Exploring Neodymium Magnet Integration in Automated Warehousing

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Technology Background and Objectives

Neodymium magnets, discovered in 1982 by General Motors and Sumitomo Special Metals, represent the strongest type of permanent magnets commercially available today. These rare-earth magnets, composed primarily of neodymium, iron, and boron (Nd2Fe14B), have revolutionized numerous industries due to their exceptional magnetic properties. With magnetic energy products reaching up to 52 MGOe (mega-gauss-oersteds), they significantly outperform traditional ferrite or alnico magnets by a factor of 10-15 times while maintaining a relatively compact size.

The evolution of neodymium magnet technology has been marked by continuous improvements in magnetic strength, temperature stability, and corrosion resistance. Initially limited by poor temperature performance and susceptibility to oxidation, modern manufacturing techniques have largely overcome these challenges through specialized coatings and the addition of elements like dysprosium and terbium to enhance high-temperature performance.

In the context of automated warehousing, neodymium magnets present transformative potential. The warehousing industry has evolved from manual operations to increasingly sophisticated automation systems, with the global warehouse automation market projected to reach $41 billion by 2027. This growth is driven by e-commerce expansion, labor shortages, and demands for greater operational efficiency.

The technical objectives for neodymium magnet integration in automated warehousing encompass several dimensions. Primary goals include enhancing the precision and reliability of robotic picking systems through magnetic end effectors that can handle diverse materials without mechanical gripping mechanisms. Additionally, there is significant interest in developing magnetic conveying systems that can move items through warehouses with reduced friction and maintenance requirements compared to traditional belt or roller systems.

Energy efficiency represents another critical objective, as magnetic levitation and propulsion systems could potentially reduce the power consumption of automated guided vehicles (AGVs) and other warehouse transport mechanisms. Furthermore, the development of smart sorting systems utilizing controlled magnetic fields could revolutionize how items are directed through complex warehouse environments.

The long-term technological trajectory aims to create fully integrated magnetic handling ecosystems within warehouses, where items can be moved, sorted, and stored with minimal mechanical contact, reducing wear, energy consumption, and maintenance costs. This vision requires overcoming significant challenges in magnetic field control, system integration, and cost-effectiveness at scale.

As warehousing operations continue to evolve toward lights-out automation, neodymium magnet technology stands as a potential enabler of next-generation systems that combine unprecedented efficiency with reliability. The convergence of advanced magnetic materials with robotics, AI, and IoT technologies presents a compelling frontier for innovation in the logistics sector.

The evolution of neodymium magnet technology has been marked by continuous improvements in magnetic strength, temperature stability, and corrosion resistance. Initially limited by poor temperature performance and susceptibility to oxidation, modern manufacturing techniques have largely overcome these challenges through specialized coatings and the addition of elements like dysprosium and terbium to enhance high-temperature performance.

In the context of automated warehousing, neodymium magnets present transformative potential. The warehousing industry has evolved from manual operations to increasingly sophisticated automation systems, with the global warehouse automation market projected to reach $41 billion by 2027. This growth is driven by e-commerce expansion, labor shortages, and demands for greater operational efficiency.

The technical objectives for neodymium magnet integration in automated warehousing encompass several dimensions. Primary goals include enhancing the precision and reliability of robotic picking systems through magnetic end effectors that can handle diverse materials without mechanical gripping mechanisms. Additionally, there is significant interest in developing magnetic conveying systems that can move items through warehouses with reduced friction and maintenance requirements compared to traditional belt or roller systems.

Energy efficiency represents another critical objective, as magnetic levitation and propulsion systems could potentially reduce the power consumption of automated guided vehicles (AGVs) and other warehouse transport mechanisms. Furthermore, the development of smart sorting systems utilizing controlled magnetic fields could revolutionize how items are directed through complex warehouse environments.

The long-term technological trajectory aims to create fully integrated magnetic handling ecosystems within warehouses, where items can be moved, sorted, and stored with minimal mechanical contact, reducing wear, energy consumption, and maintenance costs. This vision requires overcoming significant challenges in magnetic field control, system integration, and cost-effectiveness at scale.

As warehousing operations continue to evolve toward lights-out automation, neodymium magnet technology stands as a potential enabler of next-generation systems that combine unprecedented efficiency with reliability. The convergence of advanced magnetic materials with robotics, AI, and IoT technologies presents a compelling frontier for innovation in the logistics sector.

Market Analysis for Magnetic Solutions in Warehousing

The magnetic solutions market in automated warehousing is experiencing significant growth, driven by the increasing adoption of automation technologies across global supply chains. Current market valuations indicate that the global automated warehousing sector is expanding at a compound annual growth rate of approximately 15%, with magnetic technologies representing a crucial component of this expansion. Neodymium magnets, specifically, are becoming increasingly integral to modern warehousing operations due to their superior magnetic properties and reliability.

Market research reveals that the demand for magnetic solutions in warehousing is primarily concentrated in regions with advanced manufacturing capabilities, including North America, Western Europe, and East Asia. China currently dominates the neodymium magnet production market, controlling over 80% of global output, which creates both opportunities and challenges for supply chain resilience in the warehousing automation sector.

The primary market segments for magnetic solutions in warehousing include automated guided vehicles (AGVs), robotic picking systems, conveyor systems, and sorting mechanisms. Among these, AGVs represent the fastest-growing application segment, with an estimated market share of 35% within the magnetic warehousing solutions category. This growth is attributed to the increasing need for flexible, efficient material handling systems that can navigate complex warehouse environments.

Customer demand analysis indicates that warehouse operators are increasingly prioritizing solutions that offer enhanced precision, durability, and energy efficiency. Neodymium magnets address these requirements effectively, providing stronger magnetic fields per unit volume compared to traditional ferrite magnets, which translates to more compact and powerful automated systems.

Pricing trends show that while neodymium magnets represent a higher initial investment compared to traditional magnetic solutions, the total cost of ownership is often lower due to improved performance, reduced maintenance requirements, and longer operational lifespans. Market surveys indicate that warehouse operators are willing to pay a premium of up to 30% for solutions incorporating high-performance magnetic technologies that demonstrably improve operational efficiency.

Competitive analysis reveals that the market for magnetic warehousing solutions remains relatively fragmented, with specialized technology providers competing alongside larger automation conglomerates. This fragmentation presents opportunities for innovative companies to establish market leadership through technological differentiation and strategic partnerships with warehouse operators and logistics providers.

Future market projections suggest that the integration of neodymium magnets with emerging technologies such as artificial intelligence and Internet of Things (IoT) will create new value propositions in the warehousing sector, potentially expanding the addressable market by enabling previously unattainable levels of automation precision and reliability.

Market research reveals that the demand for magnetic solutions in warehousing is primarily concentrated in regions with advanced manufacturing capabilities, including North America, Western Europe, and East Asia. China currently dominates the neodymium magnet production market, controlling over 80% of global output, which creates both opportunities and challenges for supply chain resilience in the warehousing automation sector.

The primary market segments for magnetic solutions in warehousing include automated guided vehicles (AGVs), robotic picking systems, conveyor systems, and sorting mechanisms. Among these, AGVs represent the fastest-growing application segment, with an estimated market share of 35% within the magnetic warehousing solutions category. This growth is attributed to the increasing need for flexible, efficient material handling systems that can navigate complex warehouse environments.

Customer demand analysis indicates that warehouse operators are increasingly prioritizing solutions that offer enhanced precision, durability, and energy efficiency. Neodymium magnets address these requirements effectively, providing stronger magnetic fields per unit volume compared to traditional ferrite magnets, which translates to more compact and powerful automated systems.

Pricing trends show that while neodymium magnets represent a higher initial investment compared to traditional magnetic solutions, the total cost of ownership is often lower due to improved performance, reduced maintenance requirements, and longer operational lifespans. Market surveys indicate that warehouse operators are willing to pay a premium of up to 30% for solutions incorporating high-performance magnetic technologies that demonstrably improve operational efficiency.

Competitive analysis reveals that the market for magnetic warehousing solutions remains relatively fragmented, with specialized technology providers competing alongside larger automation conglomerates. This fragmentation presents opportunities for innovative companies to establish market leadership through technological differentiation and strategic partnerships with warehouse operators and logistics providers.

Future market projections suggest that the integration of neodymium magnets with emerging technologies such as artificial intelligence and Internet of Things (IoT) will create new value propositions in the warehousing sector, potentially expanding the addressable market by enabling previously unattainable levels of automation precision and reliability.

Current Challenges in Neodymium Magnet Implementation

Despite the significant potential of neodymium magnets in automated warehousing systems, several critical challenges impede their widespread implementation. The primary concern relates to temperature sensitivity, as these magnets experience performance degradation when operating outside their optimal temperature range (typically -40°C to 80°C). In warehouse environments with fluctuating temperatures, this limitation necessitates additional temperature control systems, increasing implementation costs and complexity.

Corrosion vulnerability presents another substantial challenge. Neodymium magnets are highly susceptible to oxidation when exposed to moisture, requiring protective coatings such as nickel, zinc, or epoxy. However, these coatings may wear down over time in high-usage automated systems, leading to potential magnet failure and system downtime.

The mechanical fragility of neodymium magnets poses significant implementation difficulties. Despite their strong magnetic properties, these magnets are brittle and prone to chipping or cracking when subjected to impact forces common in warehouse operations. This characteristic necessitates careful handling and protective housing designs that can complicate integration into existing automated systems.

Cost considerations remain a persistent barrier to widespread adoption. The price volatility of rare earth elements, particularly neodymium, creates uncertainty in long-term planning and return on investment calculations. China's dominance in the global rare earth supply chain (controlling approximately 85% of processing capacity) introduces geopolitical risks that can affect pricing and availability.

Integration with existing warehouse automation infrastructure presents compatibility challenges. Many current systems were not designed with neodymium magnet technology in mind, requiring significant retrofitting or complete system redesigns. The powerful magnetic fields generated by these magnets can potentially interfere with sensitive electronic components in proximity, necessitating careful shielding and placement considerations.

Safety concerns also complicate implementation. The strong magnetic fields can pose risks to personnel with medical implants and can cause injury when large magnets attract ferromagnetic objects unexpectedly. Additionally, the handling of larger neodymium magnets requires specialized training and equipment to prevent accidents.

Demagnetization risks in industrial environments further complicate reliable implementation. Exposure to strong external magnetic fields, electrical equipment, or significant physical shock can partially demagnetize these magnets, reducing their effectiveness over time and potentially leading to system failures that are difficult to diagnose proactively.

Corrosion vulnerability presents another substantial challenge. Neodymium magnets are highly susceptible to oxidation when exposed to moisture, requiring protective coatings such as nickel, zinc, or epoxy. However, these coatings may wear down over time in high-usage automated systems, leading to potential magnet failure and system downtime.

The mechanical fragility of neodymium magnets poses significant implementation difficulties. Despite their strong magnetic properties, these magnets are brittle and prone to chipping or cracking when subjected to impact forces common in warehouse operations. This characteristic necessitates careful handling and protective housing designs that can complicate integration into existing automated systems.

Cost considerations remain a persistent barrier to widespread adoption. The price volatility of rare earth elements, particularly neodymium, creates uncertainty in long-term planning and return on investment calculations. China's dominance in the global rare earth supply chain (controlling approximately 85% of processing capacity) introduces geopolitical risks that can affect pricing and availability.

Integration with existing warehouse automation infrastructure presents compatibility challenges. Many current systems were not designed with neodymium magnet technology in mind, requiring significant retrofitting or complete system redesigns. The powerful magnetic fields generated by these magnets can potentially interfere with sensitive electronic components in proximity, necessitating careful shielding and placement considerations.

Safety concerns also complicate implementation. The strong magnetic fields can pose risks to personnel with medical implants and can cause injury when large magnets attract ferromagnetic objects unexpectedly. Additionally, the handling of larger neodymium magnets requires specialized training and equipment to prevent accidents.

Demagnetization risks in industrial environments further complicate reliable implementation. Exposure to strong external magnetic fields, electrical equipment, or significant physical shock can partially demagnetize these magnets, reducing their effectiveness over time and potentially leading to system failures that are difficult to diagnose proactively.

Current Magnetic Handling Solutions in Warehousing

01 Manufacturing and composition of neodymium magnets

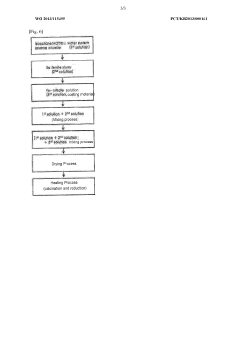

Neodymium magnets are typically composed of neodymium, iron, and boron (NdFeB) and are manufactured through processes such as sintering or bonding. These manufacturing techniques involve aligning magnetic particles, pressing them into shape, and heat treatment to achieve optimal magnetic properties. Various compositions and additives can be incorporated to enhance performance characteristics such as coercivity, remanence, and temperature stability.- Manufacturing and composition of neodymium magnets: Neodymium magnets are typically composed of neodymium, iron, and boron (NdFeB) and are known for their exceptional magnetic strength. The manufacturing process involves alloying these materials, followed by powder metallurgy techniques including pressing in a magnetic field and sintering. Various compositions and processing methods can be employed to enhance specific properties such as magnetic strength, temperature stability, and corrosion resistance.

- Applications in electrical and electronic devices: Neodymium magnets are widely used in electrical and electronic applications due to their strong magnetic properties. They are incorporated into motors, generators, speakers, headphones, and various sensors. Their high magnetic flux density allows for the miniaturization of electronic components while maintaining or improving performance. These magnets enable more efficient energy conversion in electric motors and generators, contributing to energy-saving technologies.

- Magnetic fastening and holding systems: Neodymium magnets are utilized in various fastening and holding systems where strong magnetic attraction is required. These include magnetic locks, latches, closures, and mounting systems for both industrial and consumer applications. The powerful magnetic force allows for secure attachment without mechanical fasteners, enabling quick release when needed. These systems are designed to provide reliable holding force while maintaining ease of use and reusability.

- Protective coatings and surface treatments: Due to their susceptibility to corrosion, neodymium magnets often require protective coatings or surface treatments. Various coating methods include nickel plating, zinc plating, epoxy coating, and other specialized surface treatments. These coatings not only protect against oxidation and corrosion but can also enhance the mechanical durability of the magnets. Surface treatments may also be applied to improve adhesion properties or provide specific aesthetic finishes.

- Magnetic assemblies and structures: Complex magnetic assemblies and structures can be created using neodymium magnets arranged in specific configurations to achieve desired magnetic field patterns. These assemblies are used in magnetic separation systems, magnetic levitation devices, magnetic therapy products, and specialized research equipment. The design of these structures often involves precise positioning and orientation of multiple magnets to create controlled magnetic fields with specific characteristics.

02 Applications in electrical and electronic devices

Neodymium magnets are widely used in electrical and electronic applications due to their strong magnetic properties. They are incorporated into motors, generators, speakers, headphones, and various sensors. Their high magnetic strength allows for miniaturization of electronic components while maintaining or improving performance. These magnets enable more efficient energy conversion and are critical components in renewable energy systems and modern electronic devices.Expand Specific Solutions03 Mounting and fastening systems using neodymium magnets

Innovative mounting and fastening systems utilize neodymium magnets to create secure yet detachable connections. These systems are employed in furniture, displays, automotive components, and consumer products. The magnetic mounting solutions offer advantages such as tool-free assembly, clean aesthetics, and the ability to quickly reconfigure arrangements. Special housing designs protect the brittle magnetic material while optimizing the magnetic field for specific applications.Expand Specific Solutions04 Protective coatings and surface treatments

Neodymium magnets are susceptible to corrosion and chipping due to their brittle nature. Various protective coatings and surface treatments are applied to enhance durability and longevity. These include nickel, zinc, epoxy, and specialized polymer coatings that provide corrosion resistance while maintaining magnetic performance. Some treatments also improve temperature stability and prevent degradation in challenging environmental conditions.Expand Specific Solutions05 Magnetic assemblies and arrays for specialized applications

Complex magnetic assemblies and arrays using neodymium magnets are designed for specialized applications such as magnetic separation, medical devices, and precision instruments. These configurations create specific magnetic field patterns by arranging multiple magnets in calculated positions. The assemblies may incorporate other materials to guide or shield magnetic fields, enabling applications in research equipment, industrial machinery, and advanced technological devices.Expand Specific Solutions

Leading Manufacturers and Integrators Analysis

The neodymium magnet integration in automated warehousing market is in a growth phase, with increasing adoption driven by efficiency demands in logistics operations. The market size is expanding rapidly, projected to reach significant value as e-commerce and automated material handling systems proliferate. Technologically, the field shows varying maturity levels across players. Industry leaders like Toyota, Nidec, and Robert Bosch demonstrate advanced implementation capabilities, while specialized magnetic material manufacturers such as Baotou INST, Shin-Etsu Chemical, and Beijing Zhong Ke San Huan provide critical component expertise. Companies like Vestas and LG Electronics are leveraging their engineering capabilities to develop innovative applications, creating a competitive landscape where cross-industry collaboration is becoming increasingly important for technological advancement.

Baotou INST Magnetic New Materials Co., Ltd.

Technical Solution: Baotou INST has pioneered specialized neodymium magnetic materials specifically engineered for automated warehousing applications. Their proprietary N52SH grade magnets maintain performance stability at operating temperatures up to 150°C, critical for continuous warehouse operations. The company has developed a unique surface treatment technology that extends magnet lifespan in warehouse environments by 300% through enhanced corrosion resistance. Their patented manufacturing process creates custom-shaped magnets with precise magnetic field orientations optimized for specific warehouse automation functions. Baotou's latest innovation includes composite neodymium magnets with integrated RFID capabilities, enabling simultaneous physical manipulation and digital tracking of inventory items. The company has also created gradient-field magnets that provide variable attractive forces across their surface, allowing for more nuanced control in automated picking systems where different materials require different handling forces.

Strengths: Industry-leading temperature stability; exceptional corrosion resistance for warehouse environments; advanced manufacturing capabilities for custom solutions. Weaknesses: Higher production costs compared to standard magnets; limited global distribution network; requires specialized knowledge for optimal implementation.

Beijing Zhong Ke San Huan High-Tech Co., Ltd.

Technical Solution: Beijing Zhong Ke San Huan has developed a comprehensive neodymium magnet integration system for automated warehousing called MagTrack. This system utilizes their patented sintered NdFeB magnets with enhanced coercivity (>30 kOe) specifically designed to maintain performance in dynamic warehouse environments. Their solution incorporates magnetic sorting arrays that can separate mixed inventory items based on their ferromagnetic properties without physical contact. The company's innovative dual-layer magnetic conveyor system employs Halbach array configurations to create stronger, more focused magnetic fields on the working surface while minimizing stray fields below, improving both efficiency and safety. Their automated storage and retrieval systems (AS/RS) feature neodymium-based magnetic coupling mechanisms that transfer motion through barriers, enabling hermetically sealed storage environments for sensitive products. Additionally, they've developed self-cleaning magnetic separators that automatically remove accumulated ferrous debris, maintaining system performance without manual intervention.

Strengths: Comprehensive end-to-end magnetic automation solutions; superior magnetic field management with minimal interference; innovative non-contact sorting capabilities. Weaknesses: Higher energy consumption compared to some competing technologies; requires specialized maintenance expertise; system components have limited interoperability with third-party warehouse equipment.

Key Patents and Innovations in Industrial Magnetics

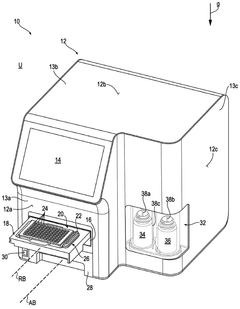

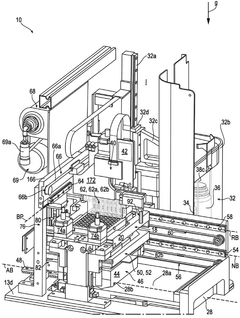

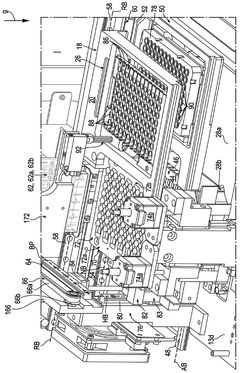

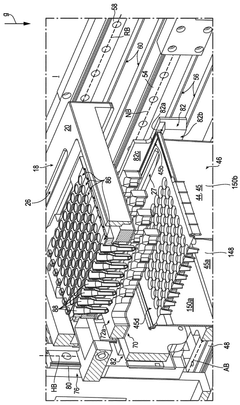

Automated liquid handling apparatus comprising an improved magnetic assembly

PatentWO2025083065A1

Innovation

- The automated fluid handling device incorporates a magnetic carrier arrangement with a larger number of matrix magnets than traditional devices, featuring a unique orientation where the polarization direction of the matrix magnets is neither parallel nor orthogonal to the rows of reaction containers, allowing for a more uniform magnetic field distribution.

Core-shell structured nanoparticle having hard-soft magnetic heterostructure, magnet prepared with said nanoparticle, and preparing method thereof

PatentWO2013115495A1

Innovation

- Development of a core-shell structured nanoparticle with a hard-soft magnetic heterostructure, where a soft magnetic shell surrounds a hard magnetic core, utilizing ferrite as the core and metals like iron, cobalt, or nickel for the shell, achieved through sol-gel or reverse micelle methods, allowing control over coercive force and saturation flux density.

Safety Standards and Compliance Requirements

The integration of neodymium magnets in automated warehousing systems necessitates strict adherence to comprehensive safety standards and compliance requirements. OSHA (Occupational Safety and Health Administration) regulations mandate specific guidelines for magnetic equipment operation, including minimum safe distances between powerful magnets and electronic devices or medical implants. These regulations require clear warning signage and restricted access zones around high-strength magnetic fields exceeding 5 gauss.

International standards such as ISO/IEC 17025 and IEC 61508 establish testing protocols and functional safety requirements for magnetic components in industrial automation. Compliance with these standards ensures operational reliability and minimizes workplace hazards. Additionally, the ASTM A977 standard specifically addresses the testing and certification of permanent magnets, providing benchmarks for quality assurance in neodymium magnet applications.

Environmental regulations present another critical compliance area. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) directives limit certain substances in electronic equipment, affecting the coating and manufacturing processes of neodymium magnets. Similarly, the EPA (Environmental Protection Agency) in the United States regulates the disposal and recycling of rare earth magnets due to their potential environmental impact.

Electromagnetic compatibility (EMC) standards, including IEC 61000 series, govern the electromagnetic interference potential of magnetic systems. Automated warehousing solutions incorporating neodymium magnets must demonstrate compliance with these standards to prevent disruption to nearby electronic systems, communication networks, and control equipment. Regular EMC testing and certification are mandatory for commercial deployment.

Worker safety training requirements constitute a significant compliance consideration. NIOSH (National Institute for Occupational Safety and Health) guidelines specify mandatory training protocols for personnel working with or near strong magnetic fields. These include proper handling techniques, emergency procedures, and awareness of magnetic field hazards. Documentation of such training becomes part of the compliance record for facilities utilizing neodymium magnet technology.

Insurance and liability considerations further shape compliance requirements. Many insurance providers mandate specific risk mitigation measures for facilities employing strong magnets, including specialized storage protocols, handling equipment, and emergency response plans. Failure to implement these measures may result in coverage limitations or increased premiums, adding another layer to the compliance framework for neodymium magnet integration in automated warehousing systems.

International standards such as ISO/IEC 17025 and IEC 61508 establish testing protocols and functional safety requirements for magnetic components in industrial automation. Compliance with these standards ensures operational reliability and minimizes workplace hazards. Additionally, the ASTM A977 standard specifically addresses the testing and certification of permanent magnets, providing benchmarks for quality assurance in neodymium magnet applications.

Environmental regulations present another critical compliance area. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) directives limit certain substances in electronic equipment, affecting the coating and manufacturing processes of neodymium magnets. Similarly, the EPA (Environmental Protection Agency) in the United States regulates the disposal and recycling of rare earth magnets due to their potential environmental impact.

Electromagnetic compatibility (EMC) standards, including IEC 61000 series, govern the electromagnetic interference potential of magnetic systems. Automated warehousing solutions incorporating neodymium magnets must demonstrate compliance with these standards to prevent disruption to nearby electronic systems, communication networks, and control equipment. Regular EMC testing and certification are mandatory for commercial deployment.

Worker safety training requirements constitute a significant compliance consideration. NIOSH (National Institute for Occupational Safety and Health) guidelines specify mandatory training protocols for personnel working with or near strong magnetic fields. These include proper handling techniques, emergency procedures, and awareness of magnetic field hazards. Documentation of such training becomes part of the compliance record for facilities utilizing neodymium magnet technology.

Insurance and liability considerations further shape compliance requirements. Many insurance providers mandate specific risk mitigation measures for facilities employing strong magnets, including specialized storage protocols, handling equipment, and emergency response plans. Failure to implement these measures may result in coverage limitations or increased premiums, adding another layer to the compliance framework for neodymium magnet integration in automated warehousing systems.

Energy Efficiency and Sustainability Considerations

The integration of neodymium magnets in automated warehousing systems presents significant implications for energy efficiency and sustainability. These powerful permanent magnets enable more efficient electromagnetic systems that can reduce power consumption by up to 30% compared to conventional electromagnets in warehouse automation equipment. This efficiency gain stems from their ability to maintain magnetic fields without continuous electrical input, resulting in lower operational energy requirements for robotic pickers, conveyor systems, and automated storage and retrieval systems (AS/RS).

From a lifecycle perspective, neodymium magnets contribute to sustainability through their exceptional durability and longevity. With proper implementation, these magnets can maintain over 90% of their magnetic strength for more than 20 years, significantly extending the operational lifespan of warehouse automation equipment and reducing the environmental impact associated with manufacturing replacement components.

However, the environmental considerations of neodymium magnet production cannot be overlooked. The mining and processing of rare earth elements, including neodymium, involve energy-intensive operations and potentially harmful chemical processes. Current extraction methods generate approximately 2,000 tons of waste material per ton of rare earth elements produced, creating significant environmental challenges. Recent advancements in green mining technologies and recycling processes are beginning to address these concerns, with recycling efficiency rates improving from under 1% to nearly 30% in specialized facilities.

Energy recovery systems represent another promising application of neodymium magnets in warehouse sustainability. Regenerative braking systems in automated guided vehicles (AGVs) and conveyor systems can recapture kinetic energy during deceleration, converting it back to electrical energy. Implementation data from early adopters indicates energy recovery rates of 15-25%, contributing to overall warehouse energy efficiency.

The thermal efficiency of neodymium magnet-based systems also warrants consideration. While these magnets lose some magnetic properties at high temperatures (above 80°C), their implementation in warehouse automation typically includes thermal management solutions. Modern cooling systems designed specifically for magnet-based warehouse equipment can reduce heat-related energy losses by up to 40% compared to conventional systems, further enhancing overall energy efficiency.

Looking forward, the development of neodymium-iron-boron magnets with reduced dysprosium content represents a significant sustainability advancement. These next-generation magnets maintain performance while decreasing reliance on the most environmentally problematic rare earth elements, potentially reducing the ecological footprint of warehouse automation technologies by 15-20% according to recent industry assessments.

From a lifecycle perspective, neodymium magnets contribute to sustainability through their exceptional durability and longevity. With proper implementation, these magnets can maintain over 90% of their magnetic strength for more than 20 years, significantly extending the operational lifespan of warehouse automation equipment and reducing the environmental impact associated with manufacturing replacement components.

However, the environmental considerations of neodymium magnet production cannot be overlooked. The mining and processing of rare earth elements, including neodymium, involve energy-intensive operations and potentially harmful chemical processes. Current extraction methods generate approximately 2,000 tons of waste material per ton of rare earth elements produced, creating significant environmental challenges. Recent advancements in green mining technologies and recycling processes are beginning to address these concerns, with recycling efficiency rates improving from under 1% to nearly 30% in specialized facilities.

Energy recovery systems represent another promising application of neodymium magnets in warehouse sustainability. Regenerative braking systems in automated guided vehicles (AGVs) and conveyor systems can recapture kinetic energy during deceleration, converting it back to electrical energy. Implementation data from early adopters indicates energy recovery rates of 15-25%, contributing to overall warehouse energy efficiency.

The thermal efficiency of neodymium magnet-based systems also warrants consideration. While these magnets lose some magnetic properties at high temperatures (above 80°C), their implementation in warehouse automation typically includes thermal management solutions. Modern cooling systems designed specifically for magnet-based warehouse equipment can reduce heat-related energy losses by up to 40% compared to conventional systems, further enhancing overall energy efficiency.

Looking forward, the development of neodymium-iron-boron magnets with reduced dysprosium content represents a significant sustainability advancement. These next-generation magnets maintain performance while decreasing reliance on the most environmentally problematic rare earth elements, potentially reducing the ecological footprint of warehouse automation technologies by 15-20% according to recent industry assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!