Emerging Techniques in Hydrochloric Acid Excellence

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Production Evolution

The production of hydrochloric acid (HCl) has undergone significant evolution since its inception in the early 19th century. Initially, HCl was primarily a byproduct of the Leblanc process for soda ash production. This method, while groundbreaking at the time, was inefficient and environmentally harmful.

The late 19th century saw the introduction of the Hargreaves process, which produced HCl by reacting salt, sulfuric acid, and air. This marked a shift towards more deliberate HCl production methods. However, the real revolution came with the development of the chlor-alkali process in the early 20th century, which remains the dominant method for HCl production today.

The chlor-alkali process, based on the electrolysis of brine, produces chlorine gas as a primary product. This chlorine is then reacted with hydrogen to form HCl. This method significantly improved production efficiency and purity, leading to a substantial increase in HCl availability for industrial applications.

In recent decades, the focus has shifted towards enhancing the sustainability and efficiency of HCl production. Membrane cell technology has largely replaced mercury cell and diaphragm cell methods in the chlor-alkali process, reducing environmental impact and improving energy efficiency. Additionally, advancements in catalytic processes have enabled more effective conversion of chlorine to HCl.

The recovery and recycling of HCl from industrial processes have also gained prominence. Techniques such as azeotropic distillation and membrane separation have been developed to purify and concentrate HCl from waste streams, aligning with circular economy principles.

Emerging techniques in HCl production are now focusing on further improving energy efficiency and reducing carbon footprint. Research is ongoing into electrocatalytic processes that could potentially produce HCl directly from hydrogen and chlorine at room temperature, bypassing the need for high-temperature reactors. Additionally, there is growing interest in utilizing renewable energy sources to power the energy-intensive chlor-alkali process.

The integration of digital technologies and advanced process control systems has also played a crucial role in optimizing HCl production. These innovations have led to improved yield, reduced waste, and enhanced safety in production facilities.

As environmental regulations become more stringent, the HCl production industry is exploring novel approaches to minimize emissions and improve overall sustainability. This includes the development of closed-loop systems and the implementation of advanced scrubbing technologies to capture and neutralize any acid gases produced during the manufacturing process.

The late 19th century saw the introduction of the Hargreaves process, which produced HCl by reacting salt, sulfuric acid, and air. This marked a shift towards more deliberate HCl production methods. However, the real revolution came with the development of the chlor-alkali process in the early 20th century, which remains the dominant method for HCl production today.

The chlor-alkali process, based on the electrolysis of brine, produces chlorine gas as a primary product. This chlorine is then reacted with hydrogen to form HCl. This method significantly improved production efficiency and purity, leading to a substantial increase in HCl availability for industrial applications.

In recent decades, the focus has shifted towards enhancing the sustainability and efficiency of HCl production. Membrane cell technology has largely replaced mercury cell and diaphragm cell methods in the chlor-alkali process, reducing environmental impact and improving energy efficiency. Additionally, advancements in catalytic processes have enabled more effective conversion of chlorine to HCl.

The recovery and recycling of HCl from industrial processes have also gained prominence. Techniques such as azeotropic distillation and membrane separation have been developed to purify and concentrate HCl from waste streams, aligning with circular economy principles.

Emerging techniques in HCl production are now focusing on further improving energy efficiency and reducing carbon footprint. Research is ongoing into electrocatalytic processes that could potentially produce HCl directly from hydrogen and chlorine at room temperature, bypassing the need for high-temperature reactors. Additionally, there is growing interest in utilizing renewable energy sources to power the energy-intensive chlor-alkali process.

The integration of digital technologies and advanced process control systems has also played a crucial role in optimizing HCl production. These innovations have led to improved yield, reduced waste, and enhanced safety in production facilities.

As environmental regulations become more stringent, the HCl production industry is exploring novel approaches to minimize emissions and improve overall sustainability. This includes the development of closed-loop systems and the implementation of advanced scrubbing technologies to capture and neutralize any acid gases produced during the manufacturing process.

Market Demand Analysis

The market demand for hydrochloric acid (HCl) has been steadily growing, driven by its widespread applications across various industries. The global hydrochloric acid market is expected to expand significantly in the coming years, with a compound annual growth rate (CAGR) projected to be robust. This growth is primarily attributed to the increasing demand from key end-use industries such as steel pickling, oil well acidizing, food processing, and chemical manufacturing.

In the steel industry, hydrochloric acid plays a crucial role in the pickling process, which removes impurities and rust from steel surfaces. As the global steel production continues to rise, particularly in emerging economies, the demand for high-quality hydrochloric acid is expected to surge. The oil and gas sector also contributes significantly to the market growth, with HCl being extensively used in well acidizing to enhance oil recovery and stimulate production.

The chemical industry remains a major consumer of hydrochloric acid, utilizing it as a key raw material in the production of various chemicals, including vinyl chloride, chlorine dioxide, and calcium chloride. The growing demand for these chemicals in diverse applications further fuels the hydrochloric acid market. Additionally, the food processing industry relies on HCl for various purposes, such as pH regulation and as a processing aid, contributing to the overall market expansion.

Emerging applications in water treatment and pharmaceuticals are creating new opportunities for hydrochloric acid manufacturers. The increasing focus on water purification and the growing pharmaceutical industry, especially in developing regions, are expected to drive additional demand for high-purity hydrochloric acid.

However, the market faces challenges related to environmental concerns and stringent regulations regarding the production and handling of hydrochloric acid. This has led to a growing emphasis on developing more sustainable and environmentally friendly production methods, creating a niche market for green hydrochloric acid solutions.

Geographically, Asia-Pacific is anticipated to dominate the hydrochloric acid market, driven by rapid industrialization, infrastructure development, and the presence of major manufacturing hubs in countries like China and India. North America and Europe are also significant markets, with steady demand from established industries and increasing focus on specialty applications.

The market trend is shifting towards the development of higher-purity grades of hydrochloric acid to meet the stringent requirements of industries such as electronics and pharmaceuticals. This trend is likely to drive innovation in purification techniques and quality control measures, potentially leading to premium pricing for high-grade products.

In the steel industry, hydrochloric acid plays a crucial role in the pickling process, which removes impurities and rust from steel surfaces. As the global steel production continues to rise, particularly in emerging economies, the demand for high-quality hydrochloric acid is expected to surge. The oil and gas sector also contributes significantly to the market growth, with HCl being extensively used in well acidizing to enhance oil recovery and stimulate production.

The chemical industry remains a major consumer of hydrochloric acid, utilizing it as a key raw material in the production of various chemicals, including vinyl chloride, chlorine dioxide, and calcium chloride. The growing demand for these chemicals in diverse applications further fuels the hydrochloric acid market. Additionally, the food processing industry relies on HCl for various purposes, such as pH regulation and as a processing aid, contributing to the overall market expansion.

Emerging applications in water treatment and pharmaceuticals are creating new opportunities for hydrochloric acid manufacturers. The increasing focus on water purification and the growing pharmaceutical industry, especially in developing regions, are expected to drive additional demand for high-purity hydrochloric acid.

However, the market faces challenges related to environmental concerns and stringent regulations regarding the production and handling of hydrochloric acid. This has led to a growing emphasis on developing more sustainable and environmentally friendly production methods, creating a niche market for green hydrochloric acid solutions.

Geographically, Asia-Pacific is anticipated to dominate the hydrochloric acid market, driven by rapid industrialization, infrastructure development, and the presence of major manufacturing hubs in countries like China and India. North America and Europe are also significant markets, with steady demand from established industries and increasing focus on specialty applications.

The market trend is shifting towards the development of higher-purity grades of hydrochloric acid to meet the stringent requirements of industries such as electronics and pharmaceuticals. This trend is likely to drive innovation in purification techniques and quality control measures, potentially leading to premium pricing for high-grade products.

Technical Challenges

The hydrochloric acid (HCl) industry faces several significant technical challenges in its pursuit of excellence. One of the primary issues is the corrosive nature of HCl, which poses substantial risks to equipment and infrastructure. This necessitates the development of advanced materials and coatings capable of withstanding prolonged exposure to highly acidic environments. Current solutions, while effective, often come with high costs or limited lifespans, creating a need for more durable and cost-effective alternatives.

Another critical challenge lies in the production process itself. Traditional methods of HCl synthesis, such as the salt-sulfuric acid process or the direct synthesis from hydrogen and chlorine, are energy-intensive and can produce unwanted by-products. Improving the efficiency of these processes while minimizing environmental impact remains a key focus area for researchers and industry professionals. This includes exploring catalytic processes that could potentially lower energy requirements and increase yield.

The transportation and storage of HCl present additional technical hurdles. Given its hazardous nature, stringent safety measures are required throughout the supply chain. Developing innovative containment systems that can ensure the safe transport of large quantities of HCl, particularly in concentrated forms, is an ongoing challenge. This extends to storage solutions that must balance safety, capacity, and accessibility for industrial applications.

Environmental concerns also drive technical challenges in the HCl industry. Emissions control, particularly for hydrogen chloride gas, is a critical area requiring continuous improvement. Advanced scrubbing technologies and closed-loop systems are being explored to minimize environmental impact and meet increasingly stringent regulations. Additionally, there is a growing need for more efficient recycling and recovery methods for HCl used in various industrial processes, aiming to reduce waste and improve overall resource utilization.

The quest for higher purity HCl for specialized applications, such as semiconductor manufacturing, presents its own set of technical challenges. Achieving ultra-high purity levels requires sophisticated purification techniques and contamination control measures throughout the production and handling processes. This demands continuous innovation in filtration, distillation, and quality control technologies.

Lastly, the integration of digital technologies and automation into HCl production and handling processes poses both opportunities and challenges. Implementing advanced process control systems, real-time monitoring, and predictive maintenance technologies can significantly enhance efficiency and safety. However, this digital transformation requires overcoming issues related to sensor reliability in harsh acidic environments, data integration across legacy systems, and ensuring cybersecurity in increasingly connected industrial settings.

Another critical challenge lies in the production process itself. Traditional methods of HCl synthesis, such as the salt-sulfuric acid process or the direct synthesis from hydrogen and chlorine, are energy-intensive and can produce unwanted by-products. Improving the efficiency of these processes while minimizing environmental impact remains a key focus area for researchers and industry professionals. This includes exploring catalytic processes that could potentially lower energy requirements and increase yield.

The transportation and storage of HCl present additional technical hurdles. Given its hazardous nature, stringent safety measures are required throughout the supply chain. Developing innovative containment systems that can ensure the safe transport of large quantities of HCl, particularly in concentrated forms, is an ongoing challenge. This extends to storage solutions that must balance safety, capacity, and accessibility for industrial applications.

Environmental concerns also drive technical challenges in the HCl industry. Emissions control, particularly for hydrogen chloride gas, is a critical area requiring continuous improvement. Advanced scrubbing technologies and closed-loop systems are being explored to minimize environmental impact and meet increasingly stringent regulations. Additionally, there is a growing need for more efficient recycling and recovery methods for HCl used in various industrial processes, aiming to reduce waste and improve overall resource utilization.

The quest for higher purity HCl for specialized applications, such as semiconductor manufacturing, presents its own set of technical challenges. Achieving ultra-high purity levels requires sophisticated purification techniques and contamination control measures throughout the production and handling processes. This demands continuous innovation in filtration, distillation, and quality control technologies.

Lastly, the integration of digital technologies and automation into HCl production and handling processes poses both opportunities and challenges. Implementing advanced process control systems, real-time monitoring, and predictive maintenance technologies can significantly enhance efficiency and safety. However, this digital transformation requires overcoming issues related to sensor reliability in harsh acidic environments, data integration across legacy systems, and ensuring cybersecurity in increasingly connected industrial settings.

Current HCl Solutions

01 Production and purification of hydrochloric acid

Various methods and processes for producing high-quality hydrochloric acid, including purification techniques to remove impurities and achieve desired concentrations. These processes may involve distillation, absorption, or other separation methods to ensure the excellence of the final product.- Production and purification of hydrochloric acid: Various methods and processes for producing high-quality hydrochloric acid, including purification techniques to remove impurities and achieve desired concentrations. These processes may involve distillation, absorption, or other separation methods to ensure the excellence of the final product.

- Applications of high-purity hydrochloric acid: High-purity hydrochloric acid finds applications in various industries, including semiconductor manufacturing, chemical processing, and pharmaceutical production. The excellent quality of the acid is crucial for these applications, ensuring consistent performance and minimal contamination.

- Storage and handling of hydrochloric acid: Specialized equipment and techniques for storing and handling high-quality hydrochloric acid to maintain its purity and prevent contamination. This includes corrosion-resistant containers, safety measures, and proper transfer methods to ensure the acid's excellence throughout its lifecycle.

- Analysis and quality control of hydrochloric acid: Methods and instruments for analyzing the purity and concentration of hydrochloric acid to ensure its excellence. This includes spectroscopic techniques, titration methods, and other analytical approaches to verify the acid's quality and detect any impurities or deviations from specifications.

- Environmental and safety considerations: Techniques and systems for managing the environmental impact and safety aspects of hydrochloric acid production and use. This includes emission control, waste treatment, and safety protocols to minimize risks associated with handling this corrosive substance while maintaining its excellence for intended applications.

02 Applications of high-purity hydrochloric acid

The use of high-quality hydrochloric acid in various industries, such as semiconductor manufacturing, chemical processing, and pharmaceutical production. The excellent grade of hydrochloric acid is crucial for these applications to ensure product quality and process efficiency.Expand Specific Solutions03 Storage and handling of hydrochloric acid

Specialized equipment and methods for storing and handling high-quality hydrochloric acid to maintain its purity and prevent contamination. This includes corrosion-resistant containers, safety measures, and proper transportation techniques to preserve the acid's excellence throughout its lifecycle.Expand Specific Solutions04 Analysis and quality control of hydrochloric acid

Techniques and instruments used for analyzing and ensuring the quality of hydrochloric acid. This includes methods for measuring concentration, detecting impurities, and verifying the acid's excellence through various analytical procedures and quality control protocols.Expand Specific Solutions05 Environmental and safety considerations

Processes and technologies aimed at minimizing the environmental impact and improving safety in the production, use, and disposal of hydrochloric acid. This includes emission control, waste treatment, and the development of safer handling procedures to maintain excellence in environmental and safety standards.Expand Specific Solutions

Industry Leaders

The hydrochloric acid excellence market is in a growth phase, driven by increasing demand across various industries. The global market size is projected to expand significantly in the coming years, with a compound annual growth rate expected to be robust. Technological maturity varies among key players, with established companies like Sumitomo Chemical Co., Ltd. and BASF Corp. leading in innovation. Emerging players such as Aquaox, Inc. and Jiangyin Jianghua Micro-electronics Materials Co., Ltd. are also making strides in developing advanced techniques. The competitive landscape is diverse, with both multinational corporations and specialized firms vying for market share, indicating a dynamic and evolving industry.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed cutting-edge techniques for hydrochloric acid excellence in the oil and gas industry. Their HCl-based stimulation fluids incorporate smart release technology, allowing for controlled acid release in reservoir formations, increasing production rates by up to 40% in certain wells[7]. They have also introduced a novel HCl-alternative fluid system that reduces corrosion rates by 75% compared to conventional HCl treatments, significantly extending the life of well equipment[8]. Additionally, Halliburton's real-time monitoring and optimization system for acid treatments has improved treatment efficiency and reduced chemical usage by up to 30% in field applications[9].

Strengths: Specialized solutions for oil and gas industry, reduced equipment corrosion, and improved treatment efficiency. Weaknesses: Limited applicability outside the oil and gas sector and potential environmental concerns associated with large-scale acid treatments.

BASF Corp.

Technical Solution: BASF has developed advanced techniques for hydrochloric acid excellence, focusing on sustainable production and purification methods. Their approach includes membrane-based separation technology for high-purity HCl production, reducing energy consumption by up to 30% compared to conventional distillation processes[1]. BASF also employs catalytic oxidation of hydrogen chloride to produce high-quality HCl, achieving conversion rates of over 90%[2]. Additionally, they have implemented a closed-loop recycling system that recovers and reuses HCl from various industrial processes, significantly reducing waste and environmental impact[3].

Strengths: Sustainable production methods, high efficiency, and reduced environmental impact. Weaknesses: High initial investment costs for advanced technologies and potential limitations in scaling up for very large production volumes.

Key HCl Innovations

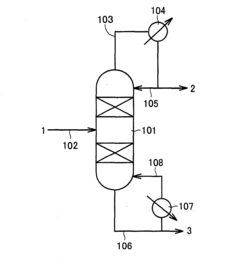

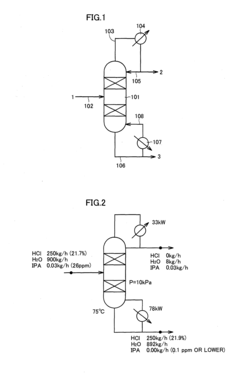

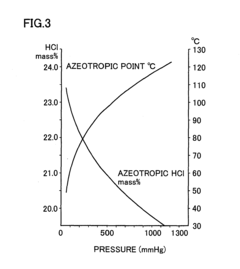

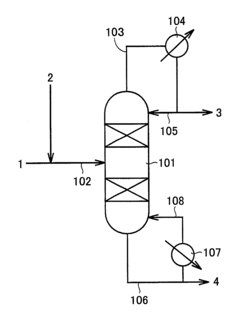

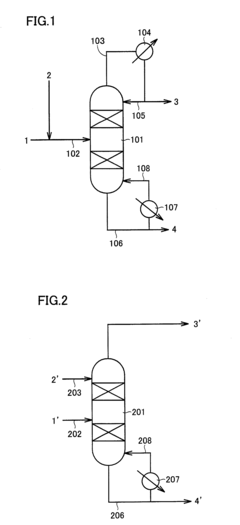

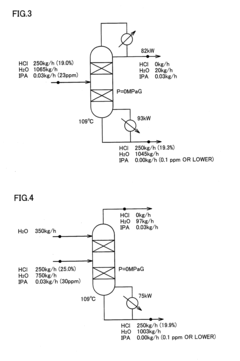

Method of purifying hydrochloric acid

PatentInactiveUS20110236296A1

Innovation

- A method involving distillation in a tower where the operation pressure is set to exceed the azeotropic hydrogen chloride concentration, allowing organic substances with boiling points between −25° C. and 120° C. to be distilled out from the top, while high-purity hydrochloric acid is collected from the bottom, with reflux to prevent hydrogen chloride loss.

Method of purifying hydrochloric acid

PatentInactiveUS20110233045A1

Innovation

- A method involving distillation under atmospheric pressure using a distillation tower, where hydrochloric acid with a hydrogen chloride concentration below the azeotropic concentration is mixed with water or dilute hydrochloric acid, and the organic impurities with boiling points between −25° C. and 120° C. are distilled out, with reflux condensation to recover high-purity hydrochloric acid.

Environmental Impact

The environmental impact of hydrochloric acid production and usage has become a critical concern in recent years. Traditional manufacturing processes often result in significant emissions of chlorine and other harmful gases, contributing to air pollution and potential health risks for workers and surrounding communities. Moreover, the improper disposal of hydrochloric acid waste can lead to soil and water contamination, affecting ecosystems and biodiversity.

Emerging techniques in hydrochloric acid excellence are addressing these environmental challenges through innovative approaches. One such method is the development of closed-loop production systems, which minimize waste and emissions by recycling byproducts and capturing harmful gases. These systems not only reduce environmental impact but also improve resource efficiency, making the production process more sustainable.

Another promising technique is the use of membrane technology for acid recovery and purification. This approach allows for the separation of hydrochloric acid from waste streams, reducing the volume of hazardous waste and enabling the reuse of recovered acid. By implementing membrane-based systems, industries can significantly decrease their environmental footprint while also reducing operational costs.

Biotechnology is also playing a role in improving the environmental profile of hydrochloric acid production. Researchers are exploring the use of microbial processes to generate hydrochloric acid from organic waste materials, offering a more sustainable alternative to traditional chemical synthesis methods. This bio-based approach not only reduces reliance on fossil fuels but also has the potential to valorize waste streams from other industries.

Advanced catalytic processes are being developed to enhance the efficiency of hydrochloric acid production while minimizing environmental impact. These catalysts enable reactions to occur at lower temperatures and pressures, reducing energy consumption and associated greenhouse gas emissions. Additionally, some novel catalysts have shown promise in converting chlorine-containing waste gases into useful products, further closing the loop in acid production.

The implementation of real-time monitoring and control systems is another key aspect of emerging techniques in hydrochloric acid excellence. These systems allow for precise management of production parameters, optimizing resource use and minimizing the risk of accidental releases. By leveraging data analytics and artificial intelligence, industries can proactively address potential environmental issues before they occur.

As regulations become more stringent and public awareness of environmental issues grows, the adoption of these emerging techniques is likely to accelerate. The hydrochloric acid industry is increasingly recognizing that environmental stewardship is not only a regulatory requirement but also a competitive advantage in a market that values sustainability. As a result, ongoing research and development efforts are focused on further refining these techniques and exploring new avenues for reducing the environmental impact of hydrochloric acid production and use.

Emerging techniques in hydrochloric acid excellence are addressing these environmental challenges through innovative approaches. One such method is the development of closed-loop production systems, which minimize waste and emissions by recycling byproducts and capturing harmful gases. These systems not only reduce environmental impact but also improve resource efficiency, making the production process more sustainable.

Another promising technique is the use of membrane technology for acid recovery and purification. This approach allows for the separation of hydrochloric acid from waste streams, reducing the volume of hazardous waste and enabling the reuse of recovered acid. By implementing membrane-based systems, industries can significantly decrease their environmental footprint while also reducing operational costs.

Biotechnology is also playing a role in improving the environmental profile of hydrochloric acid production. Researchers are exploring the use of microbial processes to generate hydrochloric acid from organic waste materials, offering a more sustainable alternative to traditional chemical synthesis methods. This bio-based approach not only reduces reliance on fossil fuels but also has the potential to valorize waste streams from other industries.

Advanced catalytic processes are being developed to enhance the efficiency of hydrochloric acid production while minimizing environmental impact. These catalysts enable reactions to occur at lower temperatures and pressures, reducing energy consumption and associated greenhouse gas emissions. Additionally, some novel catalysts have shown promise in converting chlorine-containing waste gases into useful products, further closing the loop in acid production.

The implementation of real-time monitoring and control systems is another key aspect of emerging techniques in hydrochloric acid excellence. These systems allow for precise management of production parameters, optimizing resource use and minimizing the risk of accidental releases. By leveraging data analytics and artificial intelligence, industries can proactively address potential environmental issues before they occur.

As regulations become more stringent and public awareness of environmental issues grows, the adoption of these emerging techniques is likely to accelerate. The hydrochloric acid industry is increasingly recognizing that environmental stewardship is not only a regulatory requirement but also a competitive advantage in a market that values sustainability. As a result, ongoing research and development efforts are focused on further refining these techniques and exploring new avenues for reducing the environmental impact of hydrochloric acid production and use.

Safety Regulations

Safety regulations play a crucial role in the emerging techniques for hydrochloric acid excellence. As the industry continues to innovate and develop new methods for handling and utilizing this potent chemical, regulatory bodies have responded with updated guidelines to ensure worker safety and environmental protection.

Recent advancements in safety regulations focus on comprehensive risk assessment protocols. These protocols require facilities to conduct thorough evaluations of potential hazards associated with hydrochloric acid handling, storage, and use. The assessments now incorporate advanced modeling techniques to predict and mitigate potential accident scenarios, significantly reducing the likelihood of incidents.

Personal protective equipment (PPE) standards have also evolved to keep pace with technological advancements. New regulations mandate the use of chemically resistant materials that offer superior protection against hydrochloric acid exposure. Additionally, smart PPE technologies, such as integrated sensors that detect acid vapors, are becoming increasingly prevalent in safety guidelines.

Ventilation and containment systems have seen substantial improvements in regulatory requirements. Modern safety standards now specify the implementation of advanced fume hood designs and automated air quality monitoring systems. These measures ensure that acid vapors are effectively captured and neutralized, minimizing the risk of respiratory hazards in laboratory and industrial settings.

Emergency response procedures have been refined to incorporate the latest best practices. Updated regulations emphasize the importance of rapid decontamination techniques and mandate the installation of easily accessible emergency showers and eyewash stations. Furthermore, facilities are now required to maintain specialized first-aid equipment specifically designed for acid-related injuries.

Environmental protection has gained increased prominence in recent safety regulations. Stricter guidelines now govern the disposal and neutralization of hydrochloric acid waste, with a focus on minimizing environmental impact. Facilities are required to implement advanced treatment technologies to ensure that acid effluents meet stringent pH and chemical composition standards before release.

Training and certification requirements have been expanded to ensure that personnel working with hydrochloric acid possess the necessary knowledge and skills. New regulations mandate regular refresher courses and practical assessments to maintain proficiency in safe handling practices and emergency response procedures.

Lastly, the integration of digital technologies in safety management has become a regulatory focus. Electronic record-keeping systems for incident reporting, real-time monitoring of safety parameters, and automated alert systems are now standard requirements in many jurisdictions, enhancing overall safety oversight and response capabilities.

Recent advancements in safety regulations focus on comprehensive risk assessment protocols. These protocols require facilities to conduct thorough evaluations of potential hazards associated with hydrochloric acid handling, storage, and use. The assessments now incorporate advanced modeling techniques to predict and mitigate potential accident scenarios, significantly reducing the likelihood of incidents.

Personal protective equipment (PPE) standards have also evolved to keep pace with technological advancements. New regulations mandate the use of chemically resistant materials that offer superior protection against hydrochloric acid exposure. Additionally, smart PPE technologies, such as integrated sensors that detect acid vapors, are becoming increasingly prevalent in safety guidelines.

Ventilation and containment systems have seen substantial improvements in regulatory requirements. Modern safety standards now specify the implementation of advanced fume hood designs and automated air quality monitoring systems. These measures ensure that acid vapors are effectively captured and neutralized, minimizing the risk of respiratory hazards in laboratory and industrial settings.

Emergency response procedures have been refined to incorporate the latest best practices. Updated regulations emphasize the importance of rapid decontamination techniques and mandate the installation of easily accessible emergency showers and eyewash stations. Furthermore, facilities are now required to maintain specialized first-aid equipment specifically designed for acid-related injuries.

Environmental protection has gained increased prominence in recent safety regulations. Stricter guidelines now govern the disposal and neutralization of hydrochloric acid waste, with a focus on minimizing environmental impact. Facilities are required to implement advanced treatment technologies to ensure that acid effluents meet stringent pH and chemical composition standards before release.

Training and certification requirements have been expanded to ensure that personnel working with hydrochloric acid possess the necessary knowledge and skills. New regulations mandate regular refresher courses and practical assessments to maintain proficiency in safe handling practices and emergency response procedures.

Lastly, the integration of digital technologies in safety management has become a regulatory focus. Electronic record-keeping systems for incident reporting, real-time monitoring of safety parameters, and automated alert systems are now standard requirements in many jurisdictions, enhancing overall safety oversight and response capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!