Ethylene Vinyl Acetate and the Future of Smart Materials

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Smart Materials Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a pivotal material in the development of smart materials, marking a significant milestone in materials science. The evolution of EVA from a simple copolymer to a key component in advanced applications reflects the broader trend of traditional materials being repurposed for cutting-edge technologies. This transformation aligns with the growing demand for materials that can adapt to environmental stimuli and perform multiple functions simultaneously.

The primary objective in the field of EVA smart materials is to harness the unique properties of EVA, such as its flexibility, durability, and ease of modification, to create responsive and intelligent systems. Researchers aim to develop EVA-based materials that can change their physical or chemical properties in response to external stimuli like temperature, light, or electrical fields. This adaptability opens up a wide range of potential applications across various industries, from healthcare to aerospace.

One of the key goals in EVA smart materials research is to enhance the material's ability to incorporate functional additives without compromising its core characteristics. This includes developing methods to uniformly disperse nanoparticles, conductive fillers, or phase-change materials within the EVA matrix. Such advancements could lead to the creation of self-healing materials, shape-memory polymers, or even materials with programmable properties.

Another critical objective is to improve the sustainability and eco-friendliness of EVA-based smart materials. As environmental concerns become increasingly prominent, there is a push to develop biodegradable or recyclable versions of EVA that maintain the smart functionalities. This aligns with the global trend towards more sustainable material solutions and circular economy principles.

The integration of EVA into the Internet of Things (IoT) ecosystem represents another significant research direction. Scientists are exploring ways to incorporate sensors and actuators into EVA materials, enabling them to collect and transmit data or respond to remote commands. This could revolutionize fields such as wearable technology, smart packaging, and structural health monitoring.

As we look towards the future, the development of EVA smart materials is expected to play a crucial role in addressing complex challenges across various sectors. From energy-efficient buildings that adapt to environmental conditions to advanced medical devices that respond to physiological changes, the potential applications are vast and diverse. The ongoing research in this field aims to push the boundaries of material science, creating innovative solutions that were once thought impossible.

The primary objective in the field of EVA smart materials is to harness the unique properties of EVA, such as its flexibility, durability, and ease of modification, to create responsive and intelligent systems. Researchers aim to develop EVA-based materials that can change their physical or chemical properties in response to external stimuli like temperature, light, or electrical fields. This adaptability opens up a wide range of potential applications across various industries, from healthcare to aerospace.

One of the key goals in EVA smart materials research is to enhance the material's ability to incorporate functional additives without compromising its core characteristics. This includes developing methods to uniformly disperse nanoparticles, conductive fillers, or phase-change materials within the EVA matrix. Such advancements could lead to the creation of self-healing materials, shape-memory polymers, or even materials with programmable properties.

Another critical objective is to improve the sustainability and eco-friendliness of EVA-based smart materials. As environmental concerns become increasingly prominent, there is a push to develop biodegradable or recyclable versions of EVA that maintain the smart functionalities. This aligns with the global trend towards more sustainable material solutions and circular economy principles.

The integration of EVA into the Internet of Things (IoT) ecosystem represents another significant research direction. Scientists are exploring ways to incorporate sensors and actuators into EVA materials, enabling them to collect and transmit data or respond to remote commands. This could revolutionize fields such as wearable technology, smart packaging, and structural health monitoring.

As we look towards the future, the development of EVA smart materials is expected to play a crucial role in addressing complex challenges across various sectors. From energy-efficient buildings that adapt to environmental conditions to advanced medical devices that respond to physiological changes, the potential applications are vast and diverse. The ongoing research in this field aims to push the boundaries of material science, creating innovative solutions that were once thought impossible.

Market Analysis for Smart EVA Applications

The market for smart Ethylene Vinyl Acetate (EVA) applications is experiencing significant growth, driven by the increasing demand for advanced materials in various industries. Smart EVA, which combines the versatile properties of EVA with smart functionalities, is poised to revolutionize several sectors, including consumer electronics, healthcare, automotive, and construction.

In the consumer electronics industry, smart EVA materials are finding applications in flexible displays, wearable devices, and smart packaging. The market for these applications is expected to grow rapidly, as consumers increasingly seek innovative and interactive products. The integration of smart EVA in flexible displays alone is projected to create a substantial market opportunity, with the potential to disrupt the traditional rigid display market.

The healthcare sector presents another promising avenue for smart EVA applications. Smart EVA-based medical devices, such as drug delivery systems and biosensors, are gaining traction due to their biocompatibility and adaptability. The aging population and the rising prevalence of chronic diseases are driving the demand for advanced medical technologies, creating a favorable environment for smart EVA adoption in this sector.

In the automotive industry, smart EVA materials are being explored for use in smart windows, adaptive lighting systems, and energy-efficient components. As the automotive sector shifts towards electric and autonomous vehicles, the demand for lightweight, multifunctional materials like smart EVA is expected to surge. This trend aligns with the industry's focus on improving energy efficiency and enhancing user experience.

The construction sector is also showing interest in smart EVA applications, particularly in the development of smart building materials. These materials can adapt to environmental conditions, improve energy efficiency, and enhance occupant comfort. The growing emphasis on sustainable and energy-efficient buildings is likely to drive the adoption of smart EVA in construction applications.

Market analysts predict that the global smart materials market, including smart EVA applications, will experience double-digit growth rates in the coming years. This growth is attributed to advancements in material science, increasing R&D investments, and the expanding range of applications across various industries.

However, the market for smart EVA applications also faces challenges. The relatively high cost of production and the need for specialized manufacturing processes may initially limit widespread adoption. Additionally, concerns regarding the long-term durability and recyclability of smart EVA materials need to be addressed to ensure sustainable market growth.

Despite these challenges, the overall market outlook for smart EVA applications remains highly positive. As research and development efforts continue to improve the performance and cost-effectiveness of these materials, their market penetration is expected to accelerate. The convergence of material science, electronics, and artificial intelligence is likely to unlock new possibilities for smart EVA applications, further expanding the market potential in the coming years.

In the consumer electronics industry, smart EVA materials are finding applications in flexible displays, wearable devices, and smart packaging. The market for these applications is expected to grow rapidly, as consumers increasingly seek innovative and interactive products. The integration of smart EVA in flexible displays alone is projected to create a substantial market opportunity, with the potential to disrupt the traditional rigid display market.

The healthcare sector presents another promising avenue for smart EVA applications. Smart EVA-based medical devices, such as drug delivery systems and biosensors, are gaining traction due to their biocompatibility and adaptability. The aging population and the rising prevalence of chronic diseases are driving the demand for advanced medical technologies, creating a favorable environment for smart EVA adoption in this sector.

In the automotive industry, smart EVA materials are being explored for use in smart windows, adaptive lighting systems, and energy-efficient components. As the automotive sector shifts towards electric and autonomous vehicles, the demand for lightweight, multifunctional materials like smart EVA is expected to surge. This trend aligns with the industry's focus on improving energy efficiency and enhancing user experience.

The construction sector is also showing interest in smart EVA applications, particularly in the development of smart building materials. These materials can adapt to environmental conditions, improve energy efficiency, and enhance occupant comfort. The growing emphasis on sustainable and energy-efficient buildings is likely to drive the adoption of smart EVA in construction applications.

Market analysts predict that the global smart materials market, including smart EVA applications, will experience double-digit growth rates in the coming years. This growth is attributed to advancements in material science, increasing R&D investments, and the expanding range of applications across various industries.

However, the market for smart EVA applications also faces challenges. The relatively high cost of production and the need for specialized manufacturing processes may initially limit widespread adoption. Additionally, concerns regarding the long-term durability and recyclability of smart EVA materials need to be addressed to ensure sustainable market growth.

Despite these challenges, the overall market outlook for smart EVA applications remains highly positive. As research and development efforts continue to improve the performance and cost-effectiveness of these materials, their market penetration is expected to accelerate. The convergence of material science, electronics, and artificial intelligence is likely to unlock new possibilities for smart EVA applications, further expanding the market potential in the coming years.

EVA Smart Materials: Current State and Challenges

Ethylene Vinyl Acetate (EVA) has emerged as a promising material in the development of smart materials, offering unique properties that bridge the gap between traditional polymers and advanced functional materials. However, the current state of EVA-based smart materials faces several challenges that need to be addressed to fully realize their potential.

One of the primary challenges is the optimization of EVA's mechanical properties for specific smart material applications. While EVA offers excellent flexibility and impact resistance, its strength and durability may need enhancement for certain high-performance applications. Researchers are exploring various methods to improve these properties, such as incorporating nanofillers or developing new copolymer blends.

Another significant challenge lies in the integration of smart functionalities into EVA materials. This includes the development of effective methods for incorporating sensors, actuators, or other responsive elements without compromising the material's inherent properties. Current efforts focus on techniques like in-situ polymerization, surface modification, and the creation of multi-layered structures to achieve this integration.

The scalability of production processes for EVA-based smart materials presents another hurdle. While laboratory-scale production has shown promising results, translating these processes to industrial-scale manufacturing while maintaining consistent quality and performance remains a challenge. This includes issues related to uniform dispersion of functional additives, control of crosslinking density, and optimization of processing parameters.

Environmental concerns and sustainability also pose challenges for EVA smart materials. As the demand for eco-friendly solutions grows, there is a need to develop biodegradable or recyclable EVA-based smart materials without sacrificing their functional properties. Research is ongoing to explore bio-based alternatives and improve the end-of-life management of these materials.

The long-term stability and reliability of EVA smart materials in various environmental conditions is another area of concern. Factors such as UV exposure, temperature fluctuations, and chemical interactions can affect the performance and lifespan of these materials. Developing robust formulations and protective strategies to enhance the durability of EVA smart materials is crucial for their widespread adoption.

Lastly, the cost-effectiveness of EVA smart materials compared to traditional alternatives remains a challenge. While the potential benefits are significant, the additional processing steps and specialized additives required for smart functionalities can increase production costs. Efforts are underway to optimize material formulations and manufacturing processes to make EVA smart materials more economically viable for a broader range of applications.

One of the primary challenges is the optimization of EVA's mechanical properties for specific smart material applications. While EVA offers excellent flexibility and impact resistance, its strength and durability may need enhancement for certain high-performance applications. Researchers are exploring various methods to improve these properties, such as incorporating nanofillers or developing new copolymer blends.

Another significant challenge lies in the integration of smart functionalities into EVA materials. This includes the development of effective methods for incorporating sensors, actuators, or other responsive elements without compromising the material's inherent properties. Current efforts focus on techniques like in-situ polymerization, surface modification, and the creation of multi-layered structures to achieve this integration.

The scalability of production processes for EVA-based smart materials presents another hurdle. While laboratory-scale production has shown promising results, translating these processes to industrial-scale manufacturing while maintaining consistent quality and performance remains a challenge. This includes issues related to uniform dispersion of functional additives, control of crosslinking density, and optimization of processing parameters.

Environmental concerns and sustainability also pose challenges for EVA smart materials. As the demand for eco-friendly solutions grows, there is a need to develop biodegradable or recyclable EVA-based smart materials without sacrificing their functional properties. Research is ongoing to explore bio-based alternatives and improve the end-of-life management of these materials.

The long-term stability and reliability of EVA smart materials in various environmental conditions is another area of concern. Factors such as UV exposure, temperature fluctuations, and chemical interactions can affect the performance and lifespan of these materials. Developing robust formulations and protective strategies to enhance the durability of EVA smart materials is crucial for their widespread adoption.

Lastly, the cost-effectiveness of EVA smart materials compared to traditional alternatives remains a challenge. While the potential benefits are significant, the additional processing steps and specialized additives required for smart functionalities can increase production costs. Efforts are underway to optimize material formulations and manufacturing processes to make EVA smart materials more economically viable for a broader range of applications.

Current EVA Smart Material Solutions

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be varied to achieve different characteristics, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be varied to achieve different characteristics, making it suitable for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is commonly employed in hot melt adhesives, pressure-sensitive adhesives, and sealants. The adhesive strength and flexibility of EVA-based adhesives can be tailored by adjusting the vinyl acetate content and incorporating additives.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It is commonly used in footwear, sports equipment, and building insulation. The foam can be crosslinked to improve its heat resistance and dimensional stability.

- EVA in solar panel encapsulation: EVA is a preferred material for solar panel encapsulation due to its transparency, weather resistance, and ability to protect solar cells from environmental factors. It helps to improve the durability and efficiency of photovoltaic modules. The EVA encapsulant is typically crosslinked to enhance its performance in outdoor conditions.

- Modifications and blends of EVA: EVA can be modified or blended with other polymers and additives to enhance its properties for specific applications. This includes the incorporation of flame retardants, UV stabilizers, and compatibilizers. EVA blends are used to improve impact resistance, flexibility, and processability in various products such as wire and cable insulation, packaging films, and automotive parts.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, pressure-sensitive adhesives, and sealants. The vinyl acetate content can be adjusted to optimize adhesion strength and flexibility for specific applications.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and ability to be crosslinked. It is commonly used in the manufacture of shoe soles, sports equipment padding, and building insulation materials.Expand Specific Solutions04 EVA in encapsulation of solar cells

EVA is a popular material for encapsulating solar cells in photovoltaic modules. Its transparency, weather resistance, and ability to protect the cells from moisture and mechanical stress make it an ideal choice for this application. The material can be formulated with additives to enhance UV stability and prevent yellowing.Expand Specific Solutions05 Modifications and blends of EVA

EVA can be modified or blended with other polymers to enhance its properties for specific applications. This includes crosslinking to improve heat resistance, blending with other polymers to modify mechanical properties, and incorporating additives to enhance UV stability or flame retardancy.Expand Specific Solutions

Key Players in EVA Smart Materials Industry

The Ethylene Vinyl Acetate (EVA) market and smart materials sector are experiencing significant growth, driven by increasing demand across various industries. The market is in a mature stage but continues to evolve with technological advancements. Key players like DuPont de Nemours, Celanese International, and Hanwha Chemical are leading the innovation in EVA and smart materials. These companies are investing heavily in R&D to develop advanced formulations and applications. The technology is relatively mature, but there's ongoing research to enhance properties and explore new uses. Universities such as Tianjin University and The Hong Kong University of Science & Technology are contributing to academic research, while institutions like the Council of Scientific & Industrial Research are bridging the gap between academia and industry. The market is expected to grow further as smart materials find applications in sectors like electronics, construction, and automotive.

Nitto Denko Corp.

Technical Solution: Nitto Denko has made significant strides in developing EVA-based smart materials, particularly in the field of photovoltaics and energy storage. Their research focuses on creating EVA encapsulants with enhanced UV resistance and thermal stability for solar panel applications[4]. They have developed a proprietary crosslinking technology that improves the long-term durability of EVA films in harsh environmental conditions. Nitto Denko is also exploring the use of EVA in advanced battery separators, incorporating functional additives to enhance ionic conductivity and safety[5]. Their smart EVA materials feature self-regulating properties that respond to temperature changes, making them suitable for thermal management in electronic devices.

Strengths: Strong presence in the Asian market, expertise in film and adhesive technologies. Weaknesses: May face challenges in adapting to rapidly evolving smart material requirements in diverse industries.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced EVA copolymers with enhanced properties for smart material applications. Their Elvax® series incorporates nanoparticles to create EVA nanocomposites with improved mechanical and thermal properties[1]. These materials exhibit self-healing capabilities and shape memory effects, making them suitable for various smart applications. DuPont's research focuses on optimizing the EVA copolymer composition and processing techniques to achieve specific smart functionalities, such as temperature-responsive behavior and controlled drug release in biomedical applications[2]. They have also explored the integration of conductive fillers into EVA matrices to develop flexible and stretchable electronics for wearable technology[3].

Strengths: Extensive experience in polymer science, strong R&D capabilities, and a wide range of existing EVA products. Weaknesses: Potential high costs associated with developing and scaling up new smart EVA materials.

Key Innovations in EVA Smart Materials

Encapsulants for electronic components

PatentWO2007109283A2

Innovation

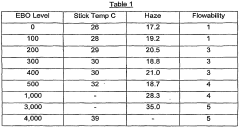

- A composition comprising crosslinked ethylene copolymer blended with fatty acid amides, specifically olefinic bisoleamides, is used to enhance the encapsulant's properties, including transparency, thermal stability, and mechanical strength, with specific concentrations of fatty acid amides that improve handling and reduce haze values.

Method for preparing ethylene-vinyl acetate with low melt index

PatentWO2014181991A1

Innovation

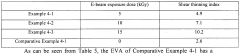

- Applying an electron beam with a defined exposure dose to an ethylene-vinyl acetate resin composition with a vinyl acetate content of 15 to 50 wt% to reduce the melt index to 10 g/10 min or less, thereby enhancing mechanical properties and processability without the need for additional modifiers like peroxides.

Environmental Impact of EVA Smart Materials

The environmental impact of EVA smart materials is a crucial consideration as these materials gain prominence in various applications. EVA, being a polymer-based material, raises concerns about its lifecycle and potential ecological footprint. The production process of EVA involves the use of petrochemicals, which can contribute to greenhouse gas emissions and resource depletion. However, the longevity and durability of EVA smart materials may offset some of these initial environmental costs by reducing the need for frequent replacements.

One of the primary environmental advantages of EVA smart materials is their potential for energy efficiency. When used in building materials or smart textiles, EVA can contribute to better insulation and temperature regulation, potentially reducing energy consumption for heating and cooling. This energy-saving aspect could lead to a significant reduction in carbon emissions over the lifetime of buildings or products incorporating EVA smart materials.

Recyclability is a key factor in assessing the environmental impact of EVA smart materials. While EVA is theoretically recyclable, the complex nature of smart materials, often incorporating sensors or other electronic components, can make the recycling process challenging. Developing effective recycling methods for these composite materials is crucial to minimize their environmental impact and promote a circular economy approach.

The potential for biodegradability in EVA smart materials is an area of ongoing research. Traditional EVA is not biodegradable, which raises concerns about its long-term environmental impact. However, researchers are exploring ways to incorporate biodegradable additives or develop bio-based alternatives that could maintain the smart properties of EVA while reducing its environmental persistence.

Water pollution is another environmental consideration for EVA smart materials. The production and disposal of these materials may release microplastics or other pollutants into water systems. Mitigating these risks requires careful management of manufacturing processes and end-of-life disposal methods.

As the adoption of EVA smart materials increases, their impact on ecosystems and wildlife becomes a growing concern. The potential for these materials to interact with natural environments, particularly in marine settings, necessitates thorough environmental risk assessments and the development of safeguards to protect biodiversity.

In conclusion, while EVA smart materials offer significant potential benefits in various applications, their environmental impact remains a complex issue. Balancing the advantages of these materials with their potential ecological drawbacks requires ongoing research, innovation in production and recycling technologies, and the development of sustainable practices throughout their lifecycle. As the field of smart materials evolves, addressing these environmental concerns will be crucial for ensuring their long-term viability and acceptance in a world increasingly focused on sustainability.

One of the primary environmental advantages of EVA smart materials is their potential for energy efficiency. When used in building materials or smart textiles, EVA can contribute to better insulation and temperature regulation, potentially reducing energy consumption for heating and cooling. This energy-saving aspect could lead to a significant reduction in carbon emissions over the lifetime of buildings or products incorporating EVA smart materials.

Recyclability is a key factor in assessing the environmental impact of EVA smart materials. While EVA is theoretically recyclable, the complex nature of smart materials, often incorporating sensors or other electronic components, can make the recycling process challenging. Developing effective recycling methods for these composite materials is crucial to minimize their environmental impact and promote a circular economy approach.

The potential for biodegradability in EVA smart materials is an area of ongoing research. Traditional EVA is not biodegradable, which raises concerns about its long-term environmental impact. However, researchers are exploring ways to incorporate biodegradable additives or develop bio-based alternatives that could maintain the smart properties of EVA while reducing its environmental persistence.

Water pollution is another environmental consideration for EVA smart materials. The production and disposal of these materials may release microplastics or other pollutants into water systems. Mitigating these risks requires careful management of manufacturing processes and end-of-life disposal methods.

As the adoption of EVA smart materials increases, their impact on ecosystems and wildlife becomes a growing concern. The potential for these materials to interact with natural environments, particularly in marine settings, necessitates thorough environmental risk assessments and the development of safeguards to protect biodiversity.

In conclusion, while EVA smart materials offer significant potential benefits in various applications, their environmental impact remains a complex issue. Balancing the advantages of these materials with their potential ecological drawbacks requires ongoing research, innovation in production and recycling technologies, and the development of sustainable practices throughout their lifecycle. As the field of smart materials evolves, addressing these environmental concerns will be crucial for ensuring their long-term viability and acceptance in a world increasingly focused on sustainability.

Intellectual Property Landscape for EVA Smart Materials

The intellectual property landscape for Ethylene Vinyl Acetate (EVA) smart materials is rapidly evolving, reflecting the growing interest and investment in this innovative field. A comprehensive analysis of patent filings and research publications reveals a significant increase in intellectual property (IP) activity over the past decade, with major players from both academia and industry contributing to the advancement of EVA-based smart materials.

Patent databases show a surge in applications related to EVA smart materials, particularly in areas such as self-healing properties, shape memory effects, and responsive behaviors to external stimuli. These patents cover a wide range of applications, from advanced packaging solutions to biomedical devices and smart textiles. The geographical distribution of patent filings indicates a global interest, with notable concentrations in the United States, Japan, South Korea, and China.

Key patent holders in this domain include multinational corporations with established presence in materials science, such as DuPont, BASF, and 3M. These companies have been actively developing and protecting technologies that enhance the smart capabilities of EVA materials. Additionally, several specialized start-ups and research institutions have emerged as significant contributors to the IP landscape, often focusing on niche applications or novel functionalization techniques.

The research publication landscape complements the patent analysis, showcasing a rich ecosystem of academic and industrial collaboration. Peer-reviewed journals in materials science, polymer chemistry, and applied physics have seen a marked increase in papers discussing EVA smart materials. These publications often precede patent filings and provide insights into emerging trends and potential future directions for IP development.

One notable trend in the IP landscape is the increasing focus on sustainability and eco-friendly solutions. Patents and research papers addressing biodegradable EVA smart materials or incorporating recycled EVA into smart material systems are gaining traction. This aligns with broader industry trends towards environmentally responsible innovation.

The IP landscape also reveals a growing emphasis on multifunctional EVA smart materials. Patents describing materials that combine multiple smart properties, such as self-healing capabilities with temperature-responsive behavior, are becoming more prevalent. This trend towards integrated functionality is likely to drive future innovation and IP generation in the field.

As the field of EVA smart materials continues to mature, the IP landscape is expected to become more complex. Cross-licensing agreements and patent pools may emerge as companies seek to navigate the increasingly crowded IP space. Furthermore, the convergence of EVA smart materials with other emerging technologies, such as Internet of Things (IoT) and artificial intelligence, is likely to create new opportunities for IP development and protection in the coming years.

Patent databases show a surge in applications related to EVA smart materials, particularly in areas such as self-healing properties, shape memory effects, and responsive behaviors to external stimuli. These patents cover a wide range of applications, from advanced packaging solutions to biomedical devices and smart textiles. The geographical distribution of patent filings indicates a global interest, with notable concentrations in the United States, Japan, South Korea, and China.

Key patent holders in this domain include multinational corporations with established presence in materials science, such as DuPont, BASF, and 3M. These companies have been actively developing and protecting technologies that enhance the smart capabilities of EVA materials. Additionally, several specialized start-ups and research institutions have emerged as significant contributors to the IP landscape, often focusing on niche applications or novel functionalization techniques.

The research publication landscape complements the patent analysis, showcasing a rich ecosystem of academic and industrial collaboration. Peer-reviewed journals in materials science, polymer chemistry, and applied physics have seen a marked increase in papers discussing EVA smart materials. These publications often precede patent filings and provide insights into emerging trends and potential future directions for IP development.

One notable trend in the IP landscape is the increasing focus on sustainability and eco-friendly solutions. Patents and research papers addressing biodegradable EVA smart materials or incorporating recycled EVA into smart material systems are gaining traction. This aligns with broader industry trends towards environmentally responsible innovation.

The IP landscape also reveals a growing emphasis on multifunctional EVA smart materials. Patents describing materials that combine multiple smart properties, such as self-healing capabilities with temperature-responsive behavior, are becoming more prevalent. This trend towards integrated functionality is likely to drive future innovation and IP generation in the field.

As the field of EVA smart materials continues to mature, the IP landscape is expected to become more complex. Cross-licensing agreements and patent pools may emerge as companies seek to navigate the increasingly crowded IP space. Furthermore, the convergence of EVA smart materials with other emerging technologies, such as Internet of Things (IoT) and artificial intelligence, is likely to create new opportunities for IP development and protection in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!