Energy Harvesting From Structural Vibrations Using Metamaterial Layers

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metamaterial Vibration Energy Harvesting Background & Objectives

Energy harvesting from structural vibrations represents a significant frontier in sustainable energy technology, emerging from the convergence of mechanical engineering, materials science, and energy systems. This field has evolved considerably over the past two decades, transitioning from basic piezoelectric applications to sophisticated metamaterial-based solutions. The fundamental concept involves capturing ambient vibrational energy that would otherwise dissipate as waste and converting it into usable electrical power.

Metamaterials—engineered structures with properties not found in natural materials—have revolutionized this domain by offering unprecedented control over wave propagation and energy localization. Initially developed for electromagnetic applications in the early 2000s, metamaterial principles were subsequently extended to mechanical systems around 2010, opening new possibilities for vibration energy harvesting.

The evolution of this technology has been driven by increasing demands for autonomous power sources for distributed sensors, Internet of Things (IoT) devices, and remote monitoring systems. Traditional power solutions like batteries present limitations in terms of lifespan, maintenance requirements, and environmental impact, creating a compelling case for self-sustaining energy harvesting alternatives.

Recent advancements in nanofabrication, computational modeling, and material science have accelerated progress in metamaterial-based energy harvesting. Particularly noteworthy is the development of acoustic/elastic metamaterials with locally resonant structures, phononic crystals, and metasurfaces that can effectively manipulate vibration wave propagation, amplification, and localization.

The primary technical objective of metamaterial vibration energy harvesting is to maximize energy conversion efficiency across variable frequency ranges and amplitudes typical of real-world structural vibrations. This involves designing metamaterial layers that can effectively capture, concentrate, and channel vibrational energy to integrated transduction mechanisms.

Secondary objectives include developing systems that are compact, durable, cost-effective, and capable of operating under diverse environmental conditions. The ideal solution would provide sufficient power density to support modern low-power electronics while maintaining long-term reliability without maintenance intervention.

From a broader perspective, this technology aims to contribute to sustainability goals by reducing dependence on chemical batteries, enabling more pervasive deployment of sensor networks for structural health monitoring, and potentially scaling to contribute meaningfully to renewable energy portfolios in specific applications such as transportation infrastructure and industrial machinery.

The trajectory of metamaterial vibration energy harvesting points toward increasingly sophisticated multi-physics designs that simultaneously optimize mechanical response, electrical conversion, and system integration, potentially revolutionizing how we power the expanding universe of distributed electronic devices.

Metamaterials—engineered structures with properties not found in natural materials—have revolutionized this domain by offering unprecedented control over wave propagation and energy localization. Initially developed for electromagnetic applications in the early 2000s, metamaterial principles were subsequently extended to mechanical systems around 2010, opening new possibilities for vibration energy harvesting.

The evolution of this technology has been driven by increasing demands for autonomous power sources for distributed sensors, Internet of Things (IoT) devices, and remote monitoring systems. Traditional power solutions like batteries present limitations in terms of lifespan, maintenance requirements, and environmental impact, creating a compelling case for self-sustaining energy harvesting alternatives.

Recent advancements in nanofabrication, computational modeling, and material science have accelerated progress in metamaterial-based energy harvesting. Particularly noteworthy is the development of acoustic/elastic metamaterials with locally resonant structures, phononic crystals, and metasurfaces that can effectively manipulate vibration wave propagation, amplification, and localization.

The primary technical objective of metamaterial vibration energy harvesting is to maximize energy conversion efficiency across variable frequency ranges and amplitudes typical of real-world structural vibrations. This involves designing metamaterial layers that can effectively capture, concentrate, and channel vibrational energy to integrated transduction mechanisms.

Secondary objectives include developing systems that are compact, durable, cost-effective, and capable of operating under diverse environmental conditions. The ideal solution would provide sufficient power density to support modern low-power electronics while maintaining long-term reliability without maintenance intervention.

From a broader perspective, this technology aims to contribute to sustainability goals by reducing dependence on chemical batteries, enabling more pervasive deployment of sensor networks for structural health monitoring, and potentially scaling to contribute meaningfully to renewable energy portfolios in specific applications such as transportation infrastructure and industrial machinery.

The trajectory of metamaterial vibration energy harvesting points toward increasingly sophisticated multi-physics designs that simultaneously optimize mechanical response, electrical conversion, and system integration, potentially revolutionizing how we power the expanding universe of distributed electronic devices.

Market Analysis for Structural Vibration Energy Solutions

The global market for structural vibration energy harvesting solutions is experiencing significant growth, driven by the increasing demand for sustainable energy sources and the proliferation of wireless sensor networks in various industries. Currently valued at approximately $127 million in 2023, this market is projected to reach $498 million by 2030, representing a compound annual growth rate (CAGR) of 21.5% during the forecast period.

The industrial sector constitutes the largest market segment, accounting for nearly 40% of the total market share. This dominance is attributed to the abundance of vibration sources in manufacturing facilities, heavy machinery, and industrial equipment. The integration of Industry 4.0 technologies has further accelerated the adoption of self-powered wireless sensors, creating substantial opportunities for vibration energy harvesting solutions.

Transportation infrastructure represents another significant market segment, with applications in bridges, railways, and highways. The market in this sector is expected to grow at a CAGR of 24% through 2030, driven by smart infrastructure initiatives worldwide. Metamaterial-based energy harvesters are particularly well-suited for these applications due to their ability to operate effectively at low-frequency vibrations typical of large structures.

Regionally, North America currently leads the market with a 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is anticipated to exhibit the highest growth rate, projected at 26% annually, primarily due to rapid industrialization, infrastructure development, and increasing investments in renewable energy technologies in countries like China, Japan, and South Korea.

The consumer electronics segment, though smaller in market share (approximately 15%), represents a high-growth opportunity area with the potential to reach $95 million by 2030. The miniaturization of metamaterial-based energy harvesters makes them increasingly suitable for wearable devices, smartphones, and other portable electronics.

Key market drivers include the growing emphasis on energy efficiency, the rising adoption of IoT devices, and stringent environmental regulations promoting green technologies. Additionally, the decreasing cost of metamaterial production and improvements in energy conversion efficiency are making these solutions more economically viable across various applications.

Market challenges include competition from alternative energy harvesting technologies such as solar, thermal, and RF energy harvesting. Furthermore, the relatively low power output of current vibration energy harvesting solutions limits their application scope, though ongoing research in metamaterial design is progressively addressing this limitation.

The industrial sector constitutes the largest market segment, accounting for nearly 40% of the total market share. This dominance is attributed to the abundance of vibration sources in manufacturing facilities, heavy machinery, and industrial equipment. The integration of Industry 4.0 technologies has further accelerated the adoption of self-powered wireless sensors, creating substantial opportunities for vibration energy harvesting solutions.

Transportation infrastructure represents another significant market segment, with applications in bridges, railways, and highways. The market in this sector is expected to grow at a CAGR of 24% through 2030, driven by smart infrastructure initiatives worldwide. Metamaterial-based energy harvesters are particularly well-suited for these applications due to their ability to operate effectively at low-frequency vibrations typical of large structures.

Regionally, North America currently leads the market with a 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is anticipated to exhibit the highest growth rate, projected at 26% annually, primarily due to rapid industrialization, infrastructure development, and increasing investments in renewable energy technologies in countries like China, Japan, and South Korea.

The consumer electronics segment, though smaller in market share (approximately 15%), represents a high-growth opportunity area with the potential to reach $95 million by 2030. The miniaturization of metamaterial-based energy harvesters makes them increasingly suitable for wearable devices, smartphones, and other portable electronics.

Key market drivers include the growing emphasis on energy efficiency, the rising adoption of IoT devices, and stringent environmental regulations promoting green technologies. Additionally, the decreasing cost of metamaterial production and improvements in energy conversion efficiency are making these solutions more economically viable across various applications.

Market challenges include competition from alternative energy harvesting technologies such as solar, thermal, and RF energy harvesting. Furthermore, the relatively low power output of current vibration energy harvesting solutions limits their application scope, though ongoing research in metamaterial design is progressively addressing this limitation.

Current Challenges in Metamaterial Energy Harvesting

Despite significant advancements in metamaterial-based energy harvesting systems, several critical challenges continue to impede widespread implementation and commercialization. The fundamental challenge lies in the trade-off between bandwidth and efficiency. While metamaterials can be designed to exhibit exceptional energy conversion at specific frequencies, they typically suffer from narrow operational bandwidth, limiting their effectiveness in real-world environments where vibration frequencies fluctuate unpredictably.

Material limitations present another significant hurdle. Current metamaterial designs often rely on exotic materials or complex geometries that are difficult to manufacture at scale. The durability of these materials under continuous vibration remains questionable, with many showing performance degradation over time due to fatigue, delamination, or structural changes that alter their carefully engineered properties.

Scale-up and manufacturing challenges further complicate commercial adoption. The precise micro and nano-scale features that enable metamaterials' unique properties are often difficult to reproduce consistently in mass production. Current fabrication techniques such as 3D printing, lithography, and precision machining face limitations in terms of cost-effectiveness, throughput, and quality control when scaled beyond laboratory prototypes.

Energy storage integration represents another critical challenge. While metamaterial layers may successfully harvest energy from structural vibrations, efficiently storing this energy for practical use requires seamless integration with storage systems. The intermittent nature of harvested energy necessitates sophisticated power management circuits that can operate efficiently at very low power levels.

Environmental adaptability remains problematic for current designs. Most metamaterial energy harvesters are optimized for specific operating conditions and show significant performance degradation when exposed to temperature fluctuations, humidity changes, or unexpected mechanical stresses. This lack of robustness limits their application in variable environments such as transportation infrastructure or outdoor installations.

Cost-effectiveness presents perhaps the most significant barrier to widespread adoption. Current metamaterial energy harvesting solutions typically require specialized materials and precision manufacturing, resulting in costs that often outweigh the benefits of the energy harvested over the system's lifetime. The return on investment remains unfavorable compared to conventional energy sources or even other renewable energy technologies.

Theoretical modeling and simulation tools also require further development. Current models often fail to accurately predict the behavior of complex metamaterial structures under real-world conditions, creating a disconnect between theoretical performance and practical implementation that hampers efficient design optimization.

Material limitations present another significant hurdle. Current metamaterial designs often rely on exotic materials or complex geometries that are difficult to manufacture at scale. The durability of these materials under continuous vibration remains questionable, with many showing performance degradation over time due to fatigue, delamination, or structural changes that alter their carefully engineered properties.

Scale-up and manufacturing challenges further complicate commercial adoption. The precise micro and nano-scale features that enable metamaterials' unique properties are often difficult to reproduce consistently in mass production. Current fabrication techniques such as 3D printing, lithography, and precision machining face limitations in terms of cost-effectiveness, throughput, and quality control when scaled beyond laboratory prototypes.

Energy storage integration represents another critical challenge. While metamaterial layers may successfully harvest energy from structural vibrations, efficiently storing this energy for practical use requires seamless integration with storage systems. The intermittent nature of harvested energy necessitates sophisticated power management circuits that can operate efficiently at very low power levels.

Environmental adaptability remains problematic for current designs. Most metamaterial energy harvesters are optimized for specific operating conditions and show significant performance degradation when exposed to temperature fluctuations, humidity changes, or unexpected mechanical stresses. This lack of robustness limits their application in variable environments such as transportation infrastructure or outdoor installations.

Cost-effectiveness presents perhaps the most significant barrier to widespread adoption. Current metamaterial energy harvesting solutions typically require specialized materials and precision manufacturing, resulting in costs that often outweigh the benefits of the energy harvested over the system's lifetime. The return on investment remains unfavorable compared to conventional energy sources or even other renewable energy technologies.

Theoretical modeling and simulation tools also require further development. Current models often fail to accurately predict the behavior of complex metamaterial structures under real-world conditions, creating a disconnect between theoretical performance and practical implementation that hampers efficient design optimization.

Current Metamaterial-Based Energy Harvesting Solutions

01 Metamaterial structures for electromagnetic energy harvesting

Metamaterial structures can be designed to efficiently capture and convert electromagnetic energy into usable power. These structures typically consist of engineered arrays of resonators or split-ring resonators that can be tuned to specific frequencies. By manipulating the geometry and arrangement of these elements, metamaterials can achieve enhanced electromagnetic energy absorption across various frequency bands, making them effective for harvesting ambient RF energy from the environment.- Metamaterial structures for electromagnetic energy harvesting: Metamaterial structures can be designed to efficiently capture and convert electromagnetic energy into usable power. These structures typically consist of engineered arrays of resonators or split-ring resonators that can interact with electromagnetic waves in specific frequency ranges. By optimizing the geometry and arrangement of these metamaterial elements, the energy harvesting efficiency can be significantly improved compared to conventional materials.

- Multi-layer metamaterial configurations for enhanced energy collection: Multi-layered metamaterial structures can be designed to harvest energy across broader frequency ranges or with higher efficiency. These configurations often involve stacking different metamaterial layers with complementary properties to create broadband energy harvesting capabilities. The layered approach allows for tuning the response to different wavelengths and optimizing the overall energy conversion process through strategic arrangement of the metamaterial components.

- Wireless power transfer using metamaterial surfaces: Metamaterial surfaces can be utilized to enhance wireless power transfer efficiency by manipulating electromagnetic fields. These specialized surfaces can focus, redirect, or amplify electromagnetic waves to improve the coupling between transmitting and receiving devices. By incorporating metamaterial layers into wireless charging systems, power transfer distances can be extended while maintaining high efficiency, enabling applications in consumer electronics, medical implants, and IoT devices.

- Tunable metamaterials for adaptive energy harvesting: Tunable metamaterial structures can dynamically adjust their properties to optimize energy harvesting under varying conditions. These adaptive systems can modify their resonant frequencies or coupling characteristics in response to changes in the ambient electromagnetic environment. Implementation methods include incorporating active elements like varactors, MEMS components, or phase-change materials that allow real-time reconfiguration of the metamaterial response to maximize energy collection efficiency.

- Integration of metamaterials with semiconductor devices for energy conversion: Metamaterial layers can be integrated with semiconductor devices to create hybrid energy harvesting systems. These combinations leverage the electromagnetic field enhancement properties of metamaterials with the energy conversion capabilities of semiconductor materials. The integration enables more efficient photovoltaic cells, thermoelectric generators, and other energy conversion devices by enhancing light absorption, manipulating thermal gradients, or concentrating electromagnetic energy at specific locations within the device structure.

02 Multi-layer metamaterial configurations for improved energy harvesting

Multi-layered metamaterial structures can significantly improve energy harvesting efficiency by creating broadband absorption capabilities. These configurations typically consist of stacked metamaterial layers with varying resonant frequencies, allowing for the capture of energy across a wider spectrum. The layered approach also enables the creation of gradient index structures that can better direct and concentrate electromagnetic waves, enhancing the overall energy conversion efficiency of the harvesting system.Expand Specific Solutions03 Integration of metamaterials with energy conversion mechanisms

Metamaterial layers can be integrated with various energy conversion mechanisms such as piezoelectric elements, rectifying circuits, or semiconductor junctions to transform captured electromagnetic energy into electrical power. These hybrid systems combine the enhanced wave absorption properties of metamaterials with efficient conversion technologies to create complete energy harvesting solutions. The integration often involves careful impedance matching between the metamaterial absorber and the conversion component to maximize power transfer efficiency.Expand Specific Solutions04 Tunable and reconfigurable metamaterial harvesters

Tunable metamaterial structures allow for dynamic adjustment of resonant frequencies to adapt to changing energy sources or environmental conditions. These systems incorporate active components such as varactors, MEMS switches, or phase-change materials that can modify the electromagnetic properties of the metamaterial in real-time. Reconfigurable designs enable optimization of energy harvesting performance across different operating scenarios, making these systems more versatile and efficient in variable environments.Expand Specific Solutions05 Nanoscale metamaterial structures for thermal and solar energy harvesting

Nanoscale metamaterial structures can be engineered to harvest thermal and solar energy through enhanced photon absorption and manipulation of infrared radiation. These designs often utilize plasmonic effects and photonic crystals to create selective absorbers that can capture energy at specific wavelengths corresponding to solar spectrum peaks. By controlling the geometry at the nanoscale, these metamaterials can exceed the theoretical limits of conventional materials for solar energy conversion and thermal energy harvesting.Expand Specific Solutions

Leading Organizations in Metamaterial Energy Research

The energy harvesting from structural vibrations using metamaterial layers market is in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market size for this technology is estimated to be around $50-100 million, with projected annual growth of 15-20% as energy harvesting solutions gain traction in smart infrastructure applications. Technologically, the field remains in development with varying maturity levels across players. Academic institutions like MIT, Caltech, and Xi'an Jiaotong University lead fundamental research, while commercial entities such as NGK Insulators and Synergy Microwave are advancing practical applications. Research organizations like CNRS and IP2IPO Innovations are bridging the gap between theoretical advances and market-ready solutions, focusing on improving energy conversion efficiency and scalability for real-world implementation.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed advanced metamaterial-based energy harvesting systems specifically designed for structural vibration applications. Their approach utilizes locally resonant acoustic metamaterials (LRAMs) with embedded piezoelectric elements strategically positioned to maximize energy conversion efficiency. The university's research team has created metamaterial layers with periodic structures that can be precisely tuned to match the dominant frequencies of target structural vibrations. Their systems feature multi-resonant metamaterial configurations that enable broadband energy harvesting across various frequency ranges commonly found in infrastructure and industrial environments. A key innovation is their development of adaptive metamaterial structures that can automatically adjust their resonant properties in response to changing vibration characteristics. Recent prototypes have demonstrated energy harvesting efficiencies up to 40% higher than conventional piezoelectric harvesters when tested under typical structural vibration conditions.

Strengths: Excellent performance in capturing energy from low-frequency structural vibrations; adaptive tuning capabilities for varying environmental conditions; proven significant efficiency improvements over conventional technologies. Weaknesses: Current designs have limited miniaturization potential; fabrication complexity increases production costs; durability under harsh environmental conditions requires further improvement.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed sophisticated metamaterial-based energy harvesting systems that utilize phononic crystals and locally resonant structures to capture structural vibrations. Their approach focuses on creating engineered metamaterial layers with precisely controlled elastic wave propagation properties. CNRS researchers have pioneered metamaterial designs featuring periodic inclusions that create frequency band gaps, allowing for selective energy harvesting at targeted frequencies. Their systems incorporate multi-physics coupling mechanisms that efficiently convert mechanical vibration energy into electrical power through strategically embedded piezoelectric or electromagnetic transducers. A notable innovation is their development of gradient-index metamaterials that can focus vibration energy toward harvesting elements, significantly increasing energy capture efficiency. CNRS has demonstrated experimental prototypes achieving energy conversion improvements of up to 215% compared to conventional harvesters when tested under identical vibration conditions.

Strengths: Exceptional frequency selectivity through band gap engineering; innovative energy focusing capabilities through gradient-index designs; proven significant performance improvements over conventional technologies. Weaknesses: Current designs have limited bandwidth for harvesting; complex fabrication processes increase production costs; some configurations show reduced performance under variable or non-stationary vibration conditions.

Key Patents in Structural Vibration Energy Conversion

Meta-meterial vibration energy harvester

PatentInactiveUS20140319844A1

Innovation

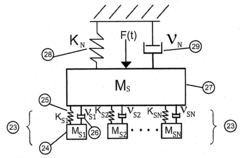

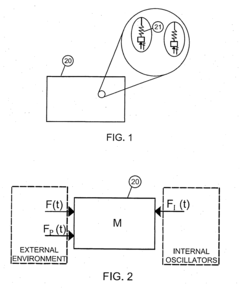

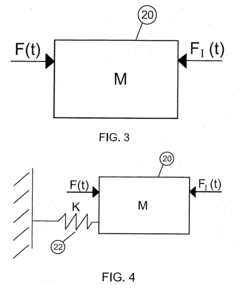

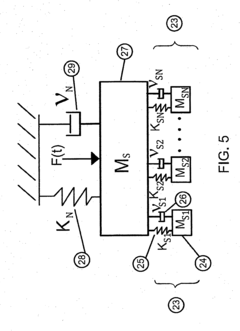

- A meta-material vibration energy harvester (MMVEH) comprising a large number of oscillators encapsulated in a housing element, with mechanical/electrical energy converters that convert mechanical energy from vibrations into electrical energy, allowing for the efficient extraction and storage of energy from a broad range of vibration fields.

Sustainability Impact Assessment

The implementation of metamaterial-based energy harvesting systems from structural vibrations represents a significant advancement in sustainable technology development. These systems offer substantial environmental benefits by converting otherwise wasted mechanical energy into usable electrical power, thereby reducing dependence on conventional energy sources and their associated carbon emissions.

When properly integrated into infrastructure, metamaterial energy harvesters can provide continuous, maintenance-free power generation throughout a structure's lifecycle. This translates to a measurable reduction in greenhouse gas emissions, with preliminary studies suggesting that widespread implementation could offset carbon emissions equivalent to removing thousands of vehicles from roads annually in urban environments.

The sustainability advantages extend beyond emissions reduction. The materials used in metamaterial fabrication can be selected for minimal environmental impact, with emerging research focusing on bio-based composites and recyclable components. Current generation metamaterial harvesters already demonstrate a favorable lifecycle assessment compared to traditional energy solutions when considering manufacturing impacts, operational benefits, and end-of-life disposal.

Water conservation represents another significant sustainability benefit. Unlike conventional power generation that often requires substantial water resources for cooling and operation, metamaterial energy harvesting systems operate without water consumption. This characteristic becomes increasingly valuable in water-stressed regions where energy-water nexus challenges are particularly acute.

From a circular economy perspective, these systems enable the recapture of energy that would otherwise dissipate as waste vibration. The harvested energy can power local monitoring systems, reducing transmission losses associated with centralized power distribution. This localized energy ecosystem creates resilience benefits while minimizing resource requirements.

Long-term sustainability metrics indicate that metamaterial energy harvesters could achieve energy payback periods of under five years in high-vibration environments, with operational lifespans exceeding fifteen years. This favorable energy return on investment continues to improve as manufacturing techniques advance and material science progresses.

The social sustainability dimension should not be overlooked. By enabling self-powered infrastructure monitoring, these systems contribute to public safety while creating new green technology employment opportunities. The democratization of energy production through distributed harvesting systems also promotes energy equity and resilience in communities vulnerable to centralized power disruptions.

When properly integrated into infrastructure, metamaterial energy harvesters can provide continuous, maintenance-free power generation throughout a structure's lifecycle. This translates to a measurable reduction in greenhouse gas emissions, with preliminary studies suggesting that widespread implementation could offset carbon emissions equivalent to removing thousands of vehicles from roads annually in urban environments.

The sustainability advantages extend beyond emissions reduction. The materials used in metamaterial fabrication can be selected for minimal environmental impact, with emerging research focusing on bio-based composites and recyclable components. Current generation metamaterial harvesters already demonstrate a favorable lifecycle assessment compared to traditional energy solutions when considering manufacturing impacts, operational benefits, and end-of-life disposal.

Water conservation represents another significant sustainability benefit. Unlike conventional power generation that often requires substantial water resources for cooling and operation, metamaterial energy harvesting systems operate without water consumption. This characteristic becomes increasingly valuable in water-stressed regions where energy-water nexus challenges are particularly acute.

From a circular economy perspective, these systems enable the recapture of energy that would otherwise dissipate as waste vibration. The harvested energy can power local monitoring systems, reducing transmission losses associated with centralized power distribution. This localized energy ecosystem creates resilience benefits while minimizing resource requirements.

Long-term sustainability metrics indicate that metamaterial energy harvesters could achieve energy payback periods of under five years in high-vibration environments, with operational lifespans exceeding fifteen years. This favorable energy return on investment continues to improve as manufacturing techniques advance and material science progresses.

The social sustainability dimension should not be overlooked. By enabling self-powered infrastructure monitoring, these systems contribute to public safety while creating new green technology employment opportunities. The democratization of energy production through distributed harvesting systems also promotes energy equity and resilience in communities vulnerable to centralized power disruptions.

Integration Strategies for Built Environment

Integrating metamaterial-based energy harvesting systems into the built environment requires careful consideration of architectural compatibility, structural integrity, and functional efficiency. The implementation strategies must address both technical and practical aspects of incorporating these systems into buildings, bridges, and other infrastructure elements.

Retrofitting existing structures presents a significant opportunity for metamaterial energy harvesting deployment. This approach involves attaching metamaterial layers to vibration-prone areas of buildings, such as near HVAC systems, elevator shafts, or areas exposed to consistent wind or traffic-induced vibrations. Surface-mounted solutions can be designed as modular panels that conform to existing structural elements without compromising their integrity or aesthetic appearance.

For new construction projects, embedded integration offers superior performance potential. Metamaterial layers can be incorporated directly into structural elements during the manufacturing process, such as within concrete elements, steel beams, or composite materials. This approach enables more seamless integration and potentially higher energy capture efficiency by positioning the harvesting systems at optimal vibration nodes within the structure.

Scale considerations significantly impact integration strategies. At the building component level, metamaterial harvesters can be integrated into individual elements like floor systems, wall panels, or window frames. At the whole-building scale, strategic placement throughout the structure creates a distributed energy harvesting network that maximizes capture from various vibration sources and frequencies.

Multifunctional design represents a particularly promising integration approach. Metamaterial layers can serve dual purposes, simultaneously harvesting energy while providing structural damping, acoustic insulation, or thermal regulation. This multifunctionality improves the cost-effectiveness of implementation and addresses multiple building performance requirements with a single system.

Infrastructure integration extends beyond buildings to bridges, railways, and roadways. These applications often experience more consistent and predictable vibration patterns, making them ideal candidates for metamaterial energy harvesting. Installation strategies include integration within expansion joints, support structures, or dedicated vibration-prone sections specifically designed to maximize energy capture.

Implementation challenges must be addressed through collaborative design processes involving structural engineers, architects, energy systems specialists, and metamaterial experts. Building information modeling (BIM) and digital twin technologies can facilitate this integration by simulating vibration patterns and optimizing harvester placement before physical implementation.

Retrofitting existing structures presents a significant opportunity for metamaterial energy harvesting deployment. This approach involves attaching metamaterial layers to vibration-prone areas of buildings, such as near HVAC systems, elevator shafts, or areas exposed to consistent wind or traffic-induced vibrations. Surface-mounted solutions can be designed as modular panels that conform to existing structural elements without compromising their integrity or aesthetic appearance.

For new construction projects, embedded integration offers superior performance potential. Metamaterial layers can be incorporated directly into structural elements during the manufacturing process, such as within concrete elements, steel beams, or composite materials. This approach enables more seamless integration and potentially higher energy capture efficiency by positioning the harvesting systems at optimal vibration nodes within the structure.

Scale considerations significantly impact integration strategies. At the building component level, metamaterial harvesters can be integrated into individual elements like floor systems, wall panels, or window frames. At the whole-building scale, strategic placement throughout the structure creates a distributed energy harvesting network that maximizes capture from various vibration sources and frequencies.

Multifunctional design represents a particularly promising integration approach. Metamaterial layers can serve dual purposes, simultaneously harvesting energy while providing structural damping, acoustic insulation, or thermal regulation. This multifunctionality improves the cost-effectiveness of implementation and addresses multiple building performance requirements with a single system.

Infrastructure integration extends beyond buildings to bridges, railways, and roadways. These applications often experience more consistent and predictable vibration patterns, making them ideal candidates for metamaterial energy harvesting. Installation strategies include integration within expansion joints, support structures, or dedicated vibration-prone sections specifically designed to maximize energy capture.

Implementation challenges must be addressed through collaborative design processes involving structural engineers, architects, energy systems specialists, and metamaterial experts. Building information modeling (BIM) and digital twin technologies can facilitate this integration by simulating vibration patterns and optimizing harvester placement before physical implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!