyst materials directly correlates with their environmental sustainability profile. Materials that maintain high efficiency over extended operational periods reduce replacement frequency, minimizing waste generation and resource consumption. Recent research indicates that certain composite materials and alloys demonstrate superior stability in industrial conditions, thereby enhancing the sustainability credentials of CO2RR systems through extended service lifetimes.

Water consumption represents another critical environmental consideration, particularly in regions experiencing water scarcity. Material compositions that enable efficient CO2 reduction in alkaline or neutral media rather than acidic environments can significantly reduce water purification requirements and associated environmental impacts. Additionally, catalysts that minimize competing hydrogen evolution reactions conserve water resources while improving CO2 conversion efficiency.

The end-of-life management of catalyst materials presents both challenges and opportunities. Developing recyclable catalyst systems or those based on biodegradable supports could substantially reduce waste generation. Recent innovations in catalyst recovery techniques, particularly for transition metal-based materials, demonstrate promising pathways toward closed-loop material cycles that align with circular economy principles.

Toxicity profiles of catalyst materials and their degradation products warrant careful consideration. While pursuing improved efficiency and durability, researchers must evaluate potential environmental release scenarios and ecological impacts. Non-toxic alternatives to traditional catalyst components, such as bismuth and tin-based materials, offer environmentally benign options with competitive performance characteristics for specific CO2 reduction pathways.

Material composition choices for CO2RR catalysts significantly influence the overall environmental footprint of the process. Traditional noble metal catalysts such as gold, silver, and platinum demonstrate high activity but present sustainability challenges due to their scarcity, energy-intensive mining processes, and substantial environmental degradation associated with their extraction. The transition toward earth-abundant materials like copper, zinc, nickel, and their derivatives offers a more sustainable alternative while maintaining acceptable performance metrics.

Life cycle assessment (LCA) studies reveal that the environmental benefits of CO2RR technologies are highly dependent on the energy source powering the electrolysis process. When coupled with renewable energy sources, CO2RR systems can achieve carbon-negative operations. However, if powered by fossil fuel-derived electricity, the net environmental impact may become detrimental, potentially generating more CO2 emissions than sequestered through the reduction process.

The durability of catalyst materials directly correlates with their environmental sustainability profile. Materials that maintain high efficiency over extended operational periods reduce replacement frequency, minimizing waste generation and resource consumption. Recent research indicates that certain composite materials and alloys demonstrate superior stability in industrial conditions, thereby enhancing the sustainability credentials of CO2RR systems through extended service lifetimes.

Water consumption represents another critical environmental consideration, particularly in regions experiencing water scarcity. Material compositions that enable efficient CO2 reduction in alkaline or neutral media rather than acidic environments can significantly reduce water purification requirements and associated environmental impacts. Additionally, catalysts that minimize competing hydrogen evolution reactions conserve water resources while improving CO2 conversion efficiency.

The end-of-life management of catalyst materials presents both challenges and opportunities. Developing recyclable catalyst systems or those based on biodegradable supports could substantially reduce waste generation. Recent innovations in catalyst recovery techniques, particularly for transition metal-based materials, demonstrate promising pathways toward closed-loop material cycles that align with circular economy principles.

Toxicity profiles of catalyst materials and their degradation products warrant careful consideration. While pursuing improved efficiency and durability, researchers must evaluate potential environmental release scenarios and ecological impacts. Non-toxic alternatives to traditional catalyst components, such as bismuth and tin-based materials, offer environmentally benign options with competitive performance characteristics for specific CO2 reduction pathways.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!