How to Optimize Supply Chains for Hydrochloric Acid?

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Supply Chain Background and Objectives

Hydrochloric acid (HCl) is a vital chemical compound widely used across various industries, including chemical manufacturing, metal processing, and water treatment. The optimization of its supply chain has become increasingly crucial due to growing demand and complex global market dynamics. This technical research report aims to explore the evolution of HCl supply chain management, analyze current trends, and identify potential areas for improvement.

The HCl supply chain has undergone significant transformations over the past decades, driven by advancements in production technologies, changing regulatory landscapes, and shifting global trade patterns. Initially, HCl was primarily a byproduct of chlor-alkali processes, but dedicated production methods have since been developed to meet specific quality and quantity requirements. This evolution has led to a more diverse and complex supply chain structure, necessitating sophisticated management approaches.

Current market trends indicate a steady increase in HCl demand, particularly in emerging economies where industrial growth is rapid. This rising demand, coupled with environmental concerns and stricter regulations, has put pressure on supply chain stakeholders to develop more efficient and sustainable practices. The industry now faces the challenge of balancing cost-effectiveness with environmental responsibility and supply reliability.

One of the primary objectives of this research is to identify key bottlenecks and inefficiencies in the existing HCl supply chain. These may include transportation challenges due to the corrosive nature of HCl, storage limitations, and the need for specialized handling equipment. By pinpointing these issues, we aim to propose targeted solutions that can enhance overall supply chain performance.

Another critical goal is to explore innovative technologies and methodologies that can revolutionize HCl supply chain management. This includes investigating the potential of digital technologies such as blockchain for improved traceability, artificial intelligence for demand forecasting, and Internet of Things (IoT) devices for real-time monitoring of storage and transportation conditions.

Furthermore, this research seeks to analyze the impact of global events, such as trade disputes and pandemics, on the HCl supply chain. Understanding these external factors is crucial for developing resilient and adaptable supply chain strategies that can withstand unforeseen disruptions.

Lastly, we aim to evaluate the potential for circular economy principles in HCl production and distribution. This involves exploring opportunities for recycling and reusing HCl in industrial processes, as well as investigating alternative production methods that may offer environmental and economic benefits.

By addressing these objectives, this technical research report will provide a comprehensive overview of the current state of HCl supply chains and offer insights into potential optimization strategies. The findings will serve as a valuable resource for industry stakeholders looking to enhance their supply chain efficiency, reduce costs, and improve sustainability in the HCl market.

The HCl supply chain has undergone significant transformations over the past decades, driven by advancements in production technologies, changing regulatory landscapes, and shifting global trade patterns. Initially, HCl was primarily a byproduct of chlor-alkali processes, but dedicated production methods have since been developed to meet specific quality and quantity requirements. This evolution has led to a more diverse and complex supply chain structure, necessitating sophisticated management approaches.

Current market trends indicate a steady increase in HCl demand, particularly in emerging economies where industrial growth is rapid. This rising demand, coupled with environmental concerns and stricter regulations, has put pressure on supply chain stakeholders to develop more efficient and sustainable practices. The industry now faces the challenge of balancing cost-effectiveness with environmental responsibility and supply reliability.

One of the primary objectives of this research is to identify key bottlenecks and inefficiencies in the existing HCl supply chain. These may include transportation challenges due to the corrosive nature of HCl, storage limitations, and the need for specialized handling equipment. By pinpointing these issues, we aim to propose targeted solutions that can enhance overall supply chain performance.

Another critical goal is to explore innovative technologies and methodologies that can revolutionize HCl supply chain management. This includes investigating the potential of digital technologies such as blockchain for improved traceability, artificial intelligence for demand forecasting, and Internet of Things (IoT) devices for real-time monitoring of storage and transportation conditions.

Furthermore, this research seeks to analyze the impact of global events, such as trade disputes and pandemics, on the HCl supply chain. Understanding these external factors is crucial for developing resilient and adaptable supply chain strategies that can withstand unforeseen disruptions.

Lastly, we aim to evaluate the potential for circular economy principles in HCl production and distribution. This involves exploring opportunities for recycling and reusing HCl in industrial processes, as well as investigating alternative production methods that may offer environmental and economic benefits.

By addressing these objectives, this technical research report will provide a comprehensive overview of the current state of HCl supply chains and offer insights into potential optimization strategies. The findings will serve as a valuable resource for industry stakeholders looking to enhance their supply chain efficiency, reduce costs, and improve sustainability in the HCl market.

Market Demand Analysis for HCl

The global market for hydrochloric acid (HCl) has been experiencing steady growth, driven by its widespread applications across various industries. The demand for HCl is primarily fueled by its use in steel pickling, oil well acidizing, food processing, and chemical manufacturing. The steel industry remains the largest consumer of HCl, accounting for a significant portion of the total market demand.

In recent years, the increasing adoption of HCl in water treatment processes has emerged as a key growth driver. As water scarcity becomes a pressing global issue, the need for efficient water treatment solutions has led to a surge in HCl demand for pH adjustment and disinfection purposes. This trend is particularly pronounced in developing regions where rapid industrialization and urbanization are driving the need for improved water management systems.

The electronics industry has also contributed to the growing demand for high-purity HCl. The production of semiconductors and other electronic components requires ultra-pure HCl, creating a niche market segment with stringent quality requirements and higher profit margins for suppliers.

Geographically, Asia-Pacific dominates the global HCl market, with China being the largest producer and consumer. The region's robust industrial growth, particularly in sectors such as chemicals, electronics, and automotive, continues to drive HCl demand. North America and Europe follow as significant markets, with steady demand from established industrial sectors.

Market analysts project the global HCl market to continue its growth trajectory in the coming years. The increasing use of HCl in the production of polyvinyl chloride (PVC) and other chlorinated compounds is expected to further boost demand. Additionally, the growing focus on sustainable practices has led to innovations in HCl recycling and recovery processes, potentially reshaping supply chain dynamics.

However, the market faces challenges such as environmental regulations and safety concerns associated with HCl handling and transportation. These factors are prompting industry players to invest in safer production methods and more efficient supply chain solutions. The development of on-site HCl generation technologies is gaining traction, offering potential benefits in terms of reduced transportation costs and improved safety profiles.

The market structure for HCl is characterized by a mix of large chemical companies and specialized producers. While some major players have integrated HCl production into their broader chemical operations, there is also a significant presence of dedicated HCl manufacturers catering to specific industry needs. This diverse supplier landscape presents both opportunities and challenges for supply chain optimization, as buyers navigate between cost-effectiveness and specialized quality requirements.

In recent years, the increasing adoption of HCl in water treatment processes has emerged as a key growth driver. As water scarcity becomes a pressing global issue, the need for efficient water treatment solutions has led to a surge in HCl demand for pH adjustment and disinfection purposes. This trend is particularly pronounced in developing regions where rapid industrialization and urbanization are driving the need for improved water management systems.

The electronics industry has also contributed to the growing demand for high-purity HCl. The production of semiconductors and other electronic components requires ultra-pure HCl, creating a niche market segment with stringent quality requirements and higher profit margins for suppliers.

Geographically, Asia-Pacific dominates the global HCl market, with China being the largest producer and consumer. The region's robust industrial growth, particularly in sectors such as chemicals, electronics, and automotive, continues to drive HCl demand. North America and Europe follow as significant markets, with steady demand from established industrial sectors.

Market analysts project the global HCl market to continue its growth trajectory in the coming years. The increasing use of HCl in the production of polyvinyl chloride (PVC) and other chlorinated compounds is expected to further boost demand. Additionally, the growing focus on sustainable practices has led to innovations in HCl recycling and recovery processes, potentially reshaping supply chain dynamics.

However, the market faces challenges such as environmental regulations and safety concerns associated with HCl handling and transportation. These factors are prompting industry players to invest in safer production methods and more efficient supply chain solutions. The development of on-site HCl generation technologies is gaining traction, offering potential benefits in terms of reduced transportation costs and improved safety profiles.

The market structure for HCl is characterized by a mix of large chemical companies and specialized producers. While some major players have integrated HCl production into their broader chemical operations, there is also a significant presence of dedicated HCl manufacturers catering to specific industry needs. This diverse supplier landscape presents both opportunities and challenges for supply chain optimization, as buyers navigate between cost-effectiveness and specialized quality requirements.

Current Challenges in HCl Supply Chain

The hydrochloric acid (HCl) supply chain faces several significant challenges that impact its efficiency and reliability. One of the primary issues is the volatility in raw material prices, particularly for salt and natural gas, which are essential components in HCl production. This price instability makes it difficult for manufacturers to maintain consistent profit margins and plan for long-term production strategies.

Transportation and storage of HCl present another set of challenges due to its corrosive nature. Specialized equipment and handling procedures are required, which increases logistics costs and complexity. The risk of accidents during transport also necessitates stringent safety measures, further complicating the supply chain process.

Regulatory compliance is an ongoing challenge for the HCl industry. Environmental regulations are becoming increasingly strict, requiring manufacturers to invest in emission control technologies and waste management systems. This not only adds to production costs but also impacts the overall supply chain design as companies must adapt their processes to meet these regulatory demands.

Demand fluctuations pose a significant challenge to HCl supply chain optimization. The diverse applications of HCl across industries such as steel pickling, oil well acidizing, and chemical manufacturing lead to unpredictable demand patterns. This variability makes it difficult for suppliers to maintain optimal inventory levels and production schedules, often resulting in either shortages or excess stock.

Global trade tensions and geopolitical issues have introduced new uncertainties into the HCl supply chain. Tariffs, trade restrictions, and changing international relationships can disrupt established supply routes and sourcing strategies. This forces companies to constantly reassess and potentially restructure their global supply networks.

The lack of supply chain visibility is another critical challenge. Many HCl supply chains suffer from inadequate real-time tracking and monitoring systems, leading to inefficiencies in inventory management and distribution. This lack of transparency can result in delayed deliveries, increased costs, and potential supply disruptions.

Lastly, the HCl industry faces challenges related to sustainability and circular economy principles. There is growing pressure to reduce the environmental impact of HCl production and use, which requires innovative approaches to recycling, waste reduction, and the development of more sustainable production methods. Integrating these sustainability goals into the existing supply chain structure presents both technical and operational challenges for the industry.

Transportation and storage of HCl present another set of challenges due to its corrosive nature. Specialized equipment and handling procedures are required, which increases logistics costs and complexity. The risk of accidents during transport also necessitates stringent safety measures, further complicating the supply chain process.

Regulatory compliance is an ongoing challenge for the HCl industry. Environmental regulations are becoming increasingly strict, requiring manufacturers to invest in emission control technologies and waste management systems. This not only adds to production costs but also impacts the overall supply chain design as companies must adapt their processes to meet these regulatory demands.

Demand fluctuations pose a significant challenge to HCl supply chain optimization. The diverse applications of HCl across industries such as steel pickling, oil well acidizing, and chemical manufacturing lead to unpredictable demand patterns. This variability makes it difficult for suppliers to maintain optimal inventory levels and production schedules, often resulting in either shortages or excess stock.

Global trade tensions and geopolitical issues have introduced new uncertainties into the HCl supply chain. Tariffs, trade restrictions, and changing international relationships can disrupt established supply routes and sourcing strategies. This forces companies to constantly reassess and potentially restructure their global supply networks.

The lack of supply chain visibility is another critical challenge. Many HCl supply chains suffer from inadequate real-time tracking and monitoring systems, leading to inefficiencies in inventory management and distribution. This lack of transparency can result in delayed deliveries, increased costs, and potential supply disruptions.

Lastly, the HCl industry faces challenges related to sustainability and circular economy principles. There is growing pressure to reduce the environmental impact of HCl production and use, which requires innovative approaches to recycling, waste reduction, and the development of more sustainable production methods. Integrating these sustainability goals into the existing supply chain structure presents both technical and operational challenges for the industry.

Existing HCl Supply Chain Solutions

01 Supply chain optimization using data analytics

Utilizing advanced data analytics and machine learning algorithms to optimize supply chain operations for hydrochloric acid. This approach involves analyzing historical data, market trends, and demand forecasts to improve inventory management, reduce costs, and enhance overall efficiency in the supply chain.- Supply chain optimization using data analytics: Utilizing advanced data analytics and machine learning algorithms to optimize supply chain operations for hydrochloric acid. This approach involves analyzing historical data, market trends, and production patterns to improve forecasting, inventory management, and distribution efficiency.

- Real-time monitoring and tracking systems: Implementing real-time monitoring and tracking systems throughout the hydrochloric acid supply chain. This includes using IoT devices, sensors, and RFID technology to track inventory levels, shipment status, and production processes, enabling quick response to disruptions and improved overall supply chain visibility.

- Sustainable and eco-friendly supply chain practices: Incorporating sustainable and eco-friendly practices in the hydrochloric acid supply chain. This involves optimizing transportation routes to reduce carbon emissions, implementing recycling and waste reduction strategies, and exploring alternative packaging solutions to minimize environmental impact.

- Collaborative supplier and customer relationships: Developing strong collaborative relationships with suppliers and customers to improve supply chain efficiency. This includes implementing vendor-managed inventory systems, establishing long-term contracts, and sharing demand forecasts to ensure a stable and responsive supply chain for hydrochloric acid.

- Risk management and contingency planning: Implementing comprehensive risk management strategies and contingency plans for the hydrochloric acid supply chain. This involves identifying potential disruptions, such as natural disasters or geopolitical events, and developing alternative sourcing options, buffer inventory strategies, and flexible production capabilities to ensure supply chain resilience.

02 Real-time monitoring and tracking systems

Implementing real-time monitoring and tracking systems throughout the hydrochloric acid supply chain. These systems use IoT sensors, RFID technology, and GPS tracking to provide continuous visibility of inventory levels, transportation status, and storage conditions, enabling proactive decision-making and rapid response to potential disruptions.Expand Specific Solutions03 Sustainable and eco-friendly supply chain practices

Incorporating sustainable and eco-friendly practices in the hydrochloric acid supply chain. This includes optimizing transportation routes to reduce carbon emissions, implementing recycling and waste reduction programs, and exploring alternative packaging solutions to minimize environmental impact while maintaining product quality and safety.Expand Specific Solutions04 Collaborative supplier network management

Developing a collaborative supplier network management system for hydrochloric acid production and distribution. This approach focuses on improving communication and coordination among suppliers, manufacturers, and distributors to streamline processes, reduce lead times, and enhance overall supply chain resilience.Expand Specific Solutions05 Risk management and contingency planning

Implementing comprehensive risk management strategies and contingency planning for the hydrochloric acid supply chain. This includes identifying potential risks, developing mitigation strategies, and creating backup plans to ensure continuous supply in the face of disruptions such as natural disasters, geopolitical events, or market fluctuations.Expand Specific Solutions

Key Players in HCl Industry

The hydrochloric acid supply chain optimization landscape is characterized by a mature market with steady growth, driven by diverse industrial applications. The global market size is estimated to be around $7-8 billion, with a CAGR of 4-5%. Key players like BASF, Covestro, and Dow Chemical dominate the market, leveraging their extensive production capabilities and distribution networks. Emerging players such as China Salt Jintan Salinization and Sichuan Yongxiang Resin are gaining traction, particularly in the Asia-Pacific region. Technological advancements focus on improving production efficiency, reducing environmental impact, and enhancing product quality. The industry is moving towards more sustainable practices, with companies like Mitsubishi Heavy Industries developing innovative recycling and purification technologies.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical Co., Ltd. has developed a sophisticated approach to optimizing hydrochloric acid supply chains, focusing on production efficiency and market responsiveness. The company utilizes advanced membrane technology in their chlor-alkali production process, which yields high-purity hydrochloric acid as a co-product[9]. This method allows for precise control over production volumes and quality. Shin-Etsu has implemented a flexible production system that can quickly adjust output based on market demand, reducing inventory costs and improving supply chain agility. The company has also invested in specialized logistics solutions, including corrosion-resistant ISO tank containers for international shipping, enabling efficient global distribution[10]. Additionally, Shin-Etsu has developed a digital twin of their supply chain, allowing for real-time monitoring and simulation of various scenarios to optimize decision-making and improve overall supply chain performance.

Strengths: High-quality production, flexible manufacturing capabilities, global distribution network. Weaknesses: Potential higher production costs due to advanced technology, sensitivity to global market fluctuations.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative approach to optimize hydrochloric acid supply chains through their ChemCycling project. This initiative focuses on recycling plastic waste chemically to produce new materials, including hydrochloric acid as a by-product[1]. The process involves converting plastic waste into pyrolysis oil, which is then used as a feedstock in BASF's production network. This circular economy approach not only optimizes the supply chain but also addresses environmental concerns. BASF has also implemented advanced logistics solutions, including real-time tracking and predictive analytics, to enhance the efficiency of hydrochloric acid distribution[2]. Their integrated supply chain management system allows for better inventory control and demand forecasting, reducing waste and improving overall supply chain performance.

Strengths: Sustainable production method, reduced environmental impact, improved resource efficiency. Weaknesses: Potential high initial investment costs, dependence on plastic waste availability.

Innovative HCl Logistics Technologies

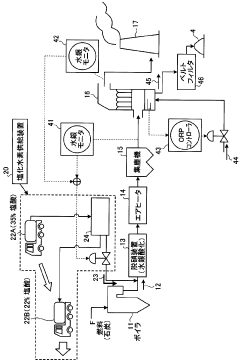

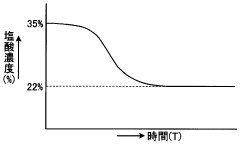

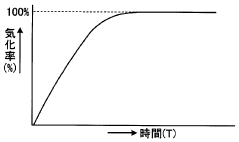

Hydrogen chloride supply apparatus, exhaust gas treatment system, and hydrogen chloride supply management system

PatentWO2009087822A1

Innovation

- A hydrogen chloride supply device and management system that includes a hydrochloric acid vaporizer, liquid level adjuster, concentration adjustment tank, and a networked management system to recycle and reuse dilute hydrochloric acid by adjusting its concentration and managing inventory, allowing for efficient transportation and utilization of hydrochloric acid as a valuable product.

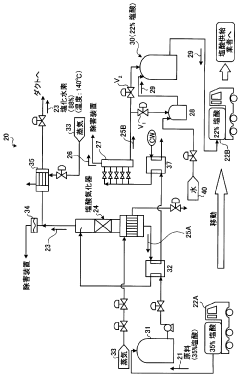

Method for flexibly controlling the use of hydrochloric acid from chemical production

PatentWO2018134239A1

Innovation

- A flexible control process for hydrochloric acid management involves neutralizing hydrochloric acid with concentrated alkali, specifically sodium hydroxide, in a multi-stage continuous process that adjusts pH values and compensates for flow and concentration variations, allowing for efficient handling and recycling of hydrochloric acid even when traditional acceptance points are unavailable.

Environmental Regulations for HCl Transport

The transportation of hydrochloric acid (HCl) is subject to stringent environmental regulations due to its corrosive and hazardous nature. These regulations aim to protect human health and the environment from potential risks associated with HCl transport. In the United States, the Environmental Protection Agency (EPA) and the Department of Transportation (DOT) are the primary regulatory bodies overseeing HCl transportation.

The EPA regulates HCl under the Resource Conservation and Recovery Act (RCRA) as a hazardous waste when discarded. This classification imposes strict requirements on handling, storage, and transportation. Transporters must comply with EPA's hazardous waste manifest system, ensuring proper documentation and tracking of HCl shipments from origin to destination.

DOT regulations, specifically 49 CFR Parts 171-180, govern the transportation of hazardous materials, including HCl. These regulations mandate specific packaging, labeling, and placarding requirements for HCl transport. HCl must be transported in UN-approved containers that meet specific performance standards for corrosion resistance and structural integrity.

Internationally, the transport of HCl is regulated by various agreements and conventions. The European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) sets standards for HCl transport in Europe. Similarly, the International Maritime Dangerous Goods (IMDG) Code regulates sea transport of hazardous materials, including HCl.

Environmental regulations also address emergency response and spill management. Transporters are required to have comprehensive emergency response plans and trained personnel to handle potential HCl spills or leaks. The U.S. Occupational Safety and Health Administration (OSHA) mandates specific safety measures for workers handling HCl during transport and transfer operations.

Air quality regulations play a crucial role in HCl transport. The Clean Air Act regulates emissions from transportation sources, including potential HCl releases. Transporters must ensure their vehicles and equipment meet emission standards and implement measures to prevent or minimize HCl vapor releases during transit.

Water protection regulations are equally important, given HCl's potential to cause severe environmental damage if released into water bodies. The Clean Water Act prohibits the discharge of hazardous substances, including HCl, into navigable waters without proper permits and treatment.

To optimize supply chains for HCl transport while adhering to these regulations, companies must invest in robust compliance management systems. This includes regular training for personnel, implementing state-of-the-art tracking and monitoring technologies, and adopting best practices for risk assessment and mitigation throughout the supply chain.

The EPA regulates HCl under the Resource Conservation and Recovery Act (RCRA) as a hazardous waste when discarded. This classification imposes strict requirements on handling, storage, and transportation. Transporters must comply with EPA's hazardous waste manifest system, ensuring proper documentation and tracking of HCl shipments from origin to destination.

DOT regulations, specifically 49 CFR Parts 171-180, govern the transportation of hazardous materials, including HCl. These regulations mandate specific packaging, labeling, and placarding requirements for HCl transport. HCl must be transported in UN-approved containers that meet specific performance standards for corrosion resistance and structural integrity.

Internationally, the transport of HCl is regulated by various agreements and conventions. The European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) sets standards for HCl transport in Europe. Similarly, the International Maritime Dangerous Goods (IMDG) Code regulates sea transport of hazardous materials, including HCl.

Environmental regulations also address emergency response and spill management. Transporters are required to have comprehensive emergency response plans and trained personnel to handle potential HCl spills or leaks. The U.S. Occupational Safety and Health Administration (OSHA) mandates specific safety measures for workers handling HCl during transport and transfer operations.

Air quality regulations play a crucial role in HCl transport. The Clean Air Act regulates emissions from transportation sources, including potential HCl releases. Transporters must ensure their vehicles and equipment meet emission standards and implement measures to prevent or minimize HCl vapor releases during transit.

Water protection regulations are equally important, given HCl's potential to cause severe environmental damage if released into water bodies. The Clean Water Act prohibits the discharge of hazardous substances, including HCl, into navigable waters without proper permits and treatment.

To optimize supply chains for HCl transport while adhering to these regulations, companies must invest in robust compliance management systems. This includes regular training for personnel, implementing state-of-the-art tracking and monitoring technologies, and adopting best practices for risk assessment and mitigation throughout the supply chain.

Risk Management in HCl Supply Chain

Risk management is a critical aspect of optimizing the supply chain for hydrochloric acid (HCl). The volatile nature of HCl and its potential hazards necessitate a comprehensive approach to mitigate risks throughout the supply chain. One of the primary concerns is the corrosive nature of HCl, which can lead to equipment damage and potential leaks during transportation and storage. To address this, companies must implement rigorous inspection and maintenance protocols for all equipment and containers used in the HCl supply chain.

Another significant risk factor is the potential for environmental contamination. Strict adherence to environmental regulations and the implementation of spill prevention and response plans are essential. This includes proper training of personnel handling HCl and the use of appropriate personal protective equipment (PPE). Companies should also consider investing in advanced monitoring systems to detect leaks or spills promptly.

Supply chain disruptions pose a considerable risk to HCl operations. Natural disasters, geopolitical events, or sudden changes in demand can significantly impact the availability and cost of HCl. To mitigate these risks, companies should diversify their supplier base and establish long-term contracts with multiple suppliers. Additionally, maintaining strategic inventory levels and implementing just-in-time delivery systems can help balance supply and demand fluctuations.

Transportation risks are particularly crucial in the HCl supply chain. Road accidents or rail incidents involving HCl can have severe consequences. To minimize these risks, companies should carefully select transportation partners with proven safety records and specialized equipment for handling hazardous materials. Implementing real-time tracking systems and optimizing transportation routes can further enhance safety and efficiency.

Market volatility and pricing risks are also significant concerns in the HCl supply chain. Fluctuations in raw material costs, changes in production capacity, and shifts in demand can impact pricing and availability. To manage these risks, companies should develop robust forecasting models and maintain flexibility in their procurement strategies. Hedging mechanisms and long-term contracts with price adjustment clauses can provide additional protection against market volatility.

Regulatory compliance is a critical aspect of risk management in the HCl supply chain. Staying abreast of changing regulations and ensuring compliance across all operations is essential to avoid legal and financial risks. This includes proper documentation, labeling, and handling procedures throughout the supply chain. Regular audits and compliance checks should be conducted to identify and address any potential regulatory issues proactively.

Another significant risk factor is the potential for environmental contamination. Strict adherence to environmental regulations and the implementation of spill prevention and response plans are essential. This includes proper training of personnel handling HCl and the use of appropriate personal protective equipment (PPE). Companies should also consider investing in advanced monitoring systems to detect leaks or spills promptly.

Supply chain disruptions pose a considerable risk to HCl operations. Natural disasters, geopolitical events, or sudden changes in demand can significantly impact the availability and cost of HCl. To mitigate these risks, companies should diversify their supplier base and establish long-term contracts with multiple suppliers. Additionally, maintaining strategic inventory levels and implementing just-in-time delivery systems can help balance supply and demand fluctuations.

Transportation risks are particularly crucial in the HCl supply chain. Road accidents or rail incidents involving HCl can have severe consequences. To minimize these risks, companies should carefully select transportation partners with proven safety records and specialized equipment for handling hazardous materials. Implementing real-time tracking systems and optimizing transportation routes can further enhance safety and efficiency.

Market volatility and pricing risks are also significant concerns in the HCl supply chain. Fluctuations in raw material costs, changes in production capacity, and shifts in demand can impact pricing and availability. To manage these risks, companies should develop robust forecasting models and maintain flexibility in their procurement strategies. Hedging mechanisms and long-term contracts with price adjustment clauses can provide additional protection against market volatility.

Regulatory compliance is a critical aspect of risk management in the HCl supply chain. Staying abreast of changing regulations and ensuring compliance across all operations is essential to avoid legal and financial risks. This includes proper documentation, labeling, and handling procedures throughout the supply chain. Regular audits and compliance checks should be conducted to identify and address any potential regulatory issues proactively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!