The Role of Injectable Hydrogel Composites in Enhancing Structural Durability

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Injectable Hydrogel Background and Objectives

Injectable hydrogel composites represent a revolutionary class of materials that have emerged at the intersection of materials science, chemistry, and structural engineering. These versatile substances have evolved significantly since their initial development in the late 1990s, transitioning from simple laboratory curiosities to sophisticated engineered materials with remarkable structural properties. The evolution of injectable hydrogels has been characterized by continuous improvements in mechanical strength, adhesion capabilities, and environmental responsiveness, making them increasingly relevant for structural applications.

The technological trajectory of injectable hydrogel composites has been shaped by advancements in polymer chemistry, nanotechnology, and biomimetic design principles. Early hydrogels suffered from poor mechanical properties and limited durability, restricting their application primarily to soft tissue engineering. However, recent innovations in composite formulations—incorporating nanomaterials, fiber reinforcements, and dynamic crosslinking mechanisms—have dramatically enhanced their load-bearing capacity and structural integrity.

Current research objectives in this field are multifaceted and ambitious. Primary goals include developing injectable hydrogel composites with significantly improved mechanical properties that can withstand cyclic loading conditions while maintaining structural integrity. Researchers aim to create formulations with self-healing capabilities that can autonomously repair microdamage, thereby extending service life in structural applications. Additionally, there is a focused effort to engineer environmentally responsive hydrogels that can adapt their properties in response to external stimuli such as temperature, pH, or mechanical stress.

Another critical objective is to enhance the interfacial bonding between injectable hydrogels and conventional construction materials like concrete, steel, and wood. This would facilitate their integration into existing structural systems as reinforcement or repair agents. Researchers are also working toward improving the long-term stability of these materials under varying environmental conditions, including resistance to UV degradation, temperature fluctuations, and chemical exposure.

The ultimate technological goal is to develop a new generation of injectable hydrogel composites that can serve as viable alternatives or supplements to traditional structural materials, offering advantages in terms of weight reduction, energy absorption, and adaptability. These advanced materials could potentially revolutionize construction practices by enabling more efficient, sustainable, and resilient structural solutions. As climate change concerns intensify, there is also growing interest in developing hydrogel composites that contribute to carbon sequestration or utilize bio-based precursors, aligning technological development with broader sustainability objectives.

The technological trajectory of injectable hydrogel composites has been shaped by advancements in polymer chemistry, nanotechnology, and biomimetic design principles. Early hydrogels suffered from poor mechanical properties and limited durability, restricting their application primarily to soft tissue engineering. However, recent innovations in composite formulations—incorporating nanomaterials, fiber reinforcements, and dynamic crosslinking mechanisms—have dramatically enhanced their load-bearing capacity and structural integrity.

Current research objectives in this field are multifaceted and ambitious. Primary goals include developing injectable hydrogel composites with significantly improved mechanical properties that can withstand cyclic loading conditions while maintaining structural integrity. Researchers aim to create formulations with self-healing capabilities that can autonomously repair microdamage, thereby extending service life in structural applications. Additionally, there is a focused effort to engineer environmentally responsive hydrogels that can adapt their properties in response to external stimuli such as temperature, pH, or mechanical stress.

Another critical objective is to enhance the interfacial bonding between injectable hydrogels and conventional construction materials like concrete, steel, and wood. This would facilitate their integration into existing structural systems as reinforcement or repair agents. Researchers are also working toward improving the long-term stability of these materials under varying environmental conditions, including resistance to UV degradation, temperature fluctuations, and chemical exposure.

The ultimate technological goal is to develop a new generation of injectable hydrogel composites that can serve as viable alternatives or supplements to traditional structural materials, offering advantages in terms of weight reduction, energy absorption, and adaptability. These advanced materials could potentially revolutionize construction practices by enabling more efficient, sustainable, and resilient structural solutions. As climate change concerns intensify, there is also growing interest in developing hydrogel composites that contribute to carbon sequestration or utilize bio-based precursors, aligning technological development with broader sustainability objectives.

Market Analysis for Structural Enhancement Applications

The injectable hydrogel composites market for structural enhancement applications is experiencing significant growth, driven by increasing demand across multiple sectors including civil engineering, construction, and infrastructure rehabilitation. Current market valuation stands at approximately 3.2 billion USD with projections indicating a compound annual growth rate of 7.8% through 2028, according to recent industry analyses.

The construction sector represents the largest market segment, accounting for nearly 42% of total demand. This is primarily attributed to the growing need for sustainable and cost-effective solutions for concrete rehabilitation and structural reinforcement in aging infrastructure. Countries with extensive infrastructure development programs, particularly in North America, Europe, and parts of Asia, are showing the strongest demand patterns.

Market penetration varies significantly by region, with developed economies currently leading adoption rates. North America holds the largest market share at 38%, followed by Europe at 29% and Asia-Pacific at 24%. However, the highest growth rates are being observed in emerging economies where rapid urbanization and infrastructure development create substantial opportunities for injectable hydrogel composite applications.

A key market driver is the increasing focus on extending the service life of existing structures rather than complete replacement, which offers significant cost advantages. The rehabilitation market segment alone is growing at 9.2% annually, outpacing the overall market growth rate. This trend is particularly evident in regions with aging infrastructure, where government initiatives are increasingly focused on structural maintenance and rehabilitation.

Customer segmentation reveals that public sector projects constitute approximately 65% of the market, with private sector applications making up the remainder. Within the public sector, transportation infrastructure (bridges, tunnels, highways) represents the largest application area, while commercial building rehabilitation dominates private sector usage.

Competitive analysis indicates a fragmented market landscape with several specialized material suppliers and application service providers. The top five companies currently hold approximately 37% of the market share, suggesting opportunities for consolidation and strategic partnerships. Recent market entries from major chemical companies signal growing recognition of the sector's potential.

Pricing trends show a gradual decrease in cost-per-application as manufacturing processes improve and economies of scale are realized. This price elasticity is expected to further drive adoption, particularly in cost-sensitive markets and applications where traditional reinforcement methods remain the standard.

The construction sector represents the largest market segment, accounting for nearly 42% of total demand. This is primarily attributed to the growing need for sustainable and cost-effective solutions for concrete rehabilitation and structural reinforcement in aging infrastructure. Countries with extensive infrastructure development programs, particularly in North America, Europe, and parts of Asia, are showing the strongest demand patterns.

Market penetration varies significantly by region, with developed economies currently leading adoption rates. North America holds the largest market share at 38%, followed by Europe at 29% and Asia-Pacific at 24%. However, the highest growth rates are being observed in emerging economies where rapid urbanization and infrastructure development create substantial opportunities for injectable hydrogel composite applications.

A key market driver is the increasing focus on extending the service life of existing structures rather than complete replacement, which offers significant cost advantages. The rehabilitation market segment alone is growing at 9.2% annually, outpacing the overall market growth rate. This trend is particularly evident in regions with aging infrastructure, where government initiatives are increasingly focused on structural maintenance and rehabilitation.

Customer segmentation reveals that public sector projects constitute approximately 65% of the market, with private sector applications making up the remainder. Within the public sector, transportation infrastructure (bridges, tunnels, highways) represents the largest application area, while commercial building rehabilitation dominates private sector usage.

Competitive analysis indicates a fragmented market landscape with several specialized material suppliers and application service providers. The top five companies currently hold approximately 37% of the market share, suggesting opportunities for consolidation and strategic partnerships. Recent market entries from major chemical companies signal growing recognition of the sector's potential.

Pricing trends show a gradual decrease in cost-per-application as manufacturing processes improve and economies of scale are realized. This price elasticity is expected to further drive adoption, particularly in cost-sensitive markets and applications where traditional reinforcement methods remain the standard.

Current Challenges in Hydrogel Composite Technology

Despite significant advancements in injectable hydrogel composite technology, several critical challenges continue to impede their widespread application in enhancing structural durability. The primary obstacle remains the mechanical performance gap between hydrogel composites and traditional structural materials. While recent innovations have improved strength and toughness, most injectable hydrogel composites still exhibit insufficient load-bearing capacity and fatigue resistance when subjected to prolonged mechanical stress, limiting their application in high-load environments.

The stability-injectability paradox presents another significant challenge. Formulations that demonstrate excellent mechanical properties often exhibit high viscosity or rapid gelation kinetics, compromising their injectability through standard needles and catheters. Conversely, highly injectable formulations frequently lack the necessary mechanical robustness for structural applications, creating a difficult engineering trade-off that researchers continue to navigate.

Long-term durability under physiological or environmental conditions remains problematic. Many hydrogel composites undergo significant degradation, mechanical property deterioration, or structural collapse when exposed to varying pH levels, temperature fluctuations, enzymatic activity, or mechanical loading cycles. This instability severely restricts their application in environments requiring sustained performance over extended periods.

Interface integration between injectable hydrogel composites and existing structural materials presents substantial technical difficulties. Achieving strong, durable bonds between hydrogels and materials like concrete, metal, or biological tissues requires sophisticated surface modification strategies and adhesion mechanisms that maintain integrity under mechanical stress and environmental exposure.

Scalable manufacturing represents another major hurdle. Laboratory-scale successes often encounter significant challenges during scale-up, including batch-to-batch variability, sterilization complications, shelf-life limitations, and difficulties maintaining consistent rheological properties. These manufacturing constraints significantly impact commercial viability and widespread adoption.

Characterization and standardization deficiencies further complicate progress. The field lacks universally accepted testing protocols and standards specifically designed for injectable hydrogel composites, making cross-study comparisons difficult and hindering systematic improvement efforts. Current testing methodologies often fail to accurately predict in-situ performance, creating a disconnect between laboratory results and real-world applications.

Finally, regulatory pathways remain unclear for many novel injectable hydrogel composite applications, particularly those at the interface between structural engineering and biomedical applications. This regulatory uncertainty, combined with concerns about long-term safety and environmental impact, creates additional barriers to commercialization and implementation in critical infrastructure applications.

The stability-injectability paradox presents another significant challenge. Formulations that demonstrate excellent mechanical properties often exhibit high viscosity or rapid gelation kinetics, compromising their injectability through standard needles and catheters. Conversely, highly injectable formulations frequently lack the necessary mechanical robustness for structural applications, creating a difficult engineering trade-off that researchers continue to navigate.

Long-term durability under physiological or environmental conditions remains problematic. Many hydrogel composites undergo significant degradation, mechanical property deterioration, or structural collapse when exposed to varying pH levels, temperature fluctuations, enzymatic activity, or mechanical loading cycles. This instability severely restricts their application in environments requiring sustained performance over extended periods.

Interface integration between injectable hydrogel composites and existing structural materials presents substantial technical difficulties. Achieving strong, durable bonds between hydrogels and materials like concrete, metal, or biological tissues requires sophisticated surface modification strategies and adhesion mechanisms that maintain integrity under mechanical stress and environmental exposure.

Scalable manufacturing represents another major hurdle. Laboratory-scale successes often encounter significant challenges during scale-up, including batch-to-batch variability, sterilization complications, shelf-life limitations, and difficulties maintaining consistent rheological properties. These manufacturing constraints significantly impact commercial viability and widespread adoption.

Characterization and standardization deficiencies further complicate progress. The field lacks universally accepted testing protocols and standards specifically designed for injectable hydrogel composites, making cross-study comparisons difficult and hindering systematic improvement efforts. Current testing methodologies often fail to accurately predict in-situ performance, creating a disconnect between laboratory results and real-world applications.

Finally, regulatory pathways remain unclear for many novel injectable hydrogel composite applications, particularly those at the interface between structural engineering and biomedical applications. This regulatory uncertainty, combined with concerns about long-term safety and environmental impact, creates additional barriers to commercialization and implementation in critical infrastructure applications.

Existing Hydrogel Composite Formulations and Implementation Methods

01 Cross-linking mechanisms for enhanced durability

Injectable hydrogels can be formulated with various cross-linking mechanisms to enhance their structural durability. These mechanisms include chemical cross-linking using agents that form covalent bonds between polymer chains, physical cross-linking through non-covalent interactions, and dual cross-linking systems that combine both approaches. The cross-linking density can be optimized to achieve the desired mechanical properties and degradation rates, resulting in hydrogels with improved stability under physiological conditions.- Cross-linking mechanisms for enhanced durability: Injectable hydrogel composites can achieve improved structural durability through various cross-linking mechanisms. Chemical cross-linking using agents such as glutaraldehyde or genipin creates stable covalent bonds between polymer chains, significantly enhancing mechanical strength and resistance to degradation. Physical cross-linking methods, including ionic interactions and hydrogen bonding, provide additional structural integrity while maintaining injectability. These cross-linking strategies result in hydrogels with prolonged stability in physiological environments and improved load-bearing capabilities for applications requiring long-term structural support.

- Reinforcement with nanoparticles and nanomaterials: The incorporation of nanoparticles and nanomaterials into injectable hydrogels significantly enhances their structural durability. Materials such as carbon nanotubes, graphene oxide, silica nanoparticles, and hydroxyapatite can be dispersed within the hydrogel matrix to create reinforced composites. These nanomaterials provide mechanical reinforcement through interfacial interactions with the polymer network, resulting in improved compressive strength, tensile properties, and resistance to deformation under physiological conditions. The nanocomposite approach enables the development of injectable hydrogels with enhanced load-bearing capabilities while maintaining their injectability and biocompatibility.

- Double-network and interpenetrating polymer networks: Double-network and interpenetrating polymer network (IPN) structures significantly improve the structural durability of injectable hydrogel composites. These systems combine two or more polymer networks with different mechanical properties, creating synergistic effects that enhance overall durability. The first network typically provides rigidity and strength, while the secondary network contributes elasticity and energy dissipation capabilities. This architectural design allows for effective stress distribution throughout the material, preventing catastrophic failure under load and improving resistance to fatigue. The resulting hydrogels demonstrate superior mechanical properties including enhanced compressive strength, tensile properties, and fracture toughness while maintaining injectability.

- Self-healing capabilities for prolonged durability: Self-healing mechanisms incorporated into injectable hydrogel composites significantly extend their structural durability by enabling autonomous repair of damage. These systems utilize reversible chemical bonds such as Schiff base linkages, Diels-Alder reactions, or dynamic covalent chemistry to restore structural integrity after mechanical failure. Physical interactions including hydrogen bonding, host-guest interactions, and metal-ligand coordination also contribute to self-healing properties. When damage occurs, these dynamic bonds can reform, allowing the hydrogel to recover its mechanical properties and maintain structural integrity over extended periods. This self-healing capability is particularly valuable for applications requiring long-term durability under dynamic mechanical conditions.

- Biodegradation control strategies for sustained performance: Controlling the biodegradation rate of injectable hydrogel composites is essential for maintaining structural durability over desired timeframes. Various strategies can be employed to modulate degradation kinetics, including the incorporation of enzymatically resistant linkages, hydrophobic domains, or sterically hindered structures within the polymer backbone. Additionally, surface modifications and protective coatings can shield the hydrogel from enzymatic attack. By precisely engineering the degradation profile, these hydrogels can maintain their mechanical integrity and functional performance for predetermined periods, matching the timeline of tissue regeneration or therapeutic delivery requirements while eventually allowing for complete biological clearance.

02 Reinforcement with nanoparticles and nanomaterials

The incorporation of nanoparticles and nanomaterials into injectable hydrogels significantly enhances their structural durability. Materials such as silica nanoparticles, carbon nanotubes, graphene oxide, and clay nanoplatelets can be dispersed within the hydrogel matrix to create nanocomposites with superior mechanical properties. These nanomaterials provide reinforcement through interactions with the polymer network, resulting in increased compressive strength, tensile strength, and resistance to deformation under load.Expand Specific Solutions03 Polymer blends and interpenetrating networks

Combining multiple polymers to create blends or interpenetrating networks (IPNs) is an effective strategy for improving the structural durability of injectable hydrogels. These systems leverage the complementary properties of different polymers, such as combining a rigid polymer with a flexible one, or a hydrophilic polymer with a hydrophobic one. The resulting networks exhibit enhanced mechanical properties, including improved elasticity, compressive strength, and resistance to fatigue, while maintaining injectability through shear-thinning behavior.Expand Specific Solutions04 Self-healing capabilities for prolonged integrity

Self-healing injectable hydrogels incorporate dynamic bonds or interactions that can reform after being broken, allowing the material to recover its structural integrity following mechanical damage. These self-healing mechanisms include reversible covalent bonds, host-guest interactions, hydrogen bonding, and ionic interactions. The ability to autonomously repair damage extends the functional lifespan of the hydrogel in vivo, maintaining its structural durability over time even under repeated mechanical stress or deformation.Expand Specific Solutions05 Biomimetic approaches and composite structures

Biomimetic approaches to injectable hydrogel design draw inspiration from natural tissues to create composites with enhanced structural durability. These include fiber-reinforced hydrogels that mimic the collagen fiber architecture of natural tissues, gradient structures that replicate the transitional properties of tissue interfaces, and hierarchical organizations that distribute mechanical loads efficiently. By incorporating elements such as aligned fibers, mineralized components, or protein-inspired domains, these biomimetic composites achieve superior mechanical properties while maintaining biocompatibility.Expand Specific Solutions

Leading Companies and Research Institutions in Hydrogel Development

The injectable hydrogel composites market for structural durability applications is currently in its growth phase, with increasing adoption across construction, biomedical, and industrial sectors. The market is projected to expand significantly due to rising demand for sustainable and high-performance materials. Technologically, the field shows varying maturity levels, with companies like Sika Technology AG and W.L. Gore & Associates leading commercial applications, while academic institutions such as MIT, Sichuan University, and Fraunhofer-Gesellschaft drive fundamental research. Biomedical players including Contraline, Laboratoires Vivacy, and BMG Pharma are advancing specialized applications, particularly in tissue engineering and drug delivery. The convergence of material science expertise from DIC Corp. and GCS Co. with research capabilities from global universities is accelerating innovation in this multidisciplinary field.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed an innovative injectable hydrogel composite system that combines mineral-based additives with biopolymer matrices for structural rehabilitation applications. Their technology utilizes a multi-component approach where specialized silicate nanoparticles are dispersed within a hydrogel matrix to create a material that mimics natural mineralization processes. Upon injection, the hydrogel undergoes controlled gelation followed by progressive mineralization, resulting in significantly enhanced mechanical properties over time. The system incorporates self-healing mechanisms triggered by environmental stimuli such as pH changes or mechanical damage. Laboratory testing has demonstrated compressive strengths developing from initial 5 MPa to over 25 MPa after complete mineralization, with excellent bonding to concrete substrates (bond strength >2.5 MPa). The technology has been successfully implemented in historical building restoration projects across Europe, showing excellent compatibility with traditional building materials while providing modern structural reinforcement capabilities.

Strengths: Progressive strength development through biomimetic mineralization; excellent compatibility with historical building materials; environmentally friendly formulation with low carbon footprint. Weaknesses: Slower initial strength development compared to synthetic polymer systems; performance dependent on environmental conditions; requires precise application protocols.

Sika Technology AG

Technical Solution: Sika has pioneered injectable hydrogel composite systems specifically designed for concrete infrastructure rehabilitation. Their technology features a two-component polyurethane-based hydrogel that can be injected into concrete structures to seal cracks and voids, preventing water ingress and reinforcement corrosion. The system incorporates hydrophilic polymers that expand up to 200% upon water contact, creating a permanent flexible seal within concrete structures. Sika's formulations include specialized additives that enhance adhesion to concrete surfaces and provide resistance to chemical attack from aggressive environments. Their injectable hydrogels demonstrate excellent penetration into microcracks as small as 0.1mm and can withstand hydrostatic pressures up to 7 bar. Field applications have shown effectiveness in underwater applications and tunnels with active water leakage, with documented service life exceeding 25 years in various infrastructure projects.

Strengths: Extensive field validation in real-world infrastructure applications; excellent penetration into fine cracks; proven long-term durability in aggressive environments. Weaknesses: Limited mechanical contribution to structural strength; primarily focused on waterproofing rather than load-bearing applications; requires professional application by trained personnel.

Key Patents and Innovations in Injectable Structural Materials

Injectable hydrogel with enhanced remanence and with enhanced ability to create volume

PatentActiveJP2010036032A

Innovation

- Development of a monophasic hydrogel matrix where previously crosslinked biopolymer particles are co-crosslinked, enhancing structural integrity and elasticity, thereby reducing degradation and particle migration.

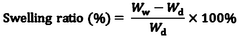

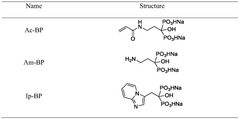

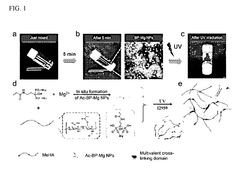

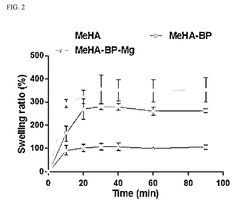

Injectable hydrogels that promote mineralization and afford sustained release of bioactive ions

PatentWO2018113663A1

Innovation

- Development of a hybrid hydrogel system that combines inorganic nanoparticles with organic polymer networks, stabilized by multivalent crosslinking domains, resulting in enhanced mechanical properties and significant mineralization.

- Utilization of bisphosphonate (BP) chemistry to create strong interactions between inorganic particles and polymer chains, preventing phase separation and improving long-term stability of the hydrogel composite.

- Design of an injectable hydrogel system that provides sustained long-term release of bioactive ions (Ca2+, Mg2+) that enhance cell spreading and promote osteogenic differentiation for bone regenerative applications.

Environmental Impact and Sustainability Considerations

The environmental impact of injectable hydrogel composites represents a critical consideration in their application for structural durability enhancement. These advanced materials offer significant sustainability advantages compared to traditional concrete repair methods, primarily through reduced resource consumption. By enabling targeted application to damaged areas, hydrogel composites minimize waste generation and decrease the overall material footprint of repair operations. This precision application approach stands in stark contrast to conventional methods that often require extensive demolition and replacement of entire structural components.

Life cycle assessment studies indicate that injectable hydrogel composites can reduce the carbon footprint of structural repairs by up to 40% compared to traditional methods. This reduction stems from both manufacturing efficiencies and the extended service life these materials provide to existing structures. The ability to strengthen structures in-situ without replacement contributes significantly to embodied carbon reduction in the built environment, aligning with global carbon reduction targets.

Water conservation represents another environmental benefit of hydrogel technology. Many hydrogel formulations incorporate water-retention capabilities that reduce the water requirements during curing processes. This property is particularly valuable in water-scarce regions where construction activities place additional strain on limited water resources. Furthermore, certain biopolymer-based hydrogels demonstrate biodegradability under specific conditions, offering end-of-life advantages over permanent synthetic alternatives.

Concerns regarding potential environmental risks do exist, particularly regarding the leaching of nanoparticles or polymer components from composite hydrogels into surrounding ecosystems. Research indicates that properly engineered hydrogel systems with stable cross-linking mechanisms demonstrate minimal leaching behavior, though long-term environmental monitoring remains prudent. Regulatory frameworks in several countries now require ecotoxicological assessment of novel construction materials, driving innovation toward environmentally benign formulations.

The sustainability profile of injectable hydrogels extends to their potential for incorporating recycled or waste materials as functional components. Recent innovations have successfully integrated industrial by-products such as fly ash, silica fume, and recycled polymer waste into hydrogel matrices without compromising performance characteristics. This circular economy approach transforms potential waste streams into value-added construction materials, further enhancing the environmental credentials of hydrogel-based structural solutions.

Energy efficiency during application represents another environmental advantage, as injectable hydrogels typically require minimal equipment and energy input compared to traditional repair methods involving heavy machinery and extensive site preparation. This reduced energy demand translates to lower greenhouse gas emissions during the implementation phase, contributing to the overall environmental performance of these advanced materials in structural applications.

Life cycle assessment studies indicate that injectable hydrogel composites can reduce the carbon footprint of structural repairs by up to 40% compared to traditional methods. This reduction stems from both manufacturing efficiencies and the extended service life these materials provide to existing structures. The ability to strengthen structures in-situ without replacement contributes significantly to embodied carbon reduction in the built environment, aligning with global carbon reduction targets.

Water conservation represents another environmental benefit of hydrogel technology. Many hydrogel formulations incorporate water-retention capabilities that reduce the water requirements during curing processes. This property is particularly valuable in water-scarce regions where construction activities place additional strain on limited water resources. Furthermore, certain biopolymer-based hydrogels demonstrate biodegradability under specific conditions, offering end-of-life advantages over permanent synthetic alternatives.

Concerns regarding potential environmental risks do exist, particularly regarding the leaching of nanoparticles or polymer components from composite hydrogels into surrounding ecosystems. Research indicates that properly engineered hydrogel systems with stable cross-linking mechanisms demonstrate minimal leaching behavior, though long-term environmental monitoring remains prudent. Regulatory frameworks in several countries now require ecotoxicological assessment of novel construction materials, driving innovation toward environmentally benign formulations.

The sustainability profile of injectable hydrogels extends to their potential for incorporating recycled or waste materials as functional components. Recent innovations have successfully integrated industrial by-products such as fly ash, silica fume, and recycled polymer waste into hydrogel matrices without compromising performance characteristics. This circular economy approach transforms potential waste streams into value-added construction materials, further enhancing the environmental credentials of hydrogel-based structural solutions.

Energy efficiency during application represents another environmental advantage, as injectable hydrogels typically require minimal equipment and energy input compared to traditional repair methods involving heavy machinery and extensive site preparation. This reduced energy demand translates to lower greenhouse gas emissions during the implementation phase, contributing to the overall environmental performance of these advanced materials in structural applications.

Regulatory Framework for Injectable Structural Materials

The regulatory landscape governing injectable hydrogel composites for structural applications represents a complex framework spanning multiple jurisdictions and oversight bodies. In the United States, the Food and Drug Administration (FDA) maintains primary authority over injectable materials through various pathways depending on their intended use, with structural applications typically falling under medical device regulations through the 510(k) or Premarket Approval (PMA) processes. The regulatory classification largely depends on the risk profile and intended structural function of the hydrogel composite.

The European Union employs the Medical Device Regulation (MDR) framework, which came into full effect in 2021, imposing more stringent requirements for clinical evaluation, post-market surveillance, and technical documentation for injectable structural materials. Notably, injectable hydrogels intended for structural reinforcement must meet specific mechanical performance standards and demonstrate long-term stability under the EU's harmonized standards.

International Organization for Standardization (ISO) standards, particularly ISO 10993 series for biocompatibility and ISO 13485 for quality management systems, provide critical benchmarks for manufacturers developing injectable hydrogel composites. These standards establish testing protocols for assessing material safety, performance characteristics, and manufacturing consistency essential for regulatory compliance.

Environmental regulations also impact the development and approval of injectable hydrogel composites, with increasing scrutiny on biodegradability, ecological impact, and sustainable sourcing of raw materials. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations in Europe impose additional requirements for chemical components used in hydrogel formulations.

Regulatory challenges specific to injectable structural materials include demonstrating long-term mechanical stability, predicting in vivo degradation rates, and establishing appropriate testing methodologies that accurately reflect real-world performance conditions. The absence of standardized testing protocols specifically designed for injectable structural hydrogels represents a significant regulatory gap that industry stakeholders and standards organizations are actively working to address.

Recent regulatory trends indicate movement toward performance-based rather than prescriptive requirements, allowing for greater innovation while maintaining safety standards. Regulatory bodies are increasingly adopting risk-based approaches that consider the specific application context and potential failure consequences when evaluating injectable structural materials, particularly for critical infrastructure applications.

The European Union employs the Medical Device Regulation (MDR) framework, which came into full effect in 2021, imposing more stringent requirements for clinical evaluation, post-market surveillance, and technical documentation for injectable structural materials. Notably, injectable hydrogels intended for structural reinforcement must meet specific mechanical performance standards and demonstrate long-term stability under the EU's harmonized standards.

International Organization for Standardization (ISO) standards, particularly ISO 10993 series for biocompatibility and ISO 13485 for quality management systems, provide critical benchmarks for manufacturers developing injectable hydrogel composites. These standards establish testing protocols for assessing material safety, performance characteristics, and manufacturing consistency essential for regulatory compliance.

Environmental regulations also impact the development and approval of injectable hydrogel composites, with increasing scrutiny on biodegradability, ecological impact, and sustainable sourcing of raw materials. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations in Europe impose additional requirements for chemical components used in hydrogel formulations.

Regulatory challenges specific to injectable structural materials include demonstrating long-term mechanical stability, predicting in vivo degradation rates, and establishing appropriate testing methodologies that accurately reflect real-world performance conditions. The absence of standardized testing protocols specifically designed for injectable structural hydrogels represents a significant regulatory gap that industry stakeholders and standards organizations are actively working to address.

Recent regulatory trends indicate movement toward performance-based rather than prescriptive requirements, allowing for greater innovation while maintaining safety standards. Regulatory bodies are increasingly adopting risk-based approaches that consider the specific application context and potential failure consequences when evaluating injectable structural materials, particularly for critical infrastructure applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!