The Role of Injectable Hydrogel Systems in Smart Textiles Development

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Injectable Hydrogel Background and Development Goals

Injectable hydrogels represent a revolutionary class of materials that combine the properties of hydrophilic polymer networks with the ability to be delivered in minimally invasive ways. The concept of injectable hydrogels emerged in the late 1990s primarily in biomedical applications, but their potential for integration with textiles has only been recognized within the last decade. These materials possess unique characteristics including high water content, biocompatibility, tunable mechanical properties, and the ability to transition from liquid to gel states under specific conditions.

The evolution of injectable hydrogels has been marked by significant advancements in polymer chemistry and processing technologies. Initially developed for tissue engineering and drug delivery applications, these systems have gradually expanded into diverse fields including smart materials and functional textiles. The convergence of hydrogel technology with textile engineering represents a particularly promising frontier, offering unprecedented opportunities for creating responsive, adaptive, and multifunctional fabric systems.

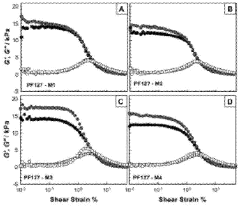

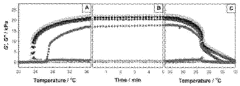

Current injectable hydrogel systems employ various gelation mechanisms, including temperature-responsive polymers (e.g., poly(N-isopropylacrylamide)), pH-sensitive materials, photo-crosslinkable systems, and self-assembling peptides. Each approach offers distinct advantages in terms of processing conditions, mechanical properties, and functional capabilities when integrated with textile substrates. The development trajectory has increasingly focused on creating systems that can be effectively incorporated into textile structures while maintaining their responsive characteristics.

The primary technical goal in this domain is to develop injectable hydrogel systems that can seamlessly integrate with textile platforms while providing enhanced functionality. This includes creating hydrogels with appropriate rheological properties for textile processing, ensuring durability during wear and washing cycles, and maintaining responsive behavior throughout the product lifecycle. Additionally, there is a strong emphasis on developing environmentally sustainable formulations that align with growing industry demands for green technologies.

Another critical objective is to establish standardized protocols for the characterization and evaluation of hydrogel-textile composites. This includes developing metrics for assessing mechanical performance, responsiveness to stimuli, durability, and biocompatibility. Such standardization is essential for facilitating industry adoption and ensuring consistent product quality across different applications and manufacturing environments.

Looking forward, the field aims to achieve scalable manufacturing processes that can transition injectable hydrogel-textile systems from laboratory prototypes to commercial products. This involves addressing challenges related to process control, quality assurance, and cost-effectiveness. The ultimate vision is to create a new generation of smart textiles that can dynamically respond to environmental conditions, physiological signals, or user inputs, thereby enabling applications ranging from healthcare monitoring to adaptive thermal regulation and beyond.

The evolution of injectable hydrogels has been marked by significant advancements in polymer chemistry and processing technologies. Initially developed for tissue engineering and drug delivery applications, these systems have gradually expanded into diverse fields including smart materials and functional textiles. The convergence of hydrogel technology with textile engineering represents a particularly promising frontier, offering unprecedented opportunities for creating responsive, adaptive, and multifunctional fabric systems.

Current injectable hydrogel systems employ various gelation mechanisms, including temperature-responsive polymers (e.g., poly(N-isopropylacrylamide)), pH-sensitive materials, photo-crosslinkable systems, and self-assembling peptides. Each approach offers distinct advantages in terms of processing conditions, mechanical properties, and functional capabilities when integrated with textile substrates. The development trajectory has increasingly focused on creating systems that can be effectively incorporated into textile structures while maintaining their responsive characteristics.

The primary technical goal in this domain is to develop injectable hydrogel systems that can seamlessly integrate with textile platforms while providing enhanced functionality. This includes creating hydrogels with appropriate rheological properties for textile processing, ensuring durability during wear and washing cycles, and maintaining responsive behavior throughout the product lifecycle. Additionally, there is a strong emphasis on developing environmentally sustainable formulations that align with growing industry demands for green technologies.

Another critical objective is to establish standardized protocols for the characterization and evaluation of hydrogel-textile composites. This includes developing metrics for assessing mechanical performance, responsiveness to stimuli, durability, and biocompatibility. Such standardization is essential for facilitating industry adoption and ensuring consistent product quality across different applications and manufacturing environments.

Looking forward, the field aims to achieve scalable manufacturing processes that can transition injectable hydrogel-textile systems from laboratory prototypes to commercial products. This involves addressing challenges related to process control, quality assurance, and cost-effectiveness. The ultimate vision is to create a new generation of smart textiles that can dynamically respond to environmental conditions, physiological signals, or user inputs, thereby enabling applications ranging from healthcare monitoring to adaptive thermal regulation and beyond.

Market Analysis for Smart Textile Applications

The smart textiles market is experiencing significant growth, with a projected market value reaching $9.3 billion by 2024 and expected to surpass $30 billion by 2030, growing at a CAGR of approximately 26%. This remarkable expansion is driven by increasing consumer demand for wearable technology that seamlessly integrates into daily life while providing enhanced functionality. Injectable hydrogel systems are emerging as a critical enabling technology in this rapidly evolving landscape, offering unique capabilities that traditional textile manufacturing methods cannot achieve.

The healthcare segment currently dominates the smart textiles market application, accounting for approximately 40% of market share. Medical applications utilizing hydrogel-enhanced textiles include wound dressings with controlled drug release, biomonitoring garments, and rehabilitation supports with temperature-responsive properties. These applications benefit from hydrogels' biocompatibility and ability to mimic biological tissues while incorporating electronic or pharmaceutical components.

Sports and fitness represents the fastest-growing segment, with an annual growth rate exceeding 30%. Consumer demand for performance-enhancing sportswear that monitors biometrics while providing adaptive support and temperature regulation is driving significant investment from major athletic apparel companies. Injectable hydrogels enable these functionalities through their stimuli-responsive properties and ability to encapsulate sensing elements.

Military and defense applications constitute another substantial market segment, valued at approximately $1.8 billion. Here, hydrogel-enhanced textiles offer capabilities such as adaptive camouflage, chemical/biological threat detection, and improved ballistic protection through strain-responsive stiffening mechanisms.

Fashion and consumer electronics segments are showing emerging interest, particularly in applications combining aesthetic appeal with functional technology. Luxury brands are exploring hydrogel-integrated textiles for color-changing garments and interactive fashion pieces, while electronics manufacturers see potential for flexible displays and interfaces embedded within everyday clothing.

Regional analysis indicates North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to expanding manufacturing capabilities and increasing consumer adoption of wearable technology.

Key market challenges include scaling production processes for hydrogel-textile integration, ensuring durability through multiple wash cycles, and addressing regulatory considerations for skin-contact applications. Despite these challenges, the convergence of textile engineering and advanced materials science through injectable hydrogel systems presents substantial market opportunities across multiple sectors.

The healthcare segment currently dominates the smart textiles market application, accounting for approximately 40% of market share. Medical applications utilizing hydrogel-enhanced textiles include wound dressings with controlled drug release, biomonitoring garments, and rehabilitation supports with temperature-responsive properties. These applications benefit from hydrogels' biocompatibility and ability to mimic biological tissues while incorporating electronic or pharmaceutical components.

Sports and fitness represents the fastest-growing segment, with an annual growth rate exceeding 30%. Consumer demand for performance-enhancing sportswear that monitors biometrics while providing adaptive support and temperature regulation is driving significant investment from major athletic apparel companies. Injectable hydrogels enable these functionalities through their stimuli-responsive properties and ability to encapsulate sensing elements.

Military and defense applications constitute another substantial market segment, valued at approximately $1.8 billion. Here, hydrogel-enhanced textiles offer capabilities such as adaptive camouflage, chemical/biological threat detection, and improved ballistic protection through strain-responsive stiffening mechanisms.

Fashion and consumer electronics segments are showing emerging interest, particularly in applications combining aesthetic appeal with functional technology. Luxury brands are exploring hydrogel-integrated textiles for color-changing garments and interactive fashion pieces, while electronics manufacturers see potential for flexible displays and interfaces embedded within everyday clothing.

Regional analysis indicates North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to expanding manufacturing capabilities and increasing consumer adoption of wearable technology.

Key market challenges include scaling production processes for hydrogel-textile integration, ensuring durability through multiple wash cycles, and addressing regulatory considerations for skin-contact applications. Despite these challenges, the convergence of textile engineering and advanced materials science through injectable hydrogel systems presents substantial market opportunities across multiple sectors.

Current Challenges in Hydrogel-Textile Integration

Despite the promising potential of injectable hydrogel systems in smart textiles, several significant challenges impede their seamless integration. The primary obstacle lies in achieving consistent mechanical compatibility between hydrogels and textile substrates. Hydrogels typically exhibit viscoelastic properties with high water content (often exceeding 90%), while textiles demonstrate more rigid, anisotropic mechanical behaviors. This fundamental mismatch creates interface stability issues during repeated deformation cycles, particularly when the textile-hydrogel composite undergoes stretching, bending, or twisting motions typical in wearable applications.

Adhesion quality represents another critical challenge, as conventional hydrogels often demonstrate poor interfacial bonding with textile fibers. The hydrophilic nature of hydrogels contrasts with many synthetic textile materials' hydrophobic characteristics, resulting in delamination and separation during use. Current adhesion promotion techniques, including surface treatments and coupling agents, frequently compromise either the hydrogel's functional properties or the textile's inherent qualities.

Durability concerns present significant barriers to commercialization. Injectable hydrogels integrated into textiles must withstand washing cycles, environmental exposure, mechanical stress, and prolonged wear. Current systems show accelerated degradation when subjected to these real-world conditions, with performance deterioration occurring within weeks rather than the months or years required for commercial viability.

Manufacturing scalability remains problematic, as current laboratory-scale injection techniques lack compatibility with established textile production lines. The precision required for hydrogel injection into specific textile regions demands specialized equipment and process controls that significantly increase production costs and complexity. The absence of standardized manufacturing protocols further complicates industrial adoption.

Electrical and thermal conductivity management presents unique challenges when integrating injectable hydrogels with electronic components in smart textiles. The high water content of hydrogels can cause short circuits or signal interference with embedded electronics, while inadequate thermal management may lead to localized overheating or compromised sensor performance.

Biocompatibility and regulatory compliance issues further complicate development efforts. For wearable applications, hydrogel-textile composites must meet stringent safety standards regarding skin contact, potential leaching of components, and allergenic responses. The complex regulatory landscape for such hybrid materials, which fall between traditional textiles and medical devices, creates uncertainty in product development pathways.

Addressing these multifaceted challenges requires interdisciplinary collaboration between materials scientists, textile engineers, and manufacturing specialists to develop next-generation injectable hydrogel systems specifically optimized for textile integration.

Adhesion quality represents another critical challenge, as conventional hydrogels often demonstrate poor interfacial bonding with textile fibers. The hydrophilic nature of hydrogels contrasts with many synthetic textile materials' hydrophobic characteristics, resulting in delamination and separation during use. Current adhesion promotion techniques, including surface treatments and coupling agents, frequently compromise either the hydrogel's functional properties or the textile's inherent qualities.

Durability concerns present significant barriers to commercialization. Injectable hydrogels integrated into textiles must withstand washing cycles, environmental exposure, mechanical stress, and prolonged wear. Current systems show accelerated degradation when subjected to these real-world conditions, with performance deterioration occurring within weeks rather than the months or years required for commercial viability.

Manufacturing scalability remains problematic, as current laboratory-scale injection techniques lack compatibility with established textile production lines. The precision required for hydrogel injection into specific textile regions demands specialized equipment and process controls that significantly increase production costs and complexity. The absence of standardized manufacturing protocols further complicates industrial adoption.

Electrical and thermal conductivity management presents unique challenges when integrating injectable hydrogels with electronic components in smart textiles. The high water content of hydrogels can cause short circuits or signal interference with embedded electronics, while inadequate thermal management may lead to localized overheating or compromised sensor performance.

Biocompatibility and regulatory compliance issues further complicate development efforts. For wearable applications, hydrogel-textile composites must meet stringent safety standards regarding skin contact, potential leaching of components, and allergenic responses. The complex regulatory landscape for such hybrid materials, which fall between traditional textiles and medical devices, creates uncertainty in product development pathways.

Addressing these multifaceted challenges requires interdisciplinary collaboration between materials scientists, textile engineers, and manufacturing specialists to develop next-generation injectable hydrogel systems specifically optimized for textile integration.

Current Hydrogel Integration Methods for Textiles

01 Composition of injectable hydrogels for drug delivery

Injectable hydrogels can be formulated with specific polymers and cross-linking agents to create effective drug delivery systems. These hydrogels can encapsulate various therapeutic agents and provide controlled release over time. The composition typically includes biocompatible polymers that can form a gel-like structure upon injection into the body, allowing for minimally invasive administration while maintaining drug stability and extending release profiles.- Composition of injectable hydrogels: Injectable hydrogels can be formulated using various polymers and cross-linking agents to create systems with desired mechanical properties. These compositions typically include natural polymers (like hyaluronic acid, collagen, or alginate), synthetic polymers, or combinations thereof. The hydrogel composition determines critical properties such as gelation time, degradation rate, and biocompatibility, which are essential for medical applications. These systems can be designed to solidify in situ after injection through various mechanisms including temperature change, pH response, or chemical cross-linking.

- Drug delivery applications of injectable hydrogels: Injectable hydrogels serve as effective drug delivery systems due to their ability to encapsulate therapeutic agents and provide controlled release. These systems can be engineered to deliver pharmaceuticals, biologics, or gene therapies with specific release kinetics. The hydrogel matrix protects the encapsulated drugs from degradation while maintaining their bioactivity. By modifying the hydrogel structure, release profiles can be tailored from rapid to sustained delivery over extended periods, improving therapeutic efficacy and reducing dosing frequency.

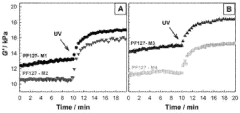

- Stimuli-responsive injectable hydrogels: Stimuli-responsive injectable hydrogels can undergo physical or chemical changes in response to specific triggers such as temperature, pH, light, or electrical signals. These smart materials can transition from liquid to gel states under physiological conditions, enabling minimally invasive administration. The responsive nature allows for on-demand drug release, self-healing properties, or shape changes that can be utilized for targeted therapies. These systems are particularly valuable for applications requiring precise temporal control over material properties or drug release.

- Tissue engineering applications of injectable hydrogels: Injectable hydrogels provide three-dimensional scaffolds for tissue engineering and regenerative medicine. These biomaterials can be designed to mimic the extracellular matrix, supporting cell adhesion, proliferation, and differentiation. By incorporating growth factors, peptides, or other bioactive molecules, these hydrogels can guide tissue formation and promote healing. The injectable nature allows for filling irregular-shaped defects and minimally invasive delivery, making them ideal for applications in cartilage repair, bone regeneration, wound healing, and soft tissue reconstruction.

- Novel cross-linking strategies for injectable hydrogels: Advanced cross-linking methods are being developed to enhance the performance of injectable hydrogels. These include enzymatic cross-linking, click chemistry reactions, photopolymerization, and dynamic covalent chemistry. These strategies allow for rapid in situ gelation with controlled mechanical properties while maintaining biocompatibility. Some systems employ dual cross-linking mechanisms to achieve both immediate stability and long-term structural integrity. These novel approaches enable the creation of hydrogels with improved mechanical strength, degradation profiles, and functional properties for various biomedical applications.

02 Stimuli-responsive injectable hydrogel systems

These hydrogel systems can respond to specific stimuli such as temperature, pH, or enzymatic activity to trigger gelation or drug release. The stimuli-responsive nature allows for precise control over when and where the hydrogel forms or releases its payload. This technology enables targeted delivery to specific tissues or organs and can be designed to respond to pathological conditions, making them particularly valuable for treating localized diseases.Expand Specific Solutions03 Injectable hydrogels for tissue engineering and regeneration

Specialized injectable hydrogels can support cell growth, differentiation, and tissue regeneration. These systems provide a three-dimensional scaffold that mimics the extracellular matrix, allowing cells to proliferate and form new tissue. The hydrogels can be loaded with growth factors, stem cells, or other bioactive molecules to enhance tissue repair and regeneration in applications such as wound healing, cartilage repair, and bone regeneration.Expand Specific Solutions04 Novel cross-linking mechanisms for injectable hydrogels

Advanced cross-linking technologies enable the formation of stable hydrogel networks after injection. These mechanisms include photo-initiated cross-linking, enzymatic cross-linking, and click chemistry approaches that allow the hydrogel to form in situ. The cross-linking strategy significantly impacts the mechanical properties, degradation rate, and biocompatibility of the resulting hydrogel, which can be tailored for specific medical applications.Expand Specific Solutions05 Injectable hydrogels with enhanced mechanical properties

Innovations in injectable hydrogel formulations have led to systems with improved mechanical strength and durability. These advanced hydrogels can withstand physiological stresses while maintaining their structure and function. Reinforcement strategies include the incorporation of nanoparticles, fiber networks, or dual-network structures that enhance the mechanical properties without compromising injectability or biocompatibility, making them suitable for load-bearing applications such as cartilage replacement or intervertebral disc repair.Expand Specific Solutions

Key Industry Players and Research Institutions

The injectable hydrogel systems market in smart textiles is currently in an emerging growth phase, characterized by increasing research activities and expanding applications. The global market is projected to grow significantly as these materials bridge the gap between traditional textiles and advanced functionalities. Leading academic institutions like MIT, Duke University, and Donghua University are driving fundamental research, while companies such as Contraline, Henkel, and Armacell JIOS Aerogels are commercializing applications. The technology maturity varies across applications, with medical implementations (led by Wisconsin Alumni Research Foundation and Tufts) showing higher readiness than industrial applications. Research collaborations between institutions like National University of Singapore and Wuhan University are accelerating development, particularly in wearable health monitoring and drug delivery systems.

Duke University

Technical Solution: Duke University has developed an innovative injectable hydrogel platform for smart textiles that combines thermoresponsive polymers with bioactive compounds. Their system utilizes a proprietary blend of natural and synthetic polymers that transition between sol and gel states at physiologically relevant temperatures, allowing for precise injection into textile structures. The hydrogels incorporate microencapsulated active ingredients that can be released in response to specific stimuli such as mechanical pressure, temperature changes, or electrical signals. Duke researchers have demonstrated textiles with embedded hydrogels capable of controlled moisture management, where water absorption and release can be triggered on demand. Their technology also features antimicrobial properties through the incorporation of silver nanoparticles within the hydrogel matrix, creating self-sterilizing textiles for healthcare applications. Recent advancements include the development of hydrogel systems with tunable mechanical properties that can adapt to different body movements and postures, enhancing comfort while maintaining functionality in wearable applications.

Strengths: Excellent biocompatibility with minimal skin irritation; sophisticated controlled release mechanisms for therapeutic compounds; good integration with various textile substrates including natural and synthetic fibers. Weaknesses: Potential limitations in long-term stability under varied environmental conditions; challenges in achieving consistent performance across different textile types; relatively complex manufacturing process requiring specialized equipment.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced injectable hydrogel systems for smart textiles that combine responsive polymers with nanoparticles to create multifunctional fabrics. Their proprietary technology utilizes shear-thinning hydrogels that can be injected into textile structures and subsequently self-heal to form stable networks. These hydrogels contain temperature and pH-responsive elements that can change properties based on environmental conditions. MIT researchers have demonstrated hydrogel-infused textiles capable of controlled drug delivery, with release rates modulated by external stimuli such as temperature changes or mechanical deformation. Their system incorporates conductive nanomaterials within the hydrogel matrix to enable electrical conductivity while maintaining flexibility and comfort. Recent developments include hydrogels with shape memory properties that can transform textile structures in response to specific triggers, creating dynamic wearable systems for both medical and consumer applications.

Strengths: Superior integration of electronic functionality with biocompatible materials; excellent mechanical properties allowing for durability during wear and washing; precise control over stimuli-responsive behavior. Weaknesses: Higher manufacturing complexity compared to conventional textile treatments; potential challenges in scaling production to industrial levels; relatively higher cost of implementation.

Core Patents and Research in Injectable Smart Materials

Injectable smart hydrogels that are sensitive to temperature and light and with increased mechanical strength, and production methods thereof

PatentWO2024072352A1

Innovation

- Incorporating chromophore functional groups, such as azobenzene and coumarin compounds, into pluronic block copolymers to enhance mechanical strength and light sensitivity, while maintaining biocompatibility.

Hydrogel matrix systems for dressing textiles

PatentInactiveEP1373631A2

Innovation

- A hydrogel matrix system is applied to textile surfaces, which increases water absorption capacity through a simple swelling process, allowing for temporary modification and easy removal during washing, and can be loaded with active substances for additional properties like deodorizing and UV protection.

Sustainability and Biodegradability Considerations

The integration of injectable hydrogel systems into smart textiles presents significant sustainability challenges and opportunities that must be carefully considered during development and implementation. Current textile production already poses substantial environmental concerns, including resource depletion, chemical pollution, and waste generation. The incorporation of hydrogel technologies introduces additional sustainability variables that require thorough assessment.

Biodegradability emerges as a critical factor in hydrogel-enhanced textiles. Traditional hydrogels often utilize synthetic polymers like polyacrylamide or polyethylene glycol that persist in the environment for extended periods. Recent research has pivoted toward naturally derived polymers such as alginate, chitosan, and cellulose derivatives that offer improved biodegradability profiles while maintaining functional performance. These bio-based alternatives decompose through natural processes, significantly reducing environmental impact at end-of-life.

Life cycle assessment (LCA) studies indicate that injectable hydrogel systems can potentially reduce the overall environmental footprint of smart textiles when designed with sustainability principles. By enabling targeted functionality without requiring whole-garment treatment, these systems minimize resource consumption and chemical usage. However, the manufacturing processes for specialized hydrogels often involve energy-intensive steps and potentially hazardous solvents that counteract these benefits.

Water consumption represents another critical sustainability consideration. While hydrogels inherently interact with water systems, their production and application can be optimized to reduce water usage. Closed-loop manufacturing systems that recycle process water and recover solvents have demonstrated up to 60% reduction in water consumption compared to conventional methods.

Toxicity concerns must be addressed throughout the hydrogel lifecycle. Non-toxic crosslinking mechanisms using enzymatic or physical crosslinking rather than chemical agents reduce environmental and human health risks. Additionally, ensuring hydrogel components do not leach harmful substances during use or disposal is essential for sustainable implementation.

Circular economy principles are increasingly being applied to hydrogel-enhanced textiles. Research into recoverable and recyclable hydrogel systems has shown promising results, with some formulations allowing for component separation and reuse. These approaches extend product lifecycles and reduce waste generation, aligning with global sustainability initiatives and regulatory frameworks.

Regulatory compliance with emerging sustainability standards presents both challenges and opportunities for hydrogel-textile integration. As environmental regulations become more stringent, particularly regarding microplastic pollution and chemical safety, hydrogel systems designed with biodegradability and non-toxicity as primary considerations will gain competitive advantage in the marketplace.

Biodegradability emerges as a critical factor in hydrogel-enhanced textiles. Traditional hydrogels often utilize synthetic polymers like polyacrylamide or polyethylene glycol that persist in the environment for extended periods. Recent research has pivoted toward naturally derived polymers such as alginate, chitosan, and cellulose derivatives that offer improved biodegradability profiles while maintaining functional performance. These bio-based alternatives decompose through natural processes, significantly reducing environmental impact at end-of-life.

Life cycle assessment (LCA) studies indicate that injectable hydrogel systems can potentially reduce the overall environmental footprint of smart textiles when designed with sustainability principles. By enabling targeted functionality without requiring whole-garment treatment, these systems minimize resource consumption and chemical usage. However, the manufacturing processes for specialized hydrogels often involve energy-intensive steps and potentially hazardous solvents that counteract these benefits.

Water consumption represents another critical sustainability consideration. While hydrogels inherently interact with water systems, their production and application can be optimized to reduce water usage. Closed-loop manufacturing systems that recycle process water and recover solvents have demonstrated up to 60% reduction in water consumption compared to conventional methods.

Toxicity concerns must be addressed throughout the hydrogel lifecycle. Non-toxic crosslinking mechanisms using enzymatic or physical crosslinking rather than chemical agents reduce environmental and human health risks. Additionally, ensuring hydrogel components do not leach harmful substances during use or disposal is essential for sustainable implementation.

Circular economy principles are increasingly being applied to hydrogel-enhanced textiles. Research into recoverable and recyclable hydrogel systems has shown promising results, with some formulations allowing for component separation and reuse. These approaches extend product lifecycles and reduce waste generation, aligning with global sustainability initiatives and regulatory frameworks.

Regulatory compliance with emerging sustainability standards presents both challenges and opportunities for hydrogel-textile integration. As environmental regulations become more stringent, particularly regarding microplastic pollution and chemical safety, hydrogel systems designed with biodegradability and non-toxicity as primary considerations will gain competitive advantage in the marketplace.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for injectable hydrogel systems represents a critical challenge in the widespread adoption of smart textile technologies. Current production methods for these specialized hydrogels often rely on laboratory-scale techniques that are difficult to translate to industrial production volumes. Batch-to-batch consistency remains problematic when scaling up from milliliter to multi-liter production, particularly for hydrogels with complex formulations incorporating conductive elements, sensors, or drug delivery components.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs for injectable hydrogel systems in smart textiles. High-purity polymers, specialized cross-linking agents, and functional additives such as conductive nanoparticles significantly drive up material costs. Equipment investment for large-scale production facilities represents another substantial cost factor, with specialized mixing, sterilization, and quality control systems requiring capital expenditures in the range of $500,000 to $2 million depending on production capacity.

Labor costs vary significantly based on geographic location, with specialized technical expertise commanding premium wages. The complexity of injectable hydrogel formulation processes necessitates skilled personnel, adding approximately 15-25% to overall production expenses. Regulatory compliance and quality assurance testing further contribute to the cost structure, particularly for hydrogels intended for medical or healthcare applications within smart textiles.

Energy consumption during production presents both economic and sustainability challenges. The precise temperature control required during hydrogel synthesis and processing demands significant energy inputs. Emerging green manufacturing approaches utilizing renewable energy sources and optimized reaction conditions show promise in reducing both environmental impact and operational costs by 15-30%.

Supply chain considerations significantly impact both scalability and cost efficiency. The limited number of suppliers for specialized hydrogel components creates vulnerability to price fluctuations and supply disruptions. Establishing robust supply networks with multiple qualified vendors represents a strategic priority for manufacturers seeking to scale production while maintaining cost competitiveness.

Recent innovations in continuous flow manufacturing techniques offer promising pathways to improved scalability. These approaches allow for more consistent product quality across larger production volumes while reducing labor requirements by 30-40% compared to traditional batch processing methods. Additionally, advances in automated quality control systems utilizing in-line spectroscopic techniques enable real-time monitoring of critical quality attributes, reducing waste and rework expenses.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs for injectable hydrogel systems in smart textiles. High-purity polymers, specialized cross-linking agents, and functional additives such as conductive nanoparticles significantly drive up material costs. Equipment investment for large-scale production facilities represents another substantial cost factor, with specialized mixing, sterilization, and quality control systems requiring capital expenditures in the range of $500,000 to $2 million depending on production capacity.

Labor costs vary significantly based on geographic location, with specialized technical expertise commanding premium wages. The complexity of injectable hydrogel formulation processes necessitates skilled personnel, adding approximately 15-25% to overall production expenses. Regulatory compliance and quality assurance testing further contribute to the cost structure, particularly for hydrogels intended for medical or healthcare applications within smart textiles.

Energy consumption during production presents both economic and sustainability challenges. The precise temperature control required during hydrogel synthesis and processing demands significant energy inputs. Emerging green manufacturing approaches utilizing renewable energy sources and optimized reaction conditions show promise in reducing both environmental impact and operational costs by 15-30%.

Supply chain considerations significantly impact both scalability and cost efficiency. The limited number of suppliers for specialized hydrogel components creates vulnerability to price fluctuations and supply disruptions. Establishing robust supply networks with multiple qualified vendors represents a strategic priority for manufacturers seeking to scale production while maintaining cost competitiveness.

Recent innovations in continuous flow manufacturing techniques offer promising pathways to improved scalability. These approaches allow for more consistent product quality across larger production volumes while reducing labor requirements by 30-40% compared to traditional batch processing methods. Additionally, advances in automated quality control systems utilizing in-line spectroscopic techniques enable real-time monitoring of critical quality attributes, reducing waste and rework expenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!