How to Create Manuals for Hydrochloric Acid Operations?

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Manual Objectives

The creation of comprehensive manuals for hydrochloric acid operations is crucial for ensuring safety, efficiency, and regulatory compliance in industrial settings. The primary objective of these manuals is to provide clear, concise, and actionable guidance for all personnel involved in handling, storing, and using hydrochloric acid. These documents serve as essential resources for training, reference, and emergency response.

One of the key goals in developing HCl manuals is to establish standardized procedures that minimize the risk of accidents and exposure. This includes detailed protocols for personal protective equipment (PPE) usage, proper handling techniques, and spill response measures. The manuals should also aim to optimize operational efficiency by outlining best practices for storage, transfer, and application of hydrochloric acid in various industrial processes.

Another critical objective is to ensure full compliance with relevant regulations and industry standards. This involves incorporating up-to-date safety data sheets (SDS), transportation guidelines, and disposal procedures that adhere to local, national, and international regulations. The manuals should be designed to facilitate regular audits and inspections, helping organizations maintain their compliance status.

Effective communication of hazards and safety measures is a paramount goal in creating these manuals. This includes clear labeling instructions, easily understandable pictograms, and concise emergency procedures that can be quickly referenced in critical situations. The manuals should strive to bridge the gap between technical information and practical application, ensuring that all users, regardless of their technical background, can understand and implement the safety protocols.

Continuous improvement and adaptability are also key objectives in manual creation. The documents should be structured to allow for easy updates as new technologies, regulations, or best practices emerge. This may involve establishing a review and revision process, incorporating feedback mechanisms, and maintaining version control to ensure all personnel have access to the most current information.

Lastly, the manuals should aim to foster a culture of safety and environmental responsibility within the organization. By emphasizing the importance of proper HCl handling and its impact on worker health and the environment, the manuals can contribute to broader organizational goals of sustainability and corporate responsibility. This holistic approach helps align operational procedures with the company's values and long-term strategic objectives.

One of the key goals in developing HCl manuals is to establish standardized procedures that minimize the risk of accidents and exposure. This includes detailed protocols for personal protective equipment (PPE) usage, proper handling techniques, and spill response measures. The manuals should also aim to optimize operational efficiency by outlining best practices for storage, transfer, and application of hydrochloric acid in various industrial processes.

Another critical objective is to ensure full compliance with relevant regulations and industry standards. This involves incorporating up-to-date safety data sheets (SDS), transportation guidelines, and disposal procedures that adhere to local, national, and international regulations. The manuals should be designed to facilitate regular audits and inspections, helping organizations maintain their compliance status.

Effective communication of hazards and safety measures is a paramount goal in creating these manuals. This includes clear labeling instructions, easily understandable pictograms, and concise emergency procedures that can be quickly referenced in critical situations. The manuals should strive to bridge the gap between technical information and practical application, ensuring that all users, regardless of their technical background, can understand and implement the safety protocols.

Continuous improvement and adaptability are also key objectives in manual creation. The documents should be structured to allow for easy updates as new technologies, regulations, or best practices emerge. This may involve establishing a review and revision process, incorporating feedback mechanisms, and maintaining version control to ensure all personnel have access to the most current information.

Lastly, the manuals should aim to foster a culture of safety and environmental responsibility within the organization. By emphasizing the importance of proper HCl handling and its impact on worker health and the environment, the manuals can contribute to broader organizational goals of sustainability and corporate responsibility. This holistic approach helps align operational procedures with the company's values and long-term strategic objectives.

Industry Demand Analysis

The demand for comprehensive manuals for hydrochloric acid operations has been steadily increasing across various industries. This surge is primarily driven by the growing use of hydrochloric acid in diverse applications, including chemical manufacturing, metal processing, and water treatment. The global hydrochloric acid market is projected to expand significantly in the coming years, with a compound annual growth rate (CAGR) of over 5% expected through 2025.

In the chemical manufacturing sector, hydrochloric acid plays a crucial role in producing various chemicals, plastics, and pharmaceuticals. As these industries continue to grow, the need for standardized and detailed operational manuals becomes more pressing. These manuals are essential for ensuring safety, efficiency, and compliance with regulatory standards.

The metal processing industry, another major consumer of hydrochloric acid, has been experiencing rapid growth, particularly in developing economies. This expansion has led to an increased demand for operational manuals that can guide workers in the proper handling and use of hydrochloric acid for metal pickling and surface treatment processes.

Water treatment facilities represent another significant market segment driving the demand for hydrochloric acid operation manuals. As global water scarcity issues intensify, there is a growing emphasis on efficient water treatment processes, many of which involve the use of hydrochloric acid. Consequently, there is a heightened need for comprehensive manuals that outline proper handling procedures and safety protocols.

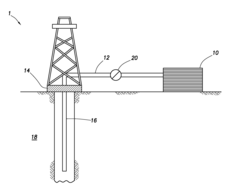

The oil and gas industry also contributes to the demand for hydrochloric acid manuals, particularly in well stimulation and acidizing operations. As exploration and production activities expand into new regions, the need for standardized operational guidelines becomes more critical.

Environmental concerns and stringent regulations regarding the handling and disposal of hazardous chemicals have further fueled the demand for detailed operational manuals. Industries are increasingly recognizing the importance of having clear, up-to-date guidelines to minimize environmental impact and ensure compliance with evolving regulatory standards.

The rising focus on workplace safety across industries has also contributed to the growing demand for comprehensive hydrochloric acid operation manuals. Companies are investing more in training programs and safety measures, with detailed manuals serving as essential resources for educating workers and preventing accidents.

In conclusion, the market demand for creating manuals for hydrochloric acid operations is robust and multifaceted, driven by industrial growth, regulatory requirements, safety concerns, and environmental considerations across various sectors. This demand is expected to continue growing as industries expand and regulations become more stringent, highlighting the critical need for comprehensive, up-to-date operational manuals in the hydrochloric acid industry.

In the chemical manufacturing sector, hydrochloric acid plays a crucial role in producing various chemicals, plastics, and pharmaceuticals. As these industries continue to grow, the need for standardized and detailed operational manuals becomes more pressing. These manuals are essential for ensuring safety, efficiency, and compliance with regulatory standards.

The metal processing industry, another major consumer of hydrochloric acid, has been experiencing rapid growth, particularly in developing economies. This expansion has led to an increased demand for operational manuals that can guide workers in the proper handling and use of hydrochloric acid for metal pickling and surface treatment processes.

Water treatment facilities represent another significant market segment driving the demand for hydrochloric acid operation manuals. As global water scarcity issues intensify, there is a growing emphasis on efficient water treatment processes, many of which involve the use of hydrochloric acid. Consequently, there is a heightened need for comprehensive manuals that outline proper handling procedures and safety protocols.

The oil and gas industry also contributes to the demand for hydrochloric acid manuals, particularly in well stimulation and acidizing operations. As exploration and production activities expand into new regions, the need for standardized operational guidelines becomes more critical.

Environmental concerns and stringent regulations regarding the handling and disposal of hazardous chemicals have further fueled the demand for detailed operational manuals. Industries are increasingly recognizing the importance of having clear, up-to-date guidelines to minimize environmental impact and ensure compliance with evolving regulatory standards.

The rising focus on workplace safety across industries has also contributed to the growing demand for comprehensive hydrochloric acid operation manuals. Companies are investing more in training programs and safety measures, with detailed manuals serving as essential resources for educating workers and preventing accidents.

In conclusion, the market demand for creating manuals for hydrochloric acid operations is robust and multifaceted, driven by industrial growth, regulatory requirements, safety concerns, and environmental considerations across various sectors. This demand is expected to continue growing as industries expand and regulations become more stringent, highlighting the critical need for comprehensive, up-to-date operational manuals in the hydrochloric acid industry.

Current Challenges

Creating comprehensive and effective manuals for hydrochloric acid operations presents several significant challenges in the current landscape. One of the primary obstacles is the complexity of safety protocols associated with handling such a corrosive and potentially dangerous substance. Ensuring that all safety measures are accurately and thoroughly documented, while maintaining clarity for users of varying expertise levels, requires a delicate balance of technical detail and accessibility.

Another challenge lies in the diverse applications of hydrochloric acid across industries, ranging from chemical manufacturing to food processing. This diversity necessitates the creation of manuals that are adaptable to different operational contexts while maintaining consistency in core safety and handling procedures. The variability in equipment, processes, and regulatory requirements across sectors further complicates the development of universally applicable manuals.

The rapidly evolving regulatory landscape poses an additional hurdle. Environmental and safety regulations governing the use and handling of hydrochloric acid are subject to frequent updates and variations across different jurisdictions. This dynamic regulatory environment demands that manuals be designed with flexibility to accommodate changes and be easily updatable, ensuring ongoing compliance and relevance.

Technical accuracy and comprehensiveness present another significant challenge. Hydrochloric acid operations involve complex chemical processes, equipment specifications, and emergency response procedures. Capturing all necessary technical details without overwhelming the user requires careful consideration of information hierarchy and presentation.

The human factor in manual creation and usage cannot be overlooked. Addressing varying levels of user expertise, language barriers, and potential misinterpretation of instructions are critical challenges. Developing manuals that effectively communicate to a diverse workforce, potentially across multiple languages and cultural contexts, adds another layer of complexity to the creation process.

Integration of digital technologies in manual creation and distribution presents both opportunities and challenges. While digital formats offer enhanced accessibility and updatability, they also introduce concerns about cybersecurity, data integrity, and ensuring access in environments where digital devices may be impractical or prohibited due to safety concerns.

Lastly, the challenge of practical usability in high-stress or emergency situations is paramount. Manuals must be designed to be quickly and easily referenced under pressure, requiring careful consideration of layout, indexing, and quick-reference features. This aspect is crucial for ensuring that critical information is readily accessible when it matters most, potentially in life-threatening situations.

Another challenge lies in the diverse applications of hydrochloric acid across industries, ranging from chemical manufacturing to food processing. This diversity necessitates the creation of manuals that are adaptable to different operational contexts while maintaining consistency in core safety and handling procedures. The variability in equipment, processes, and regulatory requirements across sectors further complicates the development of universally applicable manuals.

The rapidly evolving regulatory landscape poses an additional hurdle. Environmental and safety regulations governing the use and handling of hydrochloric acid are subject to frequent updates and variations across different jurisdictions. This dynamic regulatory environment demands that manuals be designed with flexibility to accommodate changes and be easily updatable, ensuring ongoing compliance and relevance.

Technical accuracy and comprehensiveness present another significant challenge. Hydrochloric acid operations involve complex chemical processes, equipment specifications, and emergency response procedures. Capturing all necessary technical details without overwhelming the user requires careful consideration of information hierarchy and presentation.

The human factor in manual creation and usage cannot be overlooked. Addressing varying levels of user expertise, language barriers, and potential misinterpretation of instructions are critical challenges. Developing manuals that effectively communicate to a diverse workforce, potentially across multiple languages and cultural contexts, adds another layer of complexity to the creation process.

Integration of digital technologies in manual creation and distribution presents both opportunities and challenges. While digital formats offer enhanced accessibility and updatability, they also introduce concerns about cybersecurity, data integrity, and ensuring access in environments where digital devices may be impractical or prohibited due to safety concerns.

Lastly, the challenge of practical usability in high-stress or emergency situations is paramount. Manuals must be designed to be quickly and easily referenced under pressure, requiring careful consideration of layout, indexing, and quick-reference features. This aspect is crucial for ensuring that critical information is readily accessible when it matters most, potentially in life-threatening situations.

Best Practices

01 Safety procedures for handling hydrochloric acid

Manuals for hydrochloric acid operations emphasize safety procedures, including proper personal protective equipment, emergency response protocols, and safe handling techniques to prevent accidents and exposure risks.- Safety procedures for handling hydrochloric acid: Manuals for hydrochloric acid operations emphasize safety procedures, including proper personal protective equipment, emergency response protocols, and handling techniques to minimize risks associated with this corrosive substance. These guidelines ensure worker safety and environmental protection during storage, transport, and use of hydrochloric acid.

- Production and purification methods: Manuals detail various production and purification methods for hydrochloric acid, including synthesis from hydrogen and chlorine, recovery from industrial processes, and purification techniques. These methods aim to produce high-quality hydrochloric acid for different industrial applications while optimizing efficiency and reducing waste.

- Storage and transportation guidelines: Operational manuals provide comprehensive guidelines for the safe storage and transportation of hydrochloric acid. This includes specifications for storage tanks, containment measures, labeling requirements, and transportation regulations to prevent accidents and ensure compliance with safety standards.

- Equipment maintenance and corrosion prevention: Manuals outline procedures for maintaining equipment used in hydrochloric acid operations and preventing corrosion. This includes regular inspections, cleaning protocols, and the use of corrosion-resistant materials to extend equipment lifespan and ensure operational safety.

- Environmental impact and waste management: Operational manuals address the environmental impact of hydrochloric acid and provide guidelines for proper waste management. This includes neutralization techniques, disposal methods, and strategies to minimize environmental contamination while complying with regulatory requirements.

02 Storage and transportation guidelines

Guidelines for proper storage and transportation of hydrochloric acid, including container specifications, temperature control, and ventilation requirements to maintain stability and prevent corrosion or leaks during handling and transit.Expand Specific Solutions03 Production and purification processes

Detailed procedures for the production and purification of hydrochloric acid, including reactor designs, process control parameters, and quality assurance methods to ensure consistent product quality and efficiency.Expand Specific Solutions04 Waste management and environmental considerations

Protocols for proper disposal and treatment of hydrochloric acid waste, including neutralization techniques, recycling methods, and emission control strategies to minimize environmental impact and comply with regulations.Expand Specific Solutions05 Equipment maintenance and corrosion prevention

Guidelines for maintaining equipment used in hydrochloric acid operations, including corrosion-resistant materials selection, inspection procedures, and preventive maintenance schedules to ensure longevity and safe operation of processing equipment.Expand Specific Solutions

Key Stakeholders

The competitive landscape for creating manuals for hydrochloric acid operations is characterized by a mature market with established players and a growing emphasis on safety and efficiency. The global market size for industrial chemicals, including hydrochloric acid, is substantial, with key players like Halliburton Energy Services, Schlumberger, and Covestro Deutschland AG leading the way. These companies have extensive experience in developing comprehensive operational manuals and safety protocols. The technology for handling hydrochloric acid is well-established, but there's ongoing innovation in safety measures and environmental protection. Smaller specialized firms like Blue Earth Labs and Chemspeed Technologies are also contributing to the field, focusing on niche applications and advanced research methodologies. The industry is seeing a trend towards digitalization and automation in manual creation and operational processes.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed a comprehensive approach to creating manuals for hydrochloric acid operations, focusing on safety and efficiency. Their method includes detailed risk assessments, step-by-step procedures, and advanced monitoring systems. They utilize digital platforms to ensure real-time updates and accessibility of manuals across various operational sites. The company has implemented a multi-layered safety protocol, incorporating both physical safeguards and procedural guidelines to minimize risks associated with hydrochloric acid handling[1]. Their manuals also cover environmental considerations, detailing proper disposal and neutralization techniques to comply with regulatory standards[2].

Strengths: Comprehensive safety protocols, digital accessibility, and environmental compliance. Weaknesses: May require significant resources for implementation and regular updates.

Schlumberger Canada Ltd.

Technical Solution: Schlumberger has developed an innovative approach to creating manuals for hydrochloric acid operations, leveraging their extensive experience in oilfield services. Their method integrates advanced digital technologies with traditional safety protocols. The company utilizes artificial intelligence and machine learning algorithms to analyze historical data and predict potential hazards, incorporating these insights into their manuals[3]. Schlumberger's manuals are designed with a modular structure, allowing for easy customization based on specific operational requirements and local regulations. They have also implemented virtual reality training modules to complement written manuals, providing operators with immersive, hands-on experience in a safe environment[4].

Strengths: Cutting-edge technology integration, customizable content, and interactive training components. Weaknesses: High initial investment costs and potential complexity for less tech-savvy users.

Safety Innovations

Salt of monochloroacetic acid with chelating agent for delayed acidification in the oil field industry

PatentWO2020002011A1

Innovation

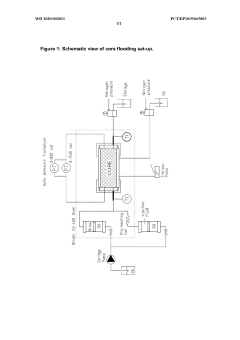

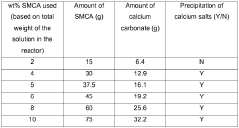

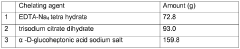

- A process using a monovalent salt of monochloroacetic acid in combination with a chelating agent having a monovalent counterion and a carbon chain with at least five hydroxyl groups, such as sodium gluconate, to inhibit calcium glycolate formation and control acidification, forming stable wormholes without scaling.

Acidizing fluids and methods for use in subterranean formations

PatentInactiveUS20160257874A1

Innovation

- A treatment fluid comprising a Lewis acid catalyst and a saccharide precursor, which reacts at temperatures of 275° F or greater to form organic acids, is used to acidize carbonate formations, forming wormholes for enhanced hydrocarbon production and reducing corrosion, without the need for additional acids or acid precursors.

Regulatory Compliance

Regulatory compliance is a critical aspect of creating manuals for hydrochloric acid operations. The handling, storage, and use of hydrochloric acid are subject to stringent regulations due to its corrosive and hazardous nature. These regulations are designed to protect workers, the environment, and the public from potential harm.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth specific guidelines for the safe handling of hydrochloric acid. OSHA's Hazard Communication Standard (HCS) requires that all employees who work with hazardous chemicals, including hydrochloric acid, be properly informed about the associated risks and safety measures. This includes providing Safety Data Sheets (SDS) and appropriate labeling for all containers.

The Environmental Protection Agency (EPA) also plays a crucial role in regulating hydrochloric acid operations. Under the Resource Conservation and Recovery Act (RCRA), hydrochloric acid is classified as a hazardous waste when discarded. This classification imposes strict requirements on its disposal and management throughout its lifecycle.

Internationally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Manuals for hydrochloric acid operations must align with GHS guidelines, ensuring consistent hazard classification and labeling across different countries and regions.

Transportation of hydrochloric acid is regulated by the Department of Transportation (DOT) in the US and similar agencies in other countries. These regulations cover packaging, labeling, and documentation requirements for the safe transport of hazardous materials.

When creating manuals for hydrochloric acid operations, it is essential to include detailed information on personal protective equipment (PPE) requirements. This typically includes chemical-resistant gloves, goggles, face shields, and appropriate respiratory protection. The manual should also outline proper emergency response procedures, including spill containment and neutralization techniques.

Storage requirements for hydrochloric acid must be clearly defined in the manual, including specifications for compatible materials, ventilation requirements, and secondary containment measures. Additionally, the manual should address proper handling techniques, such as the use of transfer pumps and closed systems to minimize exposure risks.

Regular employee training is a key component of regulatory compliance. Manuals should include a comprehensive training program that covers all aspects of hydrochloric acid handling, from basic safety precautions to advanced emergency response procedures. This training must be documented and updated regularly to reflect any changes in regulations or best practices.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth specific guidelines for the safe handling of hydrochloric acid. OSHA's Hazard Communication Standard (HCS) requires that all employees who work with hazardous chemicals, including hydrochloric acid, be properly informed about the associated risks and safety measures. This includes providing Safety Data Sheets (SDS) and appropriate labeling for all containers.

The Environmental Protection Agency (EPA) also plays a crucial role in regulating hydrochloric acid operations. Under the Resource Conservation and Recovery Act (RCRA), hydrochloric acid is classified as a hazardous waste when discarded. This classification imposes strict requirements on its disposal and management throughout its lifecycle.

Internationally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Manuals for hydrochloric acid operations must align with GHS guidelines, ensuring consistent hazard classification and labeling across different countries and regions.

Transportation of hydrochloric acid is regulated by the Department of Transportation (DOT) in the US and similar agencies in other countries. These regulations cover packaging, labeling, and documentation requirements for the safe transport of hazardous materials.

When creating manuals for hydrochloric acid operations, it is essential to include detailed information on personal protective equipment (PPE) requirements. This typically includes chemical-resistant gloves, goggles, face shields, and appropriate respiratory protection. The manual should also outline proper emergency response procedures, including spill containment and neutralization techniques.

Storage requirements for hydrochloric acid must be clearly defined in the manual, including specifications for compatible materials, ventilation requirements, and secondary containment measures. Additionally, the manual should address proper handling techniques, such as the use of transfer pumps and closed systems to minimize exposure risks.

Regular employee training is a key component of regulatory compliance. Manuals should include a comprehensive training program that covers all aspects of hydrochloric acid handling, from basic safety precautions to advanced emergency response procedures. This training must be documented and updated regularly to reflect any changes in regulations or best practices.

Environmental Impact

The creation of manuals for hydrochloric acid operations must prioritize environmental impact considerations due to the potentially hazardous nature of this chemical. Hydrochloric acid, when improperly handled or disposed of, can have severe consequences for ecosystems and human health. The environmental impact section of the manual should address several key areas to ensure responsible and sustainable practices.

Firstly, the manual must outline proper storage and containment protocols to prevent accidental spills or leaks. This includes specifying appropriate storage containers, secondary containment systems, and regular inspection procedures. By implementing robust containment measures, the risk of environmental contamination can be significantly reduced.

Secondly, the manual should provide detailed guidance on spill response and cleanup procedures. This includes immediate actions to contain spills, neutralization techniques, and proper disposal methods for contaminated materials. Emphasizing the importance of swift and effective spill management helps minimize the spread of acid and its potential impact on soil, water sources, and local flora and fauna.

The manual must also address the proper disposal of hydrochloric acid and its byproducts. This involves detailing neutralization processes, dilution techniques, and approved disposal methods that comply with local environmental regulations. Proper disposal practices are crucial in preventing soil and water pollution, as well as protecting waste management systems from corrosion and damage.

Air quality considerations should be included, focusing on the potential release of hydrogen chloride gas. The manual should outline ventilation requirements, air monitoring procedures, and emission control measures to minimize the release of harmful vapors into the atmosphere. This is particularly important in industrial settings where large quantities of hydrochloric acid are used.

Water management is another critical aspect to be covered. The manual should provide guidelines for treating acid-contaminated wastewater, including neutralization processes and monitoring procedures to ensure that effluent meets environmental standards before release. This helps protect aquatic ecosystems and maintains the quality of water resources.

Lastly, the manual should emphasize the importance of regular environmental monitoring and reporting. This includes procedures for conducting periodic assessments of soil, water, and air quality in areas where hydrochloric acid is used or stored. By implementing a robust monitoring program, potential environmental impacts can be detected early and mitigated promptly.

Firstly, the manual must outline proper storage and containment protocols to prevent accidental spills or leaks. This includes specifying appropriate storage containers, secondary containment systems, and regular inspection procedures. By implementing robust containment measures, the risk of environmental contamination can be significantly reduced.

Secondly, the manual should provide detailed guidance on spill response and cleanup procedures. This includes immediate actions to contain spills, neutralization techniques, and proper disposal methods for contaminated materials. Emphasizing the importance of swift and effective spill management helps minimize the spread of acid and its potential impact on soil, water sources, and local flora and fauna.

The manual must also address the proper disposal of hydrochloric acid and its byproducts. This involves detailing neutralization processes, dilution techniques, and approved disposal methods that comply with local environmental regulations. Proper disposal practices are crucial in preventing soil and water pollution, as well as protecting waste management systems from corrosion and damage.

Air quality considerations should be included, focusing on the potential release of hydrogen chloride gas. The manual should outline ventilation requirements, air monitoring procedures, and emission control measures to minimize the release of harmful vapors into the atmosphere. This is particularly important in industrial settings where large quantities of hydrochloric acid are used.

Water management is another critical aspect to be covered. The manual should provide guidelines for treating acid-contaminated wastewater, including neutralization processes and monitoring procedures to ensure that effluent meets environmental standards before release. This helps protect aquatic ecosystems and maintains the quality of water resources.

Lastly, the manual should emphasize the importance of regular environmental monitoring and reporting. This includes procedures for conducting periodic assessments of soil, water, and air quality in areas where hydrochloric acid is used or stored. By implementing a robust monitoring program, potential environmental impacts can be detected early and mitigated promptly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!