Evaluating Standards for Carbon-negative Concrete Lifecycle Sustainability

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Concrete, as one of the most widely used construction materials globally, has traditionally been associated with significant carbon emissions. The evolution of carbon-negative concrete technology represents a paradigm shift in construction materials science, moving from carbon-intensive processes toward solutions that actively remove carbon dioxide from the atmosphere. This technological trajectory began with conventional Portland cement concrete, which accounts for approximately 8% of global CO2 emissions, and has progressed through various stages of innovation aimed at reducing its environmental impact.

The development of carbon-negative concrete has been accelerated by increasing global awareness of climate change and the construction industry's substantial carbon footprint. Early efforts focused on reducing emissions through supplementary cementitious materials and alternative production methods. Recent breakthroughs have enabled the creation of concrete formulations that sequester more carbon than they emit throughout their lifecycle, representing a significant advancement in sustainable construction materials.

Current carbon-negative concrete technologies employ various mechanisms for carbon sequestration, including carbonation curing processes, incorporation of carbon-absorbing aggregates, and utilization of alternative binders derived from industrial byproducts. These innovations not only address environmental concerns but also often enhance concrete performance characteristics such as durability and strength, creating additional value propositions beyond sustainability.

The technical objectives for carbon-negative concrete development encompass several dimensions. Primary goals include achieving verifiable net carbon sequestration throughout the material's lifecycle, maintaining or improving structural performance compared to conventional concrete, ensuring economic viability for widespread adoption, and establishing standardized measurement protocols for carbon accounting. Additionally, researchers aim to optimize production processes for scalability and develop formulations adaptable to diverse geographic and climatic conditions.

Standardization represents a critical challenge in this emerging field. Current evaluation frameworks for concrete sustainability vary significantly across regions and organizations, creating inconsistencies in how carbon negativity is measured and verified. The establishment of comprehensive, internationally recognized standards for assessing the full lifecycle sustainability of carbon-negative concrete is essential for market acceptance, regulatory compliance, and accurate comparison of different solutions.

The trajectory of carbon-negative concrete technology points toward increasingly sophisticated carbon capture mechanisms, greater integration with circular economy principles, and enhanced performance characteristics. As this technology matures, the objectives expand beyond carbon sequestration to include broader sustainability metrics such as reduced water usage, minimized resource extraction, and improved end-of-life recyclability, reflecting a holistic approach to environmental impact assessment.

The development of carbon-negative concrete has been accelerated by increasing global awareness of climate change and the construction industry's substantial carbon footprint. Early efforts focused on reducing emissions through supplementary cementitious materials and alternative production methods. Recent breakthroughs have enabled the creation of concrete formulations that sequester more carbon than they emit throughout their lifecycle, representing a significant advancement in sustainable construction materials.

Current carbon-negative concrete technologies employ various mechanisms for carbon sequestration, including carbonation curing processes, incorporation of carbon-absorbing aggregates, and utilization of alternative binders derived from industrial byproducts. These innovations not only address environmental concerns but also often enhance concrete performance characteristics such as durability and strength, creating additional value propositions beyond sustainability.

The technical objectives for carbon-negative concrete development encompass several dimensions. Primary goals include achieving verifiable net carbon sequestration throughout the material's lifecycle, maintaining or improving structural performance compared to conventional concrete, ensuring economic viability for widespread adoption, and establishing standardized measurement protocols for carbon accounting. Additionally, researchers aim to optimize production processes for scalability and develop formulations adaptable to diverse geographic and climatic conditions.

Standardization represents a critical challenge in this emerging field. Current evaluation frameworks for concrete sustainability vary significantly across regions and organizations, creating inconsistencies in how carbon negativity is measured and verified. The establishment of comprehensive, internationally recognized standards for assessing the full lifecycle sustainability of carbon-negative concrete is essential for market acceptance, regulatory compliance, and accurate comparison of different solutions.

The trajectory of carbon-negative concrete technology points toward increasingly sophisticated carbon capture mechanisms, greater integration with circular economy principles, and enhanced performance characteristics. As this technology matures, the objectives expand beyond carbon sequestration to include broader sustainability metrics such as reduced water usage, minimized resource extraction, and improved end-of-life recyclability, reflecting a holistic approach to environmental impact assessment.

Market Analysis for Sustainable Construction Materials

The global sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. Currently valued at approximately $254 billion in 2023, this market is projected to reach $432 billion by 2028, representing a compound annual growth rate of 11.2%. Carbon-negative concrete specifically is emerging as a high-potential segment within this broader market, with early commercial applications showing promising adoption rates despite premium pricing.

Demand for carbon-negative concrete solutions is primarily concentrated in developed regions with stringent environmental regulations and carbon pricing mechanisms. North America and Europe collectively account for over 65% of current market demand, with particularly strong growth in Scandinavian countries, Germany, and the western United States. However, significant potential exists in rapidly urbanizing economies such as China and India, where construction volumes remain high and environmental policies are increasingly prioritizing sustainability.

The commercial building sector represents the largest application segment (38% of market share), followed by infrastructure projects (31%), residential construction (24%), and specialty applications (7%). Government infrastructure projects are proving particularly important as early adopters, with public procurement policies increasingly incorporating carbon footprint requirements that favor carbon-negative materials.

Market research indicates that customers are willing to pay a premium of 15-20% for carbon-negative concrete compared to conventional alternatives, provided that performance characteristics remain comparable and carbon reduction claims are verifiably certified. This price tolerance is highest among developers of premium commercial properties and public infrastructure projects with explicit sustainability mandates.

Key market drivers include increasingly stringent building codes and environmental regulations, growing corporate commitments to carbon neutrality, expanding green building certification programs, and the implementation of carbon pricing mechanisms in major markets. The EU's Carbon Border Adjustment Mechanism and similar policies emerging globally are creating strong financial incentives for low-carbon construction materials.

Barriers to wider market adoption include higher initial costs, limited production capacity, inconsistent regulatory standards for measuring carbon negativity, and technical concerns about long-term performance. The absence of universally accepted certification standards for carbon-negative concrete remains a significant market constraint, creating uncertainty for potential adopters and complicating procurement decisions.

Market forecasts suggest that carbon-negative concrete could capture 8-12% of the global concrete market by 2030, representing a potential market value exceeding $30 billion annually. This growth trajectory depends significantly on continued technological improvements, expanded production capacity, and the development of standardized certification frameworks that provide confidence in sustainability claims throughout the material lifecycle.

Demand for carbon-negative concrete solutions is primarily concentrated in developed regions with stringent environmental regulations and carbon pricing mechanisms. North America and Europe collectively account for over 65% of current market demand, with particularly strong growth in Scandinavian countries, Germany, and the western United States. However, significant potential exists in rapidly urbanizing economies such as China and India, where construction volumes remain high and environmental policies are increasingly prioritizing sustainability.

The commercial building sector represents the largest application segment (38% of market share), followed by infrastructure projects (31%), residential construction (24%), and specialty applications (7%). Government infrastructure projects are proving particularly important as early adopters, with public procurement policies increasingly incorporating carbon footprint requirements that favor carbon-negative materials.

Market research indicates that customers are willing to pay a premium of 15-20% for carbon-negative concrete compared to conventional alternatives, provided that performance characteristics remain comparable and carbon reduction claims are verifiably certified. This price tolerance is highest among developers of premium commercial properties and public infrastructure projects with explicit sustainability mandates.

Key market drivers include increasingly stringent building codes and environmental regulations, growing corporate commitments to carbon neutrality, expanding green building certification programs, and the implementation of carbon pricing mechanisms in major markets. The EU's Carbon Border Adjustment Mechanism and similar policies emerging globally are creating strong financial incentives for low-carbon construction materials.

Barriers to wider market adoption include higher initial costs, limited production capacity, inconsistent regulatory standards for measuring carbon negativity, and technical concerns about long-term performance. The absence of universally accepted certification standards for carbon-negative concrete remains a significant market constraint, creating uncertainty for potential adopters and complicating procurement decisions.

Market forecasts suggest that carbon-negative concrete could capture 8-12% of the global concrete market by 2030, representing a potential market value exceeding $30 billion annually. This growth trajectory depends significantly on continued technological improvements, expanded production capacity, and the development of standardized certification frameworks that provide confidence in sustainability claims throughout the material lifecycle.

Current Status and Challenges in Carbon-negative Concrete Development

Carbon-negative concrete development currently stands at a critical juncture globally, with significant advancements in research but limited commercial-scale implementation. Leading research institutions in Europe, North America, and Asia have demonstrated promising laboratory results, achieving carbon sequestration rates of 50-200 kg CO2 per cubic meter of concrete. However, these technologies face substantial challenges in scaling from laboratory to industrial production.

The primary technical challenge remains the development of reliable carbon capture mechanisms within the concrete manufacturing process. Current methods include direct air capture integration, mineralization processes, and novel cement formulations that actively absorb CO2 during curing. Each approach presents unique technical hurdles, particularly in maintaining structural integrity while maximizing carbon sequestration capacity.

Regulatory frameworks present another significant obstacle. The absence of standardized certification protocols for carbon-negative concrete creates market uncertainty. The European Union has made progress through its Carbon Border Adjustment Mechanism, but globally harmonized standards remain elusive. This regulatory fragmentation impedes investment and slows adoption rates across different regions.

Economic viability constitutes a third major challenge. Production costs for carbon-negative concrete currently exceed conventional concrete by 30-80%, depending on the technology employed. This premium primarily stems from energy-intensive carbon capture processes and specialized materials requirements. Without carbon pricing mechanisms or regulatory mandates, market penetration remains limited to niche applications and demonstration projects.

Supply chain constraints further complicate widespread adoption. Many carbon-negative concrete technologies require specialized materials or precise manufacturing conditions that existing concrete production facilities cannot easily accommodate. The industry faces a chicken-and-egg problem: manufacturers hesitate to invest in new infrastructure without guaranteed demand, while potential customers remain cautious about specifying materials without established supply chains.

Geographically, research leadership is concentrated in specific regions. Northern Europe, particularly Scandinavia and the Netherlands, leads in policy frameworks and commercial pilots. North American universities and startups have pioneered innovative carbon capture technologies, while China dominates in production capacity and implementation potential. This uneven development landscape creates both collaboration opportunities and competitive tensions in the emerging carbon-negative concrete ecosystem.

Performance verification represents the final significant challenge. Long-term durability data for carbon-negative concrete remains limited, creating uncertainty about lifecycle performance. Accelerated testing protocols have been developed but cannot fully simulate decades of real-world exposure and loading conditions. This knowledge gap necessitates conservative engineering approaches that may underutilize the material's potential benefits.

The primary technical challenge remains the development of reliable carbon capture mechanisms within the concrete manufacturing process. Current methods include direct air capture integration, mineralization processes, and novel cement formulations that actively absorb CO2 during curing. Each approach presents unique technical hurdles, particularly in maintaining structural integrity while maximizing carbon sequestration capacity.

Regulatory frameworks present another significant obstacle. The absence of standardized certification protocols for carbon-negative concrete creates market uncertainty. The European Union has made progress through its Carbon Border Adjustment Mechanism, but globally harmonized standards remain elusive. This regulatory fragmentation impedes investment and slows adoption rates across different regions.

Economic viability constitutes a third major challenge. Production costs for carbon-negative concrete currently exceed conventional concrete by 30-80%, depending on the technology employed. This premium primarily stems from energy-intensive carbon capture processes and specialized materials requirements. Without carbon pricing mechanisms or regulatory mandates, market penetration remains limited to niche applications and demonstration projects.

Supply chain constraints further complicate widespread adoption. Many carbon-negative concrete technologies require specialized materials or precise manufacturing conditions that existing concrete production facilities cannot easily accommodate. The industry faces a chicken-and-egg problem: manufacturers hesitate to invest in new infrastructure without guaranteed demand, while potential customers remain cautious about specifying materials without established supply chains.

Geographically, research leadership is concentrated in specific regions. Northern Europe, particularly Scandinavia and the Netherlands, leads in policy frameworks and commercial pilots. North American universities and startups have pioneered innovative carbon capture technologies, while China dominates in production capacity and implementation potential. This uneven development landscape creates both collaboration opportunities and competitive tensions in the emerging carbon-negative concrete ecosystem.

Performance verification represents the final significant challenge. Long-term durability data for carbon-negative concrete remains limited, creating uncertainty about lifecycle performance. Accelerated testing protocols have been developed but cannot fully simulate decades of real-world exposure and loading conditions. This knowledge gap necessitates conservative engineering approaches that may underutilize the material's potential benefits.

Existing Carbon-negative Concrete Formulations and Methods

01 Carbon sequestration in concrete production

Carbon-negative concrete can be produced by incorporating technologies that capture and store carbon dioxide during the manufacturing process. This includes using alternative cementitious materials that absorb CO2 during curing, implementing carbon capture systems at production facilities, and utilizing industrial by-products that have carbon-sequestering properties. These approaches can transform concrete from a carbon emitter to a carbon sink, significantly reducing its environmental footprint throughout its lifecycle.- Carbon capture and sequestration in concrete production: Technologies that capture carbon dioxide during concrete manufacturing or incorporate CO2 into the concrete mixture, resulting in a net reduction of carbon emissions. These methods involve injecting CO2 during the curing process, where it reacts with calcium compounds to form stable carbonates, effectively sequestering carbon while improving concrete strength and durability. This approach transforms traditional carbon-intensive concrete production into a carbon-negative process throughout its lifecycle.

- Alternative low-carbon binders and supplementary cementitious materials: The use of alternative binders and supplementary cementitious materials (SCMs) to replace traditional Portland cement, which significantly reduces the carbon footprint of concrete. These materials include industrial byproducts like fly ash, slag, silica fume, and natural pozzolans, as well as novel binders such as alkali-activated materials and geopolymers. These alternatives require less energy to produce and can result in concrete with lower embodied carbon while maintaining or improving performance characteristics.

- Life cycle assessment and carbon accounting methodologies: Comprehensive methodologies and systems for assessing the environmental impact of concrete throughout its entire lifecycle, from raw material extraction to end-of-life disposal or recycling. These approaches include standardized carbon accounting frameworks, digital tools for calculating embodied carbon, and certification systems that validate carbon-negative claims. Such methodologies enable accurate measurement of carbon footprints, identification of hotspots for improvement, and verification of sustainability claims in concrete production.

- Circular economy and end-of-life concrete management: Strategies for implementing circular economy principles in concrete production and use, focusing on recycling and repurposing concrete at the end of its service life. These approaches include crushing and reusing demolished concrete as aggregate in new concrete, developing reversible concrete systems that can be disassembled rather than demolished, and designing concrete structures for eventual deconstruction. These methods extend the carbon benefits of concrete by reducing the need for virgin materials and preventing waste.

- Biomass incorporation and biogenic materials in concrete: The integration of biomass and biogenic materials into concrete formulations to enhance carbon sequestration and improve sustainability. These innovations include incorporating agricultural waste products, wood fibers, algae, or other plant-based materials into concrete mixtures. Since these materials have captured carbon during their growth phase, their inclusion in concrete results in carbon storage throughout the material's lifecycle, contributing to the overall carbon-negative profile of the concrete while often providing additional benefits such as improved insulation or reduced weight.

02 Alternative binders and supplementary cementitious materials

The use of alternative binders and supplementary cementitious materials (SCMs) can reduce the carbon footprint of concrete. These include materials such as fly ash, slag, silica fume, and natural pozzolans that can partially replace traditional Portland cement. Additionally, novel binders like geopolymers and alkali-activated materials can be used to create concrete with significantly lower carbon emissions. These alternatives often require less energy to produce and can incorporate industrial waste products, contributing to a circular economy approach.Expand Specific Solutions03 Lifecycle assessment and sustainability metrics

Comprehensive lifecycle assessment (LCA) methodologies are essential for evaluating the true environmental impact of carbon-negative concrete. These assessments consider all stages from raw material extraction through manufacturing, use, and end-of-life disposal or recycling. Advanced sustainability metrics and digital tools help quantify carbon emissions, energy consumption, resource depletion, and other environmental indicators throughout the concrete's lifecycle, enabling more informed decision-making and continuous improvement in sustainable concrete production.Expand Specific Solutions04 Carbon offsetting and trading mechanisms

Carbon offsetting and trading mechanisms provide economic incentives for developing and implementing carbon-negative concrete technologies. These systems allow concrete producers to monetize their carbon reduction efforts through carbon credits, which can be traded in carbon markets. Blockchain and digital platforms are increasingly being used to verify, track, and trade carbon credits associated with sustainable concrete production, creating additional revenue streams for companies investing in green technologies while ensuring transparency and accountability in carbon accounting.Expand Specific Solutions05 End-of-life considerations and circular economy

Sustainable concrete lifecycle management includes considerations for end-of-life scenarios and circular economy principles. This involves designing concrete structures for disassembly, developing effective recycling technologies for concrete waste, and creating closed-loop systems where demolished concrete can be reused as aggregate in new concrete mixes. Advanced crushing and sorting technologies enable better recovery of materials from concrete waste, while innovative binding agents allow for higher percentages of recycled content in new concrete, reducing the need for virgin materials and further decreasing the carbon footprint.Expand Specific Solutions

Leading Organizations in Carbon-negative Concrete Innovation

The carbon-negative concrete lifecycle sustainability standards market is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The market is expanding rapidly, driven by global decarbonization initiatives, with projections suggesting significant growth as construction industries seek sustainable alternatives. From a technological maturity perspective, the field shows varied development levels across different regions. Academic institutions like Southeast University, Chongqing University, and University of Science & Technology Beijing are advancing fundamental research, while companies such as Clear Zero Carbon Technology, Sumitomo Osaka Cement, and Hazama Ando are developing commercial applications. The collaboration between research institutions and industry players like China Railway Construction Group and Nanjing Iron & Steel indicates a transition from laboratory research to practical implementation, though standardization remains a challenge requiring further development.

Clear Zero Carbon (Beijing) Technology Co., Ltd.

Technical Solution: Clear Zero Carbon has developed an integrated carbon accounting and verification system specifically for evaluating carbon-negative concrete throughout its lifecycle. Their methodology combines direct CO2 mineralization technology with comprehensive digital tracking using blockchain-based verification. The company's CarbonTrack platform monitors carbon flows from raw material extraction through end-of-life, employing IoT sensors to collect real-time data on carbon sequestration rates during curing and service life. Their standards require concrete products to demonstrate net negative emissions of at least 100kg CO2e per cubic meter over a 50-year lifecycle, with third-party verification at key stages. The company's approach incorporates both direct (Scope 1) emissions from production processes and indirect (Scope 2 & 3) emissions from energy use and supply chain activities, providing a complete carbon footprint analysis that meets international reporting standards. Their methodology also includes specific protocols for quantifying carbon mineralization rates under various environmental conditions.

Strengths: Advanced digital tracking and verification system provides transparent, tamper-proof carbon accounting; comprehensive scope coverage ensures all relevant emissions sources are captured. Weaknesses: Complex implementation requirements may limit adoption by smaller concrete producers; relatively new technology with limited long-term performance data.

Sumitomo Osaka Cement Co., Ltd.

Technical Solution: Sumitomo Osaka Cement has developed a comprehensive carbon-negative concrete lifecycle assessment framework that integrates CO2 capture during cement production with innovative carbonation curing techniques. Their approach combines traditional Portland cement with supplementary cementitious materials (SCMs) like fly ash and blast furnace slag at optimized ratios to reduce initial carbon footprint. The company's proprietary Carbon Recapture Technology enables absorption of atmospheric CO2 during concrete curing, potentially sequestering up to 300kg of CO2 per cubic meter of concrete. Their lifecycle assessment methodology tracks carbon emissions across raw material extraction, manufacturing, transportation, construction, use phase, and end-of-life recycling, with third-party verification protocols to ensure credibility of carbon negativity claims. Sumitomo's standards include specific metrics for embodied carbon reduction, operational carbon sequestration rates, and total lifecycle carbon balance.

Strengths: Established industrial-scale production capabilities with integrated carbon capture systems; comprehensive lifecycle assessment methodology with third-party verification protocols. Weaknesses: Technology requires specific curing conditions that may limit application in certain construction environments; higher initial production costs compared to conventional concrete solutions.

Key Patents and Research in CO2 Sequestration for Concrete

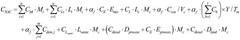

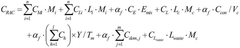

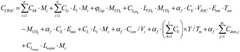

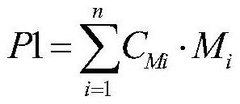

Evaluation method for full-life-cycle carbon benefit of green low-carbon concrete

PatentActiveCN119648015A

Innovation

- By dividing the full life cycle of concrete into 14 stages, the carbon dioxide emissions in each stage are calculated separately, and the life cycle carbon dioxide emissions are calculated based on the life cycle of different types of concrete, the net carbon dioxide benefits of regenerated aggregate concrete and carbonized modified regenerated aggregate concrete are determined.

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Lifecycle Assessment Methodologies for Carbon-negative Materials

Lifecycle Assessment Methodologies for Carbon-negative Materials represent a critical framework for evaluating the environmental performance of innovative construction materials. These methodologies have evolved significantly over the past decade, transitioning from simplified carbon accounting to comprehensive cradle-to-grave analyses that capture the full environmental impact spectrum.

The ISO 14040 and 14044 standards provide the foundational structure for conducting lifecycle assessments (LCAs) of carbon-negative concrete. However, these general frameworks require adaptation to address the unique characteristics of carbon-negative materials, particularly their carbon sequestration capabilities during production and service life.

Current methodologies typically divide the concrete lifecycle into distinct phases: raw material extraction, manufacturing, transportation, construction, use phase, and end-of-life. For carbon-negative concrete specifically, methodologies must accurately account for carbon dioxide removal during the curing process, which represents a fundamental departure from traditional concrete LCA approaches.

The Environmental Product Declaration (EPD) system has emerged as a standardized method for communicating LCA results, though existing EPD frameworks often struggle to properly represent negative emissions. This has prompted research into modified EPD formats specifically designed for carbon-negative materials, with organizations like the Carbon Leadership Forum leading development efforts.

Boundary definition represents a significant methodological challenge, as carbon-negative concrete assessments must consider both direct and indirect emissions across the value chain. The temporal dimension adds further complexity, as carbon sequestration benefits may extend decades beyond initial installation, requiring dynamic modeling approaches rather than static assessments.

Recent methodological innovations include the integration of uncertainty analysis through Monte Carlo simulations, allowing for more robust evaluation of carbon-negative claims. Additionally, consequential LCA approaches are gaining traction as they better capture market-mediated effects and potential leakage issues compared to traditional attributional methods.

Data quality remains a persistent challenge, with many assessments relying on proxy data or theoretical models rather than empirical measurements. This has prompted calls for standardized data collection protocols specific to carbon-negative materials, with several industry consortia working to establish open-access databases to support more accurate assessments.

The emergence of digital material passports and blockchain-based traceability systems offers promising avenues for improving data integrity throughout the assessment process, potentially enabling real-time monitoring of carbon performance across the concrete lifecycle.

The ISO 14040 and 14044 standards provide the foundational structure for conducting lifecycle assessments (LCAs) of carbon-negative concrete. However, these general frameworks require adaptation to address the unique characteristics of carbon-negative materials, particularly their carbon sequestration capabilities during production and service life.

Current methodologies typically divide the concrete lifecycle into distinct phases: raw material extraction, manufacturing, transportation, construction, use phase, and end-of-life. For carbon-negative concrete specifically, methodologies must accurately account for carbon dioxide removal during the curing process, which represents a fundamental departure from traditional concrete LCA approaches.

The Environmental Product Declaration (EPD) system has emerged as a standardized method for communicating LCA results, though existing EPD frameworks often struggle to properly represent negative emissions. This has prompted research into modified EPD formats specifically designed for carbon-negative materials, with organizations like the Carbon Leadership Forum leading development efforts.

Boundary definition represents a significant methodological challenge, as carbon-negative concrete assessments must consider both direct and indirect emissions across the value chain. The temporal dimension adds further complexity, as carbon sequestration benefits may extend decades beyond initial installation, requiring dynamic modeling approaches rather than static assessments.

Recent methodological innovations include the integration of uncertainty analysis through Monte Carlo simulations, allowing for more robust evaluation of carbon-negative claims. Additionally, consequential LCA approaches are gaining traction as they better capture market-mediated effects and potential leakage issues compared to traditional attributional methods.

Data quality remains a persistent challenge, with many assessments relying on proxy data or theoretical models rather than empirical measurements. This has prompted calls for standardized data collection protocols specific to carbon-negative materials, with several industry consortia working to establish open-access databases to support more accurate assessments.

The emergence of digital material passports and blockchain-based traceability systems offers promising avenues for improving data integrity throughout the assessment process, potentially enabling real-time monitoring of carbon performance across the concrete lifecycle.

Regulatory Framework and Policy Incentives for Green Construction

The regulatory landscape for carbon-negative concrete is evolving rapidly as governments worldwide recognize the construction sector's significant environmental impact. Current regulatory frameworks primarily focus on emission reduction targets, building codes, and procurement policies that incentivize sustainable construction practices. The European Union leads with its Green Deal and Circular Economy Action Plan, which specifically addresses construction materials through mandatory carbon footprint declarations and progressive carbon intensity limits for concrete production.

In the United States, a patchwork of state and local regulations exists, with California's Buy Clean California Act setting precedent by requiring Environmental Product Declarations (EPDs) for construction materials used in state-funded projects. This approach is gradually being adopted by other states, creating market pressure for low-carbon concrete solutions. At the federal level, the Inflation Reduction Act includes provisions for sustainable building materials, offering tax credits for manufacturers who reduce embodied carbon in construction materials.

Policy incentives for green construction have expanded significantly in recent years, moving beyond traditional energy efficiency measures to address embodied carbon in materials. Financial mechanisms include tax rebates, accelerated permitting processes, density bonuses, and preferential financing terms for projects utilizing carbon-negative concrete. The most effective policies combine "push" strategies (regulations mandating minimum performance) with "pull" incentives (financial benefits for exceeding standards).

Procurement policies represent another powerful lever, with governments increasingly using their purchasing power to drive market transformation. Several jurisdictions have implemented carbon-based procurement criteria that award contracts based partly on the carbon footprint of materials used. These policies create immediate market demand for innovative solutions while allowing the industry time to scale production capacity.

International standards organizations are working to harmonize measurement methodologies for embodied carbon, with ISO 14067 and EN 15804 providing frameworks for carbon footprint calculation. However, specific standards for carbon-negative concrete remain under development, creating challenges for cross-border recognition of environmental claims and benefits.

The regulatory gap between developed and developing economies presents both challenges and opportunities. While advanced economies implement stringent carbon regulations, emerging markets often prioritize rapid infrastructure development with fewer environmental constraints. This dichotomy creates potential for technology transfer programs and international climate finance mechanisms to accelerate adoption of carbon-negative concrete technologies in high-growth construction markets where the greatest volume of future concrete will be consumed.

In the United States, a patchwork of state and local regulations exists, with California's Buy Clean California Act setting precedent by requiring Environmental Product Declarations (EPDs) for construction materials used in state-funded projects. This approach is gradually being adopted by other states, creating market pressure for low-carbon concrete solutions. At the federal level, the Inflation Reduction Act includes provisions for sustainable building materials, offering tax credits for manufacturers who reduce embodied carbon in construction materials.

Policy incentives for green construction have expanded significantly in recent years, moving beyond traditional energy efficiency measures to address embodied carbon in materials. Financial mechanisms include tax rebates, accelerated permitting processes, density bonuses, and preferential financing terms for projects utilizing carbon-negative concrete. The most effective policies combine "push" strategies (regulations mandating minimum performance) with "pull" incentives (financial benefits for exceeding standards).

Procurement policies represent another powerful lever, with governments increasingly using their purchasing power to drive market transformation. Several jurisdictions have implemented carbon-based procurement criteria that award contracts based partly on the carbon footprint of materials used. These policies create immediate market demand for innovative solutions while allowing the industry time to scale production capacity.

International standards organizations are working to harmonize measurement methodologies for embodied carbon, with ISO 14067 and EN 15804 providing frameworks for carbon footprint calculation. However, specific standards for carbon-negative concrete remain under development, creating challenges for cross-border recognition of environmental claims and benefits.

The regulatory gap between developed and developing economies presents both challenges and opportunities. While advanced economies implement stringent carbon regulations, emerging markets often prioritize rapid infrastructure development with fewer environmental constraints. This dichotomy creates potential for technology transfer programs and international climate finance mechanisms to accelerate adoption of carbon-negative concrete technologies in high-growth construction markets where the greatest volume of future concrete will be consumed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!