Exploring Biodegradable Ethylene Vinyl Acetate Alternatives

EVA Alternatives Background and Objectives

Ethylene Vinyl Acetate (EVA) has been a cornerstone material in various industries for decades, prized for its versatility, durability, and cost-effectiveness. However, the growing global concern over environmental sustainability has sparked a critical need to explore biodegradable alternatives to this widely used polymer. This technological shift is driven by increasing environmental regulations, consumer demand for eco-friendly products, and corporate sustainability initiatives.

The primary objective of this research is to investigate and evaluate potential biodegradable substitutes for EVA that can match or exceed its performance characteristics while significantly reducing environmental impact. This exploration aims to address the end-of-life challenges associated with traditional EVA products, which often contribute to plastic pollution and landfill accumulation due to their non-biodegradable nature.

The evolution of biodegradable materials has seen significant advancements in recent years, with innovations in biopolymers and composite materials offering promising alternatives. These developments have been fueled by breakthroughs in material science, biotechnology, and green chemistry. The trend towards sustainable materials is not only a response to environmental concerns but also an opportunity for innovation and market differentiation.

Key areas of focus in this technological exploration include the development of bio-based EVA alternatives, the enhancement of existing biodegradable polymers to match EVA's properties, and the creation of novel composite materials that combine biodegradability with high performance. The research also aims to understand the degradation mechanisms of these alternatives under various environmental conditions to ensure their practical applicability.

This technological pursuit is set against a backdrop of changing global policies and industry standards that increasingly favor sustainable materials. The European Union's Single-Use Plastics Directive and similar initiatives worldwide have created a regulatory environment that encourages the adoption of biodegradable alternatives. This shift presents both challenges and opportunities for material scientists, manufacturers, and end-users across multiple sectors.

The successful development of biodegradable EVA alternatives has the potential to revolutionize industries ranging from packaging and consumer goods to construction and automotive. It could lead to a new generation of products that maintain the desired functional properties while offering improved end-of-life options, such as composting or biodegradation in natural environments.

As we embark on this exploration, it is crucial to consider not only the technical aspects of material development but also the broader implications for supply chains, manufacturing processes, and consumer behavior. The ultimate goal is to identify and develop solutions that are not only environmentally sustainable but also economically viable and technically feasible for large-scale adoption.

Market Demand for Biodegradable Polymers

The market demand for biodegradable polymers has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on plastic waste. This trend is particularly relevant for industries seeking alternatives to conventional ethylene vinyl acetate (EVA) materials.

Consumer awareness regarding the environmental impact of non-biodegradable plastics has led to a shift in preferences towards more sustainable products. This change in consumer behavior has created a substantial market opportunity for biodegradable polymers across various sectors, including packaging, agriculture, textiles, and consumer goods.

The packaging industry represents one of the largest markets for biodegradable polymers, with a growing demand for eco-friendly packaging solutions. Food packaging, in particular, has seen a surge in the adoption of biodegradable materials as companies strive to reduce their environmental footprint and meet consumer expectations for sustainable packaging options.

In the agricultural sector, biodegradable polymers are gaining traction for applications such as mulch films, seed coatings, and controlled-release fertilizers. These materials offer the advantage of decomposing naturally in the soil, eliminating the need for removal and reducing plastic pollution in agricultural environments.

The textile industry is another significant market for biodegradable polymers, with increasing demand for sustainable fibers and fabrics. Biodegradable alternatives to synthetic materials are being sought after for applications in clothing, footwear, and home textiles, driven by consumer preferences for eco-friendly fashion and home products.

The automotive and construction industries are also exploring biodegradable polymer alternatives to traditional EVA materials for applications such as insulation, sealants, and adhesives. This shift is driven by both environmental concerns and the potential for improved performance characteristics offered by some biodegradable polymers.

Government regulations and initiatives aimed at reducing plastic waste and promoting sustainable materials have further bolstered the market demand for biodegradable polymers. Many countries have implemented or are considering bans on single-use plastics, creating a favorable regulatory environment for the adoption of biodegradable alternatives.

The global market for biodegradable polymers is projected to continue its growth trajectory in the coming years. Factors such as technological advancements in polymer science, increasing investment in research and development, and the expansion of production capacities are expected to contribute to market growth and drive down costs, making biodegradable polymers more competitive with traditional materials.

As the search for biodegradable alternatives to EVA intensifies, the market is likely to see the emergence of new materials and applications. This presents opportunities for innovation and product development across various industries, potentially reshaping supply chains and manufacturing processes to accommodate these sustainable materials.

Current Challenges in Biodegradable EVA Development

The development of biodegradable alternatives to Ethylene Vinyl Acetate (EVA) faces several significant challenges. One of the primary obstacles is achieving comparable performance characteristics to traditional EVA while maintaining biodegradability. EVA's unique combination of flexibility, durability, and chemical resistance makes it difficult to replicate with biodegradable materials.

Material scientists are grappling with the complex task of developing biodegradable polymers that can match EVA's versatility across various applications, from packaging to footwear. The challenge lies in creating a material that not only biodegrades but also maintains its structural integrity and functional properties throughout its intended lifespan.

Another hurdle is the cost-effectiveness of biodegradable alternatives. Currently, most biodegradable materials are significantly more expensive to produce than conventional EVA, making widespread adoption challenging. This economic barrier is particularly pronounced in industries where profit margins are slim, and material costs play a crucial role in product pricing.

The degradation rate and environmental impact of biodegradable EVA alternatives also present challenges. Researchers must carefully balance the material's ability to break down in natural environments with its durability during use. Achieving a predictable and controllable degradation rate that aligns with various product lifecycles and disposal scenarios is a complex task.

Furthermore, the scalability of production processes for biodegradable EVA alternatives remains a significant challenge. Many promising materials developed in laboratory settings face difficulties in scaling up to industrial production levels. This includes issues related to consistent quality, processing techniques, and equipment compatibility.

Regulatory hurdles and standardization issues also complicate the development and adoption of biodegradable EVA alternatives. The lack of universally accepted standards for biodegradability and compostability creates uncertainty for manufacturers and consumers alike. Navigating the complex landscape of environmental regulations and certifications across different regions adds another layer of difficulty to the development process.

Lastly, the challenge of consumer education and market acceptance cannot be overlooked. While there is growing awareness of environmental issues, convincing consumers and industries to switch from well-established EVA products to biodegradable alternatives requires significant effort in marketing, education, and demonstration of long-term benefits.

Existing Biodegradable EVA Alternative Solutions

01 Biodegradable polymer blends as EVA alternatives

Biodegradable polymer blends can be used as alternatives to EVA. These blends often incorporate natural polymers or biodegradable synthetic polymers to create materials with similar properties to EVA but with improved biodegradability. The blends may include components such as starch, polylactic acid (PLA), or other biopolymers, which can break down more easily in the environment.- Biodegradable polymer blends as EVA alternatives: Various biodegradable polymer blends can be used as alternatives to EVA. These blends often incorporate natural polymers or biopolymers that can degrade under specific environmental conditions. The blends may include combinations of starch, polylactic acid (PLA), polyhydroxyalkanoates (PHA), or other biodegradable materials to achieve desired properties while maintaining biodegradability.

- Biodegradable additives for enhancing EVA biodegradability: Incorporating biodegradable additives into EVA formulations can enhance their overall biodegradability. These additives may include natural fibers, organic fillers, or specific enzymes that promote the breakdown of the polymer structure. By carefully selecting and integrating these additives, the biodegradation rate of EVA-based products can be significantly improved.

- Bio-based alternatives to EVA with improved biodegradability: Development of bio-based materials as alternatives to EVA focuses on utilizing renewable resources to create polymers with similar properties but enhanced biodegradability. These alternatives may be derived from plant-based sources such as vegetable oils, cellulose, or other biomass. The resulting materials aim to provide comparable performance to EVA while offering improved end-of-life biodegradation.

- Modification of EVA to enhance biodegradability: Chemical or physical modifications of EVA can be employed to improve its biodegradability. These modifications may involve introducing functional groups that are more susceptible to microbial attack, altering the polymer structure to increase its hydrophilicity, or creating more accessible degradation sites within the polymer chain. Such modifications aim to maintain EVA's desirable properties while facilitating its breakdown in the environment.

- Composite materials as biodegradable EVA alternatives: Composite materials combining biodegradable polymers with natural fibers or inorganic fillers can serve as alternatives to EVA with improved biodegradability. These composites may utilize materials such as natural rubber, cellulose fibers, or biodegradable polyesters as the matrix, reinforced with various sustainable fillers. The resulting composites aim to provide similar functionality to EVA while offering enhanced environmental compatibility.

02 Biodegradable foam materials

Biodegradable foam materials can be developed as alternatives to EVA foam. These materials often use renewable resources and are designed to decompose naturally in the environment. They may incorporate plant-based ingredients, modified starches, or other biodegradable polymers to create foam structures with properties similar to EVA foam but with enhanced biodegradability.Expand Specific Solutions03 Composite materials with improved biodegradability

Composite materials that combine biodegradable polymers with natural fibers or other biodegradable reinforcements can serve as alternatives to EVA. These composites aim to maintain the desirable properties of EVA while improving overall biodegradability. The incorporation of natural fibers or biodegradable fillers can enhance the material's ability to break down in the environment.Expand Specific Solutions04 Modified biodegradable polymers

Existing biodegradable polymers can be modified to improve their properties and make them more suitable as EVA alternatives. This may involve chemical modifications, blending with other biodegradable materials, or the use of additives to enhance specific characteristics. The goal is to create materials that match EVA's performance while maintaining biodegradability.Expand Specific Solutions05 Biodegradable adhesives and sealants

Biodegradable adhesives and sealants can be developed to replace EVA-based products in certain applications. These materials are designed to provide similar bonding or sealing properties to EVA while being able to break down naturally in the environment. They may incorporate biodegradable polymers, natural resins, or other eco-friendly components to achieve the desired functionality and biodegradability.Expand Specific Solutions

Key Players in Biodegradable Polymer Industry

The exploration of biodegradable Ethylene Vinyl Acetate (EVA) alternatives is currently in a transitional phase, with the market showing significant growth potential. The global biodegradable plastics market, which includes EVA alternatives, is projected to expand rapidly due to increasing environmental concerns and stringent regulations. Companies like Eastman Chemical Co., Braskem SA, and LG Chem Ltd. are at the forefront of developing sustainable materials, leveraging their expertise in polymer science and bio-based technologies. The technology is advancing, with various biodegradable options being researched and commercialized, but full market maturity is yet to be achieved. Collaborations between industry leaders and research institutions, such as Washington State University and Centre National de la Recherche Scientifique, are accelerating innovation in this field.

Eastman Chemical Co.

BIOTEC Biologische Naturverpackungen GmbH & Co. KG

Core Innovations in Biodegradable Polymer Research

- Combining biodegradable fiber or paper substrate with ethylene vinyl acetate for use in cigarette filters.

- Creating a bicomponent fiber with ethylene vinyl acetate as a coating around a biodegradable core material.

- Incorporating both biodegradable and non-biodegradable materials in the filter design.

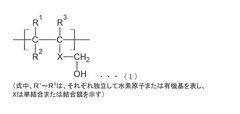

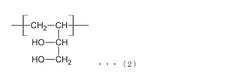

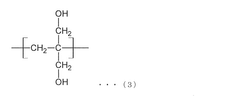

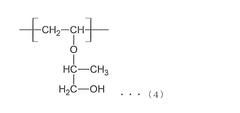

- A modified ethylene-vinyl alcohol resin with a specific range of ethylene structural units (1 to 16.5 mol%) and a structural unit containing a primary hydroxyl group in the side chain, which enhances biodegradability by improving hydrophilicity and accessibility for bacteria, while maintaining gas barrier properties.

Environmental Impact Assessment

The environmental impact assessment of biodegradable alternatives to Ethylene Vinyl Acetate (EVA) is crucial for understanding their potential benefits and drawbacks. These alternatives aim to address the environmental concerns associated with traditional EVA, which is non-biodegradable and contributes to plastic pollution.

Biodegradable EVA alternatives typically offer reduced environmental persistence compared to conventional EVA. When properly disposed of in suitable conditions, these materials can break down into natural components, potentially mitigating long-term ecological impacts. This biodegradability can significantly reduce the accumulation of plastic waste in landfills and marine environments.

However, the environmental benefits of these alternatives must be carefully evaluated across their entire lifecycle. The production process of biodegradable EVA alternatives may require different raw materials and manufacturing techniques, which could potentially have their own environmental implications. Energy consumption, water usage, and greenhouse gas emissions during production should be thoroughly assessed and compared to those of traditional EVA manufacturing.

The degradation process of these alternatives also warrants close examination. While biodegradability is generally viewed positively, it's essential to consider the byproducts of degradation and their potential effects on soil and water ecosystems. Some biodegradable plastics may leave behind microplastics or other residues that could have unforeseen environmental consequences.

Another critical aspect of the environmental impact assessment is the end-of-life management of these materials. The infrastructure and processes for collecting, sorting, and properly disposing of biodegradable EVA alternatives must be evaluated. If these materials are not correctly managed, their environmental benefits may not be fully realized.

The potential for these alternatives to contaminate recycling streams for conventional plastics should also be considered. Mixing biodegradable and non-biodegradable plastics can complicate recycling processes and potentially reduce the quality of recycled materials.

Furthermore, the assessment should include an analysis of the materials' performance in various applications. If biodegradable alternatives have shorter lifespans or require more frequent replacement than traditional EVA, this could lead to increased resource consumption and waste generation over time.

Lastly, the environmental impact assessment should consider the broader implications of transitioning to biodegradable EVA alternatives. This includes potential changes in consumer behavior, industry practices, and waste management systems. A holistic approach that considers both direct and indirect environmental effects is essential for a comprehensive understanding of these materials' ecological footprint.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in shaping the development, production, and adoption of alternatives to traditional ethylene vinyl acetate (EVA). As the global focus on sustainability intensifies, governments and international organizations are establishing increasingly stringent guidelines and standards for biodegradable materials.

At the forefront of these regulations is the European Union (EU), which has implemented comprehensive policies through its Waste Framework Directive and Packaging and Packaging Waste Directive. These directives set clear targets for recycling and biodegradability, pushing manufacturers to innovate in the field of sustainable materials. The EU has also introduced the EN 13432 standard, which specifies requirements for packaging recoverable through composting and biodegradation.

In the United States, the Federal Trade Commission (FTC) has established Green Guides to prevent deceptive marketing claims about environmental benefits, including biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims, ensuring transparency and preventing greenwashing.

The International Organization for Standardization (ISO) has developed several standards related to biodegradable materials, including ISO 17088 for compostable plastics and ISO 14855 for determining the ultimate aerobic biodegradability of plastic materials. These standards provide a global framework for testing and certifying biodegradable materials, facilitating international trade and harmonization of practices.

Emerging economies, particularly China and India, are also implementing regulations to address the environmental impact of non-biodegradable materials. China's ban on certain types of plastic waste imports has accelerated the development of biodegradable alternatives, while India has introduced strict regulations on single-use plastics, promoting the use of biodegradable materials.

The regulatory landscape is continuously evolving, with many countries introducing extended producer responsibility (EPR) schemes. These schemes hold manufacturers accountable for the entire lifecycle of their products, including disposal, further incentivizing the development of biodegradable alternatives to EVA.

As the search for biodegradable EVA alternatives progresses, manufacturers must navigate this complex regulatory environment. Compliance with these regulations not only ensures market access but also drives innovation in material science. The challenge lies in developing materials that meet both the performance requirements of EVA and the stringent biodegradability standards set by various regulatory bodies.