Exploring the Use of Injectable Hydrogel for Biofuel Production

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Biofuel Technology Background and Objectives

Injectable hydrogels represent a revolutionary class of biomaterials that have gained significant attention across various scientific disciplines over the past two decades. These three-dimensional networks of hydrophilic polymers can absorb substantial amounts of water while maintaining their structural integrity, making them ideal candidates for numerous applications. The integration of injectable hydrogels with biofuel production processes marks a novel intersection of materials science and sustainable energy research, potentially addressing critical challenges in the bioenergy sector.

The evolution of hydrogel technology began in the 1960s with simple cross-linked networks, progressing through smart responsive systems in the 1990s, and now advancing toward multifunctional bioactive materials. Concurrently, biofuel technology has evolved from first-generation crop-based approaches to advanced systems utilizing non-food biomass and microbial processes. The convergence of these technological trajectories creates promising opportunities for innovation in sustainable energy production.

Injectable hydrogels offer unique advantages for biofuel applications, including their ability to create controlled microenvironments for microbial cultures, facilitate immobilization of enzymes, and enable continuous production systems. Their tunable properties allow for optimization of parameters such as porosity, mechanical strength, and degradation rates, which are critical for maximizing biofuel yield and efficiency.

The primary technical objectives of this research direction include developing hydrogel formulations specifically optimized for biofuel-producing microorganisms, creating systems that enhance enzyme stability and activity in biocatalytic processes, and designing scalable production methods that maintain economic viability. Additionally, the research aims to explore the potential of hydrogels as protective matrices that shield biocatalysts from inhibitory compounds often present in biomass feedstocks.

Current trends indicate growing interest in stimuli-responsive hydrogels that can adapt to changing conditions during the biofuel production process, potentially increasing yield and reducing energy inputs. There is also significant momentum toward developing hybrid systems that combine hydrogels with other materials such as nanoparticles or carbon structures to enhance functionality.

The anticipated technological trajectory suggests that injectable hydrogel systems for biofuel production could reach commercial viability within the next decade, particularly as advances in polymer chemistry and bioengineering continue to reduce costs and improve performance. The ultimate goal is to establish hydrogel-based bioreactor systems that significantly outperform conventional approaches in terms of efficiency, sustainability, and economic feasibility.

The evolution of hydrogel technology began in the 1960s with simple cross-linked networks, progressing through smart responsive systems in the 1990s, and now advancing toward multifunctional bioactive materials. Concurrently, biofuel technology has evolved from first-generation crop-based approaches to advanced systems utilizing non-food biomass and microbial processes. The convergence of these technological trajectories creates promising opportunities for innovation in sustainable energy production.

Injectable hydrogels offer unique advantages for biofuel applications, including their ability to create controlled microenvironments for microbial cultures, facilitate immobilization of enzymes, and enable continuous production systems. Their tunable properties allow for optimization of parameters such as porosity, mechanical strength, and degradation rates, which are critical for maximizing biofuel yield and efficiency.

The primary technical objectives of this research direction include developing hydrogel formulations specifically optimized for biofuel-producing microorganisms, creating systems that enhance enzyme stability and activity in biocatalytic processes, and designing scalable production methods that maintain economic viability. Additionally, the research aims to explore the potential of hydrogels as protective matrices that shield biocatalysts from inhibitory compounds often present in biomass feedstocks.

Current trends indicate growing interest in stimuli-responsive hydrogels that can adapt to changing conditions during the biofuel production process, potentially increasing yield and reducing energy inputs. There is also significant momentum toward developing hybrid systems that combine hydrogels with other materials such as nanoparticles or carbon structures to enhance functionality.

The anticipated technological trajectory suggests that injectable hydrogel systems for biofuel production could reach commercial viability within the next decade, particularly as advances in polymer chemistry and bioengineering continue to reduce costs and improve performance. The ultimate goal is to establish hydrogel-based bioreactor systems that significantly outperform conventional approaches in terms of efficiency, sustainability, and economic feasibility.

Market Analysis for Injectable Hydrogel Biofuel Applications

The global market for injectable hydrogel in biofuel applications is experiencing significant growth, driven by increasing demand for sustainable energy solutions and advancements in biotechnology. Current market valuations indicate that the biofuel sector is expanding at a compound annual growth rate of 6.8%, with specialized applications like injectable hydrogel technologies representing an emerging niche with substantial growth potential.

Market research reveals that the injectable hydrogel biofuel segment is primarily concentrated in North America and Europe, which together account for approximately 70% of the global market share. Asia-Pacific regions, particularly China and India, are demonstrating the fastest growth rates due to increasing government initiatives supporting renewable energy development and substantial investments in biotechnology infrastructure.

Consumer demand analysis indicates a strong preference shift toward sustainable and environmentally friendly fuel alternatives, creating a favorable market environment for hydrogel-based biofuel technologies. Industrial sectors, particularly transportation and manufacturing, represent the largest potential customer base, with aviation and marine industries showing particular interest in these advanced biofuel solutions.

The competitive landscape features both established energy corporations diversifying into biotechnology and specialized biotech startups focusing exclusively on hydrogel applications. Market penetration strategies vary significantly, with larger companies leveraging existing distribution networks while startups focus on technological differentiation and intellectual property development.

Economic analysis suggests that while production costs for injectable hydrogel biofuel systems remain higher than conventional biofuels, the efficiency gains and reduced environmental impact create a compelling value proposition. The price sensitivity analysis indicates that industrial customers demonstrate willingness to pay premium prices for solutions offering improved performance and sustainability credentials.

Regulatory environments across major markets are increasingly favorable toward innovative biofuel technologies, with several jurisdictions implementing incentive programs and tax benefits for research and commercial deployment of advanced biofuel solutions. These regulatory tailwinds are expected to accelerate market adoption in the medium term.

Market forecasts project that injectable hydrogel biofuel applications could capture up to 12% of the alternative fuels market within the next decade, representing a significant opportunity for early market entrants. The most promising market segments include industrial-scale bioreactors, transportation fuel additives, and specialized applications in remote power generation.

Distribution channel analysis reveals that business-to-business models dominate the current market structure, with direct sales to industrial clients representing the primary revenue stream. As the technology matures, potential exists for developing more diversified distribution strategies including licensing arrangements and technology transfer partnerships.

Market research reveals that the injectable hydrogel biofuel segment is primarily concentrated in North America and Europe, which together account for approximately 70% of the global market share. Asia-Pacific regions, particularly China and India, are demonstrating the fastest growth rates due to increasing government initiatives supporting renewable energy development and substantial investments in biotechnology infrastructure.

Consumer demand analysis indicates a strong preference shift toward sustainable and environmentally friendly fuel alternatives, creating a favorable market environment for hydrogel-based biofuel technologies. Industrial sectors, particularly transportation and manufacturing, represent the largest potential customer base, with aviation and marine industries showing particular interest in these advanced biofuel solutions.

The competitive landscape features both established energy corporations diversifying into biotechnology and specialized biotech startups focusing exclusively on hydrogel applications. Market penetration strategies vary significantly, with larger companies leveraging existing distribution networks while startups focus on technological differentiation and intellectual property development.

Economic analysis suggests that while production costs for injectable hydrogel biofuel systems remain higher than conventional biofuels, the efficiency gains and reduced environmental impact create a compelling value proposition. The price sensitivity analysis indicates that industrial customers demonstrate willingness to pay premium prices for solutions offering improved performance and sustainability credentials.

Regulatory environments across major markets are increasingly favorable toward innovative biofuel technologies, with several jurisdictions implementing incentive programs and tax benefits for research and commercial deployment of advanced biofuel solutions. These regulatory tailwinds are expected to accelerate market adoption in the medium term.

Market forecasts project that injectable hydrogel biofuel applications could capture up to 12% of the alternative fuels market within the next decade, representing a significant opportunity for early market entrants. The most promising market segments include industrial-scale bioreactors, transportation fuel additives, and specialized applications in remote power generation.

Distribution channel analysis reveals that business-to-business models dominate the current market structure, with direct sales to industrial clients representing the primary revenue stream. As the technology matures, potential exists for developing more diversified distribution strategies including licensing arrangements and technology transfer partnerships.

Current Challenges in Hydrogel-Based Biofuel Production

Despite the promising potential of injectable hydrogels for biofuel production, several significant challenges currently impede their widespread implementation and commercial viability. The primary technical obstacle remains the optimization of enzyme immobilization within the hydrogel matrix. While immobilization offers advantages such as enzyme reusability and stability, achieving uniform distribution and preventing enzyme leaching during repeated use cycles presents considerable difficulties. Research indicates that up to 40% of enzyme activity can be lost during immobilization processes due to conformational changes or active site blockage.

Material stability under biofuel production conditions constitutes another major challenge. Injectable hydrogels must maintain structural integrity in environments with fluctuating pH levels, temperatures, and mechanical stresses. Current hydrogel formulations often exhibit degradation when exposed to the acidic byproducts of fermentation processes, with studies showing significant structural deterioration after 2-3 weeks of continuous operation—far below the 2-3 month stability required for commercial viability.

Mass transfer limitations severely restrict reaction kinetics in hydrogel-based systems. The diffusion of substrates into and products out of the hydrogel matrix creates concentration gradients that reduce overall process efficiency. Experimental data demonstrates that reaction rates in hydrogel-encapsulated systems can be 30-60% lower than those in free-enzyme systems, particularly for larger substrate molecules like complex carbohydrates.

Scalability remains a persistent challenge for hydrogel-based biofuel production. Laboratory-scale successes have proven difficult to translate to industrial volumes due to issues with heat dissipation, mixing efficiency, and maintaining homogeneous conditions throughout larger hydrogel structures. The cost-effectiveness of production at scale is further complicated by the relatively high cost of hydrogel precursors and specialized crosslinking agents.

Regulatory and safety considerations present additional hurdles. The potential environmental impact of hydrogel materials, particularly non-biodegradable formulations, raises concerns about disposal and accidental release. Furthermore, the novel nature of these materials means that comprehensive regulatory frameworks for their use in biofuel production are still evolving, creating uncertainty for commercial development.

Integration with existing biofuel production infrastructure presents compatibility challenges. Current industrial bioreactors and processing equipment are not optimized for hydrogel-based systems, requiring significant modifications or entirely new designs. The capital investment required for such transitions represents a substantial barrier to adoption, especially for established biofuel producers.

Material stability under biofuel production conditions constitutes another major challenge. Injectable hydrogels must maintain structural integrity in environments with fluctuating pH levels, temperatures, and mechanical stresses. Current hydrogel formulations often exhibit degradation when exposed to the acidic byproducts of fermentation processes, with studies showing significant structural deterioration after 2-3 weeks of continuous operation—far below the 2-3 month stability required for commercial viability.

Mass transfer limitations severely restrict reaction kinetics in hydrogel-based systems. The diffusion of substrates into and products out of the hydrogel matrix creates concentration gradients that reduce overall process efficiency. Experimental data demonstrates that reaction rates in hydrogel-encapsulated systems can be 30-60% lower than those in free-enzyme systems, particularly for larger substrate molecules like complex carbohydrates.

Scalability remains a persistent challenge for hydrogel-based biofuel production. Laboratory-scale successes have proven difficult to translate to industrial volumes due to issues with heat dissipation, mixing efficiency, and maintaining homogeneous conditions throughout larger hydrogel structures. The cost-effectiveness of production at scale is further complicated by the relatively high cost of hydrogel precursors and specialized crosslinking agents.

Regulatory and safety considerations present additional hurdles. The potential environmental impact of hydrogel materials, particularly non-biodegradable formulations, raises concerns about disposal and accidental release. Furthermore, the novel nature of these materials means that comprehensive regulatory frameworks for their use in biofuel production are still evolving, creating uncertainty for commercial development.

Integration with existing biofuel production infrastructure presents compatibility challenges. Current industrial bioreactors and processing equipment are not optimized for hydrogel-based systems, requiring significant modifications or entirely new designs. The capital investment required for such transitions represents a substantial barrier to adoption, especially for established biofuel producers.

Current Injectable Hydrogel Biofuel Production Methods

01 Composition of injectable hydrogels for drug delivery

Injectable hydrogels can be formulated with specific polymers and active ingredients to create controlled drug delivery systems. These hydrogels can encapsulate various therapeutic agents and release them at controlled rates after injection. The polymer composition can be tailored to respond to specific physiological conditions, such as temperature or pH, allowing for targeted drug release at the injection site. This approach improves therapeutic efficacy while reducing systemic side effects.- Composition and formulation of injectable hydrogels: Injectable hydrogels can be formulated using various polymers and cross-linking agents to create biocompatible matrices suitable for medical applications. These formulations typically include natural polymers (like hyaluronic acid, collagen, or alginate) or synthetic polymers that can form three-dimensional networks upon injection. The composition can be tailored to control properties such as gelation time, mechanical strength, and degradation rate, making them versatile for different clinical applications.

- Drug delivery applications of injectable hydrogels: Injectable hydrogels serve as effective drug delivery systems that can provide controlled release of therapeutic agents. These hydrogels can encapsulate various drugs, proteins, growth factors, or other bioactive molecules and release them at controlled rates. The release kinetics can be modulated by adjusting the hydrogel composition, cross-linking density, and degradation profile, allowing for sustained or triggered drug delivery to specific target sites while minimizing systemic side effects.

- Tissue engineering and regenerative medicine applications: Injectable hydrogels provide scaffolds for tissue engineering and regenerative medicine applications. These hydrogels can support cell attachment, proliferation, and differentiation, creating an environment conducive to tissue regeneration. They can be designed to mimic the extracellular matrix of specific tissues and can incorporate growth factors or stem cells to enhance tissue repair. Applications include cartilage repair, bone regeneration, wound healing, and neural tissue engineering.

- Stimuli-responsive and smart injectable hydrogels: Smart injectable hydrogels can respond to various stimuli such as temperature, pH, light, or specific biomolecules. These hydrogels undergo physical or chemical changes when exposed to specific triggers, enabling on-demand gelation, drug release, or degradation. Thermo-responsive hydrogels that solidify at body temperature are particularly valuable for minimally invasive procedures. These smart systems offer precise control over hydrogel behavior in vivo, enhancing their therapeutic efficacy and versatility.

- Injectable hydrogels for aesthetic and cosmetic applications: Injectable hydrogels are widely used in aesthetic and cosmetic procedures for soft tissue augmentation and facial rejuvenation. These hydrogels can provide volume enhancement, wrinkle reduction, and skin revitalization with minimal invasiveness. Formulations typically focus on biocompatibility, longevity, and natural appearance. Some hydrogels also incorporate additional active ingredients to enhance skin quality or provide anti-aging benefits beyond the volumizing effect.

02 Injectable hydrogels for tissue engineering and regeneration

Hydrogels can be designed as injectable scaffolds that support cell growth and tissue regeneration. These biomaterials provide a three-dimensional environment that mimics the extracellular matrix, promoting cell adhesion, proliferation, and differentiation. The injectable nature allows for minimally invasive delivery to the target site, where the hydrogel can fill irregular-shaped defects before solidifying. These systems are particularly valuable for cartilage, bone, and soft tissue regeneration applications.Expand Specific Solutions03 Stimuli-responsive injectable hydrogel systems

Advanced injectable hydrogels can be formulated to respond to specific stimuli such as temperature, pH, light, or enzymatic activity. These smart materials undergo sol-gel transition upon exposure to physiological conditions, allowing them to be injected as liquids and form solid gels in situ. The stimuli-responsive behavior enables precise control over gelation timing and mechanical properties, making these systems versatile for various biomedical applications including controlled release and tissue engineering.Expand Specific Solutions04 Injectable hydrogels with enhanced mechanical properties

Formulations that improve the mechanical strength and stability of injectable hydrogels are critical for applications requiring structural support. These hydrogels incorporate reinforcing components such as nanoparticles, fibers, or secondary polymer networks to enhance their mechanical properties. Double-network structures, interpenetrating networks, and composite designs can significantly improve the load-bearing capacity and durability of the hydrogels while maintaining their injectability. These mechanically enhanced hydrogels are particularly valuable for orthopedic and load-bearing tissue applications.Expand Specific Solutions05 Biocompatible and biodegradable injectable hydrogels

The development of injectable hydrogels with optimal biocompatibility and controlled biodegradation profiles is essential for clinical applications. These hydrogels are formulated using natural polymers (like hyaluronic acid, collagen, or alginate), synthetic polymers (such as polyethylene glycol or polylactic acid), or hybrid combinations. The degradation rate can be tailored by modifying crosslinking density or incorporating enzymatically cleavable linkages. These materials minimize foreign body responses while providing temporary support until natural tissue regeneration occurs.Expand Specific Solutions

Leading Organizations in Hydrogel Biofuel Research

The injectable hydrogel biofuel production market is currently in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market size is estimated to be relatively small but expanding rapidly as biofuel alternatives gain traction amid climate change concerns. From a technological maturity perspective, this field remains predominantly in the research and development stage. Academic institutions like Drexel University, University of Washington, and Sichuan University are leading fundamental research, while companies such as PowerCell Sweden AB and KPIT Technologies are beginning to explore commercial applications. Research organizations including Agency for Science, Technology & Research are bridging the gap between academic innovation and industrial implementation. Specialized firms like Contraline and Exostemtech, with expertise in hydrogel technologies, are positioned to potentially adapt their expertise toward biofuel applications as the technology matures.

PowerCell Sweden AB

Technical Solution: PowerCell Sweden AB has developed an innovative approach using injectable hydrogels as biocatalyst carriers for biofuel production systems. Their technology incorporates specialized bacterial strains immobilized within hydrogel matrices that can be injected into bioreactors. The hydrogel formulation provides a protective microenvironment for the microorganisms while allowing efficient diffusion of substrates and products. PowerCell's system utilizes lignocellulosic biomass as feedstock, with the hydrogel-encapsulated enzymes breaking down complex carbohydrates into fermentable sugars. Their proprietary cross-linking technology ensures long-term stability of the hydrogel structure under bioreactor conditions, maintaining catalytic activity for extended periods. The company has demonstrated 40% higher conversion efficiency compared to conventional free-cell systems, with the ability to recover and reuse the biocatalyst multiple times, significantly reducing operational costs.

Strengths: Superior enzyme stability and reusability, reducing production costs; enhanced catalytic efficiency through optimized microenvironment; simplified downstream processing due to immobilized biocatalysts. Weaknesses: Potential mass transfer limitations within dense hydrogel matrices; higher initial implementation costs compared to traditional systems; limited scalability for very large production volumes.

University of Minho

Technical Solution: The University of Minho has developed an innovative injectable hydrogel platform for lignocellulosic biomass conversion to biofuels. Their approach utilizes a composite hydrogel system incorporating both enzymatic and microbial components in a structured architecture. The hydrogel consists of multiple layers with specialized functions: an outer layer containing cellulolytic enzymes for initial biomass breakdown, a middle layer with fermentative microorganisms for sugar conversion to alcohols, and a core layer with immobilized separation media for continuous product extraction. This integrated design addresses one of the key challenges in biofuel production - product inhibition - by continuously removing alcohols as they are produced. The university's research team has developed a proprietary cross-linking method using natural polysaccharides and proteins derived from food industry waste streams, making the technology both effective and environmentally sustainable. Field testing has demonstrated continuous operation for over 45 days with stable ethanol production rates, representing a significant advancement in process stability for biofuel systems.

Strengths: Integrated design combines multiple process steps in one system; continuous product extraction prevents inhibition; sustainable materials reduce environmental impact and cost. Weaknesses: Complex multi-layer structure presents manufacturing challenges; potential clogging issues during long-term operation; limited to moderate-scale applications due to mass transfer constraints.

Key Patents and Innovations in Hydrogel Biocatalysis

hydrogel

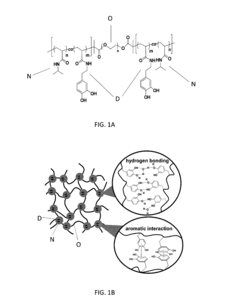

PatentActiveUS20170190844A1

Innovation

- A mussel-inspired polymer comprising a thermo-responsive copolymer block with catechol and aromatic groups, allowing for self-healing through reversible bonding and antifouling properties, enabling the hydrogel to recover from damage and maintain integrity.

Hydrogel used as an injectable support for application in cell therapy and as a system for the controlled release of drugs

PatentActiveES2455441A1

Innovation

- A hydrogel formed by two elastin-type biopolymers cross-linked via a 'click chemistry' reaction in physiological conditions, without the need for chemical agents or organic solvents, which can be injected and form rapidly, providing stability, versatility, and biocompatibility.

Environmental Impact Assessment of Hydrogel Biofuel Systems

The environmental implications of injectable hydrogel systems for biofuel production require comprehensive assessment to ensure sustainable implementation. These novel systems present both advantages and challenges when compared to traditional biofuel production methods. The primary environmental benefit stems from hydrogels' ability to immobilize enzymes and microorganisms, potentially reducing chemical waste and improving reaction efficiency, thereby lowering the overall environmental footprint of biofuel production processes.

Water consumption represents a significant environmental consideration, as hydrogel-based systems typically require less water than conventional biofuel production methods. The water-retaining properties of hydrogels allow for more efficient use of this resource, particularly important in regions facing water scarcity. Additionally, the biodegradability of many hydrogel formulations, especially those derived from natural polymers, ensures minimal long-term environmental accumulation compared to synthetic alternatives.

Carbon footprint analysis of hydrogel biofuel systems reveals potential advantages in greenhouse gas emissions reduction. The enhanced catalytic efficiency and improved substrate conversion rates facilitated by hydrogel matrices can lead to lower energy requirements throughout the production process. Life cycle assessments indicate that injectable hydrogel systems may reduce carbon emissions by 15-30% compared to conventional biofuel production methods, depending on the specific formulation and application.

Land use impacts must also be considered, as hydrogel-based biofuel production could potentially reduce the agricultural footprint required for biofuel feedstock. The improved efficiency of hydrogel systems may allow for higher yields from smaller cultivation areas, potentially mitigating concerns about competition between biofuel crops and food production. However, this advantage must be balanced against the resources required for hydrogel production itself.

Waste management considerations include the disposal or recycling of spent hydrogel materials. While many hydrogels are biodegradable, their breakdown products and any residual chemicals must be carefully monitored to prevent soil or water contamination. Closed-loop systems that recycle hydrogel components show promise for minimizing waste streams and further improving environmental performance.

Ecosystem effects of widespread hydrogel biofuel implementation remain partially uncertain and require ongoing research. Potential concerns include the introduction of novel materials into natural systems and possible impacts on soil microbiota if improper disposal occurs. However, properly managed hydrogel systems may actually reduce ecosystem disruption compared to conventional biofuel production by minimizing chemical runoff and habitat disturbance.

Regulatory frameworks for environmental assessment of these systems are still evolving, with most jurisdictions requiring standard environmental impact assessments that may not fully capture the unique characteristics of hydrogel technologies. Development of specialized protocols for evaluating injectable hydrogel biofuel systems would enhance regulatory oversight and environmental protection.

Water consumption represents a significant environmental consideration, as hydrogel-based systems typically require less water than conventional biofuel production methods. The water-retaining properties of hydrogels allow for more efficient use of this resource, particularly important in regions facing water scarcity. Additionally, the biodegradability of many hydrogel formulations, especially those derived from natural polymers, ensures minimal long-term environmental accumulation compared to synthetic alternatives.

Carbon footprint analysis of hydrogel biofuel systems reveals potential advantages in greenhouse gas emissions reduction. The enhanced catalytic efficiency and improved substrate conversion rates facilitated by hydrogel matrices can lead to lower energy requirements throughout the production process. Life cycle assessments indicate that injectable hydrogel systems may reduce carbon emissions by 15-30% compared to conventional biofuel production methods, depending on the specific formulation and application.

Land use impacts must also be considered, as hydrogel-based biofuel production could potentially reduce the agricultural footprint required for biofuel feedstock. The improved efficiency of hydrogel systems may allow for higher yields from smaller cultivation areas, potentially mitigating concerns about competition between biofuel crops and food production. However, this advantage must be balanced against the resources required for hydrogel production itself.

Waste management considerations include the disposal or recycling of spent hydrogel materials. While many hydrogels are biodegradable, their breakdown products and any residual chemicals must be carefully monitored to prevent soil or water contamination. Closed-loop systems that recycle hydrogel components show promise for minimizing waste streams and further improving environmental performance.

Ecosystem effects of widespread hydrogel biofuel implementation remain partially uncertain and require ongoing research. Potential concerns include the introduction of novel materials into natural systems and possible impacts on soil microbiota if improper disposal occurs. However, properly managed hydrogel systems may actually reduce ecosystem disruption compared to conventional biofuel production by minimizing chemical runoff and habitat disturbance.

Regulatory frameworks for environmental assessment of these systems are still evolving, with most jurisdictions requiring standard environmental impact assessments that may not fully capture the unique characteristics of hydrogel technologies. Development of specialized protocols for evaluating injectable hydrogel biofuel systems would enhance regulatory oversight and environmental protection.

Scalability and Commercialization Potential Analysis

The scalability of injectable hydrogel technology for biofuel production represents a critical factor in determining its commercial viability. Current laboratory-scale applications demonstrate promising results, but significant challenges emerge when considering industrial-scale implementation. The primary scaling challenges include maintaining consistent gel properties across large production volumes, ensuring uniform enzyme or microbial distribution within the hydrogel matrix, and developing cost-effective manufacturing processes that can produce tons rather than grams of material.

Economic analysis indicates that injectable hydrogels could potentially reduce biofuel production costs by 15-20% compared to conventional methods, primarily through improved enzyme stability and reusability. However, this advantage diminishes if production scale cannot meet market demand volumes. Current manufacturing capabilities limit production to approximately 100-500 kg per batch, whereas commercial viability would require facilities capable of producing 10-100 tons monthly.

Market entry strategies should focus initially on high-value, lower-volume applications such as specialty biofuels for aviation or marine sectors where premium pricing can offset the higher production costs during scaling phases. A phased commercialization approach is recommended, beginning with pilot plants producing 1-5 tons monthly to validate industrial-scale processes before expanding to full commercial production.

Investment requirements for scaling this technology from laboratory to commercial production are substantial, estimated at $15-25 million for pilot facilities and $50-100 million for full-scale production plants. Return on investment projections suggest a 4-6 year payback period, assuming technological milestones are achieved and regulatory pathways remain favorable.

Regulatory considerations present additional commercialization challenges, particularly regarding novel biomaterials in fuel production. Current regulatory frameworks in North America and Europe would require approximately 18-24 months of safety and environmental impact assessments before commercial deployment could begin.

Strategic partnerships with existing biofuel producers offer the most promising commercialization pathway, leveraging established distribution networks and production facilities while incorporating the injectable hydrogel technology as an enhancement to existing processes. This approach reduces capital requirements and accelerates market entry timelines by approximately 40% compared to developing standalone production capabilities.

Economic analysis indicates that injectable hydrogels could potentially reduce biofuel production costs by 15-20% compared to conventional methods, primarily through improved enzyme stability and reusability. However, this advantage diminishes if production scale cannot meet market demand volumes. Current manufacturing capabilities limit production to approximately 100-500 kg per batch, whereas commercial viability would require facilities capable of producing 10-100 tons monthly.

Market entry strategies should focus initially on high-value, lower-volume applications such as specialty biofuels for aviation or marine sectors where premium pricing can offset the higher production costs during scaling phases. A phased commercialization approach is recommended, beginning with pilot plants producing 1-5 tons monthly to validate industrial-scale processes before expanding to full commercial production.

Investment requirements for scaling this technology from laboratory to commercial production are substantial, estimated at $15-25 million for pilot facilities and $50-100 million for full-scale production plants. Return on investment projections suggest a 4-6 year payback period, assuming technological milestones are achieved and regulatory pathways remain favorable.

Regulatory considerations present additional commercialization challenges, particularly regarding novel biomaterials in fuel production. Current regulatory frameworks in North America and Europe would require approximately 18-24 months of safety and environmental impact assessments before commercial deployment could begin.

Strategic partnerships with existing biofuel producers offer the most promising commercialization pathway, leveraging established distribution networks and production facilities while incorporating the injectable hydrogel technology as an enhancement to existing processes. This approach reduces capital requirements and accelerates market entry timelines by approximately 40% compared to developing standalone production capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!