Exploring Ethylene Vinyl Acetate in Sports Equipment

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA in Sports Equipment: Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a revolutionary material in the sports equipment industry, transforming the performance and comfort of various athletic gear. The evolution of EVA in sports applications can be traced back to the 1970s when it was first introduced in footwear. Since then, its use has expanded to a wide range of sports equipment, including midsoles, insoles, padding, and protective gear.

The primary objective of exploring EVA in sports equipment is to enhance athlete performance, improve safety, and increase comfort. EVA's unique properties, such as its lightweight nature, excellent shock absorption, and durability, make it an ideal material for these purposes. As the sports industry continues to evolve, there is a growing demand for materials that can withstand intense use while providing optimal support and protection.

The development of EVA technology in sports equipment has been driven by several factors. Advancements in polymer science have led to improved formulations, allowing for better customization of EVA properties to suit specific sports applications. Additionally, the increasing focus on athlete health and injury prevention has spurred research into materials that can effectively absorb impact and reduce stress on the body.

In recent years, the sports equipment market has seen a surge in demand for sustainable and eco-friendly materials. This trend has prompted researchers and manufacturers to explore bio-based alternatives and recycling methods for EVA, aligning with the industry's growing commitment to environmental responsibility.

The global sports equipment market, valued at over $300 billion in 2021, is expected to continue its growth trajectory, with EVA playing a crucial role in this expansion. The material's versatility allows for its application in diverse sports, from running shoes to ski boots, tennis rackets to protective helmets. This widespread adoption has led to ongoing research and development efforts to further enhance EVA's properties and explore new applications.

As we delve deeper into the exploration of EVA in sports equipment, it is essential to consider the technological advancements that have shaped its current state and the potential innovations that lie ahead. The continuous improvement of EVA formulations, manufacturing processes, and integration techniques with other materials presents exciting opportunities for the future of sports equipment design and performance enhancement.

The primary objective of exploring EVA in sports equipment is to enhance athlete performance, improve safety, and increase comfort. EVA's unique properties, such as its lightweight nature, excellent shock absorption, and durability, make it an ideal material for these purposes. As the sports industry continues to evolve, there is a growing demand for materials that can withstand intense use while providing optimal support and protection.

The development of EVA technology in sports equipment has been driven by several factors. Advancements in polymer science have led to improved formulations, allowing for better customization of EVA properties to suit specific sports applications. Additionally, the increasing focus on athlete health and injury prevention has spurred research into materials that can effectively absorb impact and reduce stress on the body.

In recent years, the sports equipment market has seen a surge in demand for sustainable and eco-friendly materials. This trend has prompted researchers and manufacturers to explore bio-based alternatives and recycling methods for EVA, aligning with the industry's growing commitment to environmental responsibility.

The global sports equipment market, valued at over $300 billion in 2021, is expected to continue its growth trajectory, with EVA playing a crucial role in this expansion. The material's versatility allows for its application in diverse sports, from running shoes to ski boots, tennis rackets to protective helmets. This widespread adoption has led to ongoing research and development efforts to further enhance EVA's properties and explore new applications.

As we delve deeper into the exploration of EVA in sports equipment, it is essential to consider the technological advancements that have shaped its current state and the potential innovations that lie ahead. The continuous improvement of EVA formulations, manufacturing processes, and integration techniques with other materials presents exciting opportunities for the future of sports equipment design and performance enhancement.

Market Analysis for EVA-based Sports Products

The global market for EVA-based sports products has experienced significant growth in recent years, driven by increasing consumer awareness of the material's benefits and the rising popularity of sports and fitness activities worldwide. EVA, or Ethylene Vinyl Acetate, has become a preferred material in the sports equipment industry due to its excellent shock absorption, durability, and lightweight properties.

The sports footwear segment dominates the EVA-based sports products market, with running shoes, training shoes, and athletic footwear being the primary applications. The demand for comfortable and performance-enhancing footwear has led to a surge in the use of EVA in midsoles and insoles. Major sportswear brands such as Nike, Adidas, and Under Armour have incorporated EVA technology into their product lines, further driving market growth.

In addition to footwear, EVA has found applications in various other sports equipment categories. These include yoga mats, protective gear such as helmets and padding, and sports flooring. The versatility of EVA has allowed manufacturers to develop innovative products that cater to diverse sporting needs, expanding the market's reach across different sports disciplines.

The Asia-Pacific region has emerged as the largest market for EVA-based sports products, attributed to the growing sports participation rates, increasing disposable income, and the presence of major manufacturing hubs in countries like China and Vietnam. North America and Europe follow closely, with mature markets that continue to demand high-quality sports equipment.

Market trends indicate a growing preference for sustainable and eco-friendly sports products. This has led to the development of bio-based EVA materials and recycling initiatives for EVA products, aligning with the increasing environmental consciousness among consumers. Manufacturers are investing in research and development to create more sustainable EVA formulations without compromising on performance.

The COVID-19 pandemic has had a mixed impact on the EVA-based sports products market. While the closure of gyms and sports facilities initially led to a decline in demand, the subsequent rise in home fitness activities and outdoor sports has created new opportunities for EVA product manufacturers. The market has shown resilience and is expected to recover strongly as sports activities resume to pre-pandemic levels.

Looking ahead, the market for EVA-based sports products is projected to continue its growth trajectory. Factors such as the rising health awareness, increasing sports participation rates, and technological advancements in EVA formulations are expected to drive market expansion. The integration of smart technologies with EVA-based products, such as sensor-embedded footwear, presents exciting possibilities for future market development.

The sports footwear segment dominates the EVA-based sports products market, with running shoes, training shoes, and athletic footwear being the primary applications. The demand for comfortable and performance-enhancing footwear has led to a surge in the use of EVA in midsoles and insoles. Major sportswear brands such as Nike, Adidas, and Under Armour have incorporated EVA technology into their product lines, further driving market growth.

In addition to footwear, EVA has found applications in various other sports equipment categories. These include yoga mats, protective gear such as helmets and padding, and sports flooring. The versatility of EVA has allowed manufacturers to develop innovative products that cater to diverse sporting needs, expanding the market's reach across different sports disciplines.

The Asia-Pacific region has emerged as the largest market for EVA-based sports products, attributed to the growing sports participation rates, increasing disposable income, and the presence of major manufacturing hubs in countries like China and Vietnam. North America and Europe follow closely, with mature markets that continue to demand high-quality sports equipment.

Market trends indicate a growing preference for sustainable and eco-friendly sports products. This has led to the development of bio-based EVA materials and recycling initiatives for EVA products, aligning with the increasing environmental consciousness among consumers. Manufacturers are investing in research and development to create more sustainable EVA formulations without compromising on performance.

The COVID-19 pandemic has had a mixed impact on the EVA-based sports products market. While the closure of gyms and sports facilities initially led to a decline in demand, the subsequent rise in home fitness activities and outdoor sports has created new opportunities for EVA product manufacturers. The market has shown resilience and is expected to recover strongly as sports activities resume to pre-pandemic levels.

Looking ahead, the market for EVA-based sports products is projected to continue its growth trajectory. Factors such as the rising health awareness, increasing sports participation rates, and technological advancements in EVA formulations are expected to drive market expansion. The integration of smart technologies with EVA-based products, such as sensor-embedded footwear, presents exciting possibilities for future market development.

Current EVA Technology and Challenges in Sports Gear

Ethylene Vinyl Acetate (EVA) has become a cornerstone material in sports equipment manufacturing, offering a unique combination of properties that make it ideal for various applications. In the current landscape, EVA technology is widely utilized in the production of midsoles for athletic shoes, padding for protective gear, and components in sports accessories.

The primary advantage of EVA in sports gear lies in its excellent shock absorption and cushioning properties. This characteristic is particularly crucial in footwear, where it helps reduce the impact on joints during high-intensity activities. Modern EVA foams used in sports equipment are engineered to provide optimal energy return, enhancing athletic performance while maintaining comfort.

However, the current EVA technology faces several challenges in the sports equipment industry. One significant issue is the material's tendency to compress over time, leading to a reduction in its shock-absorbing capabilities. This compression set problem affects the longevity of sports products, particularly in high-wear areas such as shoe midsoles.

Another challenge is achieving the right balance between cushioning and stability. While softer EVA foams offer better shock absorption, they may compromise stability, which is critical in many sports applications. Manufacturers are continually working to develop EVA formulations that can provide both adequate cushioning and necessary support.

The environmental impact of EVA production and disposal is also a growing concern. Traditional EVA materials are not biodegradable, contributing to long-term environmental issues. The sports industry is under increasing pressure to develop more sustainable alternatives or improve the recyclability of EVA-based products.

Durability remains a challenge, especially in outdoor sports equipment exposed to varying weather conditions. UV radiation and extreme temperatures can degrade EVA over time, affecting its performance and appearance. Researchers are exploring ways to enhance EVA's resistance to environmental factors without compromising its desirable properties.

In response to these challenges, recent technological advancements have focused on developing EVA composites and blends. These innovations aim to enhance the material's overall performance, addressing issues such as compression set, durability, and environmental impact. Some promising developments include the incorporation of nanoparticles to improve strength and resilience, and the exploration of bio-based EVA alternatives to increase sustainability.

The sports equipment industry is also witnessing a trend towards customization, with manufacturers seeking ways to tailor EVA properties to specific sports or even individual athletes. This customization presents both opportunities and challenges, requiring more sophisticated manufacturing processes and material formulations.

The primary advantage of EVA in sports gear lies in its excellent shock absorption and cushioning properties. This characteristic is particularly crucial in footwear, where it helps reduce the impact on joints during high-intensity activities. Modern EVA foams used in sports equipment are engineered to provide optimal energy return, enhancing athletic performance while maintaining comfort.

However, the current EVA technology faces several challenges in the sports equipment industry. One significant issue is the material's tendency to compress over time, leading to a reduction in its shock-absorbing capabilities. This compression set problem affects the longevity of sports products, particularly in high-wear areas such as shoe midsoles.

Another challenge is achieving the right balance between cushioning and stability. While softer EVA foams offer better shock absorption, they may compromise stability, which is critical in many sports applications. Manufacturers are continually working to develop EVA formulations that can provide both adequate cushioning and necessary support.

The environmental impact of EVA production and disposal is also a growing concern. Traditional EVA materials are not biodegradable, contributing to long-term environmental issues. The sports industry is under increasing pressure to develop more sustainable alternatives or improve the recyclability of EVA-based products.

Durability remains a challenge, especially in outdoor sports equipment exposed to varying weather conditions. UV radiation and extreme temperatures can degrade EVA over time, affecting its performance and appearance. Researchers are exploring ways to enhance EVA's resistance to environmental factors without compromising its desirable properties.

In response to these challenges, recent technological advancements have focused on developing EVA composites and blends. These innovations aim to enhance the material's overall performance, addressing issues such as compression set, durability, and environmental impact. Some promising developments include the incorporation of nanoparticles to improve strength and resilience, and the exploration of bio-based EVA alternatives to increase sustainability.

The sports equipment industry is also witnessing a trend towards customization, with manufacturers seeking ways to tailor EVA properties to specific sports or even individual athletes. This customization presents both opportunities and challenges, requiring more sophisticated manufacturing processes and material formulations.

Current EVA Applications in Sports Equipment

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to modify the properties of the resulting material, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The adhesive strength and performance can be tailored by adjusting the EVA composition and additives.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and ability to be crosslinked. It can be used in the manufacturing of shoe soles, sports equipment padding, and building insulation materials. The foam structure and properties can be controlled through the EVA composition and foaming process.

- EVA in solar panel encapsulation: EVA is commonly used as an encapsulant material in photovoltaic modules due to its transparency, weather resistance, and ability to protect solar cells. It helps to improve the durability and efficiency of solar panels by providing a protective barrier against moisture and environmental factors.

- Modification and blending of EVA: EVA can be modified or blended with other polymers and additives to enhance its properties for specific applications. This includes crosslinking, grafting, and the addition of fillers or compatibilizers. These modifications can improve mechanical properties, thermal stability, and compatibility with other materials in various industrial applications.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base for other adhesive systems. The material's low melting point and good flow characteristics make it ideal for these applications.Expand Specific Solutions03 EVA in foam and insulation products

EVA is utilized in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it suitable for applications such as footwear, sports equipment, and building insulation. The material can be easily foamed and molded into various shapes and densities.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is commonly used as an encapsulant material in photovoltaic modules. Its transparency, weather resistance, and ability to protect solar cells from environmental factors make it an ideal choice for this application. The material helps to improve the durability and efficiency of solar panels.Expand Specific Solutions05 Modifications and blends of EVA

EVA can be modified or blended with other materials to enhance its properties or create new functionalities. This includes crosslinking, adding fillers or reinforcing agents, and blending with other polymers. These modifications can improve characteristics such as heat resistance, mechanical strength, or specific performance attributes for targeted applications.Expand Specific Solutions

Key Players in EVA Sports Equipment Manufacturing

The competitive landscape for Ethylene Vinyl Acetate (EVA) in sports equipment is characterized by a mature market with steady growth. The global EVA market size is projected to reach significant value, driven by increasing demand in various industries, including sports equipment. Technologically, EVA is well-established, with companies like DuPont, Arkema, and Celanese leading in innovation. Chinese firms such as Anta and Hanwha Solutions are expanding their presence, while specialized manufacturers like Diadora and Quanzhou Peak Shoes are leveraging EVA in sports footwear. Research institutions like Tianjin University and IIT Madras are contributing to advancements in EVA applications, indicating ongoing development in this field.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced EVA copolymers specifically for sports equipment applications. Their Elvax® series offers a range of EVA grades with varying vinyl acetate content (3-40%) and melt index, allowing for customization in different sports equipment[1]. DuPont's EVA technology focuses on enhancing impact resistance, flexibility, and durability in products such as shoe midsoles, ski boots, and protective gear. They have implemented a proprietary crosslinking process that improves the material's compression set and temperature resistance, crucial for maintaining performance in diverse sporting conditions[2]. DuPont has also introduced bio-based EVA options, addressing sustainability concerns in the sports industry[3].

Strengths: Wide range of customizable EVA grades, advanced crosslinking technology, and bio-based options. Weaknesses: Potentially higher cost compared to standard EVA, may require specialized processing equipment.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in EVA production for sports equipment. They have developed a high-performance EVA foam technology that offers superior cushioning and energy return properties, particularly suitable for athletic footwear[4]. Sinopec's EVA formulation incorporates nano-scale additives to enhance durability and reduce weight, addressing key concerns in sports equipment manufacturing. Their production process utilizes a continuous extrusion method, allowing for consistent quality and efficient large-scale production[5]. Sinopec has also focused on improving the environmental profile of their EVA, implementing a solvent-free production process that reduces VOC emissions[6].

Strengths: Large-scale production capabilities, advanced nano-additive technology, and environmentally friendly processing. Weaknesses: May face challenges in customization for niche sports applications, potential limitations in global market reach.

Innovative EVA Formulations for Enhanced Performance

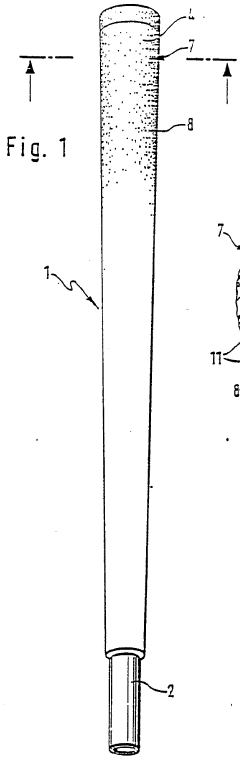

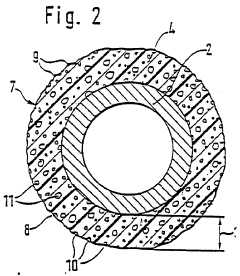

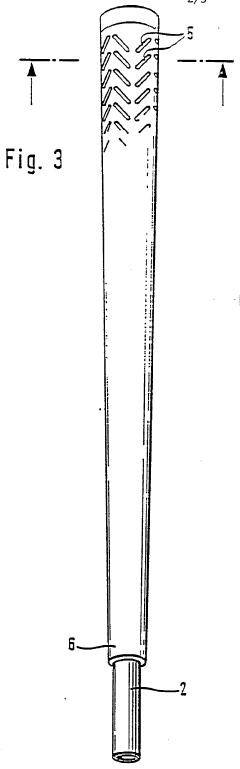

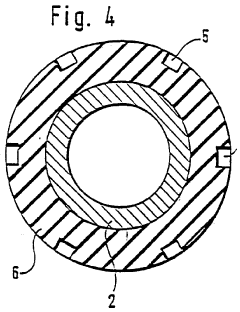

Handle with a covering made of ethylene/vinyl acetate copolymer, and sports equipment with such a handle

PatentWO1993003799A1

Innovation

- A handle core wrapped with a foamed, closed-cell polyethylene vinyl acetate sheath that provides a naturally structured surface for improved grip without additional aids, offering hydrophobic properties to prevent moisture accumulation and a soft, ergonomic fit that reduces pressure points and blistering.

Non-expanded elastomer composition based on ethylene-vinyl acetate copolymer, and use thereof for manufacturing footwear

PatentWO2014053037A8

Innovation

- A non-expanded elastomeric composition based on ethylene vinyl acetate copolymer, elastomeric polyolefin, polyorganosiloxane, and plasticizers, which can include crosslinking agents and rubbers, offering high flexibility, abrasion resistance, and a rubbery touch, with the ability to reuse vulcanized rubber residues as fillers, processed via internal mixers or twin-screw extruders.

Environmental Impact of EVA in Sports Equipment

The environmental impact of Ethylene Vinyl Acetate (EVA) in sports equipment is a complex issue that requires careful consideration. EVA has become a popular material in the sports industry due to its lightweight, durable, and shock-absorbing properties. However, its widespread use has raised concerns about its ecological footprint throughout its lifecycle.

The production of EVA involves the use of petrochemicals, which are derived from non-renewable resources. This process contributes to greenhouse gas emissions and energy consumption. Additionally, the manufacturing of EVA foam often requires the use of chemical blowing agents, which can release harmful substances into the environment if not properly managed.

During the use phase, EVA in sports equipment generally has a minimal direct environmental impact. Its durability and resistance to wear and tear contribute to longer product lifespans, potentially reducing the need for frequent replacements. However, the material's resistance to biodegradation becomes problematic at the end of its life cycle.

When EVA-containing sports equipment reaches the end of its useful life, disposal becomes a significant environmental concern. EVA is not biodegradable and can persist in landfills for extended periods. Incineration of EVA can release toxic fumes, including carbon monoxide and formaldehyde, posing risks to air quality and human health.

Recycling EVA presents challenges due to its cross-linked structure and the presence of other materials in sports equipment. While some recycling methods exist, they are not widely implemented, leading to a large portion of EVA waste ending up in landfills or incinerators.

The sports industry has begun to recognize these environmental challenges and is exploring alternatives. Some manufacturers are investigating bio-based EVA materials derived from renewable resources, which could reduce the reliance on petrochemicals. Others are focusing on improving the recyclability of EVA-containing products through innovative design and material combinations.

Efforts are also being made to develop more efficient recycling technologies for EVA. These include mechanical recycling methods that grind and reprocess the material, as well as chemical recycling techniques that break down EVA into its constituent components for reuse.

In conclusion, while EVA offers significant performance benefits in sports equipment, its environmental impact throughout its lifecycle is a growing concern. The industry faces the challenge of balancing the material's advantageous properties with the need for more sustainable practices. Future developments in bio-based alternatives, improved recycling technologies, and circular economy approaches will be crucial in mitigating the environmental impact of EVA in sports equipment.

The production of EVA involves the use of petrochemicals, which are derived from non-renewable resources. This process contributes to greenhouse gas emissions and energy consumption. Additionally, the manufacturing of EVA foam often requires the use of chemical blowing agents, which can release harmful substances into the environment if not properly managed.

During the use phase, EVA in sports equipment generally has a minimal direct environmental impact. Its durability and resistance to wear and tear contribute to longer product lifespans, potentially reducing the need for frequent replacements. However, the material's resistance to biodegradation becomes problematic at the end of its life cycle.

When EVA-containing sports equipment reaches the end of its useful life, disposal becomes a significant environmental concern. EVA is not biodegradable and can persist in landfills for extended periods. Incineration of EVA can release toxic fumes, including carbon monoxide and formaldehyde, posing risks to air quality and human health.

Recycling EVA presents challenges due to its cross-linked structure and the presence of other materials in sports equipment. While some recycling methods exist, they are not widely implemented, leading to a large portion of EVA waste ending up in landfills or incinerators.

The sports industry has begun to recognize these environmental challenges and is exploring alternatives. Some manufacturers are investigating bio-based EVA materials derived from renewable resources, which could reduce the reliance on petrochemicals. Others are focusing on improving the recyclability of EVA-containing products through innovative design and material combinations.

Efforts are also being made to develop more efficient recycling technologies for EVA. These include mechanical recycling methods that grind and reprocess the material, as well as chemical recycling techniques that break down EVA into its constituent components for reuse.

In conclusion, while EVA offers significant performance benefits in sports equipment, its environmental impact throughout its lifecycle is a growing concern. The industry faces the challenge of balancing the material's advantageous properties with the need for more sustainable practices. Future developments in bio-based alternatives, improved recycling technologies, and circular economy approaches will be crucial in mitigating the environmental impact of EVA in sports equipment.

Safety Standards for EVA in Sports Gear

Safety standards for EVA in sports gear have evolved significantly over the years, reflecting the growing emphasis on athlete protection and product quality. These standards are crucial in ensuring that sports equipment incorporating Ethylene Vinyl Acetate (EVA) meets rigorous safety requirements and performance criteria.

The primary focus of safety standards for EVA in sports gear is to address potential risks associated with impact absorption, durability, and chemical composition. Regulatory bodies such as the American Society for Testing and Materials (ASTM) and the European Committee for Standardization (CEN) have developed comprehensive guidelines for various sports equipment categories.

For impact protection, standards typically specify minimum levels of shock absorption and energy dissipation. EVA foam used in helmets, for instance, must meet stringent impact attenuation requirements. These standards often involve drop tests and other simulations to assess the material's ability to protect against concussions and other head injuries.

Durability standards ensure that EVA components in sports gear maintain their protective properties over time. This includes resistance to degradation from factors such as UV exposure, temperature fluctuations, and repeated impacts. Manufacturers must demonstrate that their EVA-based products can withstand the rigors of regular use without compromising safety.

Chemical safety is another critical aspect of EVA standards in sports equipment. Regulations limit the use of potentially harmful additives and require thorough testing for toxicity and allergenicity. This is particularly important for items that come into direct contact with the skin, such as shoe insoles and protective padding.

In recent years, there has been an increased focus on environmental safety standards for EVA in sports gear. This includes guidelines for recyclability and the use of eco-friendly manufacturing processes. Some standards now encourage the development of bio-based EVA alternatives to reduce the environmental impact of sports equipment production.

Compliance with these safety standards is typically verified through a combination of laboratory testing and field trials. Certification processes often involve third-party testing facilities to ensure impartiality and consistency in evaluations. Many sports governing bodies have adopted these standards as mandatory requirements for equipment used in official competitions.

As research in materials science and sports medicine advances, safety standards for EVA in sports gear continue to evolve. There is an ongoing effort to refine testing methodologies and update requirements to address emerging safety concerns and incorporate new technological developments. This dynamic approach ensures that safety standards remain relevant and effective in protecting athletes across various sports disciplines.

The primary focus of safety standards for EVA in sports gear is to address potential risks associated with impact absorption, durability, and chemical composition. Regulatory bodies such as the American Society for Testing and Materials (ASTM) and the European Committee for Standardization (CEN) have developed comprehensive guidelines for various sports equipment categories.

For impact protection, standards typically specify minimum levels of shock absorption and energy dissipation. EVA foam used in helmets, for instance, must meet stringent impact attenuation requirements. These standards often involve drop tests and other simulations to assess the material's ability to protect against concussions and other head injuries.

Durability standards ensure that EVA components in sports gear maintain their protective properties over time. This includes resistance to degradation from factors such as UV exposure, temperature fluctuations, and repeated impacts. Manufacturers must demonstrate that their EVA-based products can withstand the rigors of regular use without compromising safety.

Chemical safety is another critical aspect of EVA standards in sports equipment. Regulations limit the use of potentially harmful additives and require thorough testing for toxicity and allergenicity. This is particularly important for items that come into direct contact with the skin, such as shoe insoles and protective padding.

In recent years, there has been an increased focus on environmental safety standards for EVA in sports gear. This includes guidelines for recyclability and the use of eco-friendly manufacturing processes. Some standards now encourage the development of bio-based EVA alternatives to reduce the environmental impact of sports equipment production.

Compliance with these safety standards is typically verified through a combination of laboratory testing and field trials. Certification processes often involve third-party testing facilities to ensure impartiality and consistency in evaluations. Many sports governing bodies have adopted these standards as mandatory requirements for equipment used in official competitions.

As research in materials science and sports medicine advances, safety standards for EVA in sports gear continue to evolve. There is an ongoing effort to refine testing methodologies and update requirements to address emerging safety concerns and incorporate new technological developments. This dynamic approach ensures that safety standards remain relevant and effective in protecting athletes across various sports disciplines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!