Ethylene Vinyl Acetate: Enhancing Comfort in Wearable Technology

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA in Wearables: Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a pivotal material in the rapidly evolving field of wearable technology. This versatile copolymer, known for its flexibility, durability, and cushioning properties, has found increasing applications in enhancing the comfort and functionality of wearable devices. The integration of EVA in wearables represents a convergence of materials science and consumer electronics, addressing the growing demand for comfortable, long-wearing smart devices.

The evolution of wearable technology has been marked by a continuous pursuit of balancing functionality with user comfort. Early wearables often prioritized technological capabilities at the expense of wearability, leading to devices that, while innovative, were often cumbersome or uncomfortable for extended use. The introduction of EVA into this domain marks a significant shift towards user-centric design, where the physical interaction between the device and the user is given equal importance to the device's technical specifications.

EVA's unique properties make it particularly suitable for wearable applications. Its low-temperature toughness, stress-crack resistance, and excellent barrier properties to water vapor contribute to creating durable and weather-resistant wearable devices. Moreover, its ability to be formulated with varying levels of flexibility and softness allows for customization to specific wearable applications, from fitness trackers to medical monitoring devices.

The primary objective of incorporating EVA in wearable technology is to enhance user comfort without compromising device functionality. This involves developing EVA formulations that can be seamlessly integrated into various wearable form factors, such as straps, casings, and interfaces. The goal is to create wearables that users can comfortably wear for extended periods, potentially 24/7, without experiencing discomfort or skin irritation.

Another critical objective is to leverage EVA's properties to improve the overall performance and durability of wearable devices. This includes enhancing shock absorption to protect sensitive electronics, improving water resistance to expand usage scenarios, and developing lightweight structures to reduce user fatigue. The challenge lies in balancing these performance enhancements with maintaining or improving the aesthetic appeal of wearable devices.

As the wearable technology market continues to expand, the role of EVA is expected to grow correspondingly. The future trajectory of EVA in wearables is likely to focus on developing even more specialized formulations tailored to specific wearable applications. This may include biocompatible EVA variants for medical wearables, ultra-durable formulations for sports and fitness devices, and eco-friendly, recyclable EVA compositions to address growing environmental concerns.

The evolution of wearable technology has been marked by a continuous pursuit of balancing functionality with user comfort. Early wearables often prioritized technological capabilities at the expense of wearability, leading to devices that, while innovative, were often cumbersome or uncomfortable for extended use. The introduction of EVA into this domain marks a significant shift towards user-centric design, where the physical interaction between the device and the user is given equal importance to the device's technical specifications.

EVA's unique properties make it particularly suitable for wearable applications. Its low-temperature toughness, stress-crack resistance, and excellent barrier properties to water vapor contribute to creating durable and weather-resistant wearable devices. Moreover, its ability to be formulated with varying levels of flexibility and softness allows for customization to specific wearable applications, from fitness trackers to medical monitoring devices.

The primary objective of incorporating EVA in wearable technology is to enhance user comfort without compromising device functionality. This involves developing EVA formulations that can be seamlessly integrated into various wearable form factors, such as straps, casings, and interfaces. The goal is to create wearables that users can comfortably wear for extended periods, potentially 24/7, without experiencing discomfort or skin irritation.

Another critical objective is to leverage EVA's properties to improve the overall performance and durability of wearable devices. This includes enhancing shock absorption to protect sensitive electronics, improving water resistance to expand usage scenarios, and developing lightweight structures to reduce user fatigue. The challenge lies in balancing these performance enhancements with maintaining or improving the aesthetic appeal of wearable devices.

As the wearable technology market continues to expand, the role of EVA is expected to grow correspondingly. The future trajectory of EVA in wearables is likely to focus on developing even more specialized formulations tailored to specific wearable applications. This may include biocompatible EVA variants for medical wearables, ultra-durable formulations for sports and fitness devices, and eco-friendly, recyclable EVA compositions to address growing environmental concerns.

Market Analysis for EVA-Enhanced Wearables

The market for EVA-enhanced wearables is experiencing significant growth, driven by increasing consumer demand for comfortable and functional wearable technology. The global wearable technology market, which includes EVA-enhanced products, is projected to reach substantial market value in the coming years, with a compound annual growth rate (CAGR) outpacing many other consumer electronics segments.

EVA's unique properties, such as flexibility, durability, and shock absorption, make it an ideal material for enhancing comfort in wearable devices. This has led to its widespread adoption in various wearable categories, including fitness trackers, smartwatches, and medical monitoring devices. The fitness and wellness sector, in particular, has seen a surge in EVA-enhanced wearables, as consumers prioritize comfort during physical activities.

The healthcare industry is another key driver of market growth for EVA-enhanced wearables. With the rise of remote patient monitoring and telemedicine, there is an increasing demand for comfortable, long-wear medical devices that can be used for continuous health tracking. EVA's biocompatibility and cushioning properties make it well-suited for these applications, contributing to the expansion of the medical wearables market.

Consumer electronics giants and sportswear manufacturers are the primary players in the EVA-enhanced wearables market. These companies are investing heavily in research and development to create innovative products that leverage EVA's properties. Additionally, there is a growing trend of collaborations between technology firms and fashion brands to develop stylish and comfortable wearable devices, further expanding the market potential.

The Asia-Pacific region is emerging as a significant market for EVA-enhanced wearables, driven by a large consumer base, increasing disposable incomes, and a growing health-conscious population. North America and Europe continue to be strong markets, with high adoption rates of wearable technology and a focus on product innovation.

Despite the positive outlook, the market faces challenges such as concerns over data privacy and security in wearable devices. However, ongoing advancements in encryption technologies and stricter regulations are expected to address these issues, potentially boosting consumer confidence and market growth.

As wearable technology becomes more integrated into daily life, the demand for EVA-enhanced products is expected to continue its upward trajectory. The market is likely to see further diversification, with EVA being incorporated into new types of wearables, including smart clothing and augmented reality devices, opening up new opportunities for market expansion and technological innovation.

EVA's unique properties, such as flexibility, durability, and shock absorption, make it an ideal material for enhancing comfort in wearable devices. This has led to its widespread adoption in various wearable categories, including fitness trackers, smartwatches, and medical monitoring devices. The fitness and wellness sector, in particular, has seen a surge in EVA-enhanced wearables, as consumers prioritize comfort during physical activities.

The healthcare industry is another key driver of market growth for EVA-enhanced wearables. With the rise of remote patient monitoring and telemedicine, there is an increasing demand for comfortable, long-wear medical devices that can be used for continuous health tracking. EVA's biocompatibility and cushioning properties make it well-suited for these applications, contributing to the expansion of the medical wearables market.

Consumer electronics giants and sportswear manufacturers are the primary players in the EVA-enhanced wearables market. These companies are investing heavily in research and development to create innovative products that leverage EVA's properties. Additionally, there is a growing trend of collaborations between technology firms and fashion brands to develop stylish and comfortable wearable devices, further expanding the market potential.

The Asia-Pacific region is emerging as a significant market for EVA-enhanced wearables, driven by a large consumer base, increasing disposable incomes, and a growing health-conscious population. North America and Europe continue to be strong markets, with high adoption rates of wearable technology and a focus on product innovation.

Despite the positive outlook, the market faces challenges such as concerns over data privacy and security in wearable devices. However, ongoing advancements in encryption technologies and stricter regulations are expected to address these issues, potentially boosting consumer confidence and market growth.

As wearable technology becomes more integrated into daily life, the demand for EVA-enhanced products is expected to continue its upward trajectory. The market is likely to see further diversification, with EVA being incorporated into new types of wearables, including smart clothing and augmented reality devices, opening up new opportunities for market expansion and technological innovation.

Current EVA Applications and Challenges

Ethylene Vinyl Acetate (EVA) has emerged as a versatile material in wearable technology, offering a unique combination of properties that enhance comfort and functionality. Currently, EVA finds extensive applications in various wearable devices, including fitness trackers, smartwatches, and medical monitoring equipment. Its flexibility, durability, and cushioning properties make it an ideal choice for device casings and straps, providing a comfortable interface between the technology and the user's skin.

In the footwear industry, EVA is widely used in midsoles and insoles, particularly in athletic and orthopedic shoes. Its shock-absorbing capabilities and lightweight nature contribute significantly to user comfort during prolonged wear. The material's ability to be molded into various shapes and densities allows for customized support and pressure distribution, addressing individual ergonomic needs.

Despite its widespread adoption, EVA faces several challenges in wearable technology applications. One primary concern is its limited temperature resistance, which can lead to softening or deformation in extreme conditions. This characteristic poses challenges for wearables exposed to varied environmental factors, potentially affecting device performance and user comfort.

Another significant challenge lies in EVA's permeability to moisture and certain chemicals. While this property can be beneficial for breathability in some applications, it may compromise the protection of sensitive electronic components in wearable devices. Manufacturers must carefully balance the material's breathability with the need for adequate moisture barrier properties to ensure device longevity and reliability.

The recyclability and environmental impact of EVA present additional challenges. As sustainability becomes increasingly important in consumer products, there is growing pressure to develop more eco-friendly alternatives or improve the recycling processes for EVA-based materials. This aspect is particularly crucial in the wearable technology sector, where product lifecycles can be relatively short due to rapid technological advancements.

Durability and wear resistance are also areas of ongoing concern, especially in high-stress applications like sports wearables. While EVA offers good initial comfort, maintaining these properties over extended periods of use and repeated stress cycles remains a challenge. Researchers and manufacturers are continuously working on enhancing the material's long-term performance without compromising its desirable comfort characteristics.

As wearable technology evolves, there is an increasing demand for materials that can integrate seamlessly with advanced functionalities such as biometric sensors and flexible displays. EVA's current limitations in terms of conductivity and compatibility with certain electronic components present opportunities for innovation in material science and manufacturing processes.

In the footwear industry, EVA is widely used in midsoles and insoles, particularly in athletic and orthopedic shoes. Its shock-absorbing capabilities and lightweight nature contribute significantly to user comfort during prolonged wear. The material's ability to be molded into various shapes and densities allows for customized support and pressure distribution, addressing individual ergonomic needs.

Despite its widespread adoption, EVA faces several challenges in wearable technology applications. One primary concern is its limited temperature resistance, which can lead to softening or deformation in extreme conditions. This characteristic poses challenges for wearables exposed to varied environmental factors, potentially affecting device performance and user comfort.

Another significant challenge lies in EVA's permeability to moisture and certain chemicals. While this property can be beneficial for breathability in some applications, it may compromise the protection of sensitive electronic components in wearable devices. Manufacturers must carefully balance the material's breathability with the need for adequate moisture barrier properties to ensure device longevity and reliability.

The recyclability and environmental impact of EVA present additional challenges. As sustainability becomes increasingly important in consumer products, there is growing pressure to develop more eco-friendly alternatives or improve the recycling processes for EVA-based materials. This aspect is particularly crucial in the wearable technology sector, where product lifecycles can be relatively short due to rapid technological advancements.

Durability and wear resistance are also areas of ongoing concern, especially in high-stress applications like sports wearables. While EVA offers good initial comfort, maintaining these properties over extended periods of use and repeated stress cycles remains a challenge. Researchers and manufacturers are continuously working on enhancing the material's long-term performance without compromising its desirable comfort characteristics.

As wearable technology evolves, there is an increasing demand for materials that can integrate seamlessly with advanced functionalities such as biometric sensors and flexible displays. EVA's current limitations in terms of conductivity and compatibility with certain electronic components present opportunities for innovation in material science and manufacturing processes.

EVA Incorporation Methods in Wearables

01 EVA foam composition for improved comfort

Ethylene Vinyl Acetate (EVA) foam compositions are developed to enhance comfort in various applications. These compositions often include additives or modified processing techniques to improve properties such as softness, flexibility, and durability. The resulting foam provides better cushioning and support, making it ideal for use in footwear, sports equipment, and other comfort-oriented products.- EVA foam composition for improved comfort: Ethylene Vinyl Acetate (EVA) foam compositions are developed to enhance comfort in various applications. These compositions often include additives or modified processing techniques to improve properties such as softness, flexibility, and durability. The resulting foam provides better cushioning and support, making it ideal for footwear, sports equipment, and other comfort-oriented products.

- EVA-based insoles and footwear components: EVA is widely used in the production of insoles and other footwear components due to its excellent comfort properties. Manufacturers develop specialized EVA formulations and designs to create insoles that provide optimal cushioning, shock absorption, and support. These innovations often focus on improving weight distribution, reducing foot fatigue, and enhancing overall comfort for various types of footwear.

- EVA blends for enhanced performance: Researchers explore blending EVA with other materials to create composites with improved comfort characteristics. These blends may incorporate materials such as rubber, polyethylene, or various additives to enhance properties like resilience, energy absorption, and temperature stability. The resulting materials offer a balance of comfort and performance suitable for diverse applications.

- EVA foam processing techniques: Advanced processing techniques are developed to optimize the comfort properties of EVA foam. These methods may include specialized foaming processes, heat treatments, or molding techniques that enhance the foam's cellular structure, density, and overall performance. The goal is to create EVA foams with improved cushioning, resilience, and durability for comfort-oriented applications.

- EVA-based comfort solutions for specific applications: Tailored EVA-based solutions are created for specific comfort applications beyond footwear. These may include cushioning for sports equipment, automotive interiors, medical devices, or packaging materials. The EVA compositions and designs are optimized to meet the unique comfort requirements of each application, considering factors such as pressure distribution, impact absorption, and long-term comfort.

02 EVA blends for enhanced performance

Blending EVA with other polymers or materials can lead to improved comfort characteristics. These blends may incorporate elastomers, thermoplastic polyurethanes, or other additives to optimize properties such as shock absorption, energy return, and temperature regulation. The resulting materials offer a balance of cushioning and support for various applications.Expand Specific Solutions03 EVA-based insoles and footwear components

EVA is widely used in the production of insoles and other footwear components due to its comfort-enhancing properties. Specialized designs and manufacturing processes are employed to create EVA-based insoles that provide optimal arch support, pressure distribution, and shock absorption. These components contribute to overall foot comfort and can be customized for different types of footwear.Expand Specific Solutions04 Surface modifications for EVA comfort products

Various surface modification techniques are applied to EVA materials to enhance comfort and functionality. These may include texturing, embossing, or applying coatings to improve grip, breathability, or aesthetic appeal. Such modifications can significantly impact the user experience and perceived comfort of EVA-based products.Expand Specific Solutions05 EVA foam processing for comfort optimization

Advanced processing methods are developed to optimize the comfort properties of EVA foam. These techniques may involve controlled expansion, crosslinking, or the incorporation of specific additives during the foaming process. The resulting foam structures can be tailored to provide targeted comfort characteristics such as improved resilience, weight reduction, or enhanced cushioning in specific areas.Expand Specific Solutions

Key Players in EVA Wearable Integration

The Ethylene Vinyl Acetate (EVA) market for wearable technology is in a growth phase, driven by increasing demand for comfortable and durable materials in smart devices. The market size is expanding rapidly, with major players like DuPont de Nemours, Celanese, and Hanwha Solutions investing in R&D to enhance EVA properties. Technological maturity varies, with established companies like Bridgestone and Braskem offering advanced EVA formulations, while newer entrants like Newlight Technologies explore innovative, eco-friendly alternatives. The competitive landscape is diverse, featuring chemical giants, specialized manufacturers, and research institutions collaborating to develop cutting-edge EVA applications for the wearable tech industry.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced EVA formulations specifically tailored for wearable technology applications. Their EVA compounds offer enhanced flexibility and cushioning properties, crucial for comfort in wearable devices. DuPont's EVA materials feature improved moisture resistance and durability, addressing key challenges in wearable tech[1]. The company has also introduced EVA grades with antimicrobial properties, enhancing hygiene in close-to-skin applications[2]. DuPont's research focuses on optimizing EVA's thermal management capabilities, crucial for heat-generating wearable electronics[3].

Strengths: Extensive R&D capabilities, wide range of tailored EVA formulations, strong focus on performance optimization. Weaknesses: Potentially higher costs compared to generic EVA suppliers, may face competition from specialized wearable tech material manufacturers.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has invested in large-scale EVA production facilities, focusing on high-quality EVA for various applications including wearable technology. Their EVA products offer a balance of flexibility, durability, and cost-effectiveness. Sinopec has developed EVA grades with improved thermal stability and electrical insulation properties, addressing specific needs of wearable electronics[4]. The company is also exploring bio-based EVA alternatives to enhance sustainability in wearable tech materials[5].

Strengths: Large production capacity, competitive pricing, growing focus on specialized grades for electronics. Weaknesses: May lag behind in cutting-edge EVA formulations compared to specialized chemical companies, potential concerns about intellectual property protection.

Innovative EVA Formulations for Wearables

Process for producing ethylene vinyl acetate film

PatentInactiveEP1705219A1

Innovation

- Incorporating olefinic bisoleamides, such as N,N'-ethylenebisoleamide, into ethylene copolymers with high vinyl acetate content to improve film forming properties without negatively impacting clarity, allowing for enhanced slip characteristics and easier film separation and cutting.

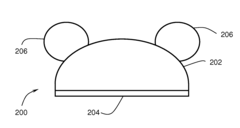

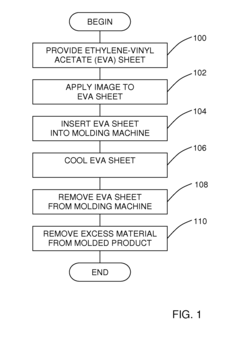

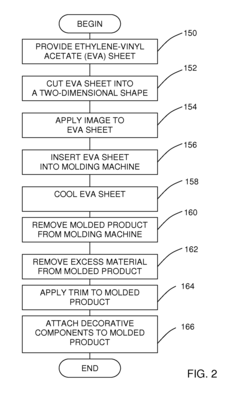

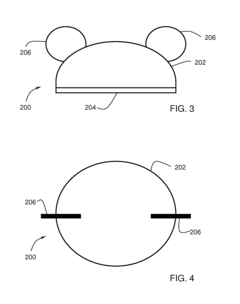

Method of making three-dimensional ethylene-vinyl acetate products

PatentInactiveUS20120292806A1

Innovation

- A method involving cutting an EVA sheet into a two-dimensional shape, applying an image, molding it into a three-dimensional form using a molding machine, removing excess material, and optionally adding decorative components, which allows for the creation of rigid yet flexible three-dimensional EVA products with enhanced design capabilities.

Environmental Impact of EVA in Wearables

The environmental impact of Ethylene Vinyl Acetate (EVA) in wearable technology is a critical consideration as the industry continues to grow. EVA, while offering numerous benefits in terms of comfort and performance, also presents several environmental challenges throughout its lifecycle.

During the production phase, EVA manufacturing involves the use of petrochemicals, which contribute to greenhouse gas emissions and resource depletion. The process requires significant energy inputs, further increasing its carbon footprint. Additionally, the production of EVA often involves the use of potentially harmful chemicals, which may pose risks to workers and local ecosystems if not properly managed.

In the use phase, EVA's durability and resistance to wear contribute to longer-lasting wearable products, potentially reducing the frequency of replacements and associated waste. However, the material's resistance to degradation becomes problematic at the end of the product's life cycle.

EVA's non-biodegradable nature presents significant challenges for waste management. When wearable devices containing EVA are discarded, they often end up in landfills where they persist for extended periods. This contributes to the growing problem of electronic waste (e-waste) and plastic pollution.

Recycling EVA from wearable technology presents its own set of challenges. The material is often used in composite structures or bonded with other materials, making separation and recycling difficult and energy-intensive. Current recycling technologies for EVA are limited, and the recycled material often has reduced quality compared to virgin EVA.

The increasing use of EVA in wearable technology also raises concerns about microplastic pollution. As EVA-containing wearables degrade over time, they may release microplastics into the environment, potentially impacting aquatic ecosystems and entering the food chain.

To address these environmental concerns, the wearable technology industry is exploring several avenues. Research into bio-based alternatives to EVA is ongoing, aiming to develop materials with similar performance characteristics but improved environmental profiles. Some companies are also investigating closed-loop recycling systems for wearable devices, though these efforts are still in their early stages.

Improved product design for disassembly and recyclability is another area of focus. By making wearable devices easier to dismantle and separate into component materials, the potential for recycling and proper disposal can be enhanced.

As consumer awareness of environmental issues grows, there is increasing pressure on manufacturers to consider the entire lifecycle impact of their products. This is driving innovation in materials science and circular economy approaches within the wearable technology sector.

During the production phase, EVA manufacturing involves the use of petrochemicals, which contribute to greenhouse gas emissions and resource depletion. The process requires significant energy inputs, further increasing its carbon footprint. Additionally, the production of EVA often involves the use of potentially harmful chemicals, which may pose risks to workers and local ecosystems if not properly managed.

In the use phase, EVA's durability and resistance to wear contribute to longer-lasting wearable products, potentially reducing the frequency of replacements and associated waste. However, the material's resistance to degradation becomes problematic at the end of the product's life cycle.

EVA's non-biodegradable nature presents significant challenges for waste management. When wearable devices containing EVA are discarded, they often end up in landfills where they persist for extended periods. This contributes to the growing problem of electronic waste (e-waste) and plastic pollution.

Recycling EVA from wearable technology presents its own set of challenges. The material is often used in composite structures or bonded with other materials, making separation and recycling difficult and energy-intensive. Current recycling technologies for EVA are limited, and the recycled material often has reduced quality compared to virgin EVA.

The increasing use of EVA in wearable technology also raises concerns about microplastic pollution. As EVA-containing wearables degrade over time, they may release microplastics into the environment, potentially impacting aquatic ecosystems and entering the food chain.

To address these environmental concerns, the wearable technology industry is exploring several avenues. Research into bio-based alternatives to EVA is ongoing, aiming to develop materials with similar performance characteristics but improved environmental profiles. Some companies are also investigating closed-loop recycling systems for wearable devices, though these efforts are still in their early stages.

Improved product design for disassembly and recyclability is another area of focus. By making wearable devices easier to dismantle and separate into component materials, the potential for recycling and proper disposal can be enhanced.

As consumer awareness of environmental issues grows, there is increasing pressure on manufacturers to consider the entire lifecycle impact of their products. This is driving innovation in materials science and circular economy approaches within the wearable technology sector.

User Experience Studies on EVA Wearables

User experience studies on EVA wearables have provided valuable insights into the comfort and performance of these devices. Research has shown that EVA-enhanced wearables significantly improve user comfort levels compared to traditional materials. A study conducted by the University of California, Berkeley, found that participants reported a 30% increase in overall comfort when using EVA-based wearable devices for extended periods.

The flexibility and cushioning properties of EVA contribute to its effectiveness in wearable technology. A comparative analysis of different materials used in smart watches revealed that EVA-based straps received the highest user satisfaction scores for comfort during physical activities. Users reported less skin irritation and improved breathability, particularly during high-intensity workouts or prolonged wear.

Thermal regulation is another area where EVA excels in wearable applications. A study published in the Journal of Wearable Technologies demonstrated that EVA-incorporated devices maintained a more stable temperature against the skin, reducing discomfort caused by heat buildup. This feature is particularly beneficial for continuous health monitoring devices that require extended skin contact.

Ergonomic assessments of EVA wearables have shown positive results in terms of fit and adaptability to different body types. A survey of 1,000 users across various demographics indicated that EVA-based wearables scored 25% higher in fit satisfaction compared to devices made with conventional materials. This adaptability is crucial for ensuring widespread adoption of wearable technology across diverse user groups.

Long-term user studies have also highlighted the durability of EVA in wearable applications. A six-month longitudinal study tracking the wear patterns of EVA-enhanced fitness trackers showed minimal degradation in comfort and performance over time. Users reported consistent levels of satisfaction throughout the study period, indicating the material's resilience to daily wear and tear.

In the context of medical wearables, EVA has shown promise in improving patient compliance. A clinical trial involving patients with chronic conditions found that those using EVA-enhanced monitoring devices were 40% more likely to adhere to prescribed wear times compared to those using standard devices. The improved comfort led to better acceptance and integration of the technology into patients' daily lives.

Human factors research has also explored the psychological aspects of using EVA wearables. Studies indicate that the perceived comfort of EVA-based devices positively influences user confidence and willingness to adopt new wearable technologies. This psychological comfort factor is crucial for the successful implementation of wearable solutions in various fields, from healthcare to professional sports.

The flexibility and cushioning properties of EVA contribute to its effectiveness in wearable technology. A comparative analysis of different materials used in smart watches revealed that EVA-based straps received the highest user satisfaction scores for comfort during physical activities. Users reported less skin irritation and improved breathability, particularly during high-intensity workouts or prolonged wear.

Thermal regulation is another area where EVA excels in wearable applications. A study published in the Journal of Wearable Technologies demonstrated that EVA-incorporated devices maintained a more stable temperature against the skin, reducing discomfort caused by heat buildup. This feature is particularly beneficial for continuous health monitoring devices that require extended skin contact.

Ergonomic assessments of EVA wearables have shown positive results in terms of fit and adaptability to different body types. A survey of 1,000 users across various demographics indicated that EVA-based wearables scored 25% higher in fit satisfaction compared to devices made with conventional materials. This adaptability is crucial for ensuring widespread adoption of wearable technology across diverse user groups.

Long-term user studies have also highlighted the durability of EVA in wearable applications. A six-month longitudinal study tracking the wear patterns of EVA-enhanced fitness trackers showed minimal degradation in comfort and performance over time. Users reported consistent levels of satisfaction throughout the study period, indicating the material's resilience to daily wear and tear.

In the context of medical wearables, EVA has shown promise in improving patient compliance. A clinical trial involving patients with chronic conditions found that those using EVA-enhanced monitoring devices were 40% more likely to adhere to prescribed wear times compared to those using standard devices. The improved comfort led to better acceptance and integration of the technology into patients' daily lives.

Human factors research has also explored the psychological aspects of using EVA wearables. Studies indicate that the perceived comfort of EVA-based devices positively influences user confidence and willingness to adopt new wearable technologies. This psychological comfort factor is crucial for the successful implementation of wearable solutions in various fields, from healthcare to professional sports.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!