Evaluating Heat Exchanger Designs for Sustainable Operations

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Technology Background and Objectives

Heat exchangers have evolved significantly since their inception in the early 20th century, transitioning from simple shell-and-tube designs to sophisticated plate, spiral, and microchannel configurations. This technological progression has been driven by increasing demands for energy efficiency, space optimization, and cost reduction across multiple industries including power generation, chemical processing, HVAC systems, and renewable energy applications.

The current trajectory of heat exchanger technology is moving toward more compact, efficient designs with enhanced heat transfer capabilities and reduced environmental impact. Recent innovations focus on advanced materials that offer superior thermal conductivity, corrosion resistance, and durability under extreme operating conditions. Computational fluid dynamics (CFD) and advanced simulation tools have revolutionized design processes, enabling precise optimization of flow patterns and heat transfer surfaces.

Sustainability has emerged as a critical driver in heat exchanger development, with increasing emphasis on reducing energy consumption, minimizing carbon footprints, and supporting circular economy principles. This shift reflects broader industry trends toward environmental responsibility and regulatory compliance with increasingly stringent emissions standards worldwide.

The primary objectives of modern heat exchanger technology development include maximizing thermal efficiency while minimizing pressure drop, reducing material usage without compromising performance, extending operational lifespan through improved fouling resistance, and developing cost-effective manufacturing techniques for complex geometries. Additionally, there is growing interest in designs that facilitate easier maintenance, cleaning, and component replacement to reduce lifecycle costs.

Emerging research areas include phase-change heat exchangers that leverage latent heat transfer, self-cleaning surfaces that mitigate fouling issues, and smart heat exchangers with integrated sensors for real-time performance monitoring and predictive maintenance. Additive manufacturing techniques are opening new possibilities for creating previously impossible geometries that maximize heat transfer surface area while minimizing material use and flow resistance.

For sustainable operations specifically, key technological goals include developing heat exchangers that operate efficiently at lower temperature differentials, designs that facilitate heat recovery from low-grade waste heat sources, and systems compatible with environmentally friendly refrigerants and working fluids. There is also significant focus on improving integration with renewable energy systems and developing heat exchangers optimized for thermal energy storage applications.

The convergence of these technological trends with sustainability imperatives presents both challenges and opportunities for innovation in heat exchanger design, manufacturing, and application across diverse industrial sectors.

The current trajectory of heat exchanger technology is moving toward more compact, efficient designs with enhanced heat transfer capabilities and reduced environmental impact. Recent innovations focus on advanced materials that offer superior thermal conductivity, corrosion resistance, and durability under extreme operating conditions. Computational fluid dynamics (CFD) and advanced simulation tools have revolutionized design processes, enabling precise optimization of flow patterns and heat transfer surfaces.

Sustainability has emerged as a critical driver in heat exchanger development, with increasing emphasis on reducing energy consumption, minimizing carbon footprints, and supporting circular economy principles. This shift reflects broader industry trends toward environmental responsibility and regulatory compliance with increasingly stringent emissions standards worldwide.

The primary objectives of modern heat exchanger technology development include maximizing thermal efficiency while minimizing pressure drop, reducing material usage without compromising performance, extending operational lifespan through improved fouling resistance, and developing cost-effective manufacturing techniques for complex geometries. Additionally, there is growing interest in designs that facilitate easier maintenance, cleaning, and component replacement to reduce lifecycle costs.

Emerging research areas include phase-change heat exchangers that leverage latent heat transfer, self-cleaning surfaces that mitigate fouling issues, and smart heat exchangers with integrated sensors for real-time performance monitoring and predictive maintenance. Additive manufacturing techniques are opening new possibilities for creating previously impossible geometries that maximize heat transfer surface area while minimizing material use and flow resistance.

For sustainable operations specifically, key technological goals include developing heat exchangers that operate efficiently at lower temperature differentials, designs that facilitate heat recovery from low-grade waste heat sources, and systems compatible with environmentally friendly refrigerants and working fluids. There is also significant focus on improving integration with renewable energy systems and developing heat exchangers optimized for thermal energy storage applications.

The convergence of these technological trends with sustainability imperatives presents both challenges and opportunities for innovation in heat exchanger design, manufacturing, and application across diverse industrial sectors.

Market Demand for Sustainable Heat Exchange Solutions

The global market for sustainable heat exchange solutions has witnessed significant growth in recent years, driven by increasing environmental regulations, rising energy costs, and growing corporate sustainability commitments. According to recent market analyses, the global heat exchanger market is projected to reach $28.5 billion by 2026, with sustainable and energy-efficient designs representing the fastest-growing segment at an annual growth rate of approximately 8.7%.

Industrial sectors, particularly chemical processing, oil and gas, power generation, and food and beverage, constitute the largest demand segments for advanced heat exchanger technologies. These industries are increasingly seeking solutions that minimize energy consumption while maximizing heat transfer efficiency, directly impacting their operational costs and environmental footprint. The chemical processing industry alone accounts for nearly 22% of the total market demand for sustainable heat exchange solutions.

Regulatory pressures have emerged as a significant market driver across regions. The European Union's Energy Efficiency Directive and similar regulations in North America and parts of Asia have established stringent energy efficiency standards that directly impact heat exchanger specifications. Companies are increasingly required to demonstrate compliance with these standards, creating a robust demand for heat exchangers that exceed minimum efficiency requirements.

The economic case for sustainable heat exchangers has strengthened considerably as energy prices continue to fluctuate globally. Organizations are increasingly evaluating heat exchanger technologies based on total cost of ownership rather than initial capital expenditure. Market research indicates that end-users are willing to pay a premium of 15-20% for heat exchangers that demonstrate superior energy efficiency and reduced maintenance requirements over their operational lifetime.

Emerging market trends include growing demand for compact heat exchangers that optimize space utilization while maintaining high efficiency, particularly in urban industrial settings and offshore applications. Additionally, there is increasing interest in heat exchangers manufactured using sustainable materials and processes, with reduced environmental impact throughout their lifecycle.

Regional analysis reveals that Asia-Pacific represents the fastest-growing market for sustainable heat exchange solutions, driven by rapid industrialization in China and India coupled with increasingly stringent environmental regulations. North America and Europe maintain significant market shares, with demand primarily focused on replacement and upgrade of existing systems to meet higher efficiency standards.

Customer requirements are evolving toward more customized solutions that address specific operational conditions while optimizing energy usage. This has created market opportunities for manufacturers capable of providing tailored heat exchanger designs supported by comprehensive performance data and lifecycle analysis tools that demonstrate long-term sustainability benefits.

Industrial sectors, particularly chemical processing, oil and gas, power generation, and food and beverage, constitute the largest demand segments for advanced heat exchanger technologies. These industries are increasingly seeking solutions that minimize energy consumption while maximizing heat transfer efficiency, directly impacting their operational costs and environmental footprint. The chemical processing industry alone accounts for nearly 22% of the total market demand for sustainable heat exchange solutions.

Regulatory pressures have emerged as a significant market driver across regions. The European Union's Energy Efficiency Directive and similar regulations in North America and parts of Asia have established stringent energy efficiency standards that directly impact heat exchanger specifications. Companies are increasingly required to demonstrate compliance with these standards, creating a robust demand for heat exchangers that exceed minimum efficiency requirements.

The economic case for sustainable heat exchangers has strengthened considerably as energy prices continue to fluctuate globally. Organizations are increasingly evaluating heat exchanger technologies based on total cost of ownership rather than initial capital expenditure. Market research indicates that end-users are willing to pay a premium of 15-20% for heat exchangers that demonstrate superior energy efficiency and reduced maintenance requirements over their operational lifetime.

Emerging market trends include growing demand for compact heat exchangers that optimize space utilization while maintaining high efficiency, particularly in urban industrial settings and offshore applications. Additionally, there is increasing interest in heat exchangers manufactured using sustainable materials and processes, with reduced environmental impact throughout their lifecycle.

Regional analysis reveals that Asia-Pacific represents the fastest-growing market for sustainable heat exchange solutions, driven by rapid industrialization in China and India coupled with increasingly stringent environmental regulations. North America and Europe maintain significant market shares, with demand primarily focused on replacement and upgrade of existing systems to meet higher efficiency standards.

Customer requirements are evolving toward more customized solutions that address specific operational conditions while optimizing energy usage. This has created market opportunities for manufacturers capable of providing tailored heat exchanger designs supported by comprehensive performance data and lifecycle analysis tools that demonstrate long-term sustainability benefits.

Current State and Challenges in Heat Exchanger Design

Heat exchanger technology has evolved significantly over the past decades, yet the industry faces substantial challenges in meeting modern sustainability requirements. Current designs predominantly rely on traditional shell-and-tube, plate, and finned-tube configurations, with incremental improvements rather than revolutionary changes. Global research indicates that while these conventional designs offer reliability, they often fall short in energy efficiency metrics critical for sustainable operations.

The primary technical challenge facing heat exchanger design is the fundamental trade-off between heat transfer efficiency and pressure drop. Enhanced surface geometries that improve heat transfer typically increase fluid resistance, resulting in higher pumping power requirements that can offset efficiency gains. This paradox remains unresolved in many commercial applications, particularly in compact heat exchangers where space constraints further complicate design optimization.

Material limitations represent another significant constraint. While advanced materials like titanium alloys and specialized polymers offer improved corrosion resistance and thermal properties, their widespread adoption is hindered by high costs and manufacturing complexities. Additive manufacturing techniques show promise for creating complex geometries but face scalability issues for industrial-sized heat exchangers.

Fouling remains a persistent challenge across industries, with deposits reducing thermal efficiency by up to 30% in some applications. Current mitigation strategies primarily focus on chemical treatments and mechanical cleaning rather than innovative design solutions that could inherently minimize fouling propensity. The economic impact of fouling is estimated at 0.25% of GDP in industrialized countries, highlighting the magnitude of this challenge.

Computational modeling capabilities, while advanced, still struggle with accurately predicting performance under variable operating conditions and over extended service periods. The gap between theoretical models and real-world performance creates uncertainty in design optimization, particularly for novel configurations or extreme operating environments.

Geographically, heat exchanger technology development shows distinct patterns. European research centers lead in theoretical modeling and simulation techniques, while Asian manufacturers, particularly in China and South Korea, dominate production volume and incremental efficiency improvements. North American companies focus on specialized applications and materials innovation, creating a fragmented global landscape of technical expertise.

Regulatory pressures and sustainability goals are driving new requirements that many current designs struggle to meet. Refrigerant phase-outs, carbon reduction targets, and water conservation mandates create complex design constraints that often conflict with traditional optimization approaches focused primarily on thermal performance and cost.

AI-assisted design tools are emerging but remain in early development stages, with limited integration into mainstream design processes. These computational approaches show promise for navigating the complex multi-parameter optimization challenges inherent in sustainable heat exchanger design.

The primary technical challenge facing heat exchanger design is the fundamental trade-off between heat transfer efficiency and pressure drop. Enhanced surface geometries that improve heat transfer typically increase fluid resistance, resulting in higher pumping power requirements that can offset efficiency gains. This paradox remains unresolved in many commercial applications, particularly in compact heat exchangers where space constraints further complicate design optimization.

Material limitations represent another significant constraint. While advanced materials like titanium alloys and specialized polymers offer improved corrosion resistance and thermal properties, their widespread adoption is hindered by high costs and manufacturing complexities. Additive manufacturing techniques show promise for creating complex geometries but face scalability issues for industrial-sized heat exchangers.

Fouling remains a persistent challenge across industries, with deposits reducing thermal efficiency by up to 30% in some applications. Current mitigation strategies primarily focus on chemical treatments and mechanical cleaning rather than innovative design solutions that could inherently minimize fouling propensity. The economic impact of fouling is estimated at 0.25% of GDP in industrialized countries, highlighting the magnitude of this challenge.

Computational modeling capabilities, while advanced, still struggle with accurately predicting performance under variable operating conditions and over extended service periods. The gap between theoretical models and real-world performance creates uncertainty in design optimization, particularly for novel configurations or extreme operating environments.

Geographically, heat exchanger technology development shows distinct patterns. European research centers lead in theoretical modeling and simulation techniques, while Asian manufacturers, particularly in China and South Korea, dominate production volume and incremental efficiency improvements. North American companies focus on specialized applications and materials innovation, creating a fragmented global landscape of technical expertise.

Regulatory pressures and sustainability goals are driving new requirements that many current designs struggle to meet. Refrigerant phase-outs, carbon reduction targets, and water conservation mandates create complex design constraints that often conflict with traditional optimization approaches focused primarily on thermal performance and cost.

AI-assisted design tools are emerging but remain in early development stages, with limited integration into mainstream design processes. These computational approaches show promise for navigating the complex multi-parameter optimization challenges inherent in sustainable heat exchanger design.

Current Sustainable Heat Exchanger Design Approaches

01 Energy-efficient heat exchanger designs

Advanced heat exchanger designs that focus on improving energy efficiency and reducing operational costs. These designs incorporate innovative geometries, enhanced heat transfer surfaces, and optimized flow patterns to maximize thermal efficiency while minimizing energy consumption. Such sustainable designs help reduce the carbon footprint of industrial processes by requiring less energy input for the same heat transfer performance.- Energy-efficient heat exchanger designs: Advanced heat exchanger designs that optimize energy efficiency through improved thermal transfer capabilities. These designs incorporate innovative geometries, enhanced surface areas, and optimized flow patterns to maximize heat transfer while minimizing energy consumption. Such sustainable designs reduce operational costs and environmental impact by requiring less energy input for the same thermal performance.

- Self-cleaning and fouling prevention systems: Systems that maintain heat exchanger efficiency by preventing or removing fouling and deposits. These technologies include automatic cleaning mechanisms, surface treatments that resist scaling, and flow optimization to reduce particulate accumulation. By maintaining clean heat transfer surfaces, these systems ensure sustained thermal performance and reduce the need for chemical cleaning agents and maintenance downtime.

- Waste heat recovery and utilization: Technologies that capture and repurpose waste heat from industrial processes or equipment operations. These systems integrate secondary heat exchangers to recover thermal energy that would otherwise be lost, redirecting it for space heating, preheating process fluids, or generating electricity. This approach significantly improves overall system efficiency and reduces primary energy consumption and associated emissions.

- Smart monitoring and control systems: Intelligent systems that continuously monitor heat exchanger performance and automatically adjust operational parameters. These systems employ sensors, data analytics, and predictive algorithms to detect inefficiencies, optimize flow rates, and balance thermal loads. By maintaining optimal operating conditions and providing early warning of potential issues, these smart systems extend equipment life and maximize energy efficiency.

- Alternative materials and manufacturing techniques: Sustainable materials and manufacturing methods that reduce environmental impact while enhancing heat exchanger performance. These innovations include corrosion-resistant alloys, bio-based composites, and additive manufacturing techniques that optimize material usage. Such approaches extend equipment lifespan, reduce maintenance requirements, and minimize the carbon footprint associated with heat exchanger production and operation.

02 Fouling mitigation and self-cleaning mechanisms

Technologies that address the common issue of fouling in heat exchangers, which reduces efficiency and increases maintenance requirements. These solutions include self-cleaning mechanisms, anti-fouling surface treatments, and innovative flow designs that minimize deposit buildup. By maintaining clean heat transfer surfaces over longer operational periods, these technologies ensure sustainable operation with reduced maintenance downtime and extended equipment lifespan.Expand Specific Solutions03 Waste heat recovery systems

Systems designed to capture and utilize waste heat from industrial processes that would otherwise be lost to the environment. These heat recovery solutions integrate with existing heat exchangers to improve overall system efficiency by redirecting thermal energy for secondary applications such as preheating, power generation, or district heating. This approach significantly reduces primary energy consumption and associated greenhouse gas emissions.Expand Specific Solutions04 Smart monitoring and control systems

Intelligent systems that continuously monitor heat exchanger performance and automatically adjust operational parameters for optimal efficiency. These systems utilize sensors, data analytics, and predictive algorithms to detect performance degradation, identify maintenance needs, and optimize operating conditions in real-time. By maintaining peak performance and preventing failures, these smart systems extend equipment life and reduce resource consumption.Expand Specific Solutions05 Alternative materials and manufacturing techniques

The use of sustainable materials and advanced manufacturing methods to produce more environmentally friendly heat exchangers. These innovations include corrosion-resistant alloys, composite materials, and additive manufacturing techniques that reduce material waste. Such approaches not only extend the operational life of heat exchangers but also reduce the environmental impact associated with their production, maintenance, and eventual disposal.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The heat exchanger design market for sustainable operations is currently in a growth phase, driven by increasing focus on energy efficiency and environmental regulations. The global market size is expanding rapidly, with projections indicating significant growth through 2030. Technologically, the field shows varying maturity levels across applications. Industry leaders like Modine Manufacturing, Siemens Gamesa, and General Electric are advancing conventional technologies, while companies such as Behr GmbH and Valeo Thermal Systems are pioneering innovations in automotive applications. Research institutions like Dalian University of Technology and Commissariat à l'énergie atomique are developing next-generation solutions. Saudi Aramco and Linde GmbH are focusing on industrial-scale implementations, creating a competitive landscape balanced between established players and emerging specialists in sustainable thermal management solutions.

Behr GmbH & Co. KG

Technical Solution: Behr has developed a comprehensive suite of sustainable heat exchanger technologies, particularly focused on automotive and mobile applications. Their layered core technology creates multi-stream heat exchangers that can simultaneously manage multiple thermal circuits within a single compact unit, reducing overall system mass by up to 25%. Behr's vacuum brazing process enables the creation of aluminum heat exchangers with complex internal geometries that maximize surface area while minimizing material usage and weight. For electric vehicle applications, their integrated thermal management modules combine multiple heat exchange functions (battery cooling, power electronics cooling, cabin climate control) into unified systems that optimize overall energy efficiency. Behr's latest generation of heat exchangers incorporates computational fluid dynamics-optimized turbulators that enhance heat transfer coefficients by creating controlled turbulence without excessive pressure drop penalties.

Strengths: Exceptional weight-to-performance ratio; designs optimized for transportation applications; advanced manufacturing capabilities for complex geometries. Weaknesses: Solutions primarily focused on mobile applications rather than industrial scale; higher cost compared to conventional designs; some advanced features require precise manufacturing tolerances.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The CEA has developed innovative Printed Circuit Heat Exchanger (PCHE) technology for extreme operating conditions, capable of withstanding pressures up to 600 bar and temperatures ranging from cryogenic to 900°C. Their diffusion bonding manufacturing process creates monolithic heat exchanger cores with near-perfect bonding between layers, eliminating traditional weak points. For sustainable operations, CEA's supercritical CO2 heat exchangers support advanced power cycles with thermal efficiencies exceeding 45%, representing a significant improvement over conventional Rankine cycles. Their compact heat exchangers for hydrogen applications feature proprietary surface treatments that mitigate hydrogen embrittlement while maintaining thermal performance. CEA's research has pioneered the use of ceramic heat exchangers for ultra-high temperature applications, enabling waste heat recovery from processes previously considered too extreme for conventional materials.

Strengths: Unparalleled expertise in extreme operating conditions; strong materials science foundation; designs optimized for emerging energy technologies like hydrogen and supercritical CO2. Weaknesses: Higher manufacturing costs than mass-produced alternatives; longer lead times for specialized designs; technology often requires adaptation for commercial-scale implementation.

Key Innovations in Energy-Efficient Heat Transfer

Performance evaluation system and method of heat exchanger

PatentActiveKR1020200062848A

Innovation

- Adaptive determination system that varies its evaluation method based on received heat source state information, enabling dynamic performance assessment of heat exchangers.

- Predictive maintenance capability through performance analysis to estimate cleaning and repair times, allowing for proactive rather than reactive maintenance scheduling.

- Selective inspection methodology that identifies specific heat exchangers requiring attention based on analysis results, optimizing maintenance resource allocation.

Development of low cost parallel and counter flowheat exchanger

PatentPendingIN202441044179A

Innovation

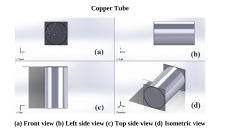

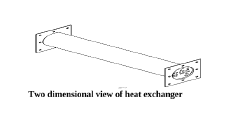

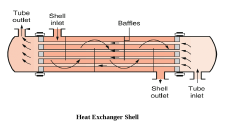

- A novel low-cost parallel and counter flow heat exchanger design with a meticulous fabrication process, incorporating a unique arrangement of components like shells, tubes, baffles, and a tube sheet, optimized for minimal fouling and pressure loss, utilizing helically coiled tubes to enhance heat transfer through centrifugal forces, and a predictive model for ideal performance conditions.

Lifecycle Assessment Methodologies

Lifecycle Assessment Methodologies for heat exchanger designs have evolved significantly in recent years, providing comprehensive frameworks to evaluate environmental impacts throughout the entire product lifecycle. These methodologies typically encompass raw material extraction, manufacturing processes, operational performance, maintenance requirements, and end-of-life disposal or recycling options. The ISO 14040 and 14044 standards serve as foundational guidelines for conducting these assessments, offering structured approaches to quantify environmental burdens associated with heat exchanger technologies.

Process-based Life Cycle Assessment (LCA) represents the most widely adopted methodology, allowing engineers to systematically analyze energy consumption, greenhouse gas emissions, water usage, and waste generation across different design configurations. This approach enables the identification of environmental hotspots within the lifecycle, facilitating targeted improvements in design parameters. For heat exchangers specifically, the operational phase typically accounts for 80-90% of lifetime environmental impacts, emphasizing the importance of efficiency optimization in sustainable design.

Input-Output LCA offers a complementary approach by incorporating economic data to capture broader supply chain impacts that might be overlooked in process-based assessments. This methodology proves particularly valuable when evaluating novel heat exchanger materials or manufacturing techniques where detailed process data may be limited. Hybrid LCA methodologies combine these approaches to leverage their respective strengths, providing more comprehensive sustainability evaluations.

Dynamic LCA represents an emerging methodology that accounts for temporal variations in environmental impacts, particularly relevant for heat exchangers operating under fluctuating conditions or integrated with renewable energy systems. This approach considers changing energy grid compositions, evolving regulatory frameworks, and technological improvements over the equipment's lifespan, offering more realistic projections of long-term environmental performance.

Consequential LCA extends beyond direct impacts to examine broader system-level changes resulting from heat exchanger implementation, including market-mediated effects and potential technology substitutions. This methodology proves especially valuable when evaluating transformative technologies like waste heat recovery systems or advanced phase-change heat exchangers that may disrupt conventional energy utilization patterns.

Social Life Cycle Assessment (S-LCA) complements environmental assessments by evaluating social impacts throughout the value chain, including labor conditions, community effects, and health implications. This holistic approach aligns with growing corporate social responsibility initiatives and sustainable development goals, providing a more comprehensive evaluation framework for heat exchanger technologies beyond purely environmental considerations.

Process-based Life Cycle Assessment (LCA) represents the most widely adopted methodology, allowing engineers to systematically analyze energy consumption, greenhouse gas emissions, water usage, and waste generation across different design configurations. This approach enables the identification of environmental hotspots within the lifecycle, facilitating targeted improvements in design parameters. For heat exchangers specifically, the operational phase typically accounts for 80-90% of lifetime environmental impacts, emphasizing the importance of efficiency optimization in sustainable design.

Input-Output LCA offers a complementary approach by incorporating economic data to capture broader supply chain impacts that might be overlooked in process-based assessments. This methodology proves particularly valuable when evaluating novel heat exchanger materials or manufacturing techniques where detailed process data may be limited. Hybrid LCA methodologies combine these approaches to leverage their respective strengths, providing more comprehensive sustainability evaluations.

Dynamic LCA represents an emerging methodology that accounts for temporal variations in environmental impacts, particularly relevant for heat exchangers operating under fluctuating conditions or integrated with renewable energy systems. This approach considers changing energy grid compositions, evolving regulatory frameworks, and technological improvements over the equipment's lifespan, offering more realistic projections of long-term environmental performance.

Consequential LCA extends beyond direct impacts to examine broader system-level changes resulting from heat exchanger implementation, including market-mediated effects and potential technology substitutions. This methodology proves especially valuable when evaluating transformative technologies like waste heat recovery systems or advanced phase-change heat exchangers that may disrupt conventional energy utilization patterns.

Social Life Cycle Assessment (S-LCA) complements environmental assessments by evaluating social impacts throughout the value chain, including labor conditions, community effects, and health implications. This holistic approach aligns with growing corporate social responsibility initiatives and sustainable development goals, providing a more comprehensive evaluation framework for heat exchanger technologies beyond purely environmental considerations.

Regulatory Standards for Energy Efficiency

Regulatory frameworks governing energy efficiency have become increasingly stringent across global markets, directly impacting heat exchanger design and implementation. The European Union's Ecodesign Directive (2009/125/EC) establishes comprehensive requirements for energy-related products, with specific provisions for heat exchange systems in industrial and commercial applications. These standards mandate minimum efficiency thresholds that vary by heat exchanger type, capacity, and application environment, with penalties for non-compliance ranging from market restrictions to substantial financial sanctions.

In the United States, the Department of Energy's appliance and equipment standards program has established minimum energy conservation standards for heat exchangers in HVAC systems, while the Environmental Protection Agency's ENERGY STAR program provides voluntary certification for high-efficiency heat exchange systems. These regulatory frameworks typically require manufacturers to demonstrate compliance through standardized testing protocols such as AHRI Standard 400 for liquid-to-liquid heat exchangers or ASHRAE Standard 90.1 for energy performance in buildings.

Asian markets present a diverse regulatory landscape, with Japan's Top Runner Program setting progressive efficiency targets based on the most efficient products currently available, while China's GB standards establish mandatory minimum energy performance requirements for industrial heat exchange equipment. These standards are increasingly harmonized with international frameworks such as ISO 16358 for testing and rating heat exchanger performance.

Emerging economies are rapidly adopting similar regulatory frameworks, often adapting international standards to local conditions. India's Bureau of Energy Efficiency has implemented star rating systems for heat exchange components in air conditioning and refrigeration systems, while Brazil's PROCEL program provides certification for energy-efficient industrial equipment including heat exchangers.

Carbon reduction initiatives further influence regulatory requirements, with many jurisdictions implementing carbon pricing mechanisms that indirectly incentivize high-efficiency heat exchanger designs. The EU Emissions Trading System and similar cap-and-trade programs in California and Quebec effectively monetize efficiency improvements by reducing carbon compliance costs for industrial operators utilizing advanced heat exchange technologies.

Compliance verification methodologies are becoming more sophisticated, with many regulatory bodies requiring detailed energy performance documentation throughout a product's lifecycle. This includes initial type testing, regular performance monitoring, and in some cases, real-time efficiency reporting through IoT-enabled systems. Manufacturers must increasingly design heat exchangers with these verification requirements in mind, incorporating monitoring capabilities and performance documentation features.

In the United States, the Department of Energy's appliance and equipment standards program has established minimum energy conservation standards for heat exchangers in HVAC systems, while the Environmental Protection Agency's ENERGY STAR program provides voluntary certification for high-efficiency heat exchange systems. These regulatory frameworks typically require manufacturers to demonstrate compliance through standardized testing protocols such as AHRI Standard 400 for liquid-to-liquid heat exchangers or ASHRAE Standard 90.1 for energy performance in buildings.

Asian markets present a diverse regulatory landscape, with Japan's Top Runner Program setting progressive efficiency targets based on the most efficient products currently available, while China's GB standards establish mandatory minimum energy performance requirements for industrial heat exchange equipment. These standards are increasingly harmonized with international frameworks such as ISO 16358 for testing and rating heat exchanger performance.

Emerging economies are rapidly adopting similar regulatory frameworks, often adapting international standards to local conditions. India's Bureau of Energy Efficiency has implemented star rating systems for heat exchange components in air conditioning and refrigeration systems, while Brazil's PROCEL program provides certification for energy-efficient industrial equipment including heat exchangers.

Carbon reduction initiatives further influence regulatory requirements, with many jurisdictions implementing carbon pricing mechanisms that indirectly incentivize high-efficiency heat exchanger designs. The EU Emissions Trading System and similar cap-and-trade programs in California and Quebec effectively monetize efficiency improvements by reducing carbon compliance costs for industrial operators utilizing advanced heat exchange technologies.

Compliance verification methodologies are becoming more sophisticated, with many regulatory bodies requiring detailed energy performance documentation throughout a product's lifecycle. This includes initial type testing, regular performance monitoring, and in some cases, real-time efficiency reporting through IoT-enabled systems. Manufacturers must increasingly design heat exchangers with these verification requirements in mind, incorporating monitoring capabilities and performance documentation features.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!