Eliminating Matrix Interference in ICP-MS: Proven Methods

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-MS Technology Evolution and Objectives

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has evolved significantly since its commercial introduction in the early 1980s. This analytical technique combines the high-temperature ICP source with a mass spectrometer, enabling the detection of metals and several non-metals at concentrations as low as one part per trillion. The evolution of ICP-MS technology has been driven by the increasing demand for ultra-trace elemental analysis across various industries including environmental monitoring, food safety, pharmaceutical research, and semiconductor manufacturing.

The initial ICP-MS systems faced significant challenges related to matrix interference, which occurs when components of the sample matrix affect the measurement of target analytes. These interferences manifested as spectral overlaps, physical effects on sample transport, and ionization suppression. Early systems utilized quadrupole mass analyzers with limited resolution, making it difficult to distinguish between analytes and interfering species with similar mass-to-charge ratios.

Throughout the 1990s, significant advancements were made in interface design and ion optics, improving ion transmission efficiency and reducing background noise. The introduction of collision/reaction cell technology in the late 1990s represented a pivotal development in addressing polyatomic interferences. These cells, positioned between the ion optics and the mass analyzer, utilize collision gases (such as helium) or reaction gases (such as hydrogen or ammonia) to eliminate interfering species through kinetic energy discrimination or chemical reactions.

The 2000s witnessed the commercialization of high-resolution ICP-MS instruments employing magnetic sector analyzers, capable of resolving many spectral interferences through superior mass resolution. Simultaneously, triple quadrupole ICP-MS systems emerged, offering enhanced interference removal capabilities through tandem mass spectrometry approaches. These developments significantly expanded the application scope of ICP-MS in complex matrices.

Recent technological innovations have focused on improving sample introduction systems, enhancing sensitivity, and developing specialized interfaces for coupling with chromatographic techniques. Advanced software algorithms for interference correction and internal standardization have further improved measurement accuracy and precision in complex matrices.

The primary objective of current ICP-MS technology development is to achieve complete elimination of matrix interferences while maintaining high sensitivity, accuracy, and throughput. This includes developing more efficient sample preparation techniques, improving collision/reaction cell technologies, enhancing detector capabilities, and implementing sophisticated data processing algorithms. The ultimate goal is to establish ICP-MS as a universal, interference-free analytical platform capable of reliable multi-elemental analysis across diverse and challenging sample matrices.

The initial ICP-MS systems faced significant challenges related to matrix interference, which occurs when components of the sample matrix affect the measurement of target analytes. These interferences manifested as spectral overlaps, physical effects on sample transport, and ionization suppression. Early systems utilized quadrupole mass analyzers with limited resolution, making it difficult to distinguish between analytes and interfering species with similar mass-to-charge ratios.

Throughout the 1990s, significant advancements were made in interface design and ion optics, improving ion transmission efficiency and reducing background noise. The introduction of collision/reaction cell technology in the late 1990s represented a pivotal development in addressing polyatomic interferences. These cells, positioned between the ion optics and the mass analyzer, utilize collision gases (such as helium) or reaction gases (such as hydrogen or ammonia) to eliminate interfering species through kinetic energy discrimination or chemical reactions.

The 2000s witnessed the commercialization of high-resolution ICP-MS instruments employing magnetic sector analyzers, capable of resolving many spectral interferences through superior mass resolution. Simultaneously, triple quadrupole ICP-MS systems emerged, offering enhanced interference removal capabilities through tandem mass spectrometry approaches. These developments significantly expanded the application scope of ICP-MS in complex matrices.

Recent technological innovations have focused on improving sample introduction systems, enhancing sensitivity, and developing specialized interfaces for coupling with chromatographic techniques. Advanced software algorithms for interference correction and internal standardization have further improved measurement accuracy and precision in complex matrices.

The primary objective of current ICP-MS technology development is to achieve complete elimination of matrix interferences while maintaining high sensitivity, accuracy, and throughput. This includes developing more efficient sample preparation techniques, improving collision/reaction cell technologies, enhancing detector capabilities, and implementing sophisticated data processing algorithms. The ultimate goal is to establish ICP-MS as a universal, interference-free analytical platform capable of reliable multi-elemental analysis across diverse and challenging sample matrices.

Market Applications and Analytical Demands

The ICP-MS (Inductively Coupled Plasma Mass Spectrometry) technology has established itself as an indispensable analytical tool across numerous industries due to its exceptional sensitivity, multi-element capabilities, and wide dynamic range. The market demand for this technology continues to grow steadily, with the global ICP-MS market valued at approximately $1.2 billion in 2022 and projected to reach $1.8 billion by 2027, representing a compound annual growth rate of 8.5%.

Environmental monitoring represents one of the largest application segments, where regulatory agencies worldwide require increasingly sensitive detection of heavy metals and other contaminants in water, soil, and air samples. The implementation of stricter environmental regulations in developed and developing nations has significantly boosted demand for advanced matrix interference elimination techniques in ICP-MS.

The pharmaceutical and biomedical sectors constitute rapidly expanding markets for ICP-MS technology. These industries require ultra-trace elemental analysis in complex biological matrices such as blood, urine, and tissue samples. The growing focus on personalized medicine and biomarker discovery has intensified the need for reliable analytical methods capable of handling challenging biological matrices without compromising detection limits or accuracy.

Food safety testing represents another critical application area with substantial growth potential. Regulatory requirements for monitoring toxic elements in food products have become more stringent globally, necessitating analytical methods that can effectively manage the diverse and complex matrices encountered in food samples. The ability to eliminate matrix effects is particularly valuable when analyzing products with high salt, fat, or protein content.

The semiconductor and electronics manufacturing industries demand extremely high-purity materials, driving the need for ultra-trace elemental analysis with minimal matrix interference. As device dimensions continue to shrink, even minute impurities can significantly impact performance, making advanced ICP-MS techniques essential for quality control and process monitoring.

Mining and metallurgical applications require robust analytical methods capable of handling samples with extremely high dissolved solid content. The economic value of accurate precious metal quantification in these industries justifies investment in sophisticated matrix elimination technologies.

Academic and research institutions represent a significant market segment, where the development of novel matrix elimination strategies often originates. The continuous push for lower detection limits and improved accuracy in complex samples drives innovation in this sector, which subsequently transfers to commercial applications.

Environmental monitoring represents one of the largest application segments, where regulatory agencies worldwide require increasingly sensitive detection of heavy metals and other contaminants in water, soil, and air samples. The implementation of stricter environmental regulations in developed and developing nations has significantly boosted demand for advanced matrix interference elimination techniques in ICP-MS.

The pharmaceutical and biomedical sectors constitute rapidly expanding markets for ICP-MS technology. These industries require ultra-trace elemental analysis in complex biological matrices such as blood, urine, and tissue samples. The growing focus on personalized medicine and biomarker discovery has intensified the need for reliable analytical methods capable of handling challenging biological matrices without compromising detection limits or accuracy.

Food safety testing represents another critical application area with substantial growth potential. Regulatory requirements for monitoring toxic elements in food products have become more stringent globally, necessitating analytical methods that can effectively manage the diverse and complex matrices encountered in food samples. The ability to eliminate matrix effects is particularly valuable when analyzing products with high salt, fat, or protein content.

The semiconductor and electronics manufacturing industries demand extremely high-purity materials, driving the need for ultra-trace elemental analysis with minimal matrix interference. As device dimensions continue to shrink, even minute impurities can significantly impact performance, making advanced ICP-MS techniques essential for quality control and process monitoring.

Mining and metallurgical applications require robust analytical methods capable of handling samples with extremely high dissolved solid content. The economic value of accurate precious metal quantification in these industries justifies investment in sophisticated matrix elimination technologies.

Academic and research institutions represent a significant market segment, where the development of novel matrix elimination strategies often originates. The continuous push for lower detection limits and improved accuracy in complex samples drives innovation in this sector, which subsequently transfers to commercial applications.

Matrix Interference Challenges in ICP-MS Analysis

Matrix interference represents one of the most significant challenges in Inductively Coupled Plasma Mass Spectrometry (ICP-MS) analysis. These interferences occur when components of the sample matrix affect the measurement of target analytes, leading to inaccurate results. The complexity of matrix interference stems from multiple sources, including spectral overlap, physical effects, and chemical interactions within the plasma or interface regions.

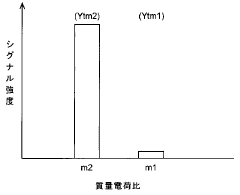

Spectral interferences arise when atomic or molecular ions have the same mass-to-charge ratio (m/z) as the analyte of interest. For example, 40Ar16O+ can interfere with 56Fe+ determination, while 40Ar35Cl+ affects 75As+ measurements. These overlaps are particularly problematic in complex environmental or biological samples where numerous elements coexist.

Physical matrix effects manifest as signal suppression or enhancement due to differences in sample transport, nebulization efficiency, or ionization conditions. High dissolved solid content (>0.2%) typically causes signal suppression through deposition on sampler and skimmer cones, reducing ion transmission efficiency. Conversely, certain organic matrices can enhance ionization efficiency for some elements, leading to artificially elevated readings.

Chemical interferences occur when matrix components alter the ionization equilibrium within the plasma or form compounds with analytes, changing their detection characteristics. Elements with high ionization potentials (e.g., As, Se) are particularly susceptible to these effects in carbon-rich matrices.

The severity of matrix interference varies significantly across sample types. Clinical samples containing high sodium and protein content present different challenges compared to environmental samples with diverse mineral compositions. Industrial samples may contain high concentrations of specific elements that create unique interference patterns requiring specialized mitigation strategies.

Modern ICP-MS instruments typically operate at resolving powers between 300-10,000 amu, which remains insufficient to separate many isobaric interferences. This fundamental limitation necessitates the development of alternative approaches for interference management rather than relying solely on instrumental resolution improvements.

The economic impact of matrix interference extends beyond analytical accuracy. Laboratories must invest in additional sample preparation equipment, specialized reagents, and longer analytical procedures to address these challenges. Furthermore, the expertise required to identify and correct for matrix effects increases operational costs and extends result turnaround times in commercial testing environments.

Spectral interferences arise when atomic or molecular ions have the same mass-to-charge ratio (m/z) as the analyte of interest. For example, 40Ar16O+ can interfere with 56Fe+ determination, while 40Ar35Cl+ affects 75As+ measurements. These overlaps are particularly problematic in complex environmental or biological samples where numerous elements coexist.

Physical matrix effects manifest as signal suppression or enhancement due to differences in sample transport, nebulization efficiency, or ionization conditions. High dissolved solid content (>0.2%) typically causes signal suppression through deposition on sampler and skimmer cones, reducing ion transmission efficiency. Conversely, certain organic matrices can enhance ionization efficiency for some elements, leading to artificially elevated readings.

Chemical interferences occur when matrix components alter the ionization equilibrium within the plasma or form compounds with analytes, changing their detection characteristics. Elements with high ionization potentials (e.g., As, Se) are particularly susceptible to these effects in carbon-rich matrices.

The severity of matrix interference varies significantly across sample types. Clinical samples containing high sodium and protein content present different challenges compared to environmental samples with diverse mineral compositions. Industrial samples may contain high concentrations of specific elements that create unique interference patterns requiring specialized mitigation strategies.

Modern ICP-MS instruments typically operate at resolving powers between 300-10,000 amu, which remains insufficient to separate many isobaric interferences. This fundamental limitation necessitates the development of alternative approaches for interference management rather than relying solely on instrumental resolution improvements.

The economic impact of matrix interference extends beyond analytical accuracy. Laboratories must invest in additional sample preparation equipment, specialized reagents, and longer analytical procedures to address these challenges. Furthermore, the expertise required to identify and correct for matrix effects increases operational costs and extends result turnaround times in commercial testing environments.

Current Matrix Interference Removal Methodologies

01 Matrix removal and separation techniques

Various techniques can be employed to remove or separate matrix components before ICP-MS analysis, reducing interference effects. These methods include chemical separation, chromatographic techniques, and physical separation processes that isolate the analytes of interest from interfering matrix components. By removing the matrix before analysis, signal suppression and spectral interferences can be significantly reduced, improving detection limits and analytical accuracy.- Matrix removal and separation techniques: Various techniques can be employed to remove or separate matrix components before ICP-MS analysis, reducing interference effects. These include chemical separation methods, physical separation processes, and specialized sample preparation protocols that isolate analytes from interfering matrix elements. These approaches help improve detection limits and analytical accuracy by eliminating or minimizing matrix-induced signal suppression or enhancement.

- Mathematical correction and calibration methods: Mathematical algorithms and calibration strategies can be applied to compensate for matrix interference in ICP-MS analysis. These include internal standardization, standard addition methods, isotope dilution techniques, and multivariate statistical approaches. By applying appropriate mathematical corrections to the raw data, analysts can account for matrix effects without requiring complete physical separation of interfering components.

- Instrument modifications and optimization: Specialized hardware configurations and instrument parameter optimization can minimize matrix interference in ICP-MS. These include collision/reaction cell technologies, high-resolution mass analyzers, alternative sample introduction systems, and optimized plasma conditions. By modifying the instrument setup or operating parameters, many common matrix interferences can be reduced or eliminated during analysis.

- Sample preparation and pretreatment methods: Effective sample preparation protocols can significantly reduce matrix interference in ICP-MS analysis. These include digestion procedures, dilution strategies, chelation techniques, and preconcentration methods. Proper sample pretreatment helps minimize the introduction of interfering species into the plasma, resulting in more accurate and precise analytical results.

- Alternative plasma sources and ionization techniques: Novel plasma configurations and alternative ionization approaches can be employed to overcome matrix interference issues in mass spectrometry. These include cold plasma techniques, mixed-gas plasmas, alternative RF generators, and hybrid ionization sources. These approaches modify the fundamental ionization process to reduce the formation of interfering species or enhance the ionization of target analytes in complex matrices.

02 Mathematical correction and calibration methods

Mathematical approaches can be used to correct for matrix interference in ICP-MS analysis. These include internal standardization, standard addition methods, isotope dilution, and multivariate statistical techniques. By applying appropriate mathematical corrections and calibration strategies, the effects of matrix-induced signal suppression or enhancement can be compensated for, leading to more accurate quantitative results even in complex sample matrices.Expand Specific Solutions03 Sample preparation and digestion optimization

Optimized sample preparation protocols can minimize matrix interference in ICP-MS analysis. This includes appropriate digestion methods (acid digestion, microwave digestion, fusion), dilution strategies, and pre-concentration techniques. By properly preparing samples before introduction to the ICP-MS system, matrix effects can be reduced while maintaining sensitivity for target analytes, resulting in more reliable analytical data.Expand Specific Solutions04 Collision/reaction cell technology

Collision and reaction cell technologies are used in ICP-MS to reduce polyatomic and isobaric interferences. These cells, positioned between the ion source and mass analyzer, use collision gases (helium, hydrogen) or reaction gases (oxygen, ammonia) to eliminate interfering species through kinetic energy discrimination or chemical reactions. This approach allows for improved detection of elements that are typically affected by spectral interferences from the sample matrix.Expand Specific Solutions05 Specialized sample introduction systems

Modified sample introduction systems can help mitigate matrix effects in ICP-MS analysis. These include specialized nebulizers, spray chambers, desolvation systems, and flow injection techniques that can reduce the amount of matrix reaching the plasma or modify how the sample interacts with the plasma. By optimizing the sample introduction process, matrix-related signal suppression, enhancement, and spectral interferences can be minimized, improving analytical performance for complex samples.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The ICP-MS matrix interference elimination market is in a growth phase, with increasing demand driven by environmental monitoring, food safety, and pharmaceutical applications. The global ICP-MS market is projected to expand significantly, valued at approximately $1.5 billion with a CAGR of 7-8%. Technologically, the field shows varying maturity levels across different solution approaches. Industry leaders Thermo Fisher Scientific and Agilent Technologies dominate with comprehensive matrix management systems, while Shimadzu, PerkinElmer (Revvity), and SPECTRO Analytical offer competitive alternatives. Emerging players like Kimia Analytics are introducing innovative torch designs for enhanced matrix tolerance. Academic institutions (EPFL, China University of Geosciences) and research organizations (A*STAR) continue contributing fundamental advancements to overcome persistent matrix interference challenges.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has developed comprehensive matrix interference elimination solutions for ICP-MS through their Triple Quadrupole ICP-MS technology (TQ-ICP-MS). Their iCAP TQ ICP-MS system utilizes a unique collision/reaction cell approach with selective reaction monitoring to effectively remove polyatomic and isobaric interferences. The system employs multiple gas modes including helium collision cell technology (CCT) for kinetic energy discrimination and reactive gases (oxygen, hydrogen, ammonia) for chemical interference removal[1]. Their proprietary QCell technology with flatapole design ensures efficient ion transmission while maintaining sensitivity. Additionally, Thermo Fisher has implemented advanced interference correction algorithms in their Qtegra software that can automatically apply mathematical corrections based on known interference patterns[3]. Their systems also feature high-resolution capabilities that can physically separate interfering species based on mass differences.

Strengths: Superior interference removal through triple quadrupole technology; versatile gas mode options for different interference types; high sensitivity maintained even with interference removal. Weaknesses: Higher operational costs due to multiple gas requirements; more complex operation requiring trained personnel; greater initial investment compared to single quadrupole systems.

Shimadzu Corp.

Technical Solution: Shimadzu Corporation has pioneered matrix interference elimination in ICP-MS through their patented mini-torch system and unique collision/reaction cell technology. Their ICPMS-2030 platform incorporates an octopole collision cell with helium gas that effectively removes polyatomic interferences through kinetic energy discrimination (KED)[2]. Shimadzu's approach includes their proprietary "Development Assistant" software that automatically optimizes collision cell parameters based on sample matrix composition. Their systems feature unique plasma temperature control technology that minimizes matrix effects at the ionization source. Additionally, Shimadzu has developed the "IntelliQuant" screening technology that identifies potential matrix interferences before quantitative analysis and suggests appropriate correction methods[4]. Their systems also employ mathematical correction models using internal standardization with their LabSolutions ICPMS software that can compensate for both spectral and non-spectral interferences through sophisticated algorithms.

Strengths: Excellent performance in high-matrix samples with minimal dilution requirements; intuitive software that simplifies method development; lower gas consumption compared to competitors. Weaknesses: Limited reaction gas options compared to triple quadrupole systems; slightly lower sensitivity for certain ultra-trace elements in complex matrices.

Key Patents and Innovations in Interference Management

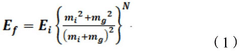

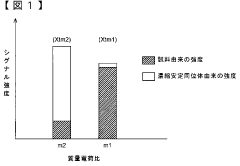

Tandem Collision/Reaction Cell for Inductively Coupled Plasma Mass Spectrometry

PatentActiveCN110277299B

Innovation

- Using a series collision/reaction cell structure, including the first and second ion guides and the middle electrode, the kinetic energy distribution of the ion beam is optimized by generating a multi-level RF confinement field and DC barrier to ensure that the analyte ions can effectively pass through the mass analysis device while blocking interfering ions.

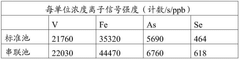

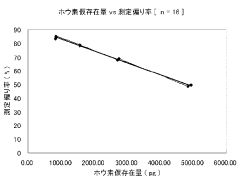

Determination Method of Trace Impurity Elements Using Inductively Coupled Plasma Mass Spectrometer

PatentInactiveJP4512605B2

Innovation

- A method involving stable isotope dilution mass spectrometry is developed, utilizing a general-purpose quadrupole ICP-MS to quantify trace elements by adding enriched stable isotopes, establishing isotope equilibrium, and correcting for recovery rates and contamination through a series of signal intensity measurements and calibration curves, without the need for precise isotope ratio measurements.

Regulatory Standards for ICP-MS Analysis

Regulatory standards for ICP-MS analysis have evolved significantly over the past decades to ensure reliable and accurate measurements across various industries. The United States Environmental Protection Agency (EPA) has established Method 6020 specifically for ICP-MS analysis, which outlines detailed procedures for sample preparation, instrument calibration, and quality control measures to minimize matrix interference effects. This method is particularly important for environmental monitoring and has been updated several times to incorporate technological advancements.

In the pharmaceutical sector, the United States Pharmacopeia (USP) and European Pharmacopoeia (EP) have implemented stringent guidelines for elemental impurity testing using ICP-MS. USP chapters <232> and <233> specifically address permissible limits for elemental impurities and analytical procedures, respectively. These standards emphasize the importance of validated methods for matrix effect mitigation to ensure accurate quantification of trace elements in drug products.

The food industry follows standards set by organizations such as AOAC International and the Food and Drug Administration (FDA), which provide protocols for sample digestion and matrix management techniques. These standards typically require demonstration of method performance through spike recovery tests in various food matrices, with acceptance criteria typically ranging from 80-120% recovery for most elements.

For clinical applications, the Clinical and Laboratory Standards Institute (CLSI) has developed guidelines that address matrix effects in biological samples. These standards emphasize the importance of appropriate internal standardization and matrix-matched calibration when analyzing complex biological matrices such as blood, urine, or tissue samples.

International Organization for Standardization (ISO) has published ISO 17294, which provides general guidance for ICP-MS applications across multiple industries. This standard emphasizes method validation procedures specifically designed to identify and quantify matrix interference effects, requiring laboratories to demonstrate their capability to overcome these challenges through appropriate quality control measures.

Regulatory compliance often requires laboratories to participate in proficiency testing programs, where unknown samples containing various matrix components are analyzed. Performance in these programs serves as an external validation of a laboratory's ability to effectively manage matrix interferences. Organizations such as the International Association of Environmental Testing Laboratories (IAETL) coordinate such programs globally, establishing performance benchmarks that laboratories must meet to maintain accreditation.

In the pharmaceutical sector, the United States Pharmacopeia (USP) and European Pharmacopoeia (EP) have implemented stringent guidelines for elemental impurity testing using ICP-MS. USP chapters <232> and <233> specifically address permissible limits for elemental impurities and analytical procedures, respectively. These standards emphasize the importance of validated methods for matrix effect mitigation to ensure accurate quantification of trace elements in drug products.

The food industry follows standards set by organizations such as AOAC International and the Food and Drug Administration (FDA), which provide protocols for sample digestion and matrix management techniques. These standards typically require demonstration of method performance through spike recovery tests in various food matrices, with acceptance criteria typically ranging from 80-120% recovery for most elements.

For clinical applications, the Clinical and Laboratory Standards Institute (CLSI) has developed guidelines that address matrix effects in biological samples. These standards emphasize the importance of appropriate internal standardization and matrix-matched calibration when analyzing complex biological matrices such as blood, urine, or tissue samples.

International Organization for Standardization (ISO) has published ISO 17294, which provides general guidance for ICP-MS applications across multiple industries. This standard emphasizes method validation procedures specifically designed to identify and quantify matrix interference effects, requiring laboratories to demonstrate their capability to overcome these challenges through appropriate quality control measures.

Regulatory compliance often requires laboratories to participate in proficiency testing programs, where unknown samples containing various matrix components are analyzed. Performance in these programs serves as an external validation of a laboratory's ability to effectively manage matrix interferences. Organizations such as the International Association of Environmental Testing Laboratories (IAETL) coordinate such programs globally, establishing performance benchmarks that laboratories must meet to maintain accreditation.

Sample Preparation Optimization Strategies

Sample preparation represents a critical first line of defense against matrix interference in ICP-MS analysis. Effective sample preparation strategies can significantly reduce or eliminate problematic matrix components before they reach the instrument, thereby enhancing analytical accuracy and precision.

Dilution remains one of the simplest yet most effective approaches for minimizing matrix effects. By reducing the concentration of matrix components, dilution directly decreases their potential for interference. Studies have shown that dilution factors between 10-100x can effectively mitigate many common matrix interferences while maintaining adequate analyte sensitivity. However, this approach requires careful balance, as excessive dilution may compromise detection limits for trace elements.

Acid digestion protocols can be optimized based on specific sample matrices. For biological samples, a combination of nitric acid and hydrogen peroxide typically provides complete mineralization while minimizing polyatomic interferences. For geological or environmental samples containing silicates, hydrofluoric acid may be necessary, though this introduces additional safety considerations and potential instrumental complications.

Microwave-assisted digestion has emerged as a superior alternative to conventional hotplate digestion, offering faster processing times, reduced contamination risk, and more complete matrix decomposition. Modern microwave systems with temperature and pressure monitoring capabilities allow for precise control of digestion parameters, enabling method optimization for specific matrix types.

Solid phase extraction (SPE) techniques provide selective removal of matrix components while concentrating analytes of interest. Chelating resins such as Chelex-100 or iminodiacetic acid-based materials have demonstrated excellent performance for separating trace metals from complex matrices including seawater, biological fluids, and industrial effluents. The development of automated SPE systems has further enhanced the reproducibility and throughput of these methods.

Matrix-matched calibration represents another powerful strategy, wherein calibration standards are prepared in solutions that mimic the sample matrix composition. This approach compensates for matrix effects by ensuring that analytes in both samples and standards experience similar interference conditions. While effective, this method requires detailed knowledge of the sample matrix composition and can be labor-intensive for highly variable sample types.

Emerging technologies such as flow injection analysis (FIA) coupled with ICP-MS offer dynamic approaches to sample preparation, allowing for automated online dilution, standard addition, and matrix removal. These systems can significantly improve sample throughput while maintaining or enhancing analytical performance through precise control of sample introduction parameters.

Dilution remains one of the simplest yet most effective approaches for minimizing matrix effects. By reducing the concentration of matrix components, dilution directly decreases their potential for interference. Studies have shown that dilution factors between 10-100x can effectively mitigate many common matrix interferences while maintaining adequate analyte sensitivity. However, this approach requires careful balance, as excessive dilution may compromise detection limits for trace elements.

Acid digestion protocols can be optimized based on specific sample matrices. For biological samples, a combination of nitric acid and hydrogen peroxide typically provides complete mineralization while minimizing polyatomic interferences. For geological or environmental samples containing silicates, hydrofluoric acid may be necessary, though this introduces additional safety considerations and potential instrumental complications.

Microwave-assisted digestion has emerged as a superior alternative to conventional hotplate digestion, offering faster processing times, reduced contamination risk, and more complete matrix decomposition. Modern microwave systems with temperature and pressure monitoring capabilities allow for precise control of digestion parameters, enabling method optimization for specific matrix types.

Solid phase extraction (SPE) techniques provide selective removal of matrix components while concentrating analytes of interest. Chelating resins such as Chelex-100 or iminodiacetic acid-based materials have demonstrated excellent performance for separating trace metals from complex matrices including seawater, biological fluids, and industrial effluents. The development of automated SPE systems has further enhanced the reproducibility and throughput of these methods.

Matrix-matched calibration represents another powerful strategy, wherein calibration standards are prepared in solutions that mimic the sample matrix composition. This approach compensates for matrix effects by ensuring that analytes in both samples and standards experience similar interference conditions. While effective, this method requires detailed knowledge of the sample matrix composition and can be labor-intensive for highly variable sample types.

Emerging technologies such as flow injection analysis (FIA) coupled with ICP-MS offer dynamic approaches to sample preparation, allowing for automated online dilution, standard addition, and matrix removal. These systems can significantly improve sample throughput while maintaining or enhancing analytical performance through precise control of sample introduction parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!