Evaluation of Electrocatalytic CO2 reduction for aerospace renewable and EV applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Reduction Technology Background and Objectives

Electrocatalytic CO2 reduction technology has evolved significantly over the past three decades, transitioning from laboratory curiosity to a promising solution for carbon neutrality goals. Initially explored in the 1980s as an electrochemical phenomenon, this technology has gained momentum since 2010 with breakthroughs in catalyst design and reaction efficiency. The fundamental process involves converting carbon dioxide into value-added chemicals and fuels using electrical energy, ideally sourced from renewable power.

The aerospace and electric vehicle sectors present unique opportunities for CO2 reduction technology implementation. For aerospace applications, the technology offers potential for in-situ resource utilization on extended missions, converting exhaled CO2 into oxygen and fuel precursors. In the EV ecosystem, it presents possibilities for carbon-neutral synthetic fuel production and battery materials manufacturing using captured carbon.

Current technological development focuses on three primary objectives. First, enhancing catalytic efficiency to achieve higher conversion rates and energy efficiency, targeting Faradaic efficiencies above 90% for specific products. Second, improving selectivity to direct reactions toward high-value products like ethanol, ethylene, or syngas components rather than less valuable methane or carbon monoxide. Third, developing scalable systems capable of industrial implementation with reduced capital costs.

The intersection of aerospace requirements and electrocatalytic CO2 reduction presents unique technical challenges, including miniaturization, operation in variable gravity environments, and integration with life support systems. For EV applications, the focus shifts to developing systems that can utilize intermittent renewable energy and potentially integrate with charging infrastructure.

Recent advancements in nanomaterial science have accelerated progress, with copper-based catalysts showing particular promise for multi-carbon product formation. Computational modeling and artificial intelligence approaches are increasingly employed to predict catalyst behavior and optimize reaction conditions, significantly reducing development timelines.

The ultimate goal of this technology evaluation is to determine feasible implementation pathways for CO2 reduction in aerospace and EV applications, considering technical readiness levels, integration requirements, and potential synergies between these sectors. This includes identifying near-term opportunities for demonstration projects and longer-term research directions to address persistent challenges in catalyst stability and system durability.

The aerospace and electric vehicle sectors present unique opportunities for CO2 reduction technology implementation. For aerospace applications, the technology offers potential for in-situ resource utilization on extended missions, converting exhaled CO2 into oxygen and fuel precursors. In the EV ecosystem, it presents possibilities for carbon-neutral synthetic fuel production and battery materials manufacturing using captured carbon.

Current technological development focuses on three primary objectives. First, enhancing catalytic efficiency to achieve higher conversion rates and energy efficiency, targeting Faradaic efficiencies above 90% for specific products. Second, improving selectivity to direct reactions toward high-value products like ethanol, ethylene, or syngas components rather than less valuable methane or carbon monoxide. Third, developing scalable systems capable of industrial implementation with reduced capital costs.

The intersection of aerospace requirements and electrocatalytic CO2 reduction presents unique technical challenges, including miniaturization, operation in variable gravity environments, and integration with life support systems. For EV applications, the focus shifts to developing systems that can utilize intermittent renewable energy and potentially integrate with charging infrastructure.

Recent advancements in nanomaterial science have accelerated progress, with copper-based catalysts showing particular promise for multi-carbon product formation. Computational modeling and artificial intelligence approaches are increasingly employed to predict catalyst behavior and optimize reaction conditions, significantly reducing development timelines.

The ultimate goal of this technology evaluation is to determine feasible implementation pathways for CO2 reduction in aerospace and EV applications, considering technical readiness levels, integration requirements, and potential synergies between these sectors. This includes identifying near-term opportunities for demonstration projects and longer-term research directions to address persistent challenges in catalyst stability and system durability.

Market Analysis for Aerospace and EV Applications

The electrocatalytic CO2 reduction market for aerospace and electric vehicle applications represents a significant growth opportunity driven by increasing environmental regulations and sustainability initiatives. The global market for carbon capture, utilization, and storage (CCUS) technologies is projected to reach $7.0 billion by 2030, with electrocatalytic approaches gaining substantial traction due to their versatility and integration potential with renewable energy systems.

In the aerospace sector, market demand is primarily fueled by stringent emission regulations and the industry's commitment to achieve net-zero carbon emissions by 2050. Major aerospace manufacturers including Airbus, Boeing, and Lockheed Martin have announced substantial investments in sustainable aviation technologies, with CO2 conversion systems emerging as a critical component of their environmental strategies. The potential market for onboard CO2 conversion systems in commercial aircraft is estimated to exceed $2.5 billion by 2035.

For electric vehicle applications, the market dynamics are shaped by the dual benefits of carbon reduction and energy storage capabilities. The integration of CO2 reduction technologies with EV charging infrastructure presents a compelling value proposition, potentially creating a $3.8 billion market by 2028. This segment is experiencing rapid growth at approximately 24% CAGR, outpacing many other clean technology markets.

Regional analysis reveals that North America currently leads in aerospace applications of CO2 reduction technologies, while Europe dominates in EV-related implementations. However, Asia-Pacific, particularly China and South Korea, is demonstrating the fastest growth rates across both sectors, supported by aggressive government policies promoting green technologies.

Customer segmentation within these markets shows distinct requirements. Aerospace customers prioritize weight efficiency, reliability, and safety certification, while EV applications emphasize cost-effectiveness, scalability, and integration with existing charging infrastructure. This divergence necessitates tailored product development strategies for each sector.

Market barriers include high initial capital costs, technological maturity concerns, and competition from alternative carbon management approaches. However, favorable policy environments, including carbon pricing mechanisms and clean energy incentives, are creating strong market pull factors that partially offset these challenges.

The competitive landscape features established industrial gas companies like Air Liquide and Linde, specialized technology providers such as Opus 12 and Twelve, and increasing participation from automotive and aerospace OEMs through strategic partnerships and internal R&D programs. This diverse ecosystem indicates a market in early maturity with significant consolidation expected as technologies prove commercial viability.

In the aerospace sector, market demand is primarily fueled by stringent emission regulations and the industry's commitment to achieve net-zero carbon emissions by 2050. Major aerospace manufacturers including Airbus, Boeing, and Lockheed Martin have announced substantial investments in sustainable aviation technologies, with CO2 conversion systems emerging as a critical component of their environmental strategies. The potential market for onboard CO2 conversion systems in commercial aircraft is estimated to exceed $2.5 billion by 2035.

For electric vehicle applications, the market dynamics are shaped by the dual benefits of carbon reduction and energy storage capabilities. The integration of CO2 reduction technologies with EV charging infrastructure presents a compelling value proposition, potentially creating a $3.8 billion market by 2028. This segment is experiencing rapid growth at approximately 24% CAGR, outpacing many other clean technology markets.

Regional analysis reveals that North America currently leads in aerospace applications of CO2 reduction technologies, while Europe dominates in EV-related implementations. However, Asia-Pacific, particularly China and South Korea, is demonstrating the fastest growth rates across both sectors, supported by aggressive government policies promoting green technologies.

Customer segmentation within these markets shows distinct requirements. Aerospace customers prioritize weight efficiency, reliability, and safety certification, while EV applications emphasize cost-effectiveness, scalability, and integration with existing charging infrastructure. This divergence necessitates tailored product development strategies for each sector.

Market barriers include high initial capital costs, technological maturity concerns, and competition from alternative carbon management approaches. However, favorable policy environments, including carbon pricing mechanisms and clean energy incentives, are creating strong market pull factors that partially offset these challenges.

The competitive landscape features established industrial gas companies like Air Liquide and Linde, specialized technology providers such as Opus 12 and Twelve, and increasing participation from automotive and aerospace OEMs through strategic partnerships and internal R&D programs. This diverse ecosystem indicates a market in early maturity with significant consolidation expected as technologies prove commercial viability.

Current Electrocatalytic CO2 Reduction Challenges

Despite significant advancements in electrocatalytic CO2 reduction technology, several critical challenges persist that hinder its widespread implementation in aerospace renewable and electric vehicle applications. The primary technical obstacle remains catalyst efficiency, with current catalysts exhibiting limited selectivity toward valuable carbon products. Most systems still favor hydrogen evolution over carbon dioxide reduction, resulting in low Faradaic efficiencies for desired products like carbon monoxide, formate, or hydrocarbons.

Energy efficiency represents another significant barrier, as the process requires substantial electrical input to overcome the thermodynamic stability of CO2 molecules. Current systems typically operate at energy efficiencies below 50%, making them less competitive compared to conventional fuel production methods. This inefficiency becomes particularly problematic for aerospace and EV applications where energy density and weight considerations are paramount.

Catalyst durability presents ongoing challenges, with many promising materials showing performance degradation after relatively short operational periods. Poisoning by trace impurities and structural changes during operation lead to diminished catalytic activity over time. For aerospace applications, where maintenance opportunities are limited, this durability issue becomes especially critical.

The reaction environment poses additional complications, particularly regarding the low solubility of CO2 in aqueous electrolytes. This limitation creates mass transport constraints that reduce overall reaction rates and efficiencies. Various gas diffusion electrode designs have been proposed to address this issue, but optimization remains incomplete for practical implementation in mobile applications.

Scale-up challenges further complicate commercial deployment, as laboratory-scale demonstrations often fail to maintain performance metrics when scaled to industrially relevant dimensions. The integration of CO2 reduction systems with existing aerospace or automotive platforms introduces additional engineering complexities related to weight, volume, and safety considerations.

Economic viability remains questionable under current conditions, with high capital costs and operational expenses exceeding the value of produced fuels or chemicals. The technology requires either significant cost reductions or policy support mechanisms to become commercially viable for transportation applications.

Regulatory and safety considerations add another layer of complexity, particularly for aerospace implementations where stringent certification requirements must be met. The production of potentially flammable gases during operation necessitates careful system design and robust safety protocols that have not yet been fully developed for mobile applications.

Energy efficiency represents another significant barrier, as the process requires substantial electrical input to overcome the thermodynamic stability of CO2 molecules. Current systems typically operate at energy efficiencies below 50%, making them less competitive compared to conventional fuel production methods. This inefficiency becomes particularly problematic for aerospace and EV applications where energy density and weight considerations are paramount.

Catalyst durability presents ongoing challenges, with many promising materials showing performance degradation after relatively short operational periods. Poisoning by trace impurities and structural changes during operation lead to diminished catalytic activity over time. For aerospace applications, where maintenance opportunities are limited, this durability issue becomes especially critical.

The reaction environment poses additional complications, particularly regarding the low solubility of CO2 in aqueous electrolytes. This limitation creates mass transport constraints that reduce overall reaction rates and efficiencies. Various gas diffusion electrode designs have been proposed to address this issue, but optimization remains incomplete for practical implementation in mobile applications.

Scale-up challenges further complicate commercial deployment, as laboratory-scale demonstrations often fail to maintain performance metrics when scaled to industrially relevant dimensions. The integration of CO2 reduction systems with existing aerospace or automotive platforms introduces additional engineering complexities related to weight, volume, and safety considerations.

Economic viability remains questionable under current conditions, with high capital costs and operational expenses exceeding the value of produced fuels or chemicals. The technology requires either significant cost reductions or policy support mechanisms to become commercially viable for transportation applications.

Regulatory and safety considerations add another layer of complexity, particularly for aerospace implementations where stringent certification requirements must be met. The production of potentially flammable gases during operation necessitates careful system design and robust safety protocols that have not yet been fully developed for mobile applications.

Current Electrocatalytic Solutions Assessment

01 Metal-based catalysts for CO2 reduction

Various metal-based catalysts can be used for electrocatalytic CO2 reduction to produce valuable chemicals. These catalysts include transition metals, metal alloys, and metal complexes that facilitate the conversion of CO2 to products like carbon monoxide, formate, or hydrocarbons. The catalytic performance depends on the metal's electronic structure, surface properties, and morphology, which can be optimized to enhance selectivity and efficiency of the CO2 reduction reaction.- Metal-based catalysts for CO2 electroreduction: Various metal-based catalysts can be employed for electrocatalytic CO2 reduction. These include transition metals, metal alloys, and metal complexes that facilitate the conversion of CO2 to valuable products such as carbon monoxide, formate, or hydrocarbons. The catalytic performance depends on the metal's electronic structure, surface properties, and morphology, which can be optimized to enhance selectivity and efficiency of the CO2 reduction process.

- Carbon-based materials as electrocatalysts: Carbon-based materials, including carbon nanotubes, graphene, and doped carbon structures, serve as effective electrocatalysts for CO2 reduction. These materials offer advantages such as high surface area, good electrical conductivity, and tunable surface chemistry. Heteroatom doping (with N, B, S, etc.) can create active sites that enhance catalytic activity and selectivity toward specific CO2 reduction products.

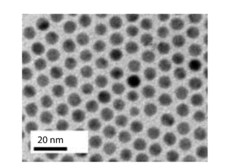

- Nanostructured catalysts for improved performance: Nanostructured catalysts with controlled morphology and composition demonstrate enhanced performance in electrocatalytic CO2 reduction. These include nanoparticles, nanowires, nanosheets, and hierarchical structures that provide high surface area, abundant active sites, and optimized mass transport properties. The nanoscale engineering of these catalysts allows for precise control over product selectivity and reaction efficiency.

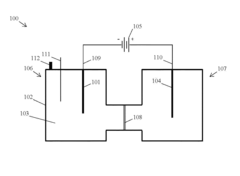

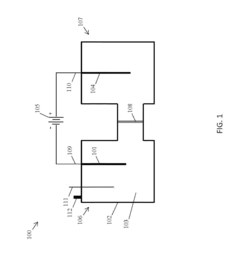

- Reactor design and system optimization: The design of electrochemical reactors and system optimization play crucial roles in efficient CO2 reduction. This includes the development of flow cells, gas diffusion electrodes, membrane electrode assemblies, and integrated systems that address mass transport limitations, improve energy efficiency, and enable continuous operation. Advanced reactor configurations can enhance CO2 utilization and product separation while minimizing energy losses.

- Electrolyte engineering for selective CO2 reduction: Electrolyte composition and properties significantly influence the selectivity and efficiency of CO2 electroreduction. Factors such as pH, ionic strength, buffer capacity, and the presence of specific ions can alter reaction pathways and product distribution. Tailored electrolytes can suppress competing hydrogen evolution reactions, stabilize reaction intermediates, and enhance the formation of desired products from CO2 reduction.

02 Carbon-based materials as electrocatalysts

Carbon-based materials serve as effective electrocatalysts for CO2 reduction due to their high surface area, good electrical conductivity, and tunable surface chemistry. These materials include carbon nanotubes, graphene, carbon dots, and nitrogen-doped carbon structures. The incorporation of heteroatoms like nitrogen, sulfur, or phosphorus into carbon frameworks can create active sites that enhance catalytic activity and selectivity toward specific CO2 reduction products.Expand Specific Solutions03 Electrode design and reactor configurations

The design of electrodes and reactor configurations plays a crucial role in electrocatalytic CO2 reduction efficiency. Advanced electrode structures with high surface area, optimized mass transport properties, and enhanced catalyst loading can significantly improve reaction rates and product selectivity. Various reactor designs, including flow cells, gas diffusion electrodes, and membrane electrode assemblies, have been developed to address challenges related to CO2 solubility, mass transfer limitations, and product separation.Expand Specific Solutions04 Bimetallic and multi-component catalyst systems

Bimetallic and multi-component catalyst systems offer enhanced performance for electrocatalytic CO2 reduction through synergistic effects between different elements. These systems can combine the beneficial properties of multiple metals or incorporate supporting materials to create unique catalytic environments. The interaction between components can modify electronic structures, create new active sites, and improve stability, leading to higher activity, selectivity, and durability compared to single-component catalysts.Expand Specific Solutions05 Process optimization and reaction conditions

Optimization of reaction conditions is essential for efficient electrocatalytic CO2 reduction. Parameters such as electrolyte composition, pH, temperature, pressure, applied potential, and current density significantly influence reaction pathways and product distribution. Advanced techniques for controlling local reaction environments, such as the use of ionic liquids, buffered solutions, or gas-diffusion layers, can enhance CO2 availability at the electrode surface and improve overall process efficiency and selectivity.Expand Specific Solutions

Key Industry Players in CO2 Conversion Technologies

The electrocatalytic CO2 reduction market for aerospace and EV applications is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size is expanding rapidly, driven by global decarbonization initiatives and renewable energy integration requirements. Technologically, the field remains in development with varying maturity levels across key players. Leading organizations include TotalEnergies and Saudi Aramco, who leverage their energy expertise; academic institutions like Tianjin University, KAIST, and Brown University contributing fundamental research breakthroughs; and specialized entities such as Faraday Technology developing application-specific solutions. Research collaboration between industry and academia is prevalent, with CNRS and various Chinese research institutes playing significant roles in advancing catalyst performance, selectivity, and durability for practical implementation.

The Governing Council of the University of Toronto

Technical Solution: The University of Toronto has pioneered breakthrough electrocatalytic CO2 reduction technology specifically tailored for aerospace and EV applications. Their research team has developed novel nitrogen-doped carbon-supported copper catalysts that demonstrate exceptional selectivity toward multi-carbon products (>80% faradaic efficiency) at low overpotentials. The university's approach incorporates innovative flow-cell designs that enable high current densities (>500 mA/cm²) while maintaining product selectivity. Their system architecture includes advanced ion-exchange membranes that minimize crossover effects and enhance overall system efficiency. For aerospace applications, they've developed lightweight, compact reactor designs capable of operating in microgravity environments, with demonstrated stability during parabolic flight testing. The technology incorporates direct coupling with renewable energy sources, particularly focusing on integration with high-altitude solar arrays for aerospace applications and grid-connected renewable sources for EV charging infrastructure.

Strengths: Superior catalyst performance with exceptional selectivity toward valuable multi-carbon products; innovative reactor designs specifically engineered for aerospace constraints; extensive validation in relevant environments. Weaknesses: Technology still at relatively early TRL level compared to industrial competitors; scale-up challenges remain for full commercial implementation; higher complexity in system integration with existing aerospace platforms.

Aramco Services Co.

Technical Solution: Aramco Services Co. has developed a comprehensive electrocatalytic CO2 reduction platform targeting aerospace and EV applications. Their approach centers on bimetallic nanostructured catalysts (primarily copper-silver and copper-zinc alloys) that demonstrate remarkable selectivity toward syngas production with tunable H2/CO ratios. This makes their technology particularly suitable for integration with downstream Fischer-Tropsch processes to produce jet fuels for aerospace applications. For EV applications, Aramco has engineered compact CO2 electrolyzer units that can be deployed at charging stations, effectively creating carbon-neutral fuel cycles. Their system operates at moderate temperatures (40-60°C) and pressures (5-10 bar), achieving current densities of 300-400 mA/cm² with energy efficiencies approaching 70%. The company has also developed proprietary gas diffusion electrodes with enhanced mass transport properties, addressing one of the key limitations in CO2 electroreduction technology.

Strengths: Exceptional catalyst stability under variable load conditions; highly integrated system design with existing infrastructure; advanced gas diffusion electrode technology enabling high current densities. Weaknesses: Higher energy requirements compared to some competing technologies; limited product selectivity toward higher-value chemicals; technology optimization still needed for extreme aerospace environments.

Critical Catalyst Technologies Analysis

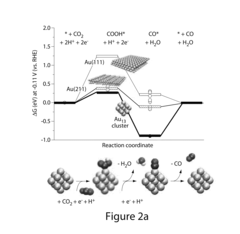

Efficient electrocatalytic conversion of CO<sub>2 </sub>to CO using ligand-protected Au<sub>25 </sub>clusters

PatentInactiveUS9139920B1

Innovation

- An Au25 electrode with a ligand-protected structure, comprising an icosahedral core of 13 atoms and a shell of six semi-ring structures, is used in an electrochemical cell with a potential of at least −0.1 volts to interact with CO2 and H+ ions, facilitating the reduction of CO2 to CO with high Faradaic efficiency and reduced overpotential.

Method for Electrocatalytic Reduction using Au Nanoparticles Tuned or Optimized for Reduction of CO2 to CO

PatentInactiveUS20160230295A1

Innovation

- The use of gold nanoparticles with a diameter of approximately 8 nm, supported on Ketjen carbon, which presents a surface structure with a higher density of CO-converting edge sites and fewer hydrogen-evolving corner sites, facilitating efficient CO2 reduction to carbon monoxide in an alkaline solution.

Environmental Impact and Sustainability Metrics

The electrocatalytic CO2 reduction process offers significant environmental benefits compared to conventional carbon-intensive technologies in aerospace and electric vehicle applications. Life cycle assessments indicate that when powered by renewable energy sources, this technology can achieve carbon neutrality or even negative emissions by effectively closing the carbon loop. The process transforms CO2 from a harmful greenhouse gas into valuable fuels and chemicals, potentially reducing global warming potential by 60-85% compared to fossil fuel-based alternatives.

Quantitative sustainability metrics reveal promising results for this technology. Energy return on investment (EROI) calculations show values between 1.5-2.8 for current systems, with projections exceeding 3.0 as catalyst efficiency improves. Water consumption metrics are favorable, with requirements of 5-12 liters per kilogram of product, significantly lower than biofuel production which can require hundreds of liters per equivalent energy output.

Land use impact remains minimal compared to other renewable technologies, requiring approximately 0.2-0.5 square meters per gigajoule of energy produced when integrated with existing infrastructure. This represents a 90% reduction compared to first-generation biofuels. Additionally, the technology demonstrates excellent performance in resource circularity metrics, with potential material recovery rates exceeding 95% for precious metal catalysts.

For aerospace applications specifically, implementation of electrocatalytic CO2 reduction could reduce the carbon footprint of aviation fuels by 70-80% when utilizing captured CO2 and renewable electricity. In EV applications, the technology enables carbon-neutral battery manufacturing processes and creates pathways for sustainable materials production.

Ecological risk assessments indicate minimal environmental hazards from catalyst materials when proper containment and recycling protocols are followed. Potential leaching of metal ions remains below environmental threshold limits in standardized tests. The technology also contributes to improved air quality metrics by reducing dependence on combustion processes that generate particulate matter and NOx emissions.

Long-term sustainability projections suggest that widespread adoption could contribute 5-8% toward global carbon reduction targets by 2050. However, these benefits are contingent upon continued improvements in catalyst selectivity, energy efficiency, and integration with renewable energy infrastructure. Comprehensive sustainability frameworks must be established to monitor and verify these environmental benefits as the technology scales from laboratory to commercial deployment.

Quantitative sustainability metrics reveal promising results for this technology. Energy return on investment (EROI) calculations show values between 1.5-2.8 for current systems, with projections exceeding 3.0 as catalyst efficiency improves. Water consumption metrics are favorable, with requirements of 5-12 liters per kilogram of product, significantly lower than biofuel production which can require hundreds of liters per equivalent energy output.

Land use impact remains minimal compared to other renewable technologies, requiring approximately 0.2-0.5 square meters per gigajoule of energy produced when integrated with existing infrastructure. This represents a 90% reduction compared to first-generation biofuels. Additionally, the technology demonstrates excellent performance in resource circularity metrics, with potential material recovery rates exceeding 95% for precious metal catalysts.

For aerospace applications specifically, implementation of electrocatalytic CO2 reduction could reduce the carbon footprint of aviation fuels by 70-80% when utilizing captured CO2 and renewable electricity. In EV applications, the technology enables carbon-neutral battery manufacturing processes and creates pathways for sustainable materials production.

Ecological risk assessments indicate minimal environmental hazards from catalyst materials when proper containment and recycling protocols are followed. Potential leaching of metal ions remains below environmental threshold limits in standardized tests. The technology also contributes to improved air quality metrics by reducing dependence on combustion processes that generate particulate matter and NOx emissions.

Long-term sustainability projections suggest that widespread adoption could contribute 5-8% toward global carbon reduction targets by 2050. However, these benefits are contingent upon continued improvements in catalyst selectivity, energy efficiency, and integration with renewable energy infrastructure. Comprehensive sustainability frameworks must be established to monitor and verify these environmental benefits as the technology scales from laboratory to commercial deployment.

Integration Strategies for Aerospace and EV Systems

The integration of electrocatalytic CO2 reduction technologies into aerospace and electric vehicle (EV) systems requires sophisticated strategies that address the unique operational requirements of both sectors. For aerospace applications, integration must consider the extreme environmental conditions, weight constraints, and reliability demands of flight systems. Conversely, EV integration focuses on optimizing energy efficiency, managing thermal conditions, and ensuring compatibility with existing battery and power management systems.

A modular approach to integration represents the most promising strategy, allowing for standardized CO2 reduction units that can be scaled and configured according to specific application requirements. These modules would incorporate catalytic reactors, CO2 capture systems, and product separation mechanisms in compact, lightweight packages. For aerospace applications, these modules could be integrated with existing environmental control systems, utilizing waste heat and potentially excess electrical capacity during certain flight phases.

In EV applications, integration with regenerative braking systems offers significant synergistic potential. The electrical energy recovered during braking could power CO2 reduction processes, effectively storing energy in chemical form rather than solely relying on battery storage. This approach could extend vehicle range while simultaneously reducing carbon footprint through active carbon capture and utilization.

Cross-platform standardization presents another critical integration strategy. Developing common interfaces, control protocols, and safety standards would accelerate adoption across both sectors while reducing development costs. This standardization would facilitate a more robust supply chain and enable faster technological iterations as improvements in catalysts and system designs emerge.

Real-time monitoring and adaptive control systems represent essential components of successful integration strategies. These systems would optimize catalyst performance based on operating conditions, manage energy distribution, and ensure safe operation across varying environmental parameters. Advanced predictive algorithms could anticipate system needs based on flight plans or driving routes, preparing the CO2 reduction systems for optimal performance.

Energy management integration strategies must address the intermittent nature of renewable energy sources in both aerospace and EV applications. For aerospace, this might involve prioritizing CO2 reduction during solar-intensive flight segments or when hydrogen fuel cells are operating at peak efficiency. In EVs, integration with smart grid systems could enable CO2 reduction during grid-charging events when renewable energy is abundant.

A modular approach to integration represents the most promising strategy, allowing for standardized CO2 reduction units that can be scaled and configured according to specific application requirements. These modules would incorporate catalytic reactors, CO2 capture systems, and product separation mechanisms in compact, lightweight packages. For aerospace applications, these modules could be integrated with existing environmental control systems, utilizing waste heat and potentially excess electrical capacity during certain flight phases.

In EV applications, integration with regenerative braking systems offers significant synergistic potential. The electrical energy recovered during braking could power CO2 reduction processes, effectively storing energy in chemical form rather than solely relying on battery storage. This approach could extend vehicle range while simultaneously reducing carbon footprint through active carbon capture and utilization.

Cross-platform standardization presents another critical integration strategy. Developing common interfaces, control protocols, and safety standards would accelerate adoption across both sectors while reducing development costs. This standardization would facilitate a more robust supply chain and enable faster technological iterations as improvements in catalysts and system designs emerge.

Real-time monitoring and adaptive control systems represent essential components of successful integration strategies. These systems would optimize catalyst performance based on operating conditions, manage energy distribution, and ensure safe operation across varying environmental parameters. Advanced predictive algorithms could anticipate system needs based on flight plans or driving routes, preparing the CO2 reduction systems for optimal performance.

Energy management integration strategies must address the intermittent nature of renewable energy sources in both aerospace and EV applications. For aerospace, this might involve prioritizing CO2 reduction during solar-intensive flight segments or when hydrogen fuel cells are operating at peak efficiency. In EVs, integration with smart grid systems could enable CO2 reduction during grid-charging events when renewable energy is abundant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!