Sustainable Development Goals via Hydrochloric Acid

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl and SDGs Background

Hydrochloric acid (HCl) and the Sustainable Development Goals (SDGs) represent an intriguing intersection of chemistry and global sustainability efforts. HCl, a strong inorganic acid, has been a cornerstone of industrial processes for centuries, playing crucial roles in various sectors including chemical manufacturing, metal processing, and food production. Its widespread use and significant environmental impact make it a relevant subject in the context of sustainable development.

The United Nations' Sustainable Development Goals, adopted in 2015, provide a blueprint for addressing global challenges and achieving a more sustainable future for all by 2030. These 17 interconnected goals encompass a wide range of issues, from poverty eradication and clean energy to responsible consumption and climate action. The relationship between HCl and the SDGs is multifaceted, involving both potential contributions and challenges.

HCl's production and use intersect with several SDGs, particularly those related to industry, innovation, and infrastructure (Goal 9), responsible consumption and production (Goal 12), and climate action (Goal 13). The acid's role in industrial processes makes it integral to discussions on sustainable industrial development and the transition to cleaner production methods. Moreover, its involvement in water treatment processes connects it to goals concerning clean water and sanitation (Goal 6).

However, the production and use of HCl also present environmental challenges that must be addressed to align with the SDGs. These include the energy-intensive nature of its production, potential for air and water pollution if not properly managed, and the need for safe handling and disposal practices. These aspects directly relate to goals focused on health and well-being (Goal 3), clean water (Goal 6), and life below water and on land (Goals 14 and 15).

Research on sustainable development goals via hydrochloric acid encompasses a broad spectrum of investigations. These range from developing more environmentally friendly production methods for HCl to exploring its potential applications in sustainable technologies. For instance, studies are being conducted on using HCl in carbon capture and utilization processes, which could contribute to climate action goals. Additionally, research is ongoing to optimize HCl use in water treatment, aiming to improve access to clean water while minimizing environmental impact.

The background of this research area is characterized by a growing recognition of the need to balance industrial progress with environmental stewardship. It reflects a shift towards circular economy principles, where waste reduction and resource efficiency are prioritized. This context sets the stage for innovative approaches to HCl production, use, and recycling that align with the broader objectives of sustainable development.

The United Nations' Sustainable Development Goals, adopted in 2015, provide a blueprint for addressing global challenges and achieving a more sustainable future for all by 2030. These 17 interconnected goals encompass a wide range of issues, from poverty eradication and clean energy to responsible consumption and climate action. The relationship between HCl and the SDGs is multifaceted, involving both potential contributions and challenges.

HCl's production and use intersect with several SDGs, particularly those related to industry, innovation, and infrastructure (Goal 9), responsible consumption and production (Goal 12), and climate action (Goal 13). The acid's role in industrial processes makes it integral to discussions on sustainable industrial development and the transition to cleaner production methods. Moreover, its involvement in water treatment processes connects it to goals concerning clean water and sanitation (Goal 6).

However, the production and use of HCl also present environmental challenges that must be addressed to align with the SDGs. These include the energy-intensive nature of its production, potential for air and water pollution if not properly managed, and the need for safe handling and disposal practices. These aspects directly relate to goals focused on health and well-being (Goal 3), clean water (Goal 6), and life below water and on land (Goals 14 and 15).

Research on sustainable development goals via hydrochloric acid encompasses a broad spectrum of investigations. These range from developing more environmentally friendly production methods for HCl to exploring its potential applications in sustainable technologies. For instance, studies are being conducted on using HCl in carbon capture and utilization processes, which could contribute to climate action goals. Additionally, research is ongoing to optimize HCl use in water treatment, aiming to improve access to clean water while minimizing environmental impact.

The background of this research area is characterized by a growing recognition of the need to balance industrial progress with environmental stewardship. It reflects a shift towards circular economy principles, where waste reduction and resource efficiency are prioritized. This context sets the stage for innovative approaches to HCl production, use, and recycling that align with the broader objectives of sustainable development.

Market Analysis for Sustainable HCl

The global market for sustainable hydrochloric acid (HCl) is experiencing significant growth, driven by increasing environmental concerns and stringent regulations on industrial emissions. This market segment is closely aligned with the United Nations Sustainable Development Goals, particularly those related to responsible consumption and production, climate action, and industry innovation.

The demand for sustainable HCl is primarily fueled by industries such as chemical manufacturing, metal processing, and water treatment. These sectors are increasingly adopting cleaner production methods to reduce their environmental footprint and comply with regulatory standards. The market is also benefiting from the growing emphasis on circular economy principles, where waste reduction and resource efficiency are paramount.

In terms of market size, the sustainable HCl segment is expected to show robust growth over the next decade. This growth is attributed to the rising adoption of green technologies in industrial processes and the increasing awareness of the environmental impact of traditional HCl production methods. The Asia-Pacific region, particularly China and India, is anticipated to be a major growth driver due to rapid industrialization and stringent environmental regulations.

The market is characterized by a shift towards innovative production methods that minimize waste and reduce energy consumption. Technologies such as the membrane cell electrolysis process for HCl production are gaining traction due to their lower environmental impact compared to traditional methods. Additionally, there is a growing trend towards the recovery and recycling of HCl from industrial waste streams, creating new market opportunities for sustainable HCl.

Key market players are investing heavily in research and development to improve the sustainability of their HCl production processes. This includes exploring renewable energy sources for production, developing more efficient catalysts, and implementing advanced waste management systems. The market is also seeing increased collaboration between chemical companies and environmental technology firms to develop integrated solutions for sustainable HCl production and use.

Despite the positive outlook, the market faces challenges such as high initial investment costs for sustainable production technologies and the need for skilled personnel to operate these advanced systems. However, these challenges are expected to be offset by long-term cost savings, improved corporate image, and potential government incentives for adopting sustainable practices.

In conclusion, the market analysis for sustainable HCl reveals a sector poised for significant growth, driven by environmental imperatives and technological advancements. As industries continue to prioritize sustainability, the demand for eco-friendly HCl solutions is expected to rise, creating new opportunities for innovation and market expansion in the coming years.

The demand for sustainable HCl is primarily fueled by industries such as chemical manufacturing, metal processing, and water treatment. These sectors are increasingly adopting cleaner production methods to reduce their environmental footprint and comply with regulatory standards. The market is also benefiting from the growing emphasis on circular economy principles, where waste reduction and resource efficiency are paramount.

In terms of market size, the sustainable HCl segment is expected to show robust growth over the next decade. This growth is attributed to the rising adoption of green technologies in industrial processes and the increasing awareness of the environmental impact of traditional HCl production methods. The Asia-Pacific region, particularly China and India, is anticipated to be a major growth driver due to rapid industrialization and stringent environmental regulations.

The market is characterized by a shift towards innovative production methods that minimize waste and reduce energy consumption. Technologies such as the membrane cell electrolysis process for HCl production are gaining traction due to their lower environmental impact compared to traditional methods. Additionally, there is a growing trend towards the recovery and recycling of HCl from industrial waste streams, creating new market opportunities for sustainable HCl.

Key market players are investing heavily in research and development to improve the sustainability of their HCl production processes. This includes exploring renewable energy sources for production, developing more efficient catalysts, and implementing advanced waste management systems. The market is also seeing increased collaboration between chemical companies and environmental technology firms to develop integrated solutions for sustainable HCl production and use.

Despite the positive outlook, the market faces challenges such as high initial investment costs for sustainable production technologies and the need for skilled personnel to operate these advanced systems. However, these challenges are expected to be offset by long-term cost savings, improved corporate image, and potential government incentives for adopting sustainable practices.

In conclusion, the market analysis for sustainable HCl reveals a sector poised for significant growth, driven by environmental imperatives and technological advancements. As industries continue to prioritize sustainability, the demand for eco-friendly HCl solutions is expected to rise, creating new opportunities for innovation and market expansion in the coming years.

HCl Production Challenges

The production of hydrochloric acid (HCl) faces several significant challenges that impact its sustainability and environmental footprint. One of the primary issues is the energy-intensive nature of the production process, particularly in the chlor-alkali method, which requires substantial electrical energy for electrolysis. This high energy demand contributes to increased carbon emissions and operational costs, making it difficult to align with sustainable development goals.

Another major challenge is the management of by-products and waste streams. The production of HCl often results in the generation of chlorine gas, which, if not properly handled, can pose serious environmental and safety risks. The need for stringent safety measures and specialized equipment for chlorine management adds complexity and cost to the production process.

The sourcing of raw materials presents additional sustainability concerns. The primary feedstock for HCl production, such as salt (NaCl) or potassium chloride (KCl), often requires extensive mining operations. These activities can lead to land degradation, habitat destruction, and water pollution, further complicating the pursuit of sustainable production methods.

Water usage is another critical challenge in HCl production. The process typically requires significant amounts of water for cooling, dilution, and purification steps. In regions facing water scarcity, this high water demand can strain local resources and ecosystems, necessitating the development of more water-efficient production techniques.

The transportation and storage of HCl also present sustainability challenges. As a highly corrosive substance, HCl requires specialized containment and handling procedures. The risk of spills or leaks during transport or storage not only poses environmental hazards but also necessitates energy-intensive safety measures and robust infrastructure.

Regulatory compliance and evolving environmental standards add another layer of complexity to HCl production. Manufacturers must continuously adapt to stricter emissions controls, waste management regulations, and safety standards, which can require significant investments in new technologies and processes.

Lastly, the circular economy concept poses a challenge for HCl production. Finding ways to recycle or repurpose waste streams and by-products from the production process is essential for improving sustainability. However, developing economically viable and technologically feasible recycling methods remains a significant hurdle for the industry.

Addressing these challenges requires a multifaceted approach, including technological innovations, process optimizations, and a shift towards more sustainable raw material sourcing and energy use. The industry must balance economic viability with environmental responsibility to align HCl production with sustainable development goals.

Another major challenge is the management of by-products and waste streams. The production of HCl often results in the generation of chlorine gas, which, if not properly handled, can pose serious environmental and safety risks. The need for stringent safety measures and specialized equipment for chlorine management adds complexity and cost to the production process.

The sourcing of raw materials presents additional sustainability concerns. The primary feedstock for HCl production, such as salt (NaCl) or potassium chloride (KCl), often requires extensive mining operations. These activities can lead to land degradation, habitat destruction, and water pollution, further complicating the pursuit of sustainable production methods.

Water usage is another critical challenge in HCl production. The process typically requires significant amounts of water for cooling, dilution, and purification steps. In regions facing water scarcity, this high water demand can strain local resources and ecosystems, necessitating the development of more water-efficient production techniques.

The transportation and storage of HCl also present sustainability challenges. As a highly corrosive substance, HCl requires specialized containment and handling procedures. The risk of spills or leaks during transport or storage not only poses environmental hazards but also necessitates energy-intensive safety measures and robust infrastructure.

Regulatory compliance and evolving environmental standards add another layer of complexity to HCl production. Manufacturers must continuously adapt to stricter emissions controls, waste management regulations, and safety standards, which can require significant investments in new technologies and processes.

Lastly, the circular economy concept poses a challenge for HCl production. Finding ways to recycle or repurpose waste streams and by-products from the production process is essential for improving sustainability. However, developing economically viable and technologically feasible recycling methods remains a significant hurdle for the industry.

Addressing these challenges requires a multifaceted approach, including technological innovations, process optimizations, and a shift towards more sustainable raw material sourcing and energy use. The industry must balance economic viability with environmental responsibility to align HCl production with sustainable development goals.

Current Sustainable HCl Solutions

01 Production methods of hydrochloric acid

Various methods are employed to produce hydrochloric acid, including direct synthesis from hydrogen and chlorine, as a byproduct in chlorination processes, and through the reaction of sulfuric acid with sodium chloride. These production methods are optimized for efficiency and purity in industrial settings.- Production methods of hydrochloric acid: Various methods are employed for the production of hydrochloric acid, including chemical reactions and industrial processes. These methods may involve the use of specific catalysts, reactants, or equipment to efficiently produce hydrochloric acid at different concentrations and purities.

- Applications in chemical processing: Hydrochloric acid is widely used in various chemical processing applications. It serves as a key reagent in industrial processes, such as metal treatment, pH adjustment, and as a catalyst in organic synthesis reactions. Its versatility makes it an essential component in many manufacturing sectors.

- Purification and treatment of hydrochloric acid: Techniques for purifying and treating hydrochloric acid are crucial for obtaining high-quality acid suitable for specific applications. These methods may include distillation, membrane separation, or chemical treatments to remove impurities and adjust the concentration of the acid.

- Safety and handling of hydrochloric acid: Given the corrosive nature of hydrochloric acid, proper safety measures and handling procedures are essential. This includes the use of specialized equipment, storage containers, and protective gear to minimize risks associated with its use and transportation.

- Environmental considerations and waste management: Environmental aspects of hydrochloric acid use and production are important considerations. This includes methods for neutralizing waste acid, reducing emissions, and implementing recycling processes to minimize environmental impact and comply with regulations.

02 Purification and concentration techniques

Hydrochloric acid purification and concentration techniques involve distillation, membrane separation, and adsorption processes. These methods aim to remove impurities and adjust the acid concentration for specific industrial applications, ensuring high-quality acid production.Expand Specific Solutions03 Industrial applications of hydrochloric acid

Hydrochloric acid finds wide-ranging industrial applications, including metal processing, chemical synthesis, food production, and water treatment. Its versatility makes it a crucial component in various manufacturing processes and environmental applications.Expand Specific Solutions04 Safety measures and handling procedures

Proper safety measures and handling procedures are essential when working with hydrochloric acid due to its corrosive nature. This includes using appropriate personal protective equipment, implementing spill containment systems, and following strict storage and transportation guidelines to minimize risks.Expand Specific Solutions05 Recycling and waste management of hydrochloric acid

Recycling and waste management strategies for hydrochloric acid focus on minimizing environmental impact and maximizing resource efficiency. These include regeneration techniques, neutralization processes, and the development of closed-loop systems to reduce acid waste and promote sustainable industrial practices.Expand Specific Solutions

Key HCl Industry Players

The research on Sustainable Development Goals via Hydrochloric Acid is in its early stages, with the market still developing. The competitive landscape is diverse, featuring academic institutions like Shanghai University and Nankai University, alongside major chemical companies such as Sumitomo Chemical, Mitsui Chemicals, and BASF. The technology's maturity is evolving, with companies like Covestro and Air Liquide potentially leading in industrial applications. The market size is expected to grow as sustainability becomes increasingly important in chemical processes. However, the technology's full potential and widespread adoption are yet to be realized, indicating a nascent but promising field with opportunities for innovation and market leadership.

Covestro Deutschland AG

Technical Solution: Covestro has made significant advancements in sustainable development using hydrochloric acid. They have developed a novel process for producing aniline, a key component in polyurethanes, using HCl and bio-based raw materials instead of conventional petroleum-based feedstocks[7]. This process reduces CO2 emissions by up to 30% compared to traditional methods. Covestro has also implemented a chlorine recycling technology that converts by-product HCl back into chlorine and hydrogen, significantly reducing waste and energy consumption in their production processes[8]. Furthermore, they have developed a sustainable polycarbonate production method that uses CO2 as a raw material, with HCl playing a crucial role in the purification process, contributing to carbon capture and utilization goals.

Strengths: Bio-based raw materials, significant CO2 reduction, efficient chlorine recycling. Weaknesses: High initial investment costs, limited to specific chemical processes.

BASF Corp.

Technical Solution: BASF has developed innovative solutions for sustainable development goals using hydrochloric acid. Their approach focuses on circular economy principles, utilizing HCl in chemical recycling processes for plastics. They have implemented a novel catalytic process that uses HCl to break down polyurethane foam waste into its original components, allowing for the production of new materials[1]. This technology not only reduces waste but also decreases the need for virgin raw materials. Additionally, BASF has developed a chlorine recycling process that converts by-product HCl back into chlorine, significantly reducing waste and energy consumption in chlorine-based production[2].

Strengths: Circular economy approach, waste reduction, energy efficiency. Weaknesses: Potential high initial investment costs, limited to specific plastic types.

Innovative HCl Research

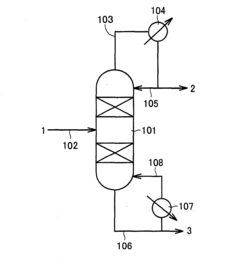

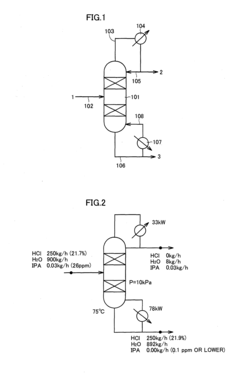

Method of purifying hydrochloric acid

PatentInactiveUS20110236296A1

Innovation

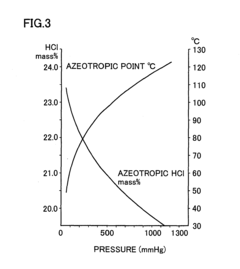

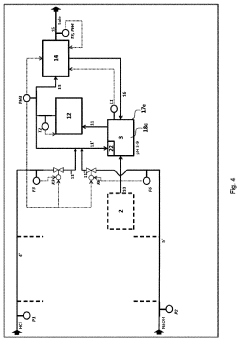

- A method involving distillation in a tower where the operation pressure is set to exceed the azeotropic hydrogen chloride concentration, allowing organic substances with boiling points between −25° C. and 120° C. to be distilled out from the top, while high-purity hydrochloric acid is collected from the bottom, with reflux to prevent hydrogen chloride loss.

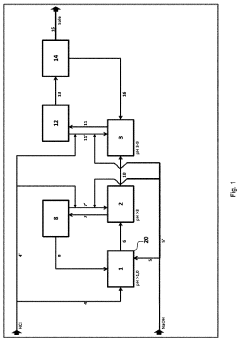

Method for flexibly controlling the use of hydrochloric acid from chemical production

PatentActiveUS20190375635A1

Innovation

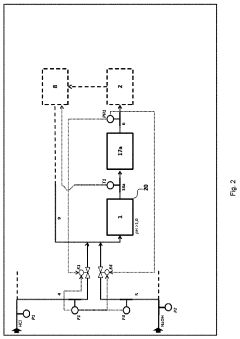

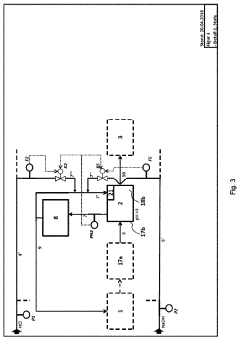

- A flexible hydrochloric acid management system that involves neutralization with concentrated alkali metal hydroxide, specifically sodium hydroxide, in a multistage continuous process to control pH and temperature, allowing for variable input concentrations and volumes, and incorporating a neutralization station to handle excess hydrochloric acid, ensuring continuous operation and efficient recycling.

Environmental Impact of HCl

The environmental impact of hydrochloric acid (HCl) is a critical consideration in the context of sustainable development goals. HCl, a strong and highly corrosive acid, has widespread industrial applications but poses significant risks to ecosystems and human health when released into the environment.

In aquatic ecosystems, HCl can cause severe acidification, leading to a rapid decrease in pH levels. This acidification disrupts the delicate balance of aquatic life, affecting fish, plants, and microorganisms. Even small changes in pH can have cascading effects throughout the food chain, potentially causing long-term ecological damage. Furthermore, the increased acidity can lead to the mobilization of toxic metals from sediments, exacerbating the environmental impact.

Terrestrial ecosystems are also vulnerable to HCl contamination. Soil acidification resulting from HCl exposure can alter nutrient availability, impacting plant growth and soil microbial communities. This can lead to reduced agricultural productivity and biodiversity loss in affected areas. Additionally, HCl can contribute to the formation of acid rain when released into the atmosphere, causing widespread environmental damage beyond the immediate point of release.

The impact of HCl on air quality is another significant concern. When released as a gas, HCl can contribute to the formation of photochemical smog and particulate matter, leading to reduced air quality and associated health risks for both humans and wildlife. Chronic exposure to HCl in the air can cause respiratory issues and exacerbate existing health conditions in vulnerable populations.

From a sustainable development perspective, addressing the environmental impact of HCl requires a multifaceted approach. This includes implementing stringent regulations on industrial emissions, developing more efficient production processes to minimize HCl generation, and investing in technologies for the safe handling and disposal of HCl waste. Additionally, promoting the use of alternative, less harmful substances in industrial processes where possible can help reduce overall HCl usage and its associated environmental risks.

Research into the environmental fate and transport of HCl is crucial for developing effective mitigation strategies. Understanding how HCl interacts with different environmental matrices and its long-term effects on ecosystems can inform more targeted and efficient remediation efforts. Moreover, ongoing monitoring of HCl levels in air, water, and soil is essential for assessing the effectiveness of control measures and identifying areas requiring further intervention.

In conclusion, addressing the environmental impact of HCl is integral to achieving sustainable development goals, particularly those related to clean water, life below water, life on land, and sustainable cities and communities. By mitigating the negative effects of HCl on ecosystems and human health, we can work towards a more sustainable and environmentally responsible future.

In aquatic ecosystems, HCl can cause severe acidification, leading to a rapid decrease in pH levels. This acidification disrupts the delicate balance of aquatic life, affecting fish, plants, and microorganisms. Even small changes in pH can have cascading effects throughout the food chain, potentially causing long-term ecological damage. Furthermore, the increased acidity can lead to the mobilization of toxic metals from sediments, exacerbating the environmental impact.

Terrestrial ecosystems are also vulnerable to HCl contamination. Soil acidification resulting from HCl exposure can alter nutrient availability, impacting plant growth and soil microbial communities. This can lead to reduced agricultural productivity and biodiversity loss in affected areas. Additionally, HCl can contribute to the formation of acid rain when released into the atmosphere, causing widespread environmental damage beyond the immediate point of release.

The impact of HCl on air quality is another significant concern. When released as a gas, HCl can contribute to the formation of photochemical smog and particulate matter, leading to reduced air quality and associated health risks for both humans and wildlife. Chronic exposure to HCl in the air can cause respiratory issues and exacerbate existing health conditions in vulnerable populations.

From a sustainable development perspective, addressing the environmental impact of HCl requires a multifaceted approach. This includes implementing stringent regulations on industrial emissions, developing more efficient production processes to minimize HCl generation, and investing in technologies for the safe handling and disposal of HCl waste. Additionally, promoting the use of alternative, less harmful substances in industrial processes where possible can help reduce overall HCl usage and its associated environmental risks.

Research into the environmental fate and transport of HCl is crucial for developing effective mitigation strategies. Understanding how HCl interacts with different environmental matrices and its long-term effects on ecosystems can inform more targeted and efficient remediation efforts. Moreover, ongoing monitoring of HCl levels in air, water, and soil is essential for assessing the effectiveness of control measures and identifying areas requiring further intervention.

In conclusion, addressing the environmental impact of HCl is integral to achieving sustainable development goals, particularly those related to clean water, life below water, life on land, and sustainable cities and communities. By mitigating the negative effects of HCl on ecosystems and human health, we can work towards a more sustainable and environmentally responsible future.

Circular Economy for HCl

The circular economy for hydrochloric acid (HCl) represents a paradigm shift in the chemical industry's approach to sustainable development. This concept aims to minimize waste, maximize resource efficiency, and reduce environmental impact by creating closed-loop systems for HCl production, use, and recovery. The circular economy model for HCl encompasses several key strategies and technologies that work in synergy to achieve these goals.

One of the primary approaches in the HCl circular economy is the implementation of advanced recycling and recovery systems. These systems are designed to capture and purify HCl from various industrial processes, allowing it to be reused in other applications. For instance, spent HCl from steel pickling operations can be regenerated through thermal decomposition or membrane separation techniques, producing high-quality acid for reuse in the same or different industries.

Another crucial aspect of the circular economy for HCl is the development of more efficient production methods. This includes the optimization of existing processes, such as the chlor-alkali process, to reduce energy consumption and minimize by-product formation. Additionally, innovative technologies like the HydroChlor process, which produces HCl directly from hydrogen and chlorine, offer more sustainable alternatives to traditional production methods.

The integration of HCl production with other industrial processes plays a significant role in the circular economy model. By-product HCl from various chemical reactions can be captured and utilized, reducing the need for dedicated HCl production. This approach not only minimizes waste but also creates valuable synergies between different industrial sectors, promoting overall resource efficiency.

Waste valorization is another key strategy in the HCl circular economy. Technologies are being developed to extract valuable materials from HCl-containing waste streams, such as recovering metals from spent pickling solutions or extracting rare earth elements from electronic waste using HCl leaching processes. These practices not only reduce waste but also create additional value streams, enhancing the economic viability of circular approaches.

The implementation of digital technologies and Industry 4.0 principles is crucial for optimizing the HCl circular economy. Advanced monitoring systems, predictive maintenance, and real-time process control enable more efficient use of resources and minimize losses throughout the HCl lifecycle. Furthermore, blockchain technology and digital tracking systems can enhance transparency and traceability in the HCl supply chain, ensuring the integrity of circular economy practices.

Collaboration and partnerships across industries and sectors are essential for realizing the full potential of the HCl circular economy. This includes cooperation between chemical producers, end-users, waste management companies, and technology providers to create integrated solutions and close material loops. Such collaborations can lead to innovative business models, such as chemical leasing, where HCl is provided as a service rather than a product, incentivizing efficient use and recovery.

One of the primary approaches in the HCl circular economy is the implementation of advanced recycling and recovery systems. These systems are designed to capture and purify HCl from various industrial processes, allowing it to be reused in other applications. For instance, spent HCl from steel pickling operations can be regenerated through thermal decomposition or membrane separation techniques, producing high-quality acid for reuse in the same or different industries.

Another crucial aspect of the circular economy for HCl is the development of more efficient production methods. This includes the optimization of existing processes, such as the chlor-alkali process, to reduce energy consumption and minimize by-product formation. Additionally, innovative technologies like the HydroChlor process, which produces HCl directly from hydrogen and chlorine, offer more sustainable alternatives to traditional production methods.

The integration of HCl production with other industrial processes plays a significant role in the circular economy model. By-product HCl from various chemical reactions can be captured and utilized, reducing the need for dedicated HCl production. This approach not only minimizes waste but also creates valuable synergies between different industrial sectors, promoting overall resource efficiency.

Waste valorization is another key strategy in the HCl circular economy. Technologies are being developed to extract valuable materials from HCl-containing waste streams, such as recovering metals from spent pickling solutions or extracting rare earth elements from electronic waste using HCl leaching processes. These practices not only reduce waste but also create additional value streams, enhancing the economic viability of circular approaches.

The implementation of digital technologies and Industry 4.0 principles is crucial for optimizing the HCl circular economy. Advanced monitoring systems, predictive maintenance, and real-time process control enable more efficient use of resources and minimize losses throughout the HCl lifecycle. Furthermore, blockchain technology and digital tracking systems can enhance transparency and traceability in the HCl supply chain, ensuring the integrity of circular economy practices.

Collaboration and partnerships across industries and sectors are essential for realizing the full potential of the HCl circular economy. This includes cooperation between chemical producers, end-users, waste management companies, and technology providers to create integrated solutions and close material loops. Such collaborations can lead to innovative business models, such as chemical leasing, where HCl is provided as a service rather than a product, incentivizing efficient use and recovery.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!