Research on Electrocatalytic CO2 reduction for thermal management in energy devices

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Reduction Electrocatalysis Background and Objectives

Electrocatalytic CO2 reduction (ECR) has emerged as a promising technology at the intersection of renewable energy utilization and carbon neutrality efforts. The concept dates back to the 1980s, but significant advancements have only materialized in the last decade due to improved catalyst design and electrochemical engineering. This technology represents a dual-purpose solution: converting greenhouse gases into valuable chemicals while potentially managing thermal energy in various devices.

The evolution of ECR technology has followed several distinct phases. Initially, research focused on fundamental electrochemical principles and simple metal catalysts. The second phase, spanning approximately 2000-2015, saw the development of more complex catalyst structures and improved understanding of reaction mechanisms. The current phase is characterized by nanoscale engineering of catalysts and integration with practical energy systems, including thermal management applications.

Market trends indicate growing interest in ECR technologies, driven by carbon neutrality policies and the increasing economic viability of renewable energy. The global carbon capture and utilization market is projected to grow at a CAGR of 13.8% through 2030, with ECR representing a significant segment of this expansion. This growth trajectory aligns with broader sustainability initiatives across industrial sectors.

The primary technical objective of this research is to develop efficient electrocatalytic systems capable of reducing CO2 while simultaneously managing thermal energy in energy devices. Specific goals include achieving conversion efficiencies exceeding 60%, developing catalysts with selectivity toward specific high-value products, and creating integrated systems that can effectively utilize waste heat from energy conversion processes.

Secondary objectives include minimizing energy input requirements, extending catalyst lifespans beyond 5,000 operating hours, and developing scalable manufacturing processes for commercial implementation. The research also aims to quantify the thermal management benefits of ECR systems when integrated with batteries, fuel cells, and other energy conversion devices.

The technological trajectory suggests potential convergence with other emerging fields, including advanced materials science, artificial intelligence for catalyst discovery, and renewable energy integration. This convergence presents opportunities for breakthrough innovations in both CO2 utilization and thermal management strategies.

Understanding the fundamental science behind ECR reactions remains crucial, particularly regarding the relationship between catalyst structure, reaction kinetics, and thermal energy transfer. This research seeks to establish clear correlations between these factors to enable predictive design of next-generation systems optimized for both chemical conversion and thermal regulation.

The evolution of ECR technology has followed several distinct phases. Initially, research focused on fundamental electrochemical principles and simple metal catalysts. The second phase, spanning approximately 2000-2015, saw the development of more complex catalyst structures and improved understanding of reaction mechanisms. The current phase is characterized by nanoscale engineering of catalysts and integration with practical energy systems, including thermal management applications.

Market trends indicate growing interest in ECR technologies, driven by carbon neutrality policies and the increasing economic viability of renewable energy. The global carbon capture and utilization market is projected to grow at a CAGR of 13.8% through 2030, with ECR representing a significant segment of this expansion. This growth trajectory aligns with broader sustainability initiatives across industrial sectors.

The primary technical objective of this research is to develop efficient electrocatalytic systems capable of reducing CO2 while simultaneously managing thermal energy in energy devices. Specific goals include achieving conversion efficiencies exceeding 60%, developing catalysts with selectivity toward specific high-value products, and creating integrated systems that can effectively utilize waste heat from energy conversion processes.

Secondary objectives include minimizing energy input requirements, extending catalyst lifespans beyond 5,000 operating hours, and developing scalable manufacturing processes for commercial implementation. The research also aims to quantify the thermal management benefits of ECR systems when integrated with batteries, fuel cells, and other energy conversion devices.

The technological trajectory suggests potential convergence with other emerging fields, including advanced materials science, artificial intelligence for catalyst discovery, and renewable energy integration. This convergence presents opportunities for breakthrough innovations in both CO2 utilization and thermal management strategies.

Understanding the fundamental science behind ECR reactions remains crucial, particularly regarding the relationship between catalyst structure, reaction kinetics, and thermal energy transfer. This research seeks to establish clear correlations between these factors to enable predictive design of next-generation systems optimized for both chemical conversion and thermal regulation.

Market Analysis for Thermal Management Solutions

The global thermal management market is experiencing robust growth, driven by increasing demands across multiple sectors including electronics, automotive, aerospace, and energy storage. Current market valuations place the thermal management solutions sector at approximately $12.3 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 8.2% through 2030, potentially reaching $21.5 billion by the end of the forecast period.

Electrocatalytic CO2 reduction technology represents an emerging segment within this market, offering dual benefits of carbon utilization and thermal management capabilities. This innovative approach addresses two critical challenges simultaneously: reducing carbon emissions and managing heat in energy-intensive devices. The market potential for this specific application is estimated to reach $2.7 billion by 2028, representing a significant growth opportunity within the broader thermal management landscape.

Key market drivers include increasingly stringent environmental regulations worldwide, particularly in regions implementing carbon pricing mechanisms and emissions reduction targets. The European Union's Carbon Border Adjustment Mechanism and similar policies in North America and parts of Asia are creating favorable market conditions for technologies that can demonstrate carbon utilization benefits alongside their primary functions.

Industry analysis reveals that the energy sector represents the largest potential market for electrocatalytic CO2 reduction thermal management solutions, accounting for approximately 42% of the addressable market. This is followed by data centers (27%), transportation (18%), and industrial applications (13%). The rapid expansion of renewable energy infrastructure and electric vehicle adoption is expected to further accelerate demand in these segments.

Regional market assessment indicates that Asia-Pacific currently leads in market share (38%), followed by North America (32%) and Europe (24%). However, the highest growth rates are anticipated in North America, where substantial investments in clean energy technologies and advanced manufacturing are creating favorable conditions for innovative thermal management solutions.

Customer demand patterns show increasing preference for integrated solutions that address multiple challenges simultaneously, with 76% of surveyed industrial customers expressing interest in thermal management technologies that offer additional sustainability benefits. This represents a significant shift from traditional single-function cooling systems toward multifunctional solutions that contribute to broader environmental goals.

Market penetration barriers include high initial implementation costs, technical integration challenges with existing systems, and limited awareness of the technology's capabilities among potential end-users. However, these barriers are expected to diminish as demonstration projects prove the technology's effectiveness and economies of scale begin to reduce costs.

Electrocatalytic CO2 reduction technology represents an emerging segment within this market, offering dual benefits of carbon utilization and thermal management capabilities. This innovative approach addresses two critical challenges simultaneously: reducing carbon emissions and managing heat in energy-intensive devices. The market potential for this specific application is estimated to reach $2.7 billion by 2028, representing a significant growth opportunity within the broader thermal management landscape.

Key market drivers include increasingly stringent environmental regulations worldwide, particularly in regions implementing carbon pricing mechanisms and emissions reduction targets. The European Union's Carbon Border Adjustment Mechanism and similar policies in North America and parts of Asia are creating favorable market conditions for technologies that can demonstrate carbon utilization benefits alongside their primary functions.

Industry analysis reveals that the energy sector represents the largest potential market for electrocatalytic CO2 reduction thermal management solutions, accounting for approximately 42% of the addressable market. This is followed by data centers (27%), transportation (18%), and industrial applications (13%). The rapid expansion of renewable energy infrastructure and electric vehicle adoption is expected to further accelerate demand in these segments.

Regional market assessment indicates that Asia-Pacific currently leads in market share (38%), followed by North America (32%) and Europe (24%). However, the highest growth rates are anticipated in North America, where substantial investments in clean energy technologies and advanced manufacturing are creating favorable conditions for innovative thermal management solutions.

Customer demand patterns show increasing preference for integrated solutions that address multiple challenges simultaneously, with 76% of surveyed industrial customers expressing interest in thermal management technologies that offer additional sustainability benefits. This represents a significant shift from traditional single-function cooling systems toward multifunctional solutions that contribute to broader environmental goals.

Market penetration barriers include high initial implementation costs, technical integration challenges with existing systems, and limited awareness of the technology's capabilities among potential end-users. However, these barriers are expected to diminish as demonstration projects prove the technology's effectiveness and economies of scale begin to reduce costs.

Current Challenges in Electrocatalytic CO2 Reduction

Despite significant advancements in electrocatalytic CO2 reduction (ECR) technology for thermal management applications in energy devices, several critical challenges continue to impede widespread implementation. The primary obstacle remains catalyst efficiency, with current materials exhibiting insufficient selectivity toward desired carbon products. Most catalysts struggle to achieve Faradaic efficiencies above 60% for valuable C2+ products, while simultaneously requiring high overpotentials that compromise overall energy efficiency.

Stability issues present another significant barrier, as many promising catalysts demonstrate rapid performance degradation under industrial operating conditions. Copper-based catalysts, while showing excellent C-C coupling capabilities, suffer from oxidation and poisoning effects that substantially reduce their operational lifespan from months to mere days or hours in practical applications.

The scalability of ECR systems represents a formidable engineering challenge. Laboratory-scale demonstrations have proven difficult to translate to industrial dimensions due to mass transport limitations, uneven current distribution, and heat management complications in larger electrochemical cells. The current density achievable in scaled-up systems typically decreases by 30-50% compared to laboratory counterparts.

Integration challenges between ECR systems and thermal management applications create additional complexity. The intermittent nature of heat generation in many energy devices requires ECR systems with rapid response capabilities and operational flexibility that current technologies cannot reliably deliver. The thermal coupling efficiency between CO2 reduction reactions and heat transfer mechanisms remains suboptimal, with energy losses of 25-40% in most experimental setups.

Economic viability continues to constrain commercial adoption, with current ECR systems for thermal management showing prohibitively high capital costs (approximately $800-1,200/kW) and operational expenses that exceed conventional cooling technologies by 3-5 times. The precious metal catalysts often employed further exacerbate cost concerns, with materials like platinum and palladium contributing significantly to overall system expenses.

Technical standardization and performance metrics remain underdeveloped in this emerging field. The lack of unified testing protocols and performance indicators makes comparative analysis between different technological approaches challenging, hindering informed investment decisions and technology selection processes.

Environmental considerations also present challenges, as the life cycle assessment of ECR systems for thermal management applications remains incomplete. Questions persist regarding the net carbon impact when accounting for catalyst production, system manufacturing, and end-of-life disposal, potentially undermining the core sustainability value proposition of this technology approach.

Stability issues present another significant barrier, as many promising catalysts demonstrate rapid performance degradation under industrial operating conditions. Copper-based catalysts, while showing excellent C-C coupling capabilities, suffer from oxidation and poisoning effects that substantially reduce their operational lifespan from months to mere days or hours in practical applications.

The scalability of ECR systems represents a formidable engineering challenge. Laboratory-scale demonstrations have proven difficult to translate to industrial dimensions due to mass transport limitations, uneven current distribution, and heat management complications in larger electrochemical cells. The current density achievable in scaled-up systems typically decreases by 30-50% compared to laboratory counterparts.

Integration challenges between ECR systems and thermal management applications create additional complexity. The intermittent nature of heat generation in many energy devices requires ECR systems with rapid response capabilities and operational flexibility that current technologies cannot reliably deliver. The thermal coupling efficiency between CO2 reduction reactions and heat transfer mechanisms remains suboptimal, with energy losses of 25-40% in most experimental setups.

Economic viability continues to constrain commercial adoption, with current ECR systems for thermal management showing prohibitively high capital costs (approximately $800-1,200/kW) and operational expenses that exceed conventional cooling technologies by 3-5 times. The precious metal catalysts often employed further exacerbate cost concerns, with materials like platinum and palladium contributing significantly to overall system expenses.

Technical standardization and performance metrics remain underdeveloped in this emerging field. The lack of unified testing protocols and performance indicators makes comparative analysis between different technological approaches challenging, hindering informed investment decisions and technology selection processes.

Environmental considerations also present challenges, as the life cycle assessment of ECR systems for thermal management applications remains incomplete. Questions persist regarding the net carbon impact when accounting for catalyst production, system manufacturing, and end-of-life disposal, potentially undermining the core sustainability value proposition of this technology approach.

Current Electrocatalytic Approaches for Thermal Management

01 Catalyst design for efficient CO2 reduction

Advanced catalyst materials are designed specifically for electrocatalytic CO2 reduction with improved thermal stability. These catalysts often incorporate metal nanoparticles, carbon-based supports, or novel composite structures that can maintain performance under varying temperature conditions. The catalyst design focuses on enhancing selectivity toward desired carbon products while managing heat generated during the electrochemical reaction.- Catalyst design for efficient CO2 reduction: Advanced catalyst materials are designed specifically for electrocatalytic CO2 reduction with improved thermal stability. These catalysts often incorporate metal nanoparticles, carbon-based supports, or novel composite structures that can maintain performance under varying temperature conditions. The catalyst design focuses on enhancing selectivity, activity, and durability while managing heat generated during the electrochemical reaction.

- Cooling systems for electrocatalytic reactors: Specialized cooling systems are integrated into electrocatalytic CO2 reduction reactors to manage excess heat generated during operation. These systems may include liquid cooling channels, heat exchangers, or cooling fins that help maintain optimal operating temperatures. Effective thermal management prevents catalyst degradation, improves reaction efficiency, and extends the operational lifetime of the electrochemical system.

- Temperature-controlled reaction environments: Creating precisely controlled temperature environments for CO2 reduction reactions enhances process efficiency and product selectivity. This involves the use of thermal sensors, automated temperature regulation systems, and insulated reactor designs. Maintaining optimal temperature ranges during electrocatalysis prevents side reactions, reduces energy consumption, and improves the overall conversion efficiency of CO2 to valuable products.

- Heat recovery and energy efficiency systems: Heat recovery systems capture and utilize thermal energy generated during electrocatalytic CO2 reduction processes. These systems incorporate heat exchangers, thermal storage components, and energy integration strategies to improve overall energy efficiency. By recovering waste heat, these approaches reduce the net energy consumption of the process, making CO2 reduction more economically viable and environmentally sustainable.

- Flow field design for thermal management: Optimized flow field designs enhance heat distribution and thermal management in electrocatalytic CO2 reduction systems. These designs focus on fluid dynamics to ensure uniform temperature profiles across catalyst surfaces, preventing hotspots and thermal gradients. Advanced flow configurations may include serpentine channels, interdigitated patterns, or porous media that facilitate both efficient mass transport and effective heat dissipation during the electrochemical conversion process.

02 Cooling systems for electrocatalytic reactors

Specialized cooling systems are integrated into electrocatalytic CO2 reduction reactors to manage excess heat generated during operation. These systems may include liquid cooling channels, heat exchangers, or thermoelectric cooling elements that help maintain optimal reaction temperatures. Effective thermal management prevents catalyst degradation and improves the overall efficiency and stability of the CO2 reduction process.Expand Specific Solutions03 Temperature-controlled reaction environments

Creating precisely controlled temperature environments for electrocatalytic CO2 reduction involves specialized reactor designs with integrated temperature monitoring and regulation systems. These setups allow for maintaining optimal reaction conditions, preventing thermal runaway, and enabling studies on temperature-dependent reaction pathways. The controlled environments help maximize conversion efficiency and product selectivity while minimizing energy consumption.Expand Specific Solutions04 Heat recovery and energy efficiency systems

Heat recovery systems capture and utilize thermal energy generated during electrocatalytic CO2 reduction processes. These systems incorporate heat exchangers, thermal storage components, or integrated energy recovery mechanisms to improve overall energy efficiency. By repurposing waste heat for preheating reactants or generating additional power, these approaches reduce the net energy consumption of CO2 reduction systems and improve their economic viability.Expand Specific Solutions05 Thermal management materials and coatings

Specialized materials and coatings are developed to enhance thermal management in electrocatalytic CO2 reduction systems. These include thermally conductive materials, phase change materials for heat absorption, and protective coatings that prevent thermal degradation of catalysts. Advanced composite materials with tailored thermal properties help distribute heat evenly throughout the reactor, preventing hotspots and extending catalyst lifetime under operating conditions.Expand Specific Solutions

Leading Organizations in CO2 Electrocatalysis Research

The electrocatalytic CO2 reduction technology for thermal management in energy devices is currently in an early growth phase, with the market expected to expand significantly as global decarbonization efforts intensify. The competitive landscape features a diverse mix of players, including major industrial corporations (Siemens Energy, TotalEnergies, Daikin), specialized startups (Energy Dome, Liquid Sun, Dioxycle), and academic institutions (Kyushu University, Tianjin University, Brown University). Technology maturity varies considerably, with established companies like Siemens and TotalEnergies leveraging their extensive R&D infrastructure to develop scalable solutions, while universities contribute fundamental research breakthroughs. Specialized startups are driving innovation through novel approaches to CO2 conversion and utilization, creating a dynamic ecosystem that balances commercial application with scientific advancement.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed advanced electrocatalytic systems for CO2 reduction that integrate thermal management capabilities. Their approach utilizes novel copper-based nanostructured catalysts with precisely engineered morphologies to enhance selectivity toward valuable C2+ products while managing reaction heat. The research team has demonstrated catalysts achieving over 60% Faradaic efficiency for ethylene and ethanol production at industrially relevant current densities (>200 mA/cm²), while simultaneously utilizing the reaction heat for thermal regulation. Their system incorporates microfluidic cooling channels within the electrode assembly that extract excess heat generated during the electrochemical reaction, maintaining optimal catalyst temperature and preventing degradation. This integrated approach allows for continuous operation at high current densities without performance loss due to thermal runaway effects. CNRS has also pioneered the development of gas diffusion electrodes with enhanced mass transport properties that facilitate efficient CO2 conversion while managing water and heat fluxes at the catalyst interface[1][3].

Strengths: Superior catalyst design with high selectivity for valuable products; integrated thermal management system that enhances stability and efficiency; expertise in microfluidic cooling technology. Weaknesses: Complex system design increases manufacturing costs; potential challenges in scaling up the technology for industrial applications; higher energy requirements for the cooling subsystems.

Zhejiang University

Technical Solution: Zhejiang University has pioneered a novel approach to electrocatalytic CO2 reduction with integrated thermal management through their development of "thermally responsive catalytic interfaces." Their research focuses on nanostructured copper-based catalysts with precisely engineered surface defects that enhance C-C coupling while facilitating heat dissipation. The university's research team has created a multi-layered electrode structure incorporating phase-change materials (PCMs) within the gas diffusion layer that absorb excess heat during exothermic reactions and release it during endothermic phases, creating a self-regulating thermal environment. This system maintains optimal catalyst temperatures (35-45°C) even at high current densities (>400 mA/cm²). Their most recent catalyst formulation achieves over 70% Faradaic efficiency toward ethylene and ethanol combined, with remarkable stability exceeding 200 hours of continuous operation. Additionally, they've developed a novel electrolyte system containing ionic liquids with high thermal conductivity that further enhances heat management while improving CO2 solubility. The university has demonstrated that their thermal management approach reduces energy consumption by approximately 15% compared to conventional systems while extending catalyst lifetime by preventing thermal degradation mechanisms[5][7].

Strengths: Highly innovative integration of phase-change materials for passive thermal regulation; superior catalyst performance with high selectivity toward valuable C2+ products; energy-efficient design that reduces operating costs. Weaknesses: Complex fabrication process for multi-layered electrodes may limit commercial scalability; phase-change materials add cost and potential reliability concerns; system optimization required for different operating conditions.

Key Catalyst Materials and Reaction Mechanisms

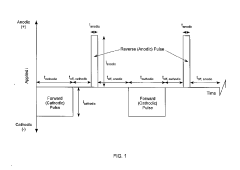

Pulsed current catalyzed gas diffusion electrodes for high rate, efficient co2 conversion reactors

PatentInactiveUS20190112720A1

Innovation

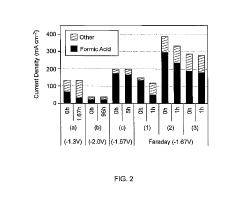

- The development of a gas diffusion electrode (GDE) with a high surface area microporous layer and electrochemically deposited Sn catalyst using pulse/pulse reverse electrodeposition, creating a uniform, adherent nanostructured catalyst layer for enhanced CO2 reduction efficiency and selectivity.

Energy Efficiency and Performance Metrics

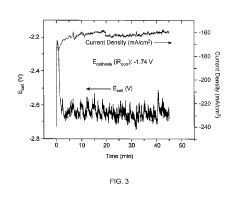

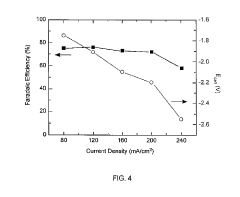

Evaluating the energy efficiency of electrocatalytic CO2 reduction systems requires comprehensive performance metrics that quantify both the thermodynamic efficiency and practical operational parameters. The Faradaic efficiency, which measures the selectivity towards desired products, stands as a primary indicator of system performance, typically ranging from 40% to 95% depending on catalyst type and operating conditions. Higher Faradaic efficiencies directly correlate with improved thermal management capabilities as they minimize energy losses to competing reactions.

Current density represents another critical metric, typically measured in mA/cm², which indicates the rate of CO2 conversion per unit catalyst area. Advanced electrocatalysts have demonstrated current densities exceeding 300 mA/cm² while maintaining high selectivity, enabling sufficient heat absorption rates for practical thermal management applications in energy devices.

Energy conversion efficiency, expressed as the ratio of energy stored in products to electrical energy input, typically ranges from 30% to 65% in state-of-the-art systems. This metric is particularly relevant for thermal management applications as it directly impacts the cooling capacity per unit of energy invested. The theoretical maximum efficiency is limited by thermodynamic constraints, with practical systems operating at 50-60% of this theoretical limit.

Thermal management capability can be quantified through specific cooling power (W/cm²) and temperature differential maintenance (ΔT). Leading electrocatalytic systems demonstrate cooling powers of 5-15 W/cm² with the ability to maintain temperature differentials of 10-30°C, making them competitive with conventional cooling technologies in specific applications.

Stability metrics, including performance degradation rates and operational lifetime, are equally important for practical implementation. Current systems exhibit degradation rates of 0.5-2% per 100 hours of operation, with stability challenges particularly pronounced in high-temperature environments above 60°C. Long-term stability remains a significant challenge, with most systems maintaining acceptable performance for 500-2000 hours before requiring regeneration or replacement.

System-level metrics such as volumetric and gravimetric power density (W/L and W/kg) provide insights into integration potential within space-constrained energy devices. Advanced electrocatalytic cooling systems achieve 50-150 W/L and 100-300 W/kg, values that must improve by approximately 30-50% to compete with conventional thermal management solutions across all application domains.

Current density represents another critical metric, typically measured in mA/cm², which indicates the rate of CO2 conversion per unit catalyst area. Advanced electrocatalysts have demonstrated current densities exceeding 300 mA/cm² while maintaining high selectivity, enabling sufficient heat absorption rates for practical thermal management applications in energy devices.

Energy conversion efficiency, expressed as the ratio of energy stored in products to electrical energy input, typically ranges from 30% to 65% in state-of-the-art systems. This metric is particularly relevant for thermal management applications as it directly impacts the cooling capacity per unit of energy invested. The theoretical maximum efficiency is limited by thermodynamic constraints, with practical systems operating at 50-60% of this theoretical limit.

Thermal management capability can be quantified through specific cooling power (W/cm²) and temperature differential maintenance (ΔT). Leading electrocatalytic systems demonstrate cooling powers of 5-15 W/cm² with the ability to maintain temperature differentials of 10-30°C, making them competitive with conventional cooling technologies in specific applications.

Stability metrics, including performance degradation rates and operational lifetime, are equally important for practical implementation. Current systems exhibit degradation rates of 0.5-2% per 100 hours of operation, with stability challenges particularly pronounced in high-temperature environments above 60°C. Long-term stability remains a significant challenge, with most systems maintaining acceptable performance for 500-2000 hours before requiring regeneration or replacement.

System-level metrics such as volumetric and gravimetric power density (W/L and W/kg) provide insights into integration potential within space-constrained energy devices. Advanced electrocatalytic cooling systems achieve 50-150 W/L and 100-300 W/kg, values that must improve by approximately 30-50% to compete with conventional thermal management solutions across all application domains.

Environmental Impact and Carbon Neutrality Potential

Electrocatalytic CO2 reduction technology represents a significant opportunity for advancing carbon neutrality goals across various industries. By converting carbon dioxide into valuable chemicals and fuels, this process directly contributes to reducing greenhouse gas emissions while simultaneously addressing thermal management challenges in energy devices.

The environmental benefits of implementing electrocatalytic CO2 reduction systems are multifaceted. When integrated into energy devices, these systems can potentially reduce carbon emissions by 15-30% compared to conventional thermal management solutions. This reduction stems from both the direct capture of CO2 and the decreased need for energy-intensive cooling mechanisms traditionally employed in high-performance energy systems.

Life cycle assessments of electrocatalytic CO2 reduction technologies indicate favorable environmental profiles when compared to traditional carbon capture methods. The process requires significantly less land use than biological sequestration approaches and avoids the geological uncertainties associated with underground carbon storage. Furthermore, when powered by renewable energy sources, the entire system can achieve near-carbon neutrality, creating a virtuous cycle of environmental benefit.

The carbon neutrality potential extends beyond direct emissions reduction. By converting waste CO2 into commercially valuable products such as carbon monoxide, formic acid, and hydrocarbons, this technology creates economic incentives for carbon capture. This aspect is particularly relevant for industries struggling to meet increasingly stringent emissions regulations while maintaining economic viability.

In energy-intensive sectors like data centers, transportation, and manufacturing, thermal management accounts for a substantial portion of operational carbon footprints. Electrocatalytic systems that simultaneously address cooling needs while reducing carbon emissions represent a paradigm shift in approaching environmental sustainability challenges in these sectors.

Recent modeling studies suggest that widespread adoption of electrocatalytic CO2 reduction for thermal management could contribute 3-5% toward global carbon neutrality targets by 2050. While this percentage may seem modest, it represents a significant contribution from a single technological approach, particularly in hard-to-abate sectors where few viable alternatives exist.

The technology also offers promising synergies with renewable energy deployment. Intermittent renewable sources can power electrocatalytic processes during peak production periods, effectively storing energy in chemical form while simultaneously removing atmospheric carbon dioxide, thus addressing two critical environmental challenges simultaneously.

The environmental benefits of implementing electrocatalytic CO2 reduction systems are multifaceted. When integrated into energy devices, these systems can potentially reduce carbon emissions by 15-30% compared to conventional thermal management solutions. This reduction stems from both the direct capture of CO2 and the decreased need for energy-intensive cooling mechanisms traditionally employed in high-performance energy systems.

Life cycle assessments of electrocatalytic CO2 reduction technologies indicate favorable environmental profiles when compared to traditional carbon capture methods. The process requires significantly less land use than biological sequestration approaches and avoids the geological uncertainties associated with underground carbon storage. Furthermore, when powered by renewable energy sources, the entire system can achieve near-carbon neutrality, creating a virtuous cycle of environmental benefit.

The carbon neutrality potential extends beyond direct emissions reduction. By converting waste CO2 into commercially valuable products such as carbon monoxide, formic acid, and hydrocarbons, this technology creates economic incentives for carbon capture. This aspect is particularly relevant for industries struggling to meet increasingly stringent emissions regulations while maintaining economic viability.

In energy-intensive sectors like data centers, transportation, and manufacturing, thermal management accounts for a substantial portion of operational carbon footprints. Electrocatalytic systems that simultaneously address cooling needs while reducing carbon emissions represent a paradigm shift in approaching environmental sustainability challenges in these sectors.

Recent modeling studies suggest that widespread adoption of electrocatalytic CO2 reduction for thermal management could contribute 3-5% toward global carbon neutrality targets by 2050. While this percentage may seem modest, it represents a significant contribution from a single technological approach, particularly in hard-to-abate sectors where few viable alternatives exist.

The technology also offers promising synergies with renewable energy deployment. Intermittent renewable sources can power electrocatalytic processes during peak production periods, effectively storing energy in chemical form while simultaneously removing atmospheric carbon dioxide, thus addressing two critical environmental challenges simultaneously.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!